Computational Modelling of Intra-Module Connections and Their Influence on the Robustness of a Steel Corner-Supported Volumetric Module

Abstract

:1. Introduction

2. Materials and Methods

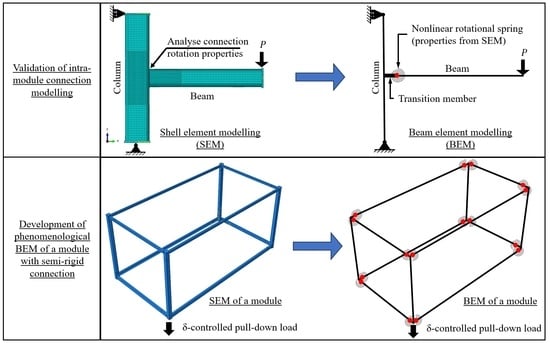

2.1. Modelling Strategy

- Validate computationally intensive SEM to existing test data for the typical intra-module connection;

- Develop computationally efficient and accurate semi-rigid BEM (SR-BEM) that is calibrated against the validated SEM and captures the moment–rotation behaviour of the connections;

- Model the entire module using fully rigid connections (FR-BEM) and compare its structural response to the SR-BEM.

2.1.1. Connection Moment–Rotation Validation of SEM

2.1.2. Moment–Rotation Calibration of SR-BEM

2.2. Framed Module Model

2.2.1. Details of the Module

2.2.2. Material Model

2.2.3. SR-BEM of Module

2.2.4. Boundary Conditions and Loading of Module Model

2.2.5. Numerical Analyses

3. Results and Discussion

3.1. Structural Response Comparison of Full Module SR-BEM and SEM Subjected to Displacement-Controlled Pull-Down Load

3.2. Robustness Assessment of FR-BEM and SR-BEM

4. Conclusions

- A new phenomenological beam element model (BEM) with bilinear/trilinear M-θ relationship for welded hollow section connections (intra-module) that captures the semi-rigidity of the connections with very good accuracy was developed;

- The developed SR-BEM requires 98.7% less computational time and 97.4% less computational effort (RAM) than a typical SEM for a similar level of structural accuracy;

- The SR-BEM performs structurally well under notional support removal when subjected to different load combinations (service, ultimate, accidental, and equivalent static accidental loads);

- For the corner column removal scenario, redistribution of loads to the internal corner supports is negligible;

- On average, a 16% increase in the horizontal support reaction (i.e., tie force) was observed in the long wall support, with a 22.3% reduction in the horizontal support reaction in the short wall support in the SR-BEM compared to the FR-BEM;

- The SR-BEM redistributed 6–7% of the vertical load from the short wall support to the long wall support when compared to the FR-BEM due to the reduced efficiency of the highly stiffness-dependent short-wall Vierendeel frame;

- An increase of at least 16% vertical displacement was identified in the SR-BEM when compared to FR-BEM under multiple residential-type line loadings;

- The results demonstrate the importance of modelling the accurate intra-module connections’ rotational stiffness in order to accurately assess the performance of MSBs under notional support removal.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN-Habitat. Housing. 2021. Available online: https://unhabitat.org/topic/housing (accessed on 16 November 2022).

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- European-Commission. A European Green Deal. 2023. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 5 July 2023).

- RIBA. Design for Manufacture and Assembly (DfMA) Overlay to the RIBA Plan of Work 2020, 2nd ed.; RIBA: London, UK, 2021. [Google Scholar]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Lowe, T. Modular Construction Emits 45% Less Carbon than Traditional Methods, Report Finds. 2022. Available online: https://www.building.co.uk/news/modular-construction-emits-45-less-carbon-than-traditional-methods-report-finds/5117779.article (accessed on 20 March 2024).

- MJH-Structural-Engineers, Ten Degrees, Croydon, UK [Photograph], (2020).

- MJH-Structural-Engineers, College Road, Croydon, UK [Photograph], (2023).

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Thai, H.-T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Selsey, R.V.; Mofid, K.; Eve, P.; Duggleby, S. Modern Methods of Construction; Savills Research: London, UK, 2020. [Google Scholar]

- Liew, J.Y.R.; Chua, Y.S.; Dai, Z. Steel concrete composite systems for modular construction of high-rise buildings. Structures 2019, 21, 135–149. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings—An overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Alembagheri, M.; Sharafi, P.; Hajirezaei, R.; Samali, B. Collapse capacity of modular steel buildings subject to module loss scenarios: The role of inter-module connections. Eng. Struct. 2020, 210, 110373. [Google Scholar] [CrossRef]

- Chua, Y.S.; Liew, J.Y.R.; Pang, S.D. Robustness of Prefabricated Prefinished Volumetric Construction (PPVC) High-rise Building. In Proceedings of the 12th International Conference on Advances in Steel-Concrete Composite Structures (ASCCS 2018), València, Spain, 27–29 June 2018. [Google Scholar] [CrossRef]

- Lawson, R.M.; Richards, J. Modular design for high-rise buildings. Proc. Inst. Civ. Eng.-Struct. Build. 2010, 163, 151–164. [Google Scholar] [CrossRef]

- Luo, F.J.; Bai, Y.; Hou, J.; Huang, Y. Progressive collapse analysis and structural robustness of steel-framed modular buildings. Eng. Fail. Anal. 2019, 104, 643–656. [Google Scholar] [CrossRef]

- Swami, G.; Thai, H.-T.; Liu, X. Structural robustness of composite modular buildings: The roles of CFST columns and inter-module connections. Structures 2023, 48, 1491–1504. [Google Scholar] [CrossRef]

- Shan, S.; Pan, W. Progressive collapse mechanisms of multi-story steel-framed modular structures under module removal scenarios. Structures 2022, 46, 1119–1133. [Google Scholar] [CrossRef]

- Peng, J.; Hou, C.; Shen, L. Progressive collapse analysis of corner-supported composite modular buildings. J. Build. Eng. 2022, 48, 103977. [Google Scholar] [CrossRef]

- BS 5950-1:2000; Structural Use of Steelwork in Building—Part 1: Code of Practice for Design–Rolled and Welded Sections. British Standards Institution: London, UK, 2000.

- GSA. General Services Administration Alternate Path Analysis and Design Guidelines for Progressive Collapse Resistance; General Services Administration: Washington, DC, USA, 2016. [Google Scholar]

- BS EN 1993-1-1:2005; Eurocode 3: Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings. British Standards Institution: London, UK, 2005.

- Thai, H.-T.; Ho, Q.V.; Li, W.; Ngo, T. Progressive collapse and robustness of modular high-rise buildings. Struct. Infrastruct. E 2021, 19, 302–314. [Google Scholar] [CrossRef]

- Chua, Y.S.; Pang, S.D.; Liew, J.Y.R.; Dai, Z. Robustness of inter-module connections and steel modular buildings under column loss scenarios. J. Build. Eng. 2022, 47, 103888. [Google Scholar] [CrossRef]

- Grotmann, D.; Sedlacek, G. Rotational Stiffness of Welded RHS Beam-to-Column Joints; Final Report No. 5BB–8/98, RWTH-Aachen; Institute of Steel Construction: Aachen, Germany, 1998. [Google Scholar]

- Havula, J.; Garifullin, M.; Heinisuo, M.; Mela, K.; Pajunen, S. Moment-rotation behavior of welded tubular high strength steel T joint. Eng. Struct. 2018, 172, 523–537. [Google Scholar] [CrossRef]

- Garifullin, M.; Pajunen, S.; Mela, K.; Heinisuo, M.; Havula, J. Initial in-plane rotational stiffness of welded RHS T joints with axial force in main member. J. Constr. Steel Res. 2017, 139, 353–362. [Google Scholar] [CrossRef]

- SIMULIA, Abaqus 2021 Documentation. 2021. Available online: https://help.3ds.com/2021/English/DSSIMULIA_Established/SIMULIA_Established_FrontmatterMap/sim-t-SIMULIA_EstablishedDocSearchOnline.htm?contextscope=all (accessed on 20 March 2024).

- Heng, S.H.; McCrum, D.; Hyland, D.; Hough, M. Robustness of Square Hollow Column Sections in Open-sided Corner-supported Modular Steel Buildings. In Civil Engineering Research in Ireland 2022 and Irish Transport Research Network 2022; Holmes, N., Paor, C.D., West, R.P., Eds.; Civil Engineering Research Association of Ireland: Dublin, Ireland; Technological University of Dublin: Dublin, Ireland; Trinity College Dublin: Dublin, Ireland, 2022; pp. 195–200. [Google Scholar]

- Chua, Y.S.; Liew, J.Y.R.; Pang, S.D. Modelling of connections and lateral behavior of high-rise modular steel buildings. J. Constr. Steel Res. 2020, 166, 105901. [Google Scholar] [CrossRef]

- Lawson, M. SCI P348: Building Design Using Modules; The Steel Construction Institute: Ascot, Australia, 2007. [Google Scholar]

- BS EN 1993-1-5:2006; Eurocode 3: Design of Steel Structures—Part 1–5: Plated Structural Elements. British Standards Institution: London, UK, 2006.

- BS EN 10025-2:2019; Hot Rolled Products of Structural Steels—Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels. British Standards Institution: London, UK, 2019.

- Uriz, P.; Filippou, F.C.; Mahin, S.A. Model for Cyclic Inelastic Buckling of Steel Braces. J. Struct. Eng. 2008, 134, 619–628. [Google Scholar] [CrossRef]

- Lawson, P.M.; Byfield, M.P.; Popo-Ola, S.O.; Grubb, P.J. Robustness of light steel frames and modular construction. Proc. Inst. Civ. Eng.—Struct. Build. 2008, 161, 3–16. [Google Scholar] [CrossRef]

- BS EN 1990:2002+A1:2005; Eurocode—Basis of Structural Design. British Standards Institution: London, UK, 2005.

- UFC 4-023-03; Design of Buildings to Resist Progressive Collapse. United States Department of Defense: Washington, DC, USA, 2016.

| Load Case | Load Types | Floor a | Finishes | Live Load b | Imposed Load c | Total Load | |

|---|---|---|---|---|---|---|---|

| Area (kN/m2) | Line d (kN/m) | ||||||

| Magnitude (kN/m2) | 3.75 | 0.5 | 1.5 | 1.0 | |||

| LC1 | Service load e (kN/m2) | 6.75 | 11.14 | ||||

| 1.0 × 3.75 | 1.0 × 0.5 | 1.0 × 1.5 | 1.0 × 1.0 | ||||

| LC2 | Ultimate load e (kN/m2) | 9.04 | 14.92 | ||||

| 1.35 × 3.75 | 1.35 × 0.5 | 1.5 × 1.5 | 1.5 × 0.7 × 1.0 | ||||

| LC3 | Accidental load e (kN/m2) | 5.30 | 8.75 | ||||

| 1.0 × 3.75 | 1.0 × 0.5 | 1.0 × 0.5 × 1.5 | 1.0 × 0.3 × 1.0 | ||||

| LC4 | Equivalent static accidental load with dynamic f (kN/m2) | 9.53 | 15.72 | ||||

| 1.5 × 1.2 × 3.75 | 1.5 × 1.2 × 0.5 | 1.5 × 0.5 × 1.5 | 1.5 × 0.5 × 1.0 | ||||

| Model | SEM | BEM | % Difference |

|---|---|---|---|

| Finite Element | S4R | B32/B32OS | - |

| No. of integration points per element | 1 | 2 | N/A |

| Total no. of finite elements | 176,972 | 100 | - |

| Computational runtime (s) | 5784 | 78 | −98.7% |

| Minimum RAM required (MB) | 661 | 17 | −97.4% |

| Normalised computational time | 30.6 | 1.3 | −95.8% |

| Load Types | Line Load (kN/m) | Model | Support Reactions (kN) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A (Fy) | B (Fx) | B (Fz) | C (Fy) | D (Fz) | E (Fy) | F (Fx) | |||

| Service | 11.14 | FR-BEM | 33.7 | 0.071 | 0.480 | 53.0 | 40.2 | 47.0 | 14.5 |

| SR-BEM | 33.7 | 0.059 | 0.366 | 56.1 | 46.6 | 43.9 | 11.2 | ||

| Ultimate | 14.92 | FR-BEM | 45.1 | 0.088 | 0.624 | 70.9 | 53.8 | 63.0 | 19.4 |

| SR-BEM | 45.1 | 0.071 | 0.469 | 75.1 | 62.4 | 58.9 | 15.0 | ||

| Accidental | 8.75 | FR-BEM | 26.5 | 0.059 | 0.385 | 41.6 | 31.6 | 36.9 | 11.3 |

| SR-BEM | 26.4 | 0.050 | 0.296 | 44.1 | 36.6 | 34.5 | 8.79 | ||

| Equivalent Static Accidental | 15.72 | FR-BEM | 47.5 | 0.091 | 0.653 | 74.7 | 56.7 | 66.3 | 20.4 |

| SR-BEM | 47.5 | 0.073 | 0.490 | 79.1 | 65.7 | 62.0 | 15.8 | ||

| Load Types | Line Load (kN/m) | Percentage Difference in Supports Reaction | ||||||

|---|---|---|---|---|---|---|---|---|

| A (Fy) | B (Fx) | B (Fz) | C (Fy) | D (Fz) | E (Fy) | F (Fx) | ||

| Service | 11.14 | 0% | −16% | −24% | 6% | 16% | −7% | −22% |

| Ultimate | 14.92 | 0% | −20% | −25% | 6% | 16% | −7% | −22% |

| Accidental | 8.75 | 0% | −15% | −23% | 6% | 16% | −7% | −23% |

| Equivalent Static Accidental | 15.72 | 0% | −20% | −25% | 6% | 16% | −7% | −22% |

| Average | - | 0% | −17.8% | −24.3% | 6% | 16% | −7% | −22.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heng, S.H.; Hyland, D.; Hough, M.; McCrum, D. Computational Modelling of Intra-Module Connections and Their Influence on the Robustness of a Steel Corner-Supported Volumetric Module. Modelling 2024, 5, 392-409. https://doi.org/10.3390/modelling5010021

Heng SH, Hyland D, Hough M, McCrum D. Computational Modelling of Intra-Module Connections and Their Influence on the Robustness of a Steel Corner-Supported Volumetric Module. Modelling. 2024; 5(1):392-409. https://doi.org/10.3390/modelling5010021

Chicago/Turabian StyleHeng, Si Hwa, David Hyland, Michael Hough, and Daniel McCrum. 2024. "Computational Modelling of Intra-Module Connections and Their Influence on the Robustness of a Steel Corner-Supported Volumetric Module" Modelling 5, no. 1: 392-409. https://doi.org/10.3390/modelling5010021

APA StyleHeng, S. H., Hyland, D., Hough, M., & McCrum, D. (2024). Computational Modelling of Intra-Module Connections and Their Influence on the Robustness of a Steel Corner-Supported Volumetric Module. Modelling, 5(1), 392-409. https://doi.org/10.3390/modelling5010021