1. Introduction

The search by man for better and newer materials has continued to grow over time and is perhaps eternal. Since the beginning of human existence on Earth, several materials have gained familiarity and acceptability over the years. These materials include bits of rock, sand, earth, and stones, as well as different ceramic artifacts such as animal skins and bones, horns, nails, leaves, and wood, as well as plant fibers such as cotton, coir, straw, hemp, jute, wool, and hair. Numerous fibers of plant and animal origin; silk fiber from insects; natural adhesive/film-forming gums and resins (such as agar, rosin, algae, shellac, etc.); fossil fuels such as lignite, coal, natural gas, petroleum, quartz, glass, metals, and alloys derived from minerals and ores; and many other substances are also included in this list.

The word “polymer” is derived from the Greek words “poly” (meaning many or much) and “mer” (meaning component), and it refers to a large molecule made up of structural repeats of one or more molecules connected by covalent chemical bonds [

1]. In other words, polymers are enormous, high-molecular-weight molecules known as macromolecules that are created by joining together several little molecules known as monomers. Polymerization is the process through which monomers join together to produce polymers. Molecules in polymers have greater molar masses and a range of physical and chemical characteristics. Polymers have the potential to be used as composites, laminates, adhesives, and coatings as well as resins, plastics, rubbers, and other types of materials. The second and third decades of the twentieth century marked the genuine birth and advancement of the science of polymer-based materials and polymers [

2]. Even though polymers were added extremely late in the material chain, they still play a significant role in our current understanding of materials. They offer originality and adaptability that no other type of material can equal in terms of application prospects, performance attributes, property range, and diversity. Polymers have played a significant role in shaping modern human civilization and culture. Even though the early-20th-century scientists, notably chemists, used to discuss polymers, there was still much uncertainty regarding the fundamental understanding of the structures of polymer molecules. For chemists dealing with polymers, it was a regular occurrence that the majority of such materials were extremely vicious and sticky in melt or solution conditions. You may easily distribute the melt or solution into thin films or pull them into fine filaments. They were more easily distinguished in solution as colloids or companion molecules. Cryoscopy attempts to determine their molecular weights from diluted solutions in appropriate solvents frequently yielded questionable, ambiguous, and occasionally extremely high values. Molecular weights of rayon and natural rubber that ranged from 45,000 to 50,000 or even higher were measured for cellulose derivatives. Because there was no structural understanding of such large or massive molecules, such high molecular weight figures revealed that the relevant polymer molecules were quite large. The idea of massive associations of much smaller molecules with short chains or cyclic structures was still preferred by chemists. The idea of the structure, size, complexity, and behavioral patterns of the molecular systems known as polymers received new support as a result of a condition of escalating crisis and perplexity. Life would appear to be quite challenging without polymers [

3,

4,

5].

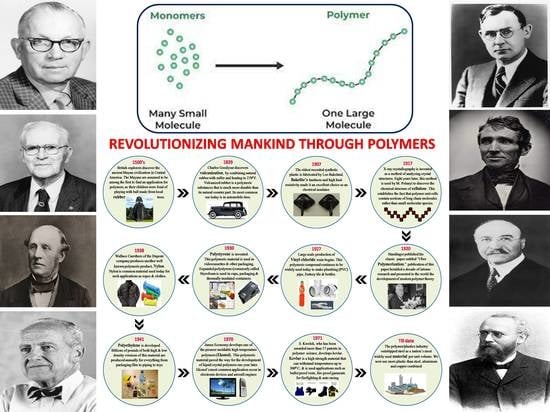

Polymer—A Recap

Polymers in the natural world have existed since the beginning of time. Natural polymers include tar and shellac, tortoise shell and horns, and tree saps such as amber and latex. These polymers were fabricated with the application of heat and pressure into useful objects such as hair ornaments and jewelry. The modification of these types of natural polymers began in the 1800s to produce many domestic and commercially useful materials. The most famous of these were vulcanized rubber, gun cotton, and celluloid. The first synthetic polymer produced was Bakelite in 1909 and followed by the first semi-synthetic fiber, rayon, which was developed in 1911 [

6]. Besides these developments, World War II was the front gate to observing significant changes in the polymer industry. Once the world went to war, our natural sources of latex, wool, silk, and other materials were cut off, forcing the use of synthetic materials. During this period, people used nylon, acrylic, neoprene, polyethylene, and many more polymers in place of natural materials. Since then, the polymer industry has continued to grow and has evolved into one of the fastest-growing industries in the world. Since then, mankind started to choose polymeric materials as the choice material. Humans have witnessed the Stone Age and gone through the bronze, iron, and steel ages into the current age, the age of polymers. There are useful polymers that have extensive use in various industries such as tires, paints, electronics, and textiles [

4,

7]. Nowadays, semiconductor devices are being fabricated based on organic polymers. Additionally, these days, biodegradable plastics are being evolved immensely. Actually, if we look around us, most things are made of polymers: the clothes we wear, the furniture, the cables, and the outer covering of various electronic gadgets (they are insulating). What would we be left with if all these polymers are removed?

Polymeric materials are very significant to our life (

Figure 1). Plastic containers of all shapes and sizes are lightweight and economically less expensive than the more traditional containers. Clothing, floor coverings, garbage disposal bags, and packaging are other polymer applications for consumables science. Polymeric materials are used in and on the soil to improve aeration, provide mulch, and promote plant growth and health. Industrially, automobile parts, windshields for fighter planes, pipes, tanks, packing materials, insulation, wood substitutes, adhesives, matrix for composites, and elastomers are all polymer applications used in the industrial market [

8,

9]. The sports aspect is not left out; playground equipment, various balls, golf clubs, swimming pools, and protective helmets are often produced from polymers. Medically too, many biomaterials, especially heart valves and blood vessels, are made of polymers such as Dacron, Teflon, and polyurethane [

10].

Without mincing words, polymers already have a wide range of applications than that of any other class of material available to man. Current applications range from coatings, foams, and packaging materials to textile and industrial fibers, optical devices, and precursors for many newly developed high-tech ceramics. In addition, polymers have extremely enriched our quality of life with their applications in the areas of agriculture and agribusiness, consumer science, industry, and sports. Polymeric materials have a vast potential for exciting new applications in the foreseeable future. New applications of polymers are being developed in diverse areas such as the conduction and storage of electricity, heat, and light; molecular-based information storage and processing; molecular composites; unique separation membranes; revolutionary new forms of food processing and packaging; health; housing; and transportation [

11]. Indeed, polymers will play an increasingly important role in all aspects of our life. The widespread applications of polymeric materials have generated a great international need to carry out research and development in polymer science and engineering. A person choosing a career in this field can expect to achieve both financial reward and personal fulfillment.

2. High-Performance Polymers [HPP]

One of the domains of polymer research is HPP. It has more than 60 years of history as a distinct field of polymer chemistry. Due to the requirement for ablative systems, high-temperature adhesives, coatings, and heat- and flame-resistant fibers, the space program has given this field of study, like many others in science, the majority of its push. HPP are all polymeric materials that have exceptional mechanical, optical, electrical, surface, and rheological properties which can resist thousands of hours at 230 °C, hundreds of hours at 300 °C, minutes at 540 °C, or seconds up to 760 °C [

12]. HPP have been discovered for a variety of applications, including films or membranes, optical and electronic devices, engineering plastics for the aerospace industry, poly(ester-amide)s, poly(ether amide)s, poly(ester-imide)s, and polyesters with better mechanical properties and higher thermal stability [

13,

14]. HPP have strong interchain connections, limited solubility, and high melting temperatures due to the rigidity and regularity of their backbone [

15,

16,

17,

18]. Therefore, despite having a great combination of properties, the majority of HPP suffer from some serious flaws, such as intractability, infusibility, and insolubility in common organic solvents, which make processing difficult and frequently restrict their utility in a variety of advanced technological applications [

19,

20,

21]. In order to improve the processability of HPP, several approaches have been used (

Figure 2), which include the following:

These structural characteristics enhance the polymer’s solubility and processability by encouraging molecular dissymmetry, preventing close interchain packing, and increasing free volume. Additionally, the processability should be improved without jeopardizing thermal stability [

22,

23,

24]. Nowadays, the engineering of macromolecules by developing and applying different sorts of advanced catalysts capable of architecting highly ordered and sequenced polymer chains with no composition drift has enlarged the performance window of polymers [

25,

26,

27,

28].

Brief History of High-Performance Polymers

When British explorers first discovered the ancient Mayan civilization in Central Asia in the early 1500s, they were introduced to polymers for the first time when their children began playing with toys made from the rubber trees. Natural rubber becomes soft at high temperatures and brittle at low temperatures, so it has limitations to be used for tires. Vulcanization, the process of adding sulfur to improve the physical characteristicsof materials (elasticity, resilience, tensile strength, viscosity, hardness, and weather resistance), allows this restriction to be overcome. Sulfur was first added to natural rubber by Friedrich Luthersdorff and Nathaniel Hayward. The vulcanization of rubber was another important achievement in polymer chemistry by Thomas Hancock (UK patent) and Charles Goodyear (American patent). Goodyear invented the vulcanization process in 1839, turning the slick natural rubber latex into an efficient elastomer for making tires. When heated with sulfur, the characteristics and strength of material were substantially enhanced. Transportation has benefited greatly from vulcanization. For the same reasons, tires made from natural rubber are not compatible with modern manufacturing processes. After the development of SBR in 1930, the use of synthetic rubbers became commonplace [

29]. The first manmade thermoplastic (celluloid) was created in 1860 when Christian F. Schonbein combined cellulose and nitric acid to create cellulose nitrate [

26,

30]. Leo Baekeland created bakelite (phenol-formaldehyde) in 1907, and thanks to its incredible heat resistance, it was a brilliant choice for an electrical insulator [

31]. Staudinger noted a decade of vigorous research for the advancement of contemporary polymer theory in his paper titled “Uber Polymerization” in 1920. Vinyl chloride resins, which are still commonly used today to make plastic bottles, PVC pipes, and tiles, started being produced on a significant basis in 1927. In the United States, Du Pont and his collaborators produced a range of innovative polymers between 1930 and 1938, including synthetic rubber, polystyrene, and more unusual compounds such as Teflon and Nylon [

32]. Several tons of polystyrene were initially produced by Dow in 1938, although scientists at ICI in England first created polyethylene in 1941 [

33]. When many naturally occurring materials, such as heavy rubber, became scarce after World War II, efforts were made to produce novel materials, particularly synthetic rubber. A family of stereospecific transition metal catalysts was independently developed in 1950 by Ziegler and Natta, who also contributed to the development of polypropylene as a commodity plastic [

34]. The aerospace sector, which continues to be the greatest consumer, was a strong driving force in the 1960s for the development of novel materials for demanding situations. The most productive decade for HPP was from 1960 to 1970, when polyimides entered the picture and the thermally most stable heterocyclic rings were inserted within polymer structures. Early on in this era, efforts were mostly directed toward improving thermal stability; processability received little attention. The development of HPP that could work effectively with more conventional materials, including metals, for aerospace and automotive applications occurred between 1960 and 1970 [

35]. More polymers will be created in the future after the current ones are developed. Since several HPPs were first made available for sale in the 1970s, it has been clear that these polymers are difficult to process due to their high structural regularity, co-planarity, and robust interchain connections, which also contribute to their high thermal stability. The work performedin the 1980s focused on figuring out how to make polymers that are easier to manufacture and how to turn them into a variety of ready-to-use materials at a reasonable price. Proton exchange membranes for fuel cells, microelectronics (interlayer dielectrics and photoresist), optical fiber waveguides, separation/barrier materials, etc. are a few more areas where research is still ongoing. A substance that can last for a long time in the air at 500 °C has long been a target of high-temperature polymer chemists. The stabilities of high-performance polymers, in the beginning, were in the 400 °C to 500 °C in the air range. The development of these polymers for thermal characteristics up to 600 °C in the air was completed in six years. Poly(phenylene) and poly(quinoxaline) had the best levels of heat stability up until that point among all of these different types of polymers. Over time, a variety of heat-resistant polymer systems have been proposed, and some of these materials are currently on the market.

Table 1 provides an overview of the polymer evolutionary history.

True stability restrictions were suspected by the middle of the 1960s, and the tractability issue was easily identifiable. At that moment, research on altering well-known systems to make more soluble and processable materials started. The backbone’s prenylation was reduced; the crystallinity was increased; flexible/bridging functional groups such as ether, alkylene, and sulfones were introduced; copolymerization was carried out; and an unrelated, random backbone structure was built.

The year 2020 was special for many reasons. One of them is the 100th anniversary of the dominant polymer science in various fields of life. The uncontrolled spread of the COVID-19 epidemic has faded the centenary celebrations of polymer science. Hermann Staudinger, first introduced the scientific community to his seminal paper on polymers in June 1920. In his scientific paper, Polymerization [

52], he shared with the world the innovative idea that a polymer is a large molecule formed by the synthesis of hundreds of monomers. Until Staudinger’s time, polymers were thought to be small colloidal substances. Staudinger’s remarkable publication led to the emergence and growth of polymer chemistry. Then, in 1922, in his own publication, Isoprene and Rubber, he popularized the idea of macromolecules. This crucial discovery later led to the emergence and growth of disciplines such as polymer chemistry, polymer science, polymer technology, and rubber technology. Then, Staudinger’s concept of ‘polymer’ had to be reluctantly accepted by the scientific community. The polymer soon became a milestone in the growth of mankind. Until then, industrial and construction activities relied on elements including wood, iron, ceramics, and glass. Polymers quickly took the place of such materials because of the attractiveness of being able to make products in any shape and form. Polymer products can be made in a light and cost-effective manner. Inspired by Hermann Staudinger, scientist Dorum also discovered that cellulose is formed by the synthesis of glucose molecules [

53]. This opened up the possibility of producing very strong nylon fibers. At the same time, polymers were accepted as the basic building blocks of organic matter.

Table 2 highlights imperative inventions in the vibrant area(s) of polymers.

3. The Golden Age of Polymers

The period from 1930 to 1940 was a golden age of synthetic polymers [

54]. The scientific community around the world has developed monomers from inexpensive materials to create synthetic polymers. Various chemical reactions (chain polymerization, condensation polymerization, etc.) to form polymers became widely used during this period. Scientists have found that changes in behavior can be caused by changes in structure. This knowledge led to great advances in the fields of home, industry, and research.

Table 3 represents the Nobel Prize winners in the polymer science field.

The study of the structure of polymers was essential to understanding their properties. As a result of the abovementioned advances, the feature that allows objects to be designed in any shape came into being. Subsequently, polymers such as polyvinyl chloride (PVC), polyurethane (PU), nylon fiber, neoprene (the first synthetic rubber), polytetrafluoroethylene (Teflon), and polystyrene (PS) became popular. Soon, many polymer industries were established in many parts of the world. With the advent of polymers, human life became smoother. Polyester-based clothing, fiberglass, nylon ropes, cogs, plastic bottles, bags, paint, glue, polyurethane foam, silicone heart valves, and many more are useful polymer products for everyday life. Thus, the use of polymers is crucial in all spheres of human life, including household, industrial, agricultural, energy, health, automotive, building, clothing, electrical, and electronics. Life without polymer products is unimaginable. Before polymers, industrial and construction activities relied on elements including wood, iron, ceramics, and glass. Polymers quickly took the place of such materials because of the attractiveness of being able to make products in any shape and form.

4. How Many Links to This Chain

As the name implies, large chains of polymers are formed by the chemical reaction of several small molecules. Thousands of tiny molecules combine to form tens of thousands to millions of molecular-weight substances. There is a correlation between molecular weight and properties of polymers. The higher the molecular size, the harder it is for chemicals to attack them. In addition, the cohesive structure also enhances chemical resistance. Molecular-weight polymers are generally insoluble in solvents. Organic compounds are made up of a combination of carbon, nitrogen, oxygen, and hydrogen. In addition to these elements, carbon can combine with four other carbon atoms to form millions of compounds of various structures, including long chains and rings. It is this characteristic known as catenation that makes the structure of polymers possible. The carbon chains form long chains that bind to each other. With the exception of rare polymers such as silicone rubber, the vast majority of commonly used ones are made of carbon chains. The cohesive bond between the carbon atoms ensures the structure of the chain. Different functional groups can be attached to the carbon atoms in the chain. For example, the functional group of PVC is chlorine, and Teflon fluorine is used in nonstick containers. These groups play an important role in determining the behavior of the polymer. In addition, the weak or strong attractions between different polymer chains determine whether they are plastic, fibrous, non-melting thermoset, or stretchable rubber. Density and semi-crystalline structures formed by stacking chains also determine their nature.

5. Why Polymers?

Today, polymers have taken the place of almost all traditional building materials, including metals, wood, glass, paper, and fiber [

55,

56,

57]. What makes them so popular? One of the most attractive features is that they can withstand even the heaviest weight. This made many items, such as chairs, doors, and utensils, lighter and easier to handle. In addition, they are durable for a long time. It does not rust like metals or rot-like wooden objects. They are not easily attacked by moisture, sunlight, or chemicals. This is because they are large molecules and have no chemical interest in carbon-carbon single bonds. This quality also contributes to the major environmental problem of plastic pollution. Materials with complex structures made of metals are not easy to melt and require temperatures in the thousands of degrees to melt. How many complex materials can be easily molded with polymers? At one or two hundred degrees, they melt into a liquid and take on the desired shape. Many plastics can be remelted, recycled, and reused. They can be formed into very thin sheets, thick materials, or soft fibers. The other advantage is that they can give attractive colors. These colors do not stick to the surface as they do on metals. The color stays with the object for a long time as it is attached to the object itself. It also makes electrical equipment safer as it does not transmit heat and electricity. Why did the old rain-soaked book bags give way to plastic bags? Since many polymers can be made transparent, lamps, transparent containers, and even the lens of the eye can be made. In addition, the price of polymer-based materials is relatively low. The groups in the polymer chain can be modified to form the required properties [

58,

59,

60]. Materials that conduct electricity, do not stick to food, do not get wet, and do not catch fire can be formed in this way. Polymers can also be made of materials that show high strength and thermal resistance. Polymers are now being used to make small houses, including 3D printing.

6. Biopolymers

Organic polymers were used long before synthetic polymers were invented. Starch and cellulose found in plants are organic polymers composed of glucose molecules. Biopolymers are proteins that are made up of amino acids in our body [

61,

62,

63]. Natural rubber is derived from the

Heveabra siliensis plant. Chitosan is also another biopolymer found in the shells of marine life. The use of organic polymers is less widespread than that of synthetic polymers [

64,

65,

66]. However, their natural decomposition and safe use in the human body add to their importance. The biggest problem created by polymers, especially plastics, is environmental pollution [

67,

68]. They lie in the soil for centuries, damaging the natural structure of the soil, mixing with water, and preventing water from seeping into the soil. Toxins released during combustion can cause many problems from shortness of breath to cancer. Unscientific use can cause disease in food and water. Studies are also underway to improve the potential of natural polymers such as cellulose, starch, and chitin. One can only hope that we will eventually find an answer to plastic pollution.

The bio-based polymer branch is a dynamic, versatile field in which bio-based polymers have reached development stages that range from the research level, via initial market adoption, to long-term established performance plastics such as cellulosic or nylon. All of them show significant market growth. Bio-based polymer production continues to grow at about 4% per year, approximately the same as petrochemical polymer production. Therefore, the market share of bio-based polymers in the polymer market remains around 2%. However, the individual development of different bio-based polymers varies. Some of the bio-based polymers actually live longer (such as bio-pet) compared to previous predictions, but many still show a slight increase, and some even show the ability to achieve significant growth trends (such as PLA). In addition, there is optimism for future prospects for some bio-based polymers, such as PEF and Bio-Polypropylene. Therefore, it is important that research cooperation occurs in various fields, including natural polymers, bioplastics, biocomposites, nanostructural materials, and polymer nanocomposites.

7. Development and Application of Biodegradable Polymer Plastics

Biodegradable polymer plastics are a new type of biodegradable plastics related to the degradation activity of polymer materials, and in the process of use, similar health and relevant application performance must be achieved with similar plastics. After the full operation, the material can be rapidly destroyed under natural environmental conditions, producing or destroying environmental fragments, and with further degradation over time, gradually returning to nature as oxidizing products (CO2 and water). In view of the environmental pollution caused by plastic wastes, environmental protection, and human needs, it is urgent to study perishable polymer materials. The chemical composition of biodegradable plastics changes over a period of time and under certain environmental conditions. Depending on the cause of the changes in their chemical composition, biodegradable plastics can be divided into two categories: biodegradable plastic and photodegradable plastic.

7.1. Degradation System of Degraded Plastics

In general, degraded plastic refers to a type of plastic that can be decomposed into smaller molecules by the action of microorganisms in the soil or in solar radiation. Degraded plastic meets the requirements of the use of products and is easy to process. Biodegradable properties: The nature of the action of sunlight on polymer materials is the integral effect of ultraviolet light on sunlight and oxygen in the air; hence, it is also called photooxidation degradation. Take polyolefin as an example to illustrate the mechanism of photooxidation degradation. In short, photo oxidation causes the polymer chain to break or crosslink, forming certain functional groups containing oxygen, such as carboxy acids, peroxides, ketones, and alcohols. Catalyst residues in polymers and the formation of peroxide and carboxyl groups introduced during processing are the main sources of decay. Under the action of microorganisms (mainly fungi, bacteria, or algae), the elimination or metabolism of polymers can cause changes in their chemical composition and molecular weight. The mode of operation can be divided into two main types:

- (1)

Biophysical activity. That is, after the promotion of microorganisms, organic cell growth, fermentation of polymers, ionization, or protonation, this physical activity in the polymer causes mechanical damage, and the high molecular weight of the polymer becomes oligomer fragments, achieving the goal of physical decay.

- (2)

Biochemical action, or the direct action of enzymes. This condition is caused by the erosion of enzymes secreted by fungi or bacteria, which leads to the decomposition or oxidative decomposition of plastics and the breakdown or oxidative destruction of insoluble polymers into new small molecular compounds (CH4, CO2, H2, CO2, etc.).

There are generally two theories about the method of biodegradation of polymer materials. One is an aggressive wound from the end of the chain. Therefore, structural features such as composition, main- and side-chain structure, the size of end groups, and the presence or absence of spatial steric resistance are important factors affecting their degradation performance. Among them, the main-chain properties are more influential. If the main chain of the polymer contains easily hydrated bonds, it easily undergoes biodegradation. Second, if the spine is flexible, the rate of degeneration is relatively fast, while the rate of decline is slow if the spine is rigid and regular. The biodegradation of polymer materials by branching and crosslinking is reduced. For example, the introduction of hydrophobic groups at the end of the molecular chain of polylactic acid (PLA) reduces erosion in the early stages of degradation. This is because, in the actual decomposition process, the erosion of PLA mainly depends on the structure of the molecular network, and the addition of hydrophobic groups causes its erosion rate to decrease [

69]. In addition, some researchers have studied the chemical composition of polymers and the relative molecular weight of substances that play an important role in their degradation.

7.2. Development of Biodegradable Plastics

The direction of future developments of biodegradable plastics is as follows:

- (1)

Prepare biodegradable plastics by studying the biodegradation mechanism of the destroyed polymers and the block copolymerization of biodegradable plastics using existing standard polymers, microbial polymers, and natural polymers.

- (2)

Focus on controlling the rate of degradation and develop effective degradation promoters and stabilizers to improve the biodegradable performance of perishable plastics, reduce their cost, and expand the market application.

- (3)

Research and establish a unified definition of degraded plastics, enrich and improve biodegradation assessment methods, and further understand degradation mechanisms.

8. Microplastics: The New Face of Pollution

Microplastics are one of the many facets of plastic pollution. The plastics we leave behind decompose under the influence of sunlight, heat, wind, and pressure to form smaller particles. Thus, microplastics are plastic particles less than five millimeters in size. Due to their small weight and size, they can spread from one place to another by air and water. Therefore, they are ubiquitous and can be found anywhere, regardless of source. Studies show that microplastics are presents everywhere, including in the air we breathe, the water we drink, and the food we eat.

8.1. How to Get to Nature?

Manmade materials are the sources of microplastics. They appear in nature in two main forms—engineered microplastic polymers used as compounds for many everyday materials and microparticles that decompose fromlarge plastic materials. These can be called primary sources and secondary sources, respectively. Primary sources include personal care products, textiles, paints, and motor vehicles. When synthetic fabrics are machine-washed, the polymer fibers from the fabric reach the soil or water through the wastewater. Plastic polymers contained in toothpaste, soaps, and cosmetics also reach the environment in this way. The most important secondary sources are plastics used in the construction, mulching, and irrigation of greenhouses and playhouses on farms. Microplastics have also been found to be abundant in household and industrial waste. Microplastics are found in different sources that mix with soil and water and flow into the oceans. Due to their small size and weight, they stay in the air and are carried away by the wind. Substantial microplastics have been found even in areas where there is no human habitation or other human intervention. Thus, microplastics cause plastic contamination to reach a distance from the source. Oceans have been found to contain more microplastic particles than other parts of the environment. Studies show that the amount of microplastics in seawater has increased five-fold in ten years. They accumulate on beaches, especially in tourist areas. Fresh water sources are also not free from these micropollutants. Microplastics have been found in large quantities in soils, including on farmland. Soil microplastics comprise up to seven percent of the total microplastics.

8.2. Physical and Chemical Properties

Microplastic particles have different shapes, sizes, colors, and chemical compositions. Microplastics are particles that are less than five millimeters in size. Those below 100 nm are considered nanoparticles [

70]. Some researchers consider nanoplastics to be smaller than a micrometer. However, microplastics are generally understood to be between 100 nm and 5 mm in diameter. Microplastic particles of various sizes are found within this range. They appear as thin, rounded, or other-shaped crystals and long fibers. Polyethylene, polypropylene, nylon, polyethylene terephthalate, polyvinyl chloride, polyester, polystyrene, polysulfone, polycarbonate, polyurethane, polymethylmethacrylate, and cellulose acetate are very different. The chemical nature of microplastics varies according to the source.

8.3. Environmental Threats

Microplastics of various shapes, sizes, and chemical compositions from different sources can reach soils and water bodies, including the oceans, causing adverse changes to the natural physical, chemical, and biological composition of the area. Once they enter the soil, they mix with the soil structure due to natural biological activities, water filtration, and agricultural activities. Reservoirs are subdivided into basal sediments and water. Subsequently, the bioinorganic, organic, and inorganic elements in the soil and water react differently and cause many chemical and physical changes. The chemical and physical composition of plastic polymers is important in determining such functions. These activities cause serious changes in the structure of the soil and water. Very small microplastics enter the body of living organisms through the airways and food and affect vital functions. Microplastics have been found in microscopic aquatic planks, copypods, bivalves, worms, and even large fish and waterfowl. Through the food chain, they reach significant numbers of high-ranking organisms. Studies also show that microplastics can adversely affect the health of these organisms. Microplastics reach not only marine life but also living organisms, including humans, through food, air, and water. They have been found to adversely affect the growth of earthworms and plants. Microplastics cause stunted growth and reduced fertility in many organisms, both vertebrate and non-vertebrate blocks, and other damage to the digestive and respiratory systems. It also affects the production and function of enzymes and hormones. Microplastics have been shown to affect plant growth and metabolism in a number of ways. Seed germination rate, root and stem growth, and chlorophyll levels have been found to be significantly reduced in the presence of microplastic polymers. Microplastics mixed with soil have been found to filter through water and mix with groundwater. Studies have shown that large amounts of carbon dioxide are usually found on the ocean floor in the form of microplastic particles. Polyaromatic hydrocarbons with hydrophobicity can easily adhere to the waterproofing surface of microplastics. Hazardous chemicals get carried away with microplastics in this way. Thus, these chemicals can spread abnormally. There are studies showing that microplastics accelerate the diffusion of toxic heavy metals and polychlorinated biphenyls into seawater. In this way, some harmful microorganisms and algae have been found to stick to the surface of microplastic particles and carry them over long distances. Sewage treatment plants using advanced technologies are capable of separating microplastic particles in water. Efforts are being made around the world to combat plastic pollution. However, waste disposal plans have yet to be formulated to address microbial pollution through microplastics. Despite the fact that burning plastics produces carbon dioxide responsible for global warming and its non-biodegradable nature, one can yet agree on the fact that, with recent advancements, plastic polymers will transform our lives and add value to everybody’s quality of life. Until and unless we find another compound in place of plastic polymers or an ecofriendly way of using carbon to create them, we would not be able to replace them. Plastics simply make up too much of everything we produce.

Each polymer degrades with time, resulting in a loss of strength, quality, and molecular weight. We know that most polymers take 100–1000 years to completely degrade. Byproducts of biodegradable polymers include carbon dioxide, methane, water, and inorganic chemicals, as well as biomass that may be readily scavenged by microbes. They degrade extremely quickly in comparison to non-biodegradable polymers. Many pro-oxidants (ferromanganese and cobalt salts) are formulated for use in composting, garbage, and soil treatment polymers. According to scientific recommendations and studies, these additives may regulate the life of plastic films and goods when combined with conventional polymers in the right proportions, enabling plastic waste to be destroyed without having to be collected and disposed of. This oxidized molecular fragment is biodegradable and hydrophilic, according to studies, and the molar mass value is reduced by more than a tenth. It has been reported that polymers containing the above additives are fragmented into smaller parts that are invisible to the naked eye, but it is unclear whether these parts are truly biodegradable—that is, whether they are accessible to microflora (bacteria, fungi, etc.) to convert and assimilate carbon in any substrate—and if so, at what rate.

Figure 3 depicts the ongoing debate over these materials.

In the biodegradation process, deterioration/fragmentation is an early step. At this point, residue fragmentation and crosslinking with moisture, heat, sunshine, and/or enzymes create persistent residues, which weaken or break the polymer chains. Biodegradation is the next stage of this process. Only when the fragmented residues are fully absorbed as food or energy by the microorganism at an appropriate pace does biodegradation begin. Because it has yet to be shown, the fragmentation of photodegradable (fragmentable) polymers by biodegradation based on polyethylene with pro-oxidants remains an open concern. It failed because of conflicting biodegradable standards and specifications. The most recent developments are bio-based polymers produced from bacterial fermentation, which are focused on the creation of monomers made of cellulose, fatty acids, and starch from renewable resources.

9. Pharmaceutical Polymers

Water is the primary component of humans and is necessary for life on Earth. But unlike “bags of water,” all types of living things are actually quite organized. This particular organization is dependent on other substances, macromolecules, or polymers, which may hold and organize water in the form of natural hydrogels. Many polymers come from nature (mineral, vegetal, or animal). Many of them have been around for ages. The most prevalent macromolecule in the kingdom of plants is cellulose. Cellulose, a polysaccharide and dimer of glucose, is made up of repeating units of cellobiose. As the primary component of arthropods’ shells, chitin, a polymer of N-acetyl glucosamine, is found abundantly across the animal kingdom. Life is well recognized to depend on proteins and nucleic acids, which are also natural polymers that hold and shape water. The emergence of synthetic polymers, which may be made, using a variety of techniques and processes for polymerizing one or more monomers, has led to an even greater variety of characteristics and uses. Contrary to many polymers of natural origin, purely synthetic polymers lack immunogenicity, which is a very interesting property in the context of health.

9.1. Applications in Formulations

9.1.1. Tablets

The polymer is utilized in tablets as a disintegrant and binder. Ethyl cellulose, HPMC, starch, gelatin, and polyvinylpyrrolidine are among the binders that hold the powder particle in a wet mass of different polymers. Sucrose, glucose, alginates, polyvinylpyrrolidine, sodium CMC, starch, and cellulose are examples of disintegrants that speed up medication action and shorten the time of dissolving [

71].

9.1.2. Capsules

The suppleness and hardness of gelatin are dependent on the plasticizer, which is made of a variety of polymers employed in the capsule. Various types of polymers are used to regulate the release rate of the capsule. The creation and use of colloidal polymer particles with core-shell architecture have undergone recent advances. The cores and shells of the capsules can be modified in a number of ways to create multifunctional, navigable nanocarriers and/or nanoreactors. Emulsion-templated polymer nanocapsules received special attention because they effectively encapsulate and distribute hydrophobic substances while also protecting them from the environment and triggering their release [

72].

9.1.3. Natural Coating Agents

Even though they are occasionally still utilized, natural polymers such as shellac and zein hardly ever fulfill modern demands [

73]. Since they have a negative impact on the environment, chlorinated hydrocarbons such as methylene chloride and chloroform should only be used in certain circumstances. Organic solvents should be avoided completely. Aqueous solutions can also be used to treat methylcellulose and hydroxypropyl methylcellulose of low molecular weight. As so-called pseudolatexes, ethyl cellulose and cellulose acetate phthalate are accessible as aqueous dispersions. An outline of the nature and characteristics of acrylic polymers—the most often used cellulosic—is given. The solubility characteristics of EUDRAGIT

® acrylic polymers are tailored to the digestive tract’s circumstances. In terms of purity, they meet extremely strict specifications. High resistance to external impacts during storage and complete skin friendliness, or indifference to biological fluids and tissue, is additional qualities of high caliber. Only a few milligrams of acrylic polymer is taken together with the active component when using coated tablets and about 150 mg per day when using some sustained-release medications. Thus, an adult consumes around 2 mg of polymer per kilogram of body weight.

9.1.4. Disperse Systems

Polymers such as polyvinylpyrrolidine, ethyl cellulose, etc. are used in biphasic systems such as emulsions and suspensions to disperse one phase into another phase, such as water dispersing in the oil phase or vice versa. Particulate matter, or the dispersed phase, is disseminated throughout the dispersion medium with the aid of the aforementioned dispersing agent polymer. Drug content dispersion in the oil in water in an oil-type emulsion is quite challenging, but it is easily created when a polymer is used as a dispersing agent.

9.1.5. Film Coatings of Solid Dosage Forms

Chitosan works effectively as a coating agent for common solid dosage forms such as tablets because of its film-forming properties. Additionally, its ability to form a gel and matrix makes it helpful for solid dose forms such as granules, microparticles, etc. Microcrystalline chitosan was investigated by Sakkinen and colleagues as gel-forming excipients for matrix-type medication granules. The degree of deacetylation, molecular weight, and crystallinity were shown to be variables that influenced the release rates from the chitosan-based granules. It has been proven that pairing negatively charged biomolecules including gelatin, alginic acid, and hyaluronic acid with positively charged chitosan results in new matrices with special properties for regulated drug release.

9.1.6. Taste Masked by Spray Drying

Drug and chitosan are dissolved in an appropriate solvent. After fully loading the drug into the polymer and agitating it for 24 h using a magnetic stirrer, the complex is sonicated by an ultracentrifuge, dried by spray drying, and tested for taste masking and its bitterness threshold concentration. The characterization of complexes is accomplished with the aid of XRPD, FT-IR, DSC, and SEM. If complexation is successful, the percentage of the drug content is calculated, and the complexes’ equivalent weight is collected and formulated. The chitosan-drug combination tablet dissolves and produces a sustained release of the active ingredient.

9.1.7. Transdermal Drug Delivery Systems (Patches)

Different polymers are used in the creation of transdermal patches. Polymers are the backbone of a transdermal drug delivery system. Different polymers are used in the creation of transdermal patches. For supporting drugs in drug reservoirs, a baking material made of polymer is also prepared. An effective transdermal drug delivery method is built on polymers. Systems for transdermal distribution are made of multilayered polymeric laminates, which have two polymeric layers sandwiching a drug reservoir or a drug-polymer matrix between an outer impervious backing layer and an inner polymeric layer that acts as an adhesive and/or rate-controlling membrane. The following three types of transdermal drug delivery systems provide a general classification [

74].

9.2. Specific Polymers in Pharmaceuticals

9.2.1. Albumin

Additionally called Alba, serum albumin is its chemical name. Among natural polymers is albumin. With a molecular weight of around 6650 and a single polypeptide chain made up of 585 amino acids, human serum albumin is a protein. It has medicinal and stabilizing properties. In parenteral pharmaceutical formulations, albumin is largely employed as an excipient and stabilizing ingredient. Microspheres and microcapsules for drug delivery systems are also made with albumin [

75].

9.2.2. Alginate

Another natural polymer with excellent mucoadhesive qualities is alginate, which is similarly secure, non-immunogenic, and affordable. Alginate microspheres or microparticles with sizes ranging from 1 micron to more than 30 microns have been successfully administered orally to produce excellent immune responses. As a thickening and emulsion stabilizer, alginate is also employed [

76].

9.2.3. Carrageenan

A polymer that is hydrophilic is carrageenan. It is also known as an extract from condors. It has a variety of properties, including emulsifying, gel base, stabilizing, suspending, sustained-release, and viscosity-increasing properties. Carrageenan, i-carrageenan, k-carrageenan, and l-carrageenan are its chemical names. If employed as a suspending agent, carrageenan can hide the chalkiness of an antacid suspension [

77].

9.2.4. Chitosan

A natural polymer, chitosan has been extensively employed in a variety of sectors, including the food processing, waste management, pharmaceutical, and medical fields. It is less harmful, biocompatible, and biodegradable. In pharmaceutical applications, chitosan is frequently utilized as an excipient in formulations. It has been utilized in protein and gene delivery, oral absorption enhancement, and mucoadhesive applications [

78].

9.2.5. Collagen

Due to its biocompatibility and simplicity of processing by physical or chemical crosslinking reactions, collagen has been employed for controlled drug administration and tissue engineering applications. Collagen is one of the primary components of numerous tissues in the body [

79].

9.2.6. Dextran

Another natural polymer is dextran. It can be created using

Leuconostoc mesenteroides by fermenting a medium containing sucrose. Dextran fractions are easily soluble in water as well as other solvents such ethylene glycol, methyl sulfide, and form amide [

80].

9.2.7. Ethyl Cellulose

Ethyl cellulose is also chemically known as cellulose ethyl ether. It is a hydrophobic, inert, stable, and nontoxic polymer. Additionally, it can be utilized as a coating agent, flavoring agent, tablet binder, tablet filler, and viscosity-raising agent and in sustained-release products such as film-coated tablets, microspheres, microcapsules, and matrix tablets for both soluble and poorly soluble medicines [

81].

9.2.8. Gelatin

It also goes by the name Cryogen. A biodegradable matrix substance called gelatin is employed in an implanted delivery device. As a coating agent, film-forming agent, gelling agent, suspending agent, tablet binder, and viscosity-increasing agent, gelatin has a variety of uses. When a medicine is microencapsulated, the active ingredient is enclosed in a tiny capsule made of gelatin [

82].

9.2.9. Guar Gum

A hydrophilic polymer is guar gum. It is a galatomannan and is also referred to as galactosol and guar flour. It is mostly the ground endosperm of the leguminosae plant known as guar beans (Cyamopsiste-tragonoloba). It functions as a disintegrant and binder in solid dosage forms and a suspending, thickening, and stabilizing agent in oral and topical formulations as well as a controlled-release carrier [

83].

9.2.10. Hydroxy Ethyl Cellulose

A semi-synthetic, hydrophilic polymer is hydroxyethyl cellulose. It also goes by the name Cellulose Hydroxyl Ethylate. It functions as a binder and film-coating agent for tablets as well as a thickening agent in ophthalmic and topical formulations. It can be found in lubrication products for dry lips, contact lens care, and dry eyes [

84].

9.2.11. Polyester

It is a condensation polymer, according to the polymerization type. The polyester family is the largest group of researched biodegradable polymers. These polymers have been utilized as cell transplantation scaffolds, suture plates, and fixtures for fracture fixation systems [

85].

9.2.12. Polyethylene

Synthetic and additive polymers include polyethylene. The chain growth polymerization of polyethylene is also well recognized. Plastic matrix materials are frequently made of it. It has been used for an altered drug-release pattern. It is used in inert compressed plastic matrix-based sustained-release tablets [

86].

9.2.13. Polyethylene Glycol

It also goes by the name carbowax. Chemically, it is known as poly-hydro-o-hydroxyl (oxy-1,2-ethanediyl). The class of water-soluble linear polymers known as polyethylene glycols is created when ethylene oxide is combined with monoethylene or diethylene glycol. Polyethylene glycol is a natural polymer, according to the source. Polyethylene glycol is a waxy, hygroscopic material that is stable, hydrophilic, and basically nonirritating to the skin. In order to control medication release, polyethylene glycol is frequently combined with hydrophobic polymers due to its outstanding film-forming abilities and solubility in organic solvents. As an illustration, consider polyethylene glycol 400, 300, 200, etc. [

87].

9.2.14. Polyglycolic Acid

Both manufactured and biodegradable polymers exist in polyglycolic acid. By methods of polycondensation or ring-opening polymerization, it can be prepared beginning with glycolic acid. It is the most straightforward linear, aliphatic polyester and is referred to as a tough fiber as a polymer. The kind and content of the monomer affect the solubility of polyglycolic acid [

88].

9.2.15. Polypropylene

The usage of plastic or polymeric materials for tablet packaging has grown significantly, notably for unit-dose hospital containers, which occasionally employ aluminum foils. Common polymeric materials used to accommodate various tablet packaging shapes and sizes include polypropylene [

89].

10. Composite Materials

The assembly of two or more materials that results in a material with qualities that are better than those of the individual materials is known as a composite material [

64]. The term “reinforcement arrangements” (also known as “fillers”) now refers to those materials (either an extender or conductive) employed to alter and advance the physicomechanical properties of a component (such as plastics). Fillers and reinforcements may also be used to lower material costs by reducing the volume of matrix resin required. Fillers are used to modify or enhance properties such as thermal conductivity, electrical resistivity, friction, wear resistance, and flame resistance. The load’s cohesiveness and direction are ensured by the matrix. Additionally, the stresses that the composite is under might be transferred to the load. The materials produced in this way are very heterogeneous and frequently anisotropic. The composition of the matrix and the load, their form and quantity, the quality of the interface, and the production method may all affect the qualities of the composite material. There are numerous combinations that may be imagined because the matrix and the reinforcement can both be made of metallic, ceramic, or plastic materials. In most cases, the composite material is made up of a continuous phase and one or more discontinuous phases. The composite is referred to as hybrid when there are numerous discontinuous phases present, each of a distinct character. The reinforcement or reinforcing material is the discontinuous phase, while the continuous phase is known as the matrix. Components with complementary mechanical and physical qualities are mixed to create composite materials. It is feasible to enhance the mechanical and thermal properties of a polymer matrix by adding reinforcements with high modularity and superior tensile strength. The advantage of composites with a polymer matrix over metals is the manufacturing process, which enables the production of parts with complex shapes. This includes their lower density, which results in lower fuel consumption, higher speed in competitive sports, or longer ranges and higher payloads for missiles [

66].

The matrix, fibers, and additives or fillers make up the majority of the composition of composite materials [

90].

10.1. Matrix

The matrix may be elastomeric, thermoplastic, or thermosetting in nature. The function of the matrix is to connect the reinforcing fibers, disperse the restrictions, offer the structure’s chemical resistance, and supply the end product with the appropriate form. The selection of the matrix is based on the purpose for which the composite material is to be used. In the context of this investigation, composite materials have purposefully been restricted to those made of organic matrices [

67].

10.1.1. Thermoplastic Matrices

The linear chains that make up the thermoplastic matrices can change while they are still molten, representing the fact that the macromolecules in the melt have a dynamic state. The thermoplastic matrices are heated in the majority of production procedures, and then the completed product is shaped using molding, injection, extrusion, or thermoforming before being cooled to maintain its shape. This procedure can be undone. Thermoplastics come in a broad variety of forms today, each with a unique set of intriguing features. For usage in a variety of goods, they may be made as clear as glass, as hard as metal and concrete, or as flexible as rubber. They have good corrosion resistance, do not rust, and make great thermal and electrical insulators. Thermoplastics are the perfect material for a variety of applications because of their light weight, excellent mechanical strength, and resilience to environmental factors [

91].

10.1.2. Thermosetting Matrices

They are typically liquid at ambient temperature, but during application, under the influence of heat and a substance called a hardener, they solidify. Crosslinking, a chemical reaction that creates strong three-dimensional links between the molecules, transforms the compound. The substance treated, as a result of this irreversible procedure, becomes infusible and insoluble in most solvents (alcohols, ketones, and hydrocarbons). They are useful for molding big components with short, long, or woven fibers because they are generally stiffer than thermoplastic matrices, resist creep better, and are less brittle. Polyesters, phenoplasts, epoxy resins, polyurethanes, and polyimides are the most widely used thermosetting matrices [

92,

93].

10.2. Reinforcement

The skeleton or reinforcement makes up the structure that gives mechanical strength (tensile strength and rigidity). In order to transform from an elongated particle to a continuous fiber, it must be of a filamentary character (organic or inorganic fiber). E glass fiber is the most popular and is utilized in more than 95% of applications. Aramid fiber, popularly known as Kevlar, is also of tremendous interest. In general, the fibers in a composite construction (anisotropic) perform well in traction, but in contrast to metallic structures (isotropic), they perform less well in compression and continue to exhibit modest shear resistance. Additionally, fibers or their derivative forms are the most common types of reinforcement [

68].

10.3. Filler

Any inert component that, when added to the basic polymer, enables appreciable modification of the mechanical, electrical, or thermal characteristics, improvement of the surface appearance, or simply a reduction in the cost of the changed material is referred to as a filler. Fillers of all different types and forms are frequently included in thermosetting materials at high rates of up to 60% by mass [

69]. The filler to use for a particular polymer depends on the adjustments that are desired for the final product (

Table 4).

10.4. Additives

Substances that are physically combined with polymers are known as additives (adjuvants). The purpose of an additive is to change or enhance the usage characteristics of final materials or the rheological behavior of polymers in a processing machine (physical properties and environmental stability). Additives are organic, organometallic substances that are utilized in small amounts and frequently have lower molecular weights than the polymer. The majority of the time, additives is categorized according to their primary function, such as plasticizers, stabilizers, lubricants, colors, and anti-shock agents, whose primary purposes are theoretically understood [

70].

11. Challenges and Possibilities

The fact that many polymers and polymer products are not biodegradable is the main problem the industry faces today. They are quickly becoming one of the most terrifying sources of environmental degradation. Adjusting recyclable polymers (thermoplastic) for reuse and optimizing the usage of non-recyclable polymers (thermosetting plastic) are both desired in the current environment. Research and production of biodegradable polymers are now underway. Researchers from India have created a polymer that breaks down entirely in natural environments. There has been some encouraging research on their absorption and use. There is a great deal of untapped potential in polymer research, which has a profound effect on people’s daily lives. Medical device production, synthetic organ synthesis, and the creation of novel materials for the production of energy storage equipment all rely heavily on polymers. Environmentally safe polymers are on the horizon. I hope that the breakthroughs toward that singular goalwill motivate researchers in polymer science and other fields to produce discoveries that benefit humanity for the next century.

Could we string together molecules like pearls on a necklace? This is not only feasible but has been made possible by these molecular chains, which in turn altered our actual physical environment. The chemistry of long chains heralded the end of a period characterized by the use of materials whose life spans were severely limited by exposure to the elements. No other area of science has been both criticized and lauded to the same degree. The large molecules known as polymers are the focus here. From prosthetic heart valves to chairs to spaceship components to sanitary napkins to cancer therapy, the applications and potential of these materials are vast. Depending on their make-up and function, they fall into one of four categories: plastics, rubbers, synthetic fibers, or adhesives. This area of study encompasses both natural and manmade materials, including rubber from trees and cellulose from plants as well as polythene and polyvinyl chloride (PVC). It is a curious family that includes insulating conductors and materials that absorb water yet do not become wet. Their variety and usefulness are also expanding rapidly.

Professor Jöns Jacob Berzelius is credited with giving a name to the polymer. While isolated studies may be traced back to the eighteenth century, it was not until the second decade of the twentieth century that the discipline saw any significant progress. Germany’s scientist Hermann Staudinger released his “On Polymerization” research in 1920. Subsequently, there was a time of intense discussion and widespread criticism. The scientific community could not understand the chemical links between the enormous molecules and their unknown chemistry. The revolutionary work by Staudinger was the first step in developing a whole new academic discipline. Thus, he is credited as the first polymer scientist. This year marks a significant milestone in the history of polymer science: it is the 100th anniversary of the field. The amount of progress that has been achieved in this area during the last century is staggering.

The molecular weight of materials such as rubber and cellulose was found to be much greater than that of typical materials as early as the eighteenth century. Those first produced were semi-synthetic polymers such as cellulose-based paroxysm and celluloid. Plastic bakelite is the first of its kind to be mass-produced. The architect responsible for its construction was Leo Henrik Arthur Baekeland, who finished the structure in 1907. However, scientists have not altered their composition in any way. Hermann Schrodinger subsequently detailed the polymers’ chemical characteristics. Many novel polymers were discovered during World War I and II as scientists looked for more effective weapon materials. The accidental discovery of polythene in 1939 led to the creation of the most frequently used thermoplastic today. Currently, scientists all around the globe are working to create polymers with unusual thermal characteristics including natural breakdown and conductivity.

We inquired about the future of polymer research, but we need to round out our perspective by examining our current situation and the difficulties we are currently facing. From synthesis to physics to engineering to theory and from physical to biological to therapeutic aspects as well as from fundamental to applied themes, polymer research has always required a wide range of competencies. The fact that more and more polymer-related topics are appearing in new scientific journals that are not specifically related to the polymer field is a recent challenge associated with this growing interdisciplinarity, even though it truly represents the enormous bandwidth of contributions to polymer science. This readily results in a dilution effect and a decline in the acknowledgment of contributions made by the field of polymer science, especially in times when research is increasingly evaluated by bibliometric data and impact factors. We must confront this issue collectively and devise ways to account for this asymmetry.

In addition to its interdisciplinarity, the polymer community has long been renowned for connecting academia and industry, and other chemical societies have even expressed envy for it. Although we are unsure if the long-term agreement between the two parties still holds, we are adamant that fundamental research will always be a significant catalyst for business, as we have seen since Staudinger’s early days of polymer science. According to Stephen Z.D. Cheng, it is even more crucial to stress the value of creating strong ties between researchers from academia and commercial productions today. Instead of weakening it, this relationship has to be further enhanced. To us, a future without polymers is inconceivable. They are essential to the development of new antibiotics, regenerative medicine, ink-jet-based decentralized manufacturing, lightweight composite materials for windmills, and e-mobility, up to the exploration of space, to name just a few from an essentially endless list. At least for the foreseeable future, this sociological “market pool” will keep us busy, and although the polymer sector and the linked job market will alter, they will still be successful and brimming with chances.

It is comforting to see that the vector that has propelled polymer research from the first iterations of Staudinger’s concept to its present standing as a burgeoning, highly important industry and enabling area is unbroken. But it is our duty to continue to be the ones influencing the direction of polymer science. Even though Herrmann Staudinger’s struggles with the idea of macromolecular structures are well-known, they also serve as an example of scientific rigor. Such persistence and passion, in our opinion, will be required to meet the aforementioned difficulties of the present and the future, advance our discipline, and ensure that polymer research continues to flourish over the coming century. It is up to us to make investments in our field, maintain communication, and take care of our multilingual, interdisciplinary, and diverse field. One important aspect is reading and writing papers in well-managed journals, and we are pleased to be a part of such an effort.

12. Conclusions

The demand for polymer research is growing quickly because of the significance of fieldin daily lives. The manufacture of polymeric components, such as green, sustainable, energy-efficient, high-quality, and low-priced components, will ensure that the best solutions are accessible all over the world and that such polymers are the material of the new millennium. Through studies and research, scientists and researchers continue to improve this material in an effort to provide the best products with sustainable features. Improved knowledge of polymer engineering is helping these professionals land good jobs in the rubber, polymer, petroleum, and oil industries. In contrast, there is less emphasis on polymer end-of-life fates. Moving forward, we propose a greater emphasis on chemical recycling, which sees value in plastic waste and encourages a closed-loop plastic economy. To assist us on the path to sustainability, the synthetic polymer community should seek out the systems viewpoint provided by life cycle assessment on a regular basis.