Degradation of Epoxy–Particles Composites Exposed to UV and Gamma Radiation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Zinc Oxide Particles

2.2. Epoxy Resin

2.3. Preparation of the Resin Containing Zinc Oxide Particles

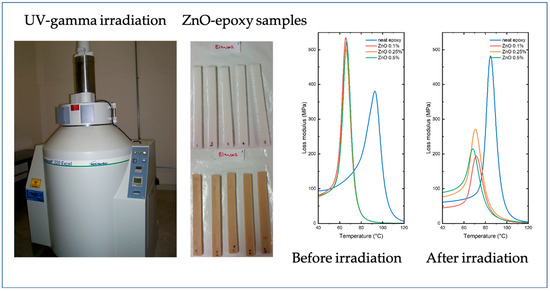

2.4. Exposure to Gamma Radiation

2.5. Thermal Characterization

2.6. Mechanical Characterization

3. Results

3.1. Morphology of Zinc Oxide Particles

3.2. Thermal Performance of Epoxy-ZnO Composite

3.3. Mechanical Performance of Epoxy-ZnO Composite

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Franco-Urquiza, E.A.; Dollinger, A.; Torres-Arellano, M.; Piedra, S.; Llanas, P.I.A.; Rentería-Rodríguez, V.; Pérez, C.Z. Innovation in Aircraft Cabin Interior Panels Part I: Technical Assessment on Replacing the Honeycomb with Structural Foams and Evaluation of Optimal Curing of Prepreg Fiberglass. Polymers 2021, 13, 3207. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; Llanas, P.I.A.; Rentería-Rodríguez, V.; Saleme, R.S.; Aguilar, R.R.; Pérez, C.Z.; Torres-Arellano, M.; Piedra, S. Innovation in Aircraft Cabin Interior Panels. Part II: Technical Assessment on Replacing Glass Fiber with Thermoplastic Polymers and Panels Fabricated Using Vacuum Forming Process. Polymers 2021, 13, 3258. [Google Scholar] [CrossRef] [PubMed]

- Torres-Arellano, M.; Bolom-Martínez, M.d.J.; Franco-Urquiza, E.A.; Pérez-Mora, R.; Jiménez-Arévalo, O.A.; Olivier, P. Bearing Strength and Failure Mechanisms of Riveted Woven Carbon Composite Joints. Aerospace 2021, 8, 105. [Google Scholar] [CrossRef]

- Wong, T.; Tam, W.; Etches, J.A.; Wang, W.; Leng, J.; Lau, K. Feasibility of using ZnO/epoxy filled hollowed glass fibres (HGFs) for UV resistant polymer composites. Mater. Lett. 2014, 128, 220–223. [Google Scholar] [CrossRef]

- Mehrparvar, A. Cubesat Design Specifications Rev. 13; California Polytechnic State University: San Luis Obispo, CA, USA; Stanford University: Stanford, CA, USA, 2014. [Google Scholar]

- Corpino, S.; Caldera, M.; Nichele, F.; Masoero, M.; Viola, N. Thermal design and analysis of a nanosatellite in low earth orbit. Acta Astronaut. 2015, 115, 247–261. [Google Scholar] [CrossRef] [Green Version]

- Niaki, K.S.; Anvari, A.; Farhani, F. Aluminum and composite materials for satellite structures—A comparison of thermal performance. Mater. Sci. Res. India 2007, 4, 25–34. [Google Scholar] [CrossRef]

- Diao, F.; Zhang, Y.; Liu, Y.; Fang, J.; Luan, W. g-Ray irradiation stability and damage mechanism of glycidyl amine epoxy resin. Nucl. Instrum. Methods Phys. Res. Sect. B 2016, 383, 227–233. [Google Scholar] [CrossRef]

- Armstrong, T.W.; Colborn, B.L. Evaluation of Trapped Radiation, Model Uncertainties for Spacecraft Design; Science Applications Intemational Corporation: Prospect, TN, USA, 2000; pp. 1–47. [Google Scholar]

- Bath, B.R.; Upadhyaya, N.; Kulkarni, R. Total radiation dose at geostationary orbit. IEEE Trans. Nucl. Sci. 2005, 52, 530–534. [Google Scholar] [CrossRef]

- Condruz, M.R.; Voicu, L.R.; Puscasu, C.; Vintila, I.S.; Sima, M.; Deaconu, M.; Dragasanu, L. Composite material designs for lightweight space packaging structures. INCAS Bull. 2018, 10, 13–25. [Google Scholar]

- Piedra, S.; Torres, M.; Ledesma, S. Thermal Numerical Analysis of the Primary Composite Structure of a CubeSat. Aerospace 2019, 6, 97. [Google Scholar] [CrossRef] [Green Version]

- Quero, G.; Vaiano, P.; Fienga, F.; Giaquinto, M.; Di Meo, V.; Gorine, G.; Casolaro, P.; Campajola, L.; Breglio, G.; Crescitelli, A.; et al. A novel Lab-on-Fiber Radiation Dosimeter for Ultra-high Dose Monitoring. Sci. Rep. 2018, 8, 17841. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ravotti, F. Dosimetry Techniques and Radiation Test Facilities for Total Ionizing Dose Testing. IEEE Trans. Nucl. Sci. 2018, 65, 1140–1463. [Google Scholar] [CrossRef] [Green Version]

- Torres, M.; Franco-Urquiza, E.A.; González-García, P.; Bárcena-Balderas, J.; Piedra, S.; Madera-Santana, T.; Meléndrez-Amavizca, R.; Quintana-Owen, P. Characterization of Epoxy-Nanoparticle Composites Exposed to Gamma & UV Radiation for Aerospace Applications. Nano Hybrids Compos. 2019, 27, 53–65. [Google Scholar] [CrossRef]

- Qin, L.; Shing, C.; Sawyer, S.; Dutta, P.S. Enhanced ultraviolet sensitivity of zinc oxide nanoparticle photoconductors by surface passivation. Opt. Mater. 2011, 33, 359–362. [Google Scholar] [CrossRef]

- Torres, M.; Rentería, A.V.; Alcántara, P.I.; Franco-Urquiza, E. Mechanical properties and fracture behaviour of agave fibers bio-based epoxy laminates reinforced with zinc oxide. J. Ind. Text. 2020, 51, 5847S–5868S. [Google Scholar] [CrossRef]

- Wong, T.; Lau, K.; Tam, W.; Leng, J.; Etches, J.A. UV resistibility of a nano-ZnO/glass fibre reinforced epoxy composite. Mater. Des. 2014, 56, 254–257. [Google Scholar] [CrossRef]

- Wong, T.; Lau, K.; Tam, W.; Leng, J.; Wang, W.; Li, W.; Wei, H. Degradation of nano-ZnO particles filled styrene-based and epoxy-based SMPs under UVA exposure. Compos. Struct. 2015, 132, 1056–1064. [Google Scholar] [CrossRef]

- Al Naim, A.; Alnaim, N.; Ibrahim, S.S.; Metwally, S.M. Effect of gamma irradiation on the mechanical properties of PVC/ZnO polymer nanocomposite. J. Radiat. Res. Appl. Sci. 2017, 10, 165–171. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Song, L.; Liu, S.; Pei, X.; Zhao, Y.; Min, C.; Shao, R.; Ma, T.; Yin, Y.; Xu, Z.; et al. Metal-organic framework nanoparticles as a free radical scavenger improving the stability of epoxy under high dose gamma radiation. Polym. Degrad. Stab. 2023, 207, 110231. [Google Scholar] [CrossRef]

- Wang, H.; Li, N.; Xu, Z.; Tian, X.; Mai, W.; Li, J.; Chen, C.; Chen, L.; Fu, H.; Zhang, X. Enhanced sheet-sheet welding and interfacial wettability of 3D graphene networks as radiation protection in gamma-irradiated epoxy composites. Compos. Sci. Technol. 2018, 157, 57–66. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, H.; Sun, S. Preparation and Characterization of ZnO Nanoparticles Supported on Amorphous SiO2. Nanomaterials 2017, 7, 217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Camacho, N.; May-Crespo, J.F.; Rojas-Trigos, J.B.; Martínez, K.; Marín, E.; Mondragón-Rodríguez, G.C. Thermal properties and degradation kinetics of epoxy-γ-alumina and epoxy-zinc oxide lightweight composites. Rev. Mex. Fís. 2020, 66, 479–489. [Google Scholar] [CrossRef]

- Chen, K.; Zhao, X.; Zhang, F.; Wu, X.; Huang, W.; Liu, W.; Wang, X. Influence of gamma irradiation on the molecular dynamics and mechanical properties of epoxy resin. Polym. Degrad. Stab. 2019, 168, 108940. [Google Scholar] [CrossRef]

- Wachowski, L.; Hofman, M. Application of TG-DTG analysis in the study of the ammoxidised carbon materials. J. Therm. Anal. Calorim. 2006, 83, 379–383. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; May-Crespo, J.F.; Escalante-Velázquez, C.A.; Pérez-Mora, R.; González-García, P. Thermal Degradation Kinetics of ZnO/polyester Nanocomposites. Polymers 2020, 12, 1753. [Google Scholar] [CrossRef] [PubMed]

- Parimalam, M.; Islam, M.R.; Yunus, R.M. Effects of nano- and micro-sized inorganic filers on the performance of epoxy hybrid nano coatings. Polym. Polym. Compos. 2019, 27, 82–91. [Google Scholar]

- Liu, Y.; Zhang, S.; Pei, X.; Shi, H.; Li, D.; Xu, Z.; Li, S.; Xue, Y.; Song, L. Free radical scavenging behavior of multidimensional nanomaterials in 𝛾-irradiated epoxy resin and mechanical and thermal performance of 𝛾-irradiated composites. Compos. Part C 2021, 4, 100095. [Google Scholar] [CrossRef]

- Yan, M.; Liu, L.; Chen, L.; Li, N.; Jiang, Y.; Xu, Z.; Jing, M.; Hu, Y.; Liu, L.; Zhang, X. Radiation resistance of carbon fiber-reinforced epoxy composites optimized synergistically by carbon nanotubes in interface area/matrix. Compos. Part B 2019, 172, 447–457. [Google Scholar] [CrossRef]

| Property | Value 1 |

|---|---|

| Density cured (kg/m3) | 1.08 |

| Mixing ratio by weight | 100/32 |

| Tg (°C) | 88 |

| Curing (h @ °C) | 24 @ 25 °C |

| Viscosity mixed at 25 °C (mPa·s) | 550 |

| Pot life (500 g) at 25 °C (min) | 140 |

| Composite | 1st Pic (°C) | 2nd Pic (°C) | 3rd Pic (°C) |

|---|---|---|---|

| Neat epoxy | 342.65 | 518.71 | 692.82 |

| 0.1% | 343.65 | 521.81 | 706.07 |

| 0.25% | 343.95 | 520.43 | 701.25 |

| 0.5% | 344.81 | 521.64 | 698.54 |

| Composite | 1st Pic (°C) | 2nd Pic (°C) | 3rd Pic (°C) |

|---|---|---|---|

| Neat epoxy | 335.57 | 514.31 | 658.53 |

| 0.1% | 343.98 | 516.22 | 699.44 |

| 0.25% | 337.00 | 523.69 | 690.97 |

| 0.5% | 342.40 | 516.39 | 683.71 |

| Composite | Ultimate Strength (MPa) | Ultimate Strain | Flexural Modulus (GPa) |

|---|---|---|---|

| Neat epoxy | 112.13 ± 6.2 | 0.029 ± 0.001 | 4.3 ± 0.33 |

| 0.1% | 65.81 ± 7.9 | 0.016 ± 0.001 | 4.9 ± 0.49 |

| 0.25% | 51.10 ± 1.7 | 0.017 ± 0.003 | 3.2 ± 0.63 |

| 0.5% | 48.55 ± 12.9 | 0.021 ± 0.001 | 2.9 ± 0.47 |

| Composite | Ultimate Strength (MPa) | Ultimate Strain | Flexural Modulus (GPa) |

|---|---|---|---|

| Neat epoxy | 38.01 ± 4.6 | 0.051 ± 0.004 | 0.77 ± 0.16 |

| 0.1% | 28.71 ± 1.5 | 0.074 ± 0.003 | 0.48 ± 0.02 |

| 0.25% | 27.70 ± 6.69 | 0.092 ± 0.027 | 0.30 ± 0.13 |

| 0.5% | 25.11 ± 8.45 | 0.062 ± 0.029 | 0.29 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres, M.; Burdin, L.; Rentería-Rodríguez, A.V.; Franco-Urquiza, E.A. Degradation of Epoxy–Particles Composites Exposed to UV and Gamma Radiation. Chemistry 2023, 5, 559-570. https://doi.org/10.3390/chemistry5010040

Torres M, Burdin L, Rentería-Rodríguez AV, Franco-Urquiza EA. Degradation of Epoxy–Particles Composites Exposed to UV and Gamma Radiation. Chemistry. 2023; 5(1):559-570. https://doi.org/10.3390/chemistry5010040

Chicago/Turabian StyleTorres, Mauricio, Louise Burdin, A. Victoria Rentería-Rodríguez, and Edgar A. Franco-Urquiza. 2023. "Degradation of Epoxy–Particles Composites Exposed to UV and Gamma Radiation" Chemistry 5, no. 1: 559-570. https://doi.org/10.3390/chemistry5010040

APA StyleTorres, M., Burdin, L., Rentería-Rodríguez, A. V., & Franco-Urquiza, E. A. (2023). Degradation of Epoxy–Particles Composites Exposed to UV and Gamma Radiation. Chemistry, 5(1), 559-570. https://doi.org/10.3390/chemistry5010040