Polymer-Infiltrated Ceramic Network Produced by Direct Ink Writing: The Effects of Manufacturing Design on Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

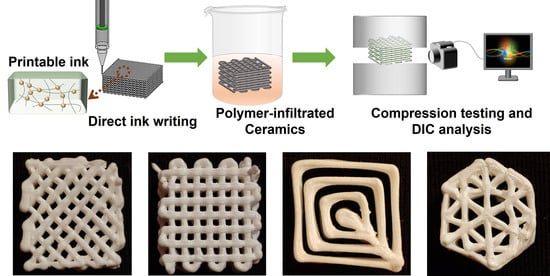

2.2. Preparation of Zirconia-Based PICN

2.2.1. Preparation of Zirconia Scaffolds via Direct Ink Writing Method

2.2.2. Preparation of the Polymer-Infiltrated Ceramic Networks

2.3. Characterization

3. Results and Discussion

3.1. Microstructural Characterization

3.2. Characterization of Zirconia Scaffolds

3.2.1. Structure Characterization

3.2.2. Shrinkage and Density

3.2.3. Characterization of Macropores

3.2.4. Tomography Characterization

3.3. Characterization of PICN Hybrid Material

3.4. Mechanical Characterization

3.4.1. Effect of Copolymer Infiltration

3.4.2. Effect of Specimen Geometry

3.5. Failure Analysis

4. Conclusions

- (1)

- Phase transformation was detected after sintering, compared to as-received ceramic powder. The tetragonal phase became predominant, accounting for approximately 100%, whereas the monoclinic one significantly decreased;

- (2)

- The feasibility of fabricating zirconia scaffolds with dimensionally stable and various geometries has been proven. The printing defects observed in the scaffolds mainly depend on the type of geometry of the samples;

- (3)

- Copolymer infiltration was more significant than 80% for all the geometries studied, reaching 95% for CY-A.chords. The presence of polymer in the PICN samples reduced the effect of the defects observed in the scaffolds;

- (4)

- PICN samples were more capable of withstanding higher stresses. The C-grid 0 and C-grid 45 geometries had the highest compression stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015.

- Sodeyama, M.K.; Ikeda, H.; Nagamatsu, Y.; Masaki, C.; Hosokawa, R.; Shimizu, H. Printable PICN composite mechanically compatible with human teeth. J. Dent. Res. 2021, 100, 1475–1481. [Google Scholar] [CrossRef]

- Danforth, S.C. Fused deposition of ceramics: A new technique for the rapid fabrication of ceramic components. Mater. Technol. 1995, 10, 144–146. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Chen, Q.; Fu, X.; Li, Y. Effect of particle size distribution on the preparation of ZTA ceramic paste applying for stereolithography 3D printing. Powder Technol. 2020, 359, 314–322. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Ding, G.; Bai, X.; Fang, D. Effects of fine grains and sintering additives on stereolithography additive manufactured Al2O3 ceramic. Ceram. Int. 2021, 47, 2303–2310. [Google Scholar] [CrossRef]

- Miao, G.; Du, W.; Moghadasi, M.; Pei, Z.; Ma, C. Ceramic binder jetting additive manufacturing: Effects of granulation on properties of feedstock powder and printed and sintered parts. Addit. Manuf. 2020, 36, 101542. [Google Scholar] [CrossRef]

- Du, W.; Singh, M.; Singh, D. Binder jetting additive manufacturing of silicon carbide ceramics: Development of bimodal powder feedstocks by modeling and experimental methods. Ceram. Int. 2020, 46, 19701–19707. [Google Scholar] [CrossRef]

- Ratsimba, A.; Zerrouki, A.; Tessier-Doyen, N.; Nait-Ali, B.; André, D.; Duport, P.; Neveu, A.; Tripathi, N.; Francqui, F.; Delaizir, G. Densification behaviour and three-dimensional printing of Y2O3 ceramic powder by selective laser sintering. Ceram. Int. 2021, 47, 7465–7474. [Google Scholar] [CrossRef]

- Sun, J.; Chen, X.; Wade-Zhu, J.; Binner, J.; Bai, J. A comprehensive study of dense zirconia components fabricated by additive manufacturing. Addit. Manuf. 2021, 43, 101994. [Google Scholar] [CrossRef]

- Hodásová, L.; Sans, J.; Molina, B.G.; Alemán, C.; Llanes, L.; Fargas, G.; Armelin, E. Polymer infiltrated ceramic networks with biocompatible adhesive and 3D-printed highly porous scaffolds. Addit. Manuf. 2021, 39, 101850. [Google Scholar] [CrossRef]

- Martínez-Vázquez, F.J.; Sánchez-González, E.; Borrero-López, O.; Miranda, P.; Pajares, A.; Guiberteau, F. Novel bioinspired composites fabricated by robocasting for dental applications. Ceram. Int. 2021, 47, 21343–21349. [Google Scholar] [CrossRef]

- Hodásová, L.; Morena, A.G.; Tzanov, T.; Fargas, G.; Llanes, L.; Alemán, C.; Armelin, E. 3D-printed polymer-infiltrated ceramic network with antibacterial biobased silver nanoparticles. ACS Appl. Bio Mater. 2022, 5, 4803–4813. [Google Scholar] [CrossRef]

- Zhang, D.; Peng, E.; Borayek, R.; Ding, J. Controllable ceramic green-body configuration for complex ceramic architectures with fine features. Adv. Funct. Mater. 2019, 29, 1807082. [Google Scholar] [CrossRef]

- Conrad, H.J.; Seong, W.J.; Pesun, I.J. Current ceramic materials and systems with clinical recommendations: A systematic review. J. Prosthet. Dent. 2007, 98, 389–404. [Google Scholar] [CrossRef]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. Off. Publ. Acad. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Eldafrawy, M.; Nguyen, J.-F.; Mainjot, A.K.; Sadoun, M.J. A functionally graded PICN material for biomimetic CAD-CAM blocks. J. Dent. Res. 2018, 97, 1324–1330. [Google Scholar] [CrossRef]

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef]

- Saláta, J.; Szabó, F.; Csuti, P.; Antal, M.; Márton, P.; Hermann, P.; Borbély, J.; Ábrám, E. Effect of thickness, translucency, and substrates on the masking ability of a polymer-infiltrated ceramic-network material. J. Esthet. Restor. Dent. 2023, 35, 886–895. [Google Scholar] [CrossRef]

- Facenda, J.C.; Borba, M.; Corazza, P.H. A literature review on the new polymer-infiltrated ceramic-network material (PICN). J. Esthet. Restor. Dent. 2018, 30, 281–286. [Google Scholar] [CrossRef]

- Li, K.; Kou, H.; Rao, J.; Liu, C.; Ning, C. Fabrication of enamel-like structure on polymer-infiltrated zirconia ceramics. Dent. Mater. 2021, 37, 245–255. [Google Scholar] [CrossRef]

- Ikemoto, S.; Nagamatsu, Y.; Masaki, C.; Hosokawa, R.; Ikeda, H. Development of zirconia-based polymer-infiltrated ceramic network for dental restorative material. J. Mech. Behav. Biomed. Mater. 2023, 150, 106320. [Google Scholar] [CrossRef]

- Hodásová, L.; Alemán, C.; Del Valle, L.J.; Llanes, L.; Fargas, G.; Armelin, E. 3D-printed polymer-infiltrated ceramic network with biocompatible adhesive to potentiate dental implant applications. Materials 2021, 14, 5513. [Google Scholar] [CrossRef]

- Li, J.; Cui, B.; Lin, Y.; Deng, X.; Li, M.; Nan, C. High strength and toughness in chromatic polymer-infiltrated zirconia ceramics. Dent. Mater. 2016, 32, 1555–1563. [Google Scholar] [CrossRef]

- Shahzad, A.; Lazoglu, I. Direct ink writing (DIW) of structural and functional ceramics: Recent achievements and future challenges. Compos. Part B Eng. 2021, 225, 109249. [Google Scholar] [CrossRef]

- Zhang, J.; Yarahmadi, M.; Cabezas, L.; Serra, M.; Elizalde, S.; Cabrera, J.M.; Llanes, L.; Fargas, G. Robocasting of dense 8Y zirconia parts: Rheology, printing, and mechanical properties. J. Eur. Ceram. Soc. 2022, 43, 2794–2804. [Google Scholar] [CrossRef]

- Tosoh Tosoh Zirconia Brochure. Available online: https://www.rbhltd.com/wp-content/uploads/2019/05/Tosoh-Zirconia-Brochure.pdf (accessed on 21 March 2022).

- Yarahmadi, M.; Barcelona, P.; Fargas, G.; Xuriguera, E.; Roa, J.J. Optimization of the ceramic ink used in direct ink writing through rheological properties characterization of zirconia-based ceramic materials. Ceram. Int. 2022, 48, 4775–4781. [Google Scholar] [CrossRef]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration curve for quantitative analysis of the monoclinic-tetragonal ZrO2 system by X-ray diffraction. J. Am. Ceram. Soc. 1984, 67, C-119–C-121. [Google Scholar] [CrossRef]

- Awwad, A.M.; Salem, N.M.; Abdeen, A.O. Biosynthesis of silver nanoparticles using Olea europaea leaves extract and its antibacterial activity. Nanosci. Nanotechnol. 2012, 2, 164–170. [Google Scholar] [CrossRef]

- Wang, F.; Teng, X.; Hu, X.; Jiang, Y.; Guo, X.; Li, L.; Liu, X.; Liu, X.; Lu, H. Damage and failure analysis of a SiCf/SiC ceramic matrix composite using digital image correlation and acoustic emission. Ceram. Int. 2022, 48, 4699–4709. [Google Scholar] [CrossRef]

- Biegler, M.; Graf, B.; Rethmeier, M. In-situ distortions in LMD additive manufacturing walls can be measured with digital image correlation and predicted using numerical simulations. Addit. Manuf. 2018, 20, 101–110. [Google Scholar] [CrossRef]

- Isaac, J.P.; Dondeti, S.; Tippur, H.V. Crack initiation and growth in additively printed ABS: Effect of print architecture studied using DIC. Addit. Manuf. 2020, 36, 101536. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 62001. [Google Scholar] [CrossRef]

- Dong, Y.L.; Pan, B. A review of speckle pattern fabrication and assessment for digital image correlation. Exp. Mech. 2017, 57, 1161–1181. [Google Scholar] [CrossRef]

- Périé, J.N.; Calloch, S.; Cluzel, C.; Hild, F. Analysis of a multiaxial test on a C/C composite by using digital image correlation and a damage model. Exp. Mech. 2002, 42, 318–328. [Google Scholar] [CrossRef]

- Bastawros, A.F.; Bart-Smith, H.; Evans, A.G. Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J. Mech. Phys. Solids 2000, 48, 301–302. [Google Scholar] [CrossRef]

- Wattrisse, B.; Chrysochoos, A.; Muracciole, J.M.; Némoz-Gaillard, M. Analysis of strain localization during tensile tests by digital image correlation. Exp. Mech. 2001, 41, 29–39. [Google Scholar] [CrossRef]

- Lo, C.; Sano, T.; Hogan, J.D. Microstructural and mechanical characterization of variability in porous advanced ceramics using X-ray computed tomography and digital image correlation. Mater. Charact. 2019, 158, 109929. [Google Scholar] [CrossRef]

- Bannunah, A.M. Biomedical applications of zirconia-based nanomaterials: Challenges and future perspectives. Molecules 2023, 28, 5428. [Google Scholar] [CrossRef]

- Tovar-Vargas, D.; Turon-Vinas, M.; Anglada, M.; Jimenez-Pique, E. Enhancement of mechanical properties of ceria-calcia stabilized zirconia by alumina reinforcement. J. Eur. Ceram. Soc. 2020, 40, 3714–3722. [Google Scholar] [CrossRef]

- Yarahmadi, M.; Roa, J.J.; Zhang, J.; Cabezas, L.; Ortiz-Membrado, L.; Llanes, L.; Fargas, G. Micromechanical properties of yttria-doped zirconia ceramics manufactured by direct ink writing. J. Eur. Ceram. Soc. 2022, 43, 2884–2893. [Google Scholar] [CrossRef]

- Kitano, Y.; Mori, Y.; Ishitani, A.; Masaki, T. Rhombohedral phase in Y2O3-partially-stabilized ZrO2. J. Am. Ceram. Soc. 1988, 71, C-34–C-36. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity measurements and analysis for metal additive manufacturing process control. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 494. [Google Scholar] [CrossRef] [PubMed]

| Typical Properties | 3Y-ZrO2 |

|---|---|

| Particle size (nm) | 90 |

| Specific surface area (m2/g) | 7 ± 2 |

| Density T (g/cm3) | 6.05 |

| Bending strength 1 (MPa) | 1200 |

| Hardness 2 (HV 10) | 1250 |

| Phase | Vx (%) | 2θ (°) | β (rad) | cos (θ) | D (nm) | |

|---|---|---|---|---|---|---|

| Powder | Tetragonal | ~68 | 30 | 0.005 | 0.965 | 30 |

| Monoclinic | ~32 | 28 | 0.006 | 0.97 | 22 | |

| Sintered samples | Tetragonal | ~100 | 30 | 0.003 | 0.966 | 48 |

| Monoclinic | - | - | - | - | - |

| Sample | 3D-Printed Zirconia Scaffold | 3D-Printed Zirconia with Copolymer Infiltrated (PICN) | |

|---|---|---|---|

| Shrinkage | Density (g/cm3) | Infiltration (%) | |

| C-rectilinear | 31.4 ± 3.3 | 5.79 ± 0.04 | 89.6 ± 0.7 |

| C-grid 0 | 31.4 ± 1.2 | 5.72 ± 0.13 | 93.0 ± 0.5 |

| C-grid 45 | 28.9 ± 0.8 | 5.66 ± 0.15 | 91.3 ± 1.3 |

| C-concentric | 29.3 ± 1.5 | 5.75 ± 0.02 | 90.7 ± 0.2 |

| CY-A.chords | 27.3 ± 2.8 | 5.72 ± 0.07 | 94.9 ± 3.5 |

| H-triangles p. | 30.6 ± 1.3 | 5.74 ± 0.04 | 84.7 ± 9.6 |

| Sample | σmax (MPa) | εcompression (%) | |

|---|---|---|---|

| Zirconia scaffolds | C-rectilinear | 4.5 ± 0.8 | 2.6 ± 0.7 |

| C-grid 0 | 56.4 ± 13.1 | 2.4 ± 0.2 | |

| C-grid 45 | 62.7 ± 3.0 | 3.5 ± 0.1 | |

| C-concentric | 31.8 ± ** | 3.2 ± ** | |

| CY-A.Chords | 61.7 ± 7.4 | 2.3 ± 1.0 | |

| H-triangles p. | 36.0 ± 8.1 | 2.4 ± 0.5 | |

| PICN hybrid materials | PICN C-rectilinear | 65.4 ± 6.8 | 3.1 ± 0.1 |

| PICN C-grid 0 | 71.6 ± 2.2 | 2.5 ± 0.3 | |

| PICN C-grid 45 | 68.7 ± 0.1 | 2.6 ± 1.0 | |

| PICN C-concentric | 94.6 ± 0.6 | 2.7 ± 0.6 | |

| PICN CY-A.Chords | 160.1 ± 2.7 | 2.2 ± * | |

| PICN H-triangles p. | 80.9 ± * | 2.0 ± * | |

| Samples with 100% | C-100% | 56.0 ± 7.5 | 3.8 ± 0.3 |

| CY-100% | 92.4 ± ** | 2.2 ± ** | |

| H-100% | 48.1 ± ** | 5.7 ± ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Pou, P.; Hodásová, L.; Yarahmadi, M.; Elizalde, S.; Cabrera, J.-M.; Llanes, L.; Armelin, E.; Fargas, G. Polymer-Infiltrated Ceramic Network Produced by Direct Ink Writing: The Effects of Manufacturing Design on Mechanical Properties. Ceramics 2024, 7, 436-451. https://doi.org/10.3390/ceramics7020028

Zhang J, Pou P, Hodásová L, Yarahmadi M, Elizalde S, Cabrera J-M, Llanes L, Armelin E, Fargas G. Polymer-Infiltrated Ceramic Network Produced by Direct Ink Writing: The Effects of Manufacturing Design on Mechanical Properties. Ceramics. 2024; 7(2):436-451. https://doi.org/10.3390/ceramics7020028

Chicago/Turabian StyleZhang, Junhui, Paula Pou, Ludmila Hodásová, Mona Yarahmadi, Sergio Elizalde, Jose-Maria Cabrera, Luis Llanes, Elaine Armelin, and Gemma Fargas. 2024. "Polymer-Infiltrated Ceramic Network Produced by Direct Ink Writing: The Effects of Manufacturing Design on Mechanical Properties" Ceramics 7, no. 2: 436-451. https://doi.org/10.3390/ceramics7020028

APA StyleZhang, J., Pou, P., Hodásová, L., Yarahmadi, M., Elizalde, S., Cabrera, J. -M., Llanes, L., Armelin, E., & Fargas, G. (2024). Polymer-Infiltrated Ceramic Network Produced by Direct Ink Writing: The Effects of Manufacturing Design on Mechanical Properties. Ceramics, 7(2), 436-451. https://doi.org/10.3390/ceramics7020028