Mechanical Properties of Polymeric Materials (Closed)

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Analysis and Characterization".

Viewed by 16670Editor

Interests: polymer chemistry; synthesis and modification of polymers; antimicrobial polymers; active surfaces; material characterization

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

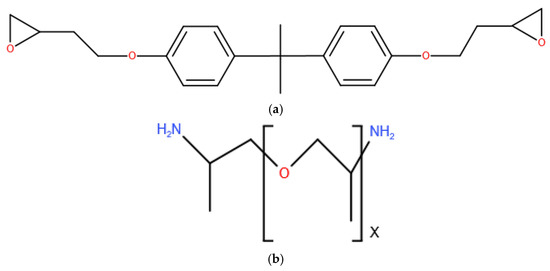

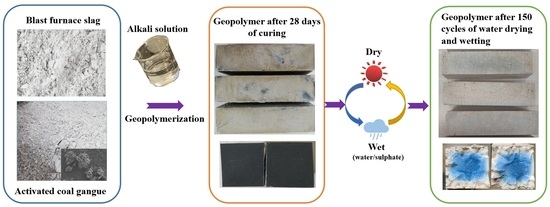

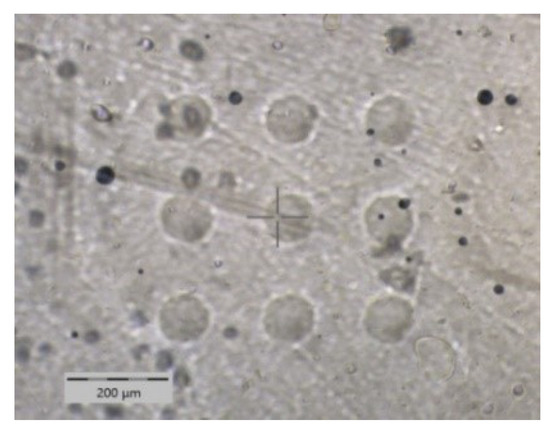

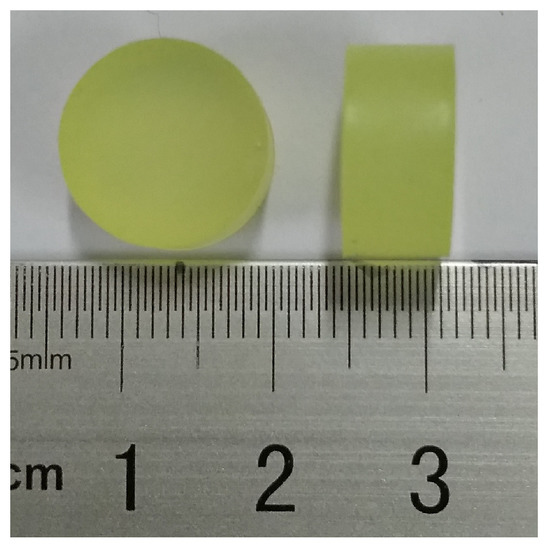

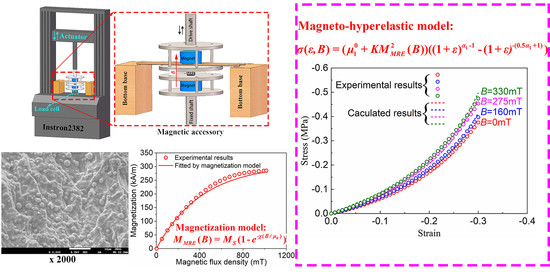

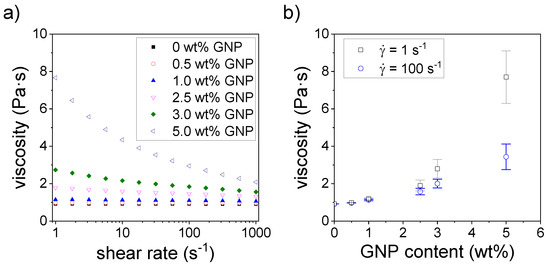

Polymeric materials have coexisted with us since the discovery, more than one century ago now, of the first synthetic polymer named Bakelite. Nowadays, researchers are looking for new pathways to obtain polymeric materials with advanced or improved properties that are more environmentally friendly and are also derived from renewable sources. As is well-known, one of the main properties of materials is their mechanical behavior. It is important to know what their response is when they are brought under the application of external forces. In the case of polymers, since they are viscoelastic materials having the characteristics of solids and viscous liquids, their properties are time-and temperature-dependent. Therefore, the rate of the stimulus application, the temperature at which is imposed, as well as their molecular weight, processing conditions, crystallinity degree, polymer composition, among others, must be taken into account. Moreover, the incorporation of additives (fillers, plasticizers, colorants, etc.) in the case of polymeric-based materials where polymer is the main component undoubtedly modifies the ultimate behavior. The physico-chemical nature of these additives along with the interfaces between both components change the final performance and, consequently, the range of applications.

The Special Issue aims to collect research on the mechanical properties of polymeric materials, having in mind the wide-range scope of the terminology. Both original contributions and reviews are all welcome.

Dr. Marta Fernández-García

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

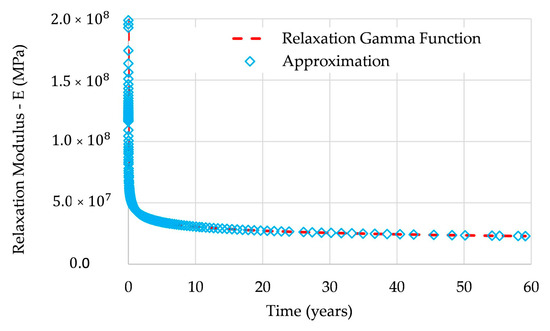

- Elasticity and viscoelasticity

- Tensile strength

- Elongation

- Compression

- Bending

- Brittleness

- Hardness (micro and nanohardness)

- Stiffness

- Toughness

- Isotropy and anisotropy

- Stress relaxation

- Creep compliance

- Resilience

- Impact resistance

- Damping

- Fracture toughness

- Fatigue

- Shear stress

- Scratch

Related Special Issue

- Mechanical and Advanced Properties of Polymers in Polymers (7 articles - displayed below)