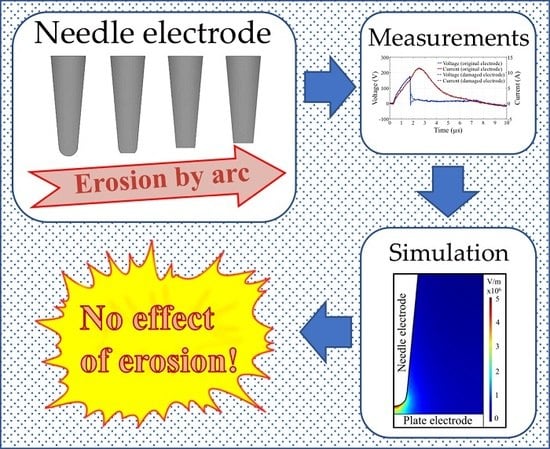

Analysis of the Preheating Phase of Micro-Arc Discharge in Seawater, Operated Using a Needle-to-Plane Electrode with Variation in the Tip Shape

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Current and Voltage Waveforms

3.2. Optical Emission Spectrometry

3.3. Mathematical Model

- —

- LCR oscillation model with defined steps in time, with variable resistor instead of electrodes immersed in the 10ASW;

- —

- Local process in the discharge gap and surrounding seawater using parameters calculated in the first block and dimensions from the experimental setup.

3.4. Results of Mathematical Modeling

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, H.-G.; Lee, H.; Kim, S.-J.; Kim, D.-H.; Kim, J.-S.; Kang, S.-Y.; Jung, S.-C. Synthesis of manganese nanoparticles in the liquid phase plasma. J. Nanosci. Nanotechnol. 2013, 13, 6103–6108. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-J.; Kim, B.H.; Chung, M.C.; Ahn, H.-G.; Kim, S.-C.; Kim, H.-G.; Jung, S.-C. The synthesis of nickel nanoparticles by liquid phase plasma processing. J. Nanosci. Nanotechnol. 2013, 13, 1997–2000. [Google Scholar] [CrossRef] [PubMed]

- Oh, J.-S.; Szili, E.J.; Ito, S.; Hong, S.-H.; Gaur, N.; Furuta, H.; Short, R.D.; Hatta, A. Slow molecular transport of plasma-generated reactive oxygen and nitrogen species and O2 through agarose as surrogate for tissue. Plasma Med. 2016, 5, 125–143. [Google Scholar] [CrossRef]

- Tung, N.H.; Chikae, M.; Ukita, Y.; Viet, P.H.; Takamura, Y. Sensing technique of silver nanoparticles as labels for immunoassay using liquid electrode plasma atomic emission spectrometry. Anal. Chem. 2012, 84, 1210–1213. [Google Scholar] [CrossRef] [PubMed]

- Akiyama, H. Streamer Discharges in Liquids and their Applications. lEEE Trans. Dielectr. Electr. Insul. 2000, 7, 646–653. [Google Scholar] [CrossRef]

- Ito, M.; Oh, J.S.; Ohta, T.; Shiratani, M.; Hori, M. Current status and future prospects of agricultural applications using atmospheric-pressure plasma technologies. Plasma Process. Polym. 2018, 15, e1700073. [Google Scholar] [CrossRef]

- Gamaleev, V.; Kajikawa, K.; Takeda, K.; Hiramatsu, M. Investigation of Nanographene Produced by In-Liquid Plasma for Development of Highly Durable Polymer Electrolyte Fuel Cells. C 2018, 4, 65. [Google Scholar] [CrossRef]

- Iwata, N.; Gamaleev, V.; Hashizume, H.; Oh, J.; Ohta, T.; Ishikawa, K.; Hori, M.; Ito, M. Simultaneous achievement of antimicrobial property and plant growth promotion using plasma-activated benzoic compound solution. Plasma Process. Polym. 2019, e1900023. [Google Scholar] [CrossRef]

- Iwata, N.; Gamaleev, V.; Oh, J.-S.; Ohta, T.; Hori, M.; Ito, M. Investigation on the long-term bactericidal effect and chemical composition of radical-activated water. Plasma Process. Polym. 2019, e1900055. [Google Scholar] [CrossRef]

- Kohara, Y.; Terui, Y.; Ichikawa, M.; Yamamoto, K.; Shirasaki, T.; Kohda, K.; Yamamoto, T.; Takamura, Y. Atomic emission spectrometry in liquid electrode plasma using an hourglass microchannel. J. Anal. At. Spectrom. 2015, 30, 2125–2128. [Google Scholar] [CrossRef]

- Kohara, Y.; Terui, Y.; Ichikawa, M.; Shirasaki, T.; Yamamoto, K.; Yamamoto, T.; Takamura, Y. Characteristics of liquid electrode plasma for atomic emission spectrometry. J. Anal. At. Spectrom. 2012, 27, 1457. [Google Scholar] [CrossRef]

- Gamaleev, V.; Okamura, Y.; Kitamura, K.; Hashimoto, Y.; Oh, J.-S.; Furuta, H.; Hatta, A. Investigation of microplasma discharge in sea water for optical emission spectroscopy. Jpn. J. Appl. Phys. 2016, 55, 07LC03. [Google Scholar] [CrossRef]

- Gamaleev, V.; Furuta, H.; Hatta, A. Atomic Emission Spectroscopy of Microarc Discharge in Sea Water for On-Site Detection of Metals. IEEE Trans. Plasma Sci. 2019, 47, 1841–1850. [Google Scholar] [CrossRef]

- Van Khoai, D.; Miyahara, H.; Yamamoto, T.; Tue, P.T.; Okino, A.; Takamura, Y. Development of AC-driven liquid electrode plasma for sensitive detection of metals. Jpn. J. Appl. Phys. 2016, 55, 02BC23. [Google Scholar] [CrossRef]

- Gamaleev, V.; Furuta, H.; Hatta, A. Generation of micro-arc discharge plasma in highly pressurized seawater. Appl. Phys. Lett. 2018, 113, 214102. [Google Scholar] [CrossRef]

- Seepersad, Y.; Pekker, M.; Shneider, M.N.; Fridman, A.; Dobrynin, D. Investigation of positive and negative modes of nanosecond pulsed discharge in water and electrostriction model of initiation. J. Phys. D Appl. Phys. 2013, 46, 355201. [Google Scholar] [CrossRef] [Green Version]

- Schoenbach, K.; Kolb, J.; Xiao, S.; Katsuki, S.; Minamitani, Y.; Joshi, R. Electrical breakdown of water in microgaps. Plasma Sources Sci. Technol. 2008, 17, 024010. [Google Scholar] [CrossRef]

- Jin, Y.; Cho, C.; Ryoo, H.; Kim, J.; Rim, G. Long Gap Discharge in Water. J. Korean Phys. Soc. 2011, 59, 3640–3643. [Google Scholar] [CrossRef]

- Vetchinin, S.P.; Vasilyak, L.M.; Pecherkin, V.Y.; Panov, V.A.; Son, E.E. Spark discharge in conductive liquid with microbubbles. J. Phys. Conf. Ser. 2016, 774, 012183. [Google Scholar] [CrossRef] [Green Version]

- Gavrilov, I.M.; Kukhta, V.R.; Lopatin, V.V.; Petrov, P.G. Dynamics of prebreakdown phenomena in a uniform field in water. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 496–502. [Google Scholar] [CrossRef]

- An, W.; Baumung, K.; Bluhm, H. Underwater streamer propagation analyzed from detailed measurements of pressure release. J. Appl. Phys. 2007, 101, 053302. [Google Scholar] [CrossRef]

- Devins, J.C.; Rzad, S.J.; Schwabe, R.J. Breakdown and prebreakdown phenomena in liquids. J. Appl. Phys. 1981, 52, 4531–4545. [Google Scholar] [CrossRef]

- Kitano, A.; Iiduka, A.; Yamamoto, T.; Ukita, Y.; Tamiya, E.; Takamura, Y. Highly sensitive elemental analysis for Cd and Pb by liquid electrode plasma atomic emission spectrometry with quartz glass chip and sample flow. Anal. Chem. 2011, 83, 9424–9430. [Google Scholar] [CrossRef] [PubMed]

- Gamaleev, V.; Furuta, H.; Hatta, A. Detection of metal contaminants in seawater by spectral analysis of microarc discharge. Jpn. J. Appl. Phys. 2018, 57, 0102B8. [Google Scholar] [CrossRef]

- Khoai, D.V.; Yamamoto, T.; Ukita, Y.; Takamura, Y. On-chip solid phase extraction-liquid electrode plasma atomic emission spectrometry for detection of trace lead. Jpn. J. Appl. Phys. 2014, 53, 05FS01. [Google Scholar] [CrossRef]

- Wilson, C.G.; Gianchandani, Y.B. Spectral detection of metal contaminants in water using an on-chip microglow discharge. IEEE Trans. Electron Devices 2002, 49, 2317–2322. [Google Scholar] [CrossRef]

- Raizer, Y.P. Gas Discharge Physics, 1st ed.; Allen, J.E., Ed.; Springer: Berlin/Heidelberg, Germany, 1991; ISBN 978-3-642-64760-4. [Google Scholar]

- Lu, Q.; Yang, S.; Sun, D.; Zheng, J.; Li, Y.; Yu, J.; Su, M. Direct determination of Cu by liquid cathode glow discharge-atomic emission spectrometry. Spectrochim. Acta Part B At. Spectrosc. 2016, 125, 136–139. [Google Scholar] [CrossRef]

- Bostrom, K.; Kunzendorf, H. Marine Mineral Exploration. Elsevier Oceanogr. Ser. 1986, 41, 21–53. [Google Scholar] [CrossRef]

- Glasby, G.P. Deep Seabed Mining: Past Failures and Future Prospects. Mar. Georesources Geotechnol. 2002, 20, 161–176. [Google Scholar] [CrossRef]

- Bruneton, P. Geological environment of the Cigar Lake uranium deposit. Can. J. Earth Sci. 1993, 30, 653–673. [Google Scholar] [CrossRef]

- Gamaleev, V.; Oh, J.; Furuta, H.; Hatta, A. Investigation of Effect of Needle Electrode Configuration on Microplasma Discharge Process in Sea Water. IEEE Trans. Plasma Sci. 2017, 45, 754–760. [Google Scholar] [CrossRef]

- Jones, H.M.; Kunhardt, E.E. The influence of pressure and conductivity on the pulsed breakdown of water. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 1016–1025. [Google Scholar] [CrossRef]

- Xiao, P.; Staack, D. Microbubble generation by microplasma in water. J. Phys. D Appl. Phys. 2014, 47, 355203. [Google Scholar] [CrossRef]

- Atrazhev, V.M.; Vorob’ev, V.S.; Timoshkin, I.V.; Given, M.J.; Macgregor, S.J. Mechanisms of Impulse Breakdown in Liquid: The Role of Joule Heating and Formation of Gas Cavities. IEEE Trans. Plasma Sci. 2010, 38, 2644–2651. [Google Scholar] [CrossRef]

- Potocký, Š.; Saito, N.; Takai, O. Needle electrode erosion in water plasma discharge. Thin Solid Films 2009, 518, 918–923. [Google Scholar] [CrossRef]

- Lide, D.R.; Baysinger, G. CRC Handbook of Chemistry and Physics, 83rd ed.; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Sauerheber, R.; Heinz, B. Temperature Effects on Conductivity of Seawater and Physiologic Saline, Mechanism and Significance. Chem. Sci. J. 2015, 6, 109. [Google Scholar] [CrossRef]

- Hayashi, M. Water For Environmental Monitoring and Geophysical Data Inversion. Environ. Monit. Assess. 2004, 96, 119–128. [Google Scholar] [CrossRef]

- Pawlowicz, R. The electrical conductivity of seawater at high temperatures and salinities. Desalin. J. 2012, 300, 32–39. [Google Scholar] [CrossRef]

| Composition of 10ASW | Elemental Concentration | ||

|---|---|---|---|

| Ingredient | Mass (g) | Element | Concentration (mol/kg) |

| NaCl | 23.939 | Cl | 0.549 |

| MgCl2 + 6H2O | 10.849 | Na | 0.468 |

| Na2SO4 | 3.994 | Mg | 0.055 |

| CaCl2 | 1.123 | S | 0.028 |

| KCl | 0.667 | Ca | 0.01 |

| NaHCO3 | 0.196 | K | 0.009 |

| KBr | 0.098 | C | 0.0023 |

| H3BO3 | 0.027 | Br | 0.0008 |

| SrCl2 + H2O | 0.004 | B | 0.00046 |

| NaF | 0.003 | F | 0.000053 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamaleev, V.; Hiramatsu, M.; Ito, M.; Furuta, H.; Hatta, A. Analysis of the Preheating Phase of Micro-Arc Discharge in Seawater, Operated Using a Needle-to-Plane Electrode with Variation in the Tip Shape. Plasma 2019, 2, 303-315. https://doi.org/10.3390/plasma2030022

Gamaleev V, Hiramatsu M, Ito M, Furuta H, Hatta A. Analysis of the Preheating Phase of Micro-Arc Discharge in Seawater, Operated Using a Needle-to-Plane Electrode with Variation in the Tip Shape. Plasma. 2019; 2(3):303-315. https://doi.org/10.3390/plasma2030022

Chicago/Turabian StyleGamaleev, Vladislav, Mineo Hiramatsu, Masafumi Ito, Hiroshi Furuta, and Akimitsu Hatta. 2019. "Analysis of the Preheating Phase of Micro-Arc Discharge in Seawater, Operated Using a Needle-to-Plane Electrode with Variation in the Tip Shape" Plasma 2, no. 3: 303-315. https://doi.org/10.3390/plasma2030022

APA StyleGamaleev, V., Hiramatsu, M., Ito, M., Furuta, H., & Hatta, A. (2019). Analysis of the Preheating Phase of Micro-Arc Discharge in Seawater, Operated Using a Needle-to-Plane Electrode with Variation in the Tip Shape. Plasma, 2(3), 303-315. https://doi.org/10.3390/plasma2030022