Carbon Footprint and Total Cost Evaluation of Different Bio-Plastics Waste Treatment Strategies

Abstract

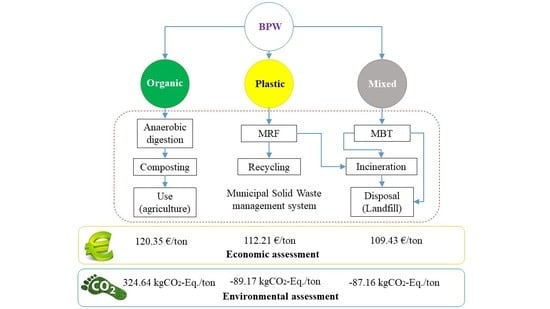

:1. Introduction

2. Materials and Methods

2.1. Framework

2.2. Goal and Scope Definition

2.3. Inventory

2.4. Impact Assessment

2.4.1. Environmental

2.4.2. Economic

3. Results

3.1. Mass and Energy Inventory

3.2. Economic Results

3.3. Environmental Results

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- PlasticsEurope. Plastics Europe; Association of Plastics Manufacturers: Washington, DC, USA, 2020. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horton, A.A.; Barnes, D.K.A. Microplastic pollution in a rapidly changing world: Implications for remote and vulnerable marine ecosystems. Sci. Total Environ. 2020, 738, 140349. [Google Scholar] [CrossRef] [PubMed]

- Mazhandu, Z.S.; Muzenda, E.; Mamvura, T.A.; Belaid, M.; Nhubu, T. Integrated and consolidated review of plastic waste management and bio-based biodegradable plastics: Challenges and opportunities. Sustainability 2020, 12, 8360. [Google Scholar] [CrossRef]

- European Bioplastics Bioplastics Market Development Update 2019. Available online: https://www.european-bioplastics.org/market/ (accessed on 6 June 2022).

- De Gisi, S.; Gadaleta, G.; Gorrasi, G.; La Mantia, F.P.; Notarnicola, M.; Sorrentino, A. The role of (bio)degradability on the management of petrochemical and bio-based plastic waste. J. Environ. Manag. 2022, 310, 114769. [Google Scholar] [CrossRef]

- Girotto, F.; Lavagnolo, M.C.; Pivato, A.; Cossu, R. Acidogenic fermentation of the organic fraction of municipal solid waste and cheese whey for bio-plastic precursors recovery—Effects of process conditions during batch tests. Waste Manag. 2017, 70, 71–80. [Google Scholar] [CrossRef] [PubMed]

- Gadaleta, G.; De Gisi, S.; Picuno, C.; Heerenklage, J.; Cafiero, L.; Oliviero, M.; Notarnicola, M.; Kuchta, K.; Sorrentino, A. The influence of bio-plastics for food packaging on combined anaerobic digestion and composting treatment of organic municipal waste. Waste Manag. 2022, 144, 87–97. [Google Scholar] [CrossRef]

- Bandini, F.; Frache, A.; Ferrarini, A.; Taskin, E.; Cocconcelli, P.S.; Puglisi, E. Fate of Biodegradable Polymers under Industrial Conditions for Anaerobic Digestion and Aerobic Composting of Food Waste. J. Polym. Environ. 2020, 28, 2539–2550. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2018, 58, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Cucina, M.; De Nisi, P.; Trombino, L.; Tambone, F.; Adani, F. Degradation of bioplastics in organic waste by mesophilic anaerobic digestion, composting and soil incubation. Waste Manag. 2021, 134, 67–77. [Google Scholar] [CrossRef]

- Decreto Legislativo Decreto Legislativo 29 Aprile 2010, n. 75, 2010. Riordino e Revisione Della Disciplina in Materia di Fertilizzanti, a Norma Dell’articolo 13 Della Legge 7 Luglio 2009 n. 88. Gazz. Uff. n. 121—Suppl. Ordin. n.106, Roma. 2010. Available online: www.gazzettaufficiale.it/eli/gu/2010/05/26/121/so/106/sg/pdf (accessed on 6 June 2022).

- Cucina, M.; de Nisi, P.; Tambone, F.; Adani, F. The role of waste management in reducing bioplastics’ leakage into the environment: A review. Bioresour. Technol. 2021, 337, 125459. [Google Scholar] [CrossRef]

- Bandini, F.; Taskin, E.; Vaccari, F.; Soldano, M.; Piccinini, S.; Frache, A.; Remelli, S.; Menta, C.; Cocconcelli, P.S.; Puglisi, E. Anaerobic digestion and aerobic composting of rigid biopolymers in bio-waste treatment: Fate and effects on the final compost. Bioresour. Technol. 2022, 351, 126934. [Google Scholar] [CrossRef] [PubMed]

- Battista, F.; Frison, N.; Bolzonella, D. Can bioplastics be treated in conventional anaerobic digesters for food waste treatment? Environ. Technol. Innov. 2021, 22, 101393. [Google Scholar] [CrossRef]

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of bio-based plastics on current recycling of plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef] [Green Version]

- Kuciel, S.; Kuźniar, P.; Nykiel, M. Biodegradable polymers in the general waste stream—The issue of recycling with polyethylene packaging materials. Polymers 2018, 63, 31–37. [Google Scholar] [CrossRef]

- Muenmee, S.; Chiemchaisri, W.; Chiemchaisri, C. Enhancement of biodegradation of plastic wastes via methane oxidation in semi-aerobic landfill. Int. Biodeterior. Biodegrad. 2016, 113, 244–255. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Grosso, M. Bioplastics and waste management. Waste Manag. 2018, 78, 800–801. [Google Scholar] [CrossRef]

- Liu, J.; Huang, Z.; Wang, X. Economic and environmental assessment of carbon emissions from demolition waste based on LCA and LCC. Sustainability 2020, 12, 6683. [Google Scholar] [CrossRef]

- Oldfield, T.L.; White, E.; Holden, N.M. The implications of stakeholder perspective for LCA of wasted food and green waste. J. Clean. Prod. 2018, 170, 1554–1564. [Google Scholar] [CrossRef]

- ISPRA. Rapporto Rifiuti Urbani Edizione 2021; Institute for Environmental Protection and Research (ISPRA): Rome, Italy, 2021. [Google Scholar]

- Dolci, G.; Venturelli, V.; Catenacci, A.; Ciapponi, R.; Malpei, F.; Romano Turri, S.E.; Grosso, M. Evaluation of the anaerobic degradation of food waste collection bags made of paper or bioplastic. J. Environ. Manag. 2022, 305, 114331. [Google Scholar] [CrossRef]

- IPLA spa—Istituto per le Piante da Legno e l’Ambiente. Composition Analysis Evaluation of LHV of Mixed Municipal Waste to Incineration; Istituto per le Piante da Legno e l’Ambiente: Torino, Italy, 2015. (In Italian) [Google Scholar]

- D’Onza, G.; Greco, G.; Allegrini, M. Full cost accounting in the analysis of separated waste collection efficiency: A methodological proposal. J. Environ. Manag. 2016, 167, 59–65. [Google Scholar] [CrossRef]

- Molino, A.; De Gisi, S.; Petta, L.; Franzese, A.; Casella, P.; Marino, T.; Notarnicola, M. Experimental and theoretical investigation on the recovery of green chemicals and energy from mixed agricultural wastes by coupling anaerobic digestion and supercritical water gasification. Chem. Eng. J. 2019, 370, 1101–1110. [Google Scholar] [CrossRef]

- Gadaleta, G.; De Gisi, S.; Binetti, S.M.C.; Notarnicola, M. Outlining a comprehensive techno-economic approach to evaluate the performance of an advanced sorting plant for plastic waste recovery. Process Saf. Environ. Prot. 2020, 143, 248–261. [Google Scholar] [CrossRef]

- Gadaleta, G.; Todaro, F.; De Gisi, S.; Gadaleta, V.; Notarnicola, M. Evaluating the performance of a Municipal Solid Waste MBT plant. Ing. Dell’Ambiente 2021, 8, 91–102. (In Italian) [Google Scholar] [CrossRef]

- Gala, A.; Guerrero, M.; Serra, J.M. Characterization of post-consumer plastic film waste from mixed MSW in Spain: A key point for the successful implementation of sustainable plastic waste management strategies. Waste Manag. 2020, 111, 22–33. [Google Scholar] [CrossRef]

- Van der Harst, E.; Potting, J. A critical comparison of ten disposable cup LCAs. Environ. Impact Assess. Rev. 2013, 43, 86–96. [Google Scholar] [CrossRef]

- Di Maria, F.; Sisani, F. Effectiveness of municipal solid waste incinerators in replacing other fuels. A primary energy balance approach for the EU28. Waste Manag. Res. 2018, 36, 942–951. [Google Scholar] [CrossRef]

- Xin-Gang, Z.; Gui-Wu, J.; Ang, L.; Yun, L. Technology, cost, a performance of waste-to-energy incineration industry in China. Renew. Sustain. Energy Rev. 2016, 55, 115–130. [Google Scholar] [CrossRef]

- IPCC Intergovernmental Panel on Climate Change. Fifth Assessment Report: Climate Change. 2013. Available online: https://www.ipcc.ch/report/ar5/syr/ (accessed on 6 June 2022).

- Marrucci, L.; Marchi, M.; Daddi, T. Improving the carbon footprint of food and packaging waste management in a supermarket of the Italian retail sector. Waste Manag. 2020, 105, 594–603. [Google Scholar] [CrossRef]

- Gadaleta, G.; De Gisi, S.; Notarnicola, M. Feasibility analysis on the adoption of decentralized anaerobic co-digestion for the treatment of municipal organic waste with energy recovery in urban districts of metropolitan areas. Int. J. Environ. Res. Public Health 2021, 18, 1820. [Google Scholar] [CrossRef]

- Palese, A.M.; Persiani, A.; D’Adamo, C.; Pergola, M.; Pastore, V.; Sileo, R.; Ippolito, G.; Lombardi, M.A.; Celano, G. Composting as manure disposal strategy in small/medium-size livestock farms: Some demonstrations with operative indications. Sustainability 2020, 12, 3315. [Google Scholar] [CrossRef] [Green Version]

- Rigamonti, L.; Borghi, G.; Martignon, G.; Grosso, M. Life cycle costing of energy recovery from solid recovered fuel produced in MBT plants in Italy. Waste Manag. 2019, 99, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Bozorgirad, M.A.; Zhang, H.; Haapala, K.R.; Murthy, G.S. Environmental impact and cost assessment of incineration and ethanol production as municipal solid waste management strategies. Int. J. Life Cycle Assess. 2013, 18, 1502–1512. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Di Maria, F. A comparative study of issues, challenges and strategies of bio-waste management in India and Italy. Detritus 2018, 1, 8–17. [Google Scholar] [CrossRef]

- Gadaleta, G.; De Gisi, S.; Todaro, F.; Campanaro, V.; Teodosiu, C.; Notarnicola, M. Sustainability assessment of municipal solid waste separate collection and treatment systems in a large metropolitan area. Sustain. Prod. Consum. 2021, 29, 328–340. [Google Scholar] [CrossRef]

- Coelho, L.M.G.; Lange, L.C. Applying life cycle assessment to support environmentally sustainable waste management strategies in Brazil. Resour. Conserv. Recycl. 2018, 128, 438–450. [Google Scholar] [CrossRef]

- Yang, N.; Zhang, H.; Chen, M.; Shao, L.M.; He, P.J. Greenhouse gas emissions from MSW incineration in China: Impacts of waste characteristics and energy recovery. Waste Manag. 2012, 32, 2552–2560. [Google Scholar] [CrossRef] [PubMed]

- Sohoo, I.; Ritzkowski, M.; Heerenklage, J.; Kuchta, K. Biochemical methane potential assessment of municipal solid waste generated in Asian cities: A case study of Karachi, Pakistan. Renew. Sustain. Energy Rev. 2021, 135, 110175. [Google Scholar] [CrossRef]

| Waste Treatment | Expense/Revenue | Ref. | |

|---|---|---|---|

| Organic | Anaerobic digestion plant operational cost | 105 | [35] |

| Anaerobic digestion plant operational cost | 13 | [36] | |

| Organic waste transportation cost | 183 | [25] | |

| Plastic | Waste sorting revenue (recycling) | 210 | [27] |

| Waste sorting revenue (PLASMIX) | 75 | [27] | |

| Fines for waste contamination | 4.25 | [27] | |

| MRF operational cost | 159 | [27] | |

| Plastic waste transportation cost | 224 | [25] | |

| Mixed | MBT operational cost | 31 | [37] |

| Incineration plant operational cost | 31 | [38] | |

| Mixed waste transportation cost | 79 | [25] | |

| Disposal in landfill tariff | 120 | [39] |

| Treatment | Stream | Organic | Plastic | Mixed |

|---|---|---|---|---|

| AD + composting | Input [kg] | 372.66 | 353.82 | 353.82 |

| Compost [kg] | 98.71 | 93.78 | 93.78 | |

| % BPW in compost [%] | 5.00 | 0.00 | 0.00 | |

| Biogas produced [m3CH4] | 54.87 | 46.61 | 46.61 | |

| Electric energy [kWh] | 187.78 | 159.51 | 159.51 | |

| Thermal energy [kWh] | 268.25 | 222.87 | 222.87 | |

| MRF | Input [kg] | 79.77 | 98.61 | 79.77 |

| Recycled [kg] | 37.77 | 37.77 | 37.77 | |

| PLASMIX [kg] | 42.07 | 60.91 | 42.07 | |

| MBT | Input [kg] | 547.57 | 547.57 | 566.41 |

| RDF [kg] | 178.51 | 178.51 | 193.10 | |

| SOF [kg] | 233.10 | 233.10 | 233.10 | |

| Incineration | Input [kg] | 220.58 | 239.42 | 235.17 |

| Electric energy [kWh] | 224.45 | 239.31 | 235.59 | |

| Thermal energy [kWh] | 555.13 | 591.90 | 582.69 | |

| Ashes [kg] | 6.62 | 7.18 | 7.06 | |

| Total | Waste landfilled [kg] | 333.50 | 240.28 | 240.16 |

| Electric energy [kWh] | 412.23 | 398.82 | 395.09 | |

| Thermal energy [kWh] | 823.39 | 819.77 | 810.55 |

| Organic | Plastic | Mixed | ||||

|---|---|---|---|---|---|---|

| EUR | % | EUR | % | EUR | % | |

| EXPENSES | 250.93 | 241.36 | 236.01 | |||

| Organic | 123.92 | 49.4% | 106.41 | 44.1% | 106.41 | 45.1% |

| Treatment | 43.97 | 17.5% | 41.75 | 17.3% | 41.75 | 17.7% |

| Landfill | 11.85 | 4.7% | 0.00 | 0.0% | 0.00 | 0.0% |

| Transportation | 68.10 | 27.2% | 64.66 | 26.8% | 64.66 | 27.4% |

| Plastic | 30.93 | 12.3% | 38.23 | 15.9% | 30.93 | 13.1% |

| Fines | 0.34 | 0.1% | 0.42 | 0.2% | 0.34 | 0.1% |

| Treatment | 12.69 | 5.1% | 15.68 | 6.5% | 12.69 | 5.4% |

| Transportation | 17.90 | 7.1% | 22.13 | 9.2% | 17.90 | 7.6% |

| Mixed | 96.08 | 38.3% | 96.72 | 40.0% | 98.67 | 41.8% |

| Treatment (MBT) | 17.14 | 6.8% | 17.14 | 7.1% | 17.73 | 7.5% |

| Treatment (Inc.) | 6.73 | 2.7% | 7.31 | 3.0% | 7.18 | 3.0% |

| Landfill | 28.77 | 11.5% | 28.83 | 11.9% | 28.82 | 12.2% |

| Transportation | 43.44 | 17.3% | 43.44 | 18.0% | 44.94 | 19.1% |

| REVENUES | 130.58 | 129.15 | 126.58 | |||

| Organic | 49.63 | 38.0% | 42.16 | 32.6% | 42.16 | 33.3% |

| Energy | 49.63 | 38.0% | 42.16 | 32.6% | 42.16 | 33.3% |

| Plastic | 11.08 | 8.5% | 12.49 | 9.7% | 11.08 | 8.7% |

| Recycling | 7.92 | 6.1% | 7.92 | 6.1% | 7.92 | 6.3% |

| PLASMIX | 3.16 | 2.4% | 4.57 | 3.6% | 3.16 | 2.5% |

| Mixed | 69.87 | 53.5% | 74.50 | 57.7% | 73.34 | 58.0% |

| Energy | 69.87 | 53.5% | 74.50 | 57.7% | 73.34 | 58.0% |

| COST | 120.35 | 112.21 | 109.43 | |||

| Treatment | Organic | Plastic | Mixed |

|---|---|---|---|

| MRF | 1.24 | 1.53 | 1.24 |

| AD + composting | −54.6 | −47.2 | −47.2 |

| MBT | 11.4 | 11.4 | 11.8 |

| Incineration | 30.6 | 21.8 | 22 |

| Landfill | 454 | 54.3 | 56 |

| Recycling | −118 | −131 | −131 |

| Total | 324.64 | −89.17 | −87.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gadaleta, G.; De Gisi, S.; Todaro, F.; Notarnicola, M. Carbon Footprint and Total Cost Evaluation of Different Bio-Plastics Waste Treatment Strategies. Clean Technol. 2022, 4, 570-583. https://doi.org/10.3390/cleantechnol4020035

Gadaleta G, De Gisi S, Todaro F, Notarnicola M. Carbon Footprint and Total Cost Evaluation of Different Bio-Plastics Waste Treatment Strategies. Clean Technologies. 2022; 4(2):570-583. https://doi.org/10.3390/cleantechnol4020035

Chicago/Turabian StyleGadaleta, Giovanni, Sabino De Gisi, Francesco Todaro, and Michele Notarnicola. 2022. "Carbon Footprint and Total Cost Evaluation of Different Bio-Plastics Waste Treatment Strategies" Clean Technologies 4, no. 2: 570-583. https://doi.org/10.3390/cleantechnol4020035

APA StyleGadaleta, G., De Gisi, S., Todaro, F., & Notarnicola, M. (2022). Carbon Footprint and Total Cost Evaluation of Different Bio-Plastics Waste Treatment Strategies. Clean Technologies, 4(2), 570-583. https://doi.org/10.3390/cleantechnol4020035