Structure and Properties of Highly Porous Alumina-Based Ceramic Materials after Heating by Concentrated Solar Radiation

Abstract

:1. Introduction

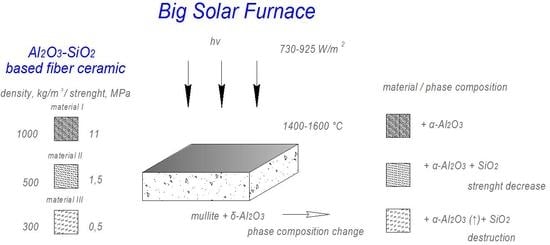

2. Materials and Methods

| Material I | Material II | Material III | |

|---|---|---|---|

| Density, kg/m3 | 1000 | 500 | 300 |

| Porosity, % vol. | 50 | 80 | 93 |

| Chemical composition | 73%Al2O3–27%SiO2 | 73%Al2O3–27%SiO2 | 75%Al2O3–25%SiO2 |

| Phase composition | Mullite (3Al2O3·2SiO2), δ-Al2O3 | Mullite (3Al2O3·2SiO2), δ-Al2O3 | Mullite (3Al2O3·2SiO2), δ-Al2O3 |

| Thermal conductivity coefficient, W/(m*K) | 20 °C–0.27 1000 °C–0.32 1600 °C–0.51 | 20 °C–0.11 1000 °C–0.25 1600 °C–0.48 | 20 °C–0.07 1000 °C–0.22 1600 °C–0.37 |

3. Results and Discussion

3.1. Phase Composition

3.2. Microstructure

3.3. Elemental Composition

3.4. Compressive Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mittenbühler, A.; Jung, J. Ceramic materials under high temperature heat transfer conditions. J. Nucl. Mater. 1990, 171, 54–62. [Google Scholar] [CrossRef]

- Chen, H.; Sui, X.; Zhou, C.; Wang, C.; Yin, C.; Liu, F. Preparation and characterization of mullite fiber-reinforced Al2O3-SiO2 aerogel composites. Key Eng. Mater. 2015, 697, 360–363. [Google Scholar] [CrossRef]

- Wen, S.; Ren, H.; Zhu, J.; Bi, Y.; Zhang, L. Fabrication of Al2O3 aerogel-SiO2 fiber composite with enhanced thermal insulation and high heat resistance. J. Porous Mater. 2019, 26, 1027–1034. [Google Scholar] [CrossRef]

- Wen, S.; Zhu, J.; Yin, Q.; Bi, Y.; Ren, H.; Zhang, L. Fabrication of infrared opacifiers loaded Al2O3 aerogel-SiO2 fiber mat composites with high thermal resistance. Int. J. Nanosci. 2020, 19, 1950021. [Google Scholar] [CrossRef]

- Li, C.-H.; Hu, L.; Zou, Y.; Liu, J.-A.; Xiao, J.-H.; Wu, J.-M.; Shi, Y.-S. Fabrication of Al2O3-SiO2 ceramics through combined selective laser sintering and SiO2-sol infiltration. Int. J. Appl. Ceram. Technol. 2020, 17, 255–263. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Liu, J.; Wang, M.; Yun, Z. Preparation and properties of SiO2/Al2O3-SiO2 fiber mat composite materials. Key Eng. Mater. 2016, 680, 129–132. [Google Scholar] [CrossRef]

- Chen, Y.T.; Chong, K.K.; Lim, C.S.; Lim, B.H.; Tan, K.K.; Aliman, O.; Bligh, T.P.; Tan, B.K.; Ismail, G. Report of the first prototype of non-imaging focusing heliostat and its application in high temperature solar furnace. Sol. Energy 2002, 72, 531–544. [Google Scholar] [CrossRef]

- Fend, T.; Hoffschmidt, B.; Pitz-Paal, R.; Reutter, O.; Rietbrock, P. Porous materials as open volumetric solar receivers: Experimental determination of thermophysical and heat transfer properties. Energy 2004, 29, 823–833. [Google Scholar] [CrossRef]

- Pierrat, B.; Balat-Pichelin, M.; Silvestroni, L.; Sciti, D. High temperature oxidation of ZrC-20%MoSi2 in air for future solar receivers. Sol. Energy Mater. Sol. Cells 2011, 95, 2228–2237. [Google Scholar] [CrossRef]

- Paizullakhanov, M.S.; Faiziev, S.A.; Nurmatov, S. Studying refractoriness of silicon-carbide materials fabricated in a Big Solar Furnace. Appl. Sol. Energy 2007, 43, 268–269. [Google Scholar] [CrossRef]

- Lugovoy, A.A.; Babashov, V.G.; Karpov, U.V. The thermal diffusivity of the gradient thermal insulation material. Tr. VIAM (Proc. VIAM) 2014, 2, 1–10. [Google Scholar] [CrossRef]

- Vlasova, M.; Kakazey, M.; Castro Hernandez, A.; Márquez Aguilar, P.A.; Guardian Tapia, R.; Mel’nikov, I.V.; Petrovsky, V.N. Surface changes in Al2O3–base composite ceramics under action of laser treatment. Ceram. Int. 2019, 45, 5454–5466. [Google Scholar] [CrossRef]

- Cappelli, E.; Orlando, S.; Sciti, D.; Montozzi, M.; Pandolfi, L. Ceramic surface modifications induced by pulsed laser treatment. Appl. Surf. Sci. 2000, 154–155, 682–688. [Google Scholar] [CrossRef]

- Suleimanov, S.K.; Babashov, V.G.; Dzhanklich, M.U.; Dyskin, V.G.; Daskovskii, M.I.; Skripachev, S.Y.; Kulagina, N.A.; Arushanov, G.M. Behavior of a heat-protective material based on Al2O3 and SiO2 fibers under exposure to concentrated solar energy flux. Refract. Ind. Ceram. 2021, 61, 675–679. [Google Scholar] [CrossRef]

- Babashov, V.G.; Suleimanov, S.K.; Skripachev, S.Y.; Basargin, O.V.; Lyulyukina, G.Y. Phase transformations in high-temperature fiber materials exposed to non-equilibrium flow of heat and light. Glass Ceram. 2020, 76, 374–380. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babashov, V.G.; Suleimanov, S.K.; Daskovskii, M.I.; Shein, E.A.; Stolyankov, Y.V. Structure and Properties of Highly Porous Alumina-Based Ceramic Materials after Heating by Concentrated Solar Radiation. Ceramics 2022, 5, 24-33. https://doi.org/10.3390/ceramics5010003

Babashov VG, Suleimanov SK, Daskovskii MI, Shein EA, Stolyankov YV. Structure and Properties of Highly Porous Alumina-Based Ceramic Materials after Heating by Concentrated Solar Radiation. Ceramics. 2022; 5(1):24-33. https://doi.org/10.3390/ceramics5010003

Chicago/Turabian StyleBabashov, Vladimir G., Sultan Kh. Suleimanov, Mikhail I. Daskovskii, Evgeny A. Shein, and Yurii V. Stolyankov. 2022. "Structure and Properties of Highly Porous Alumina-Based Ceramic Materials after Heating by Concentrated Solar Radiation" Ceramics 5, no. 1: 24-33. https://doi.org/10.3390/ceramics5010003

APA StyleBabashov, V. G., Suleimanov, S. K., Daskovskii, M. I., Shein, E. A., & Stolyankov, Y. V. (2022). Structure and Properties of Highly Porous Alumina-Based Ceramic Materials after Heating by Concentrated Solar Radiation. Ceramics, 5(1), 24-33. https://doi.org/10.3390/ceramics5010003