State-of-the-Art Polymer Science and Technology in Singapore

Share This Topical Collection

Editors

Dr. Somen K. Bhudolia

Dr. Somen K. Bhudolia

Dr. Somen K. Bhudolia

Dr. Somen K. Bhudolia

E-Mail

Website

Collection Editor

Materials Scientist (Sr)-Non-Metallics, Materials Science Lab, Halliburton Completion Tools, 11 Tuas South Avenue 12, Singapore 637131, Singapore

Interests: thermoplastic composites; out of autoclave processes; non crimp fabrics; thin ply composites; microwave curing; fusion joining of thermoplastic composites; automation and mass production of composite structures; aerospace structures; acrylic Elium-based composites

Special Issues, Collections and Topics in MDPI journals

Dr. Sunil Chandrakant Joshi

Dr. Sunil Chandrakant Joshi

Dr. Sunil Chandrakant Joshi

Dr. Sunil Chandrakant Joshi

E-Mail

Website

Collection Editor

School of Mechanical and Aerospace Engineering, Nanyang Technological University, Singapore 50 Nanyang Ave, Singapore 639798, Singapore

Interests: thermoplastic composites; fibre reinforced aerospace composites and structures; multi-functional composites; numerical simulation and optimization of composite manufacturing processes; analysis and testing of thermal controls for micro-satellites; thermo-mechanical analysis of coated and composite structures

Special Issues, Collections and Topics in MDPI journals

Dr. Swee Leong Sing

Dr. Swee Leong Sing

Dr. Swee Leong Sing

Dr. Swee Leong Sing

E-Mail

Website

Collection Editor

Department of Mechanical Engineering, National University of Singapore, 9 Engineering Drive 1, Singapore 117575, Singapore

Interests: lasers (high power); laser-materials interactions; laser based advanced manufacturing; powder bed fusion; additive manufacturing; 3D printing

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Polymer science is a rapidly developing field of research and innovation. Different research groups in Singapore are active in varied research directions of polymer science and technology and making a significant contribution to the global and national efforts for socioeconomic development at both scientific and applied research. Research activities include polymer synthesis and processing, polymer composites (material and manufacturing innovation), polymer and composite characterization, and polymer physics. Singapore’s polymer and composites scientists collaborate with local as well as international industries and innovation enterprises and are significantly contributing to innovative polymeric material development and processing technologies for aerospace, automotive, marine, and offshore, pharmaceutics, medicine, food products, and construction applications. This Topical Collection aims to present a wider picture of state-of-the-art research directions in the science and technology of polymers and composites in Singapore.

Dr. Somen K. Bhudolia

Dr. Wei Min Huang

Dr. Sunil Chandrakant Joshi

Dr. Swee Leong Sing

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- polymer technology

- polymer processing

- thermosetting and thermoplastic polymers

- polymer characterization and properties

- polymer physics

- polymer and composites and simulations

- polymers and polymer composites for advanced technologies and applications

- polymers and composites for Industry 4.0

Published Papers (8 papers)

Open AccessArticle

A Modeling Framework for the Thermoforming of Carbon Fiber Reinforced Thermoplastic Composites

by

Long Bin Tan, Wern Sze Teo, Yi Wen Cheah and Sridhar Narayanaswamy

Cited by 1 | Viewed by 1206

Abstract

A comprehensive modeling framework for the thermoforming of polymer matrix woven laminate composite was developed. Two numerical indicators, the slip path length and traction magnitude, have been identified to be positively correlated to matrix smearing and wrinkling defects. The material model has been

[...] Read more.

A comprehensive modeling framework for the thermoforming of polymer matrix woven laminate composite was developed. Two numerical indicators, the slip path length and traction magnitude, have been identified to be positively correlated to matrix smearing and wrinkling defects. The material model has been calibrated with picture-frame experimental results, and the prediction accuracy for intra-ply shear and thickness distribution was examined with measurements of the physically formed parts. Specifically, thickness prediction for most locations on the formed parts was accurate within an 11.6% error margin. However, at two points with significant intra-ply shear, the prediction errors increased to around 20%. Finally, a parametric study was conducted to determine the relationship between various process parameters and the quality of the formed part. For the trapezoidal part, orienting the laminate at 45 degrees to the mold axis reduces the likelihood of matrix smear and wrinkling defects. Although this laminate orientation yielded a greater spatial variation in part thickness, the thickness deviation is lower than that for the 0-degree orientation case. Two forming analyses were conducted with ramp rates of 25 mm/s and 80 mm/s to match the equipment’s operational limits. It was observed that higher forming rates led to a greater likelihood of defects, as evidenced by a 15% and 10% increase in the formed part areas with longer slip paths and higher traction magnitudes, respectively. It was discovered that shallower molds benefit from faster ramp rates, while deeper molds require slower rates to manage extensive shearing, stretching and bending. Faster forming rates lead to smaller thickness increases at high intra-ply shear regions, indicating a shift from intra-ply shear to out-of-plane bending due to the visco-plastic effect of the molten laminate and can negatively impact part quality. Lastly, it was shown that a well-conceived strategy using darts could improve the part quality by reducing the magnitude of the defect indicators.

Full article

►▼

Show Figures

Open AccessArticle

A Comparative Study on the Self-Healing Characterizations and Formulation Optimization of Polyurea Coating

by

Xinrui Shen, Zhenyuan Dong, Celine Sim and Yuanzhe Li

Cited by 7 | Viewed by 2372

Abstract

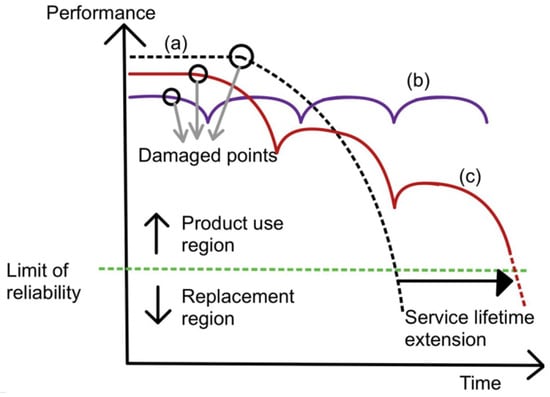

Self-healing materials, especially self-healing polyurea/polyurethane, to replace traditional coating has been of increasing interest in the past decade. The frequency of regular maintenance work can also be reduced as the coating is capable of forming bonds at ruptured sites. This reduces the cost

[...] Read more.

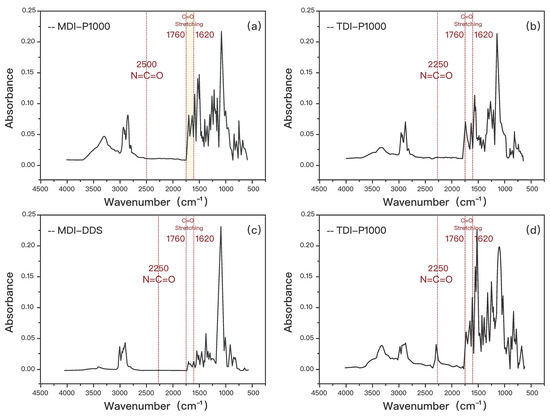

Self-healing materials, especially self-healing polyurea/polyurethane, to replace traditional coating has been of increasing interest in the past decade. The frequency of regular maintenance work can also be reduced as the coating is capable of forming bonds at ruptured sites. This reduces the cost of maintenance and the risk involved in workers engaging in maintenance work. The extremely short curing time of polyurea coating could potentially outweigh the cost due to its short down time. With a high self-healing efficiency, self-healing polyurea could be the ultimate choice of protective coating. This report aims to find the optimum formulation for fabrication of polyurea with a high self-healing efficiency. This is conducted by changing the composition of the components chosen for formulation of polyurea. The choice of isocyanate and amine is varied to explore its impact on chain mobility and microphase separation, which are important factors affecting self-healing efficiency. A series of characterizations, including ATR-FTIR, DSC, optical microscope and mechanical tester, is used to analyze the factors affecting the self-healing efficiency of fabricated polyurea and to eventually determine the best formulation. The ideal formulation of toluene 2,4 diisocyanate-amine (TDI-P1000) polyurea managed to achieve a self-healing of 42%. Further studies could be done to include multiple healing mechanisms after different area of polyurea to boost its self-healing efficiency after repeated healing.

Full article

►▼

Show Figures

Open AccessArticle

Prediction and Optimization of Process Parameters for Composite Thermoforming Using a Machine Learning Approach

by

Long Bin Tan and Nguyen Dang Phuc Nhat

Cited by 7 | Viewed by 3449

Abstract

Thermoforming is a process where the laminated sheet is pre-heated to the desired forming temperature before being pressed and cooled between the molds to give the final formed part. Defects such as wrinkles, matrix-smear or ply-splitting could occur if the process is not

[...] Read more.

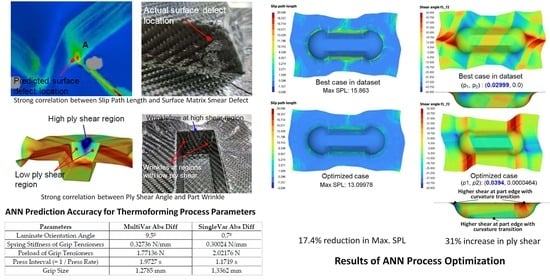

Thermoforming is a process where the laminated sheet is pre-heated to the desired forming temperature before being pressed and cooled between the molds to give the final formed part. Defects such as wrinkles, matrix-smear or ply-splitting could occur if the process is not optimized. Traditionally, for thermoforming of fiber-reinforced composites, engineers would either have to perform numerous physical trial and error experiments or to run a large number of high-fidelity simulations in order to determine satisfactory combinations of process parameters that would yield a defect-free part. Such methods are expensive in terms of equipment and raw material usage, mold fabrication cost and man-hours. In the last decade, there has been an ongoing trend of applying machine learning methods to engineering problems, but none for woven composite thermoforming. In this paper, two applications of artificial neural networks (ANN) are presented. The first is the use of ANN to analyze full-field contour results from simulation so as to predict the process parameters resulting in the quality of the formed product. Results show that the developed ANN can predict some input parameters reasonably well from just inspecting the images of the thermoformed laminate. The second application is to optimize the process parameters that would result in a quality part through the objectives of minimizing the maximum slip-path length and maximizing the regions of the laminate with a predesignated shear angle range. Our results show that the ANN can provide reasonable optimization of the process parameters to yield improved product quality. Overall, the results from the ANNs are encouraging when compared against experimental data. The image analysis method proposed here for machine learning is novel for composite manufacturing as it can potentially be combined with machine vision in the actual manufacturing operation to provide active feedback to ensure quality products.

Full article

►▼

Show Figures

Open AccessReview

Mini-Review of Self-Healing Mechanism and Formulation Optimization of Polyurea Coating

by

Junzhi Luo, Tao Wang, Celine Sim and Yuanzhe Li

Cited by 28 | Viewed by 4836

Abstract

Self-healing polymers are categorized as smart materials that are capable of surface protection and prevention of structural failure. Polyurethane/polyurea, as one of the representative coatings, has also attracted attention for industrial applications. Compared with polyurethane, polyurea coating, with a similar formation process, provides

[...] Read more.

Self-healing polymers are categorized as smart materials that are capable of surface protection and prevention of structural failure. Polyurethane/polyurea, as one of the representative coatings, has also attracted attention for industrial applications. Compared with polyurethane, polyurea coating, with a similar formation process, provides higher tensile strength and requires shorter curing time. In this paper, extrinsic and intrinsic mechanisms are reviewed to address the efficiency of the self-healing process. Moreover, formulation optimization and strategic improvement to ensure self-healing within a shorter period of time with acceptable recovery of mechanical strength are also discussed. The choice and ratio of diisocyanates, as well as the choice of chain extender, are believed to have a crucial effect on the acceleration of the self-healing process and enhance self-healing efficiency during the preparation of polyurea coatings.

Full article

►▼

Show Figures

Open AccessArticle

In Situ Observation of Shear-Induced Jamming Front Propagation during Low-Velocity Impact in Polypropylene Glycol/Fumed Silica Shear Thickening Fluids

by

Anatoli Kurkin, Vitali Lipik, Xin Zhang and Alfred Tok

Cited by 3 | Viewed by 1890

Abstract

Shear jamming, a relatively new type of phase transition from discontinuous shear thickening into a solid-like state driven by shear in dense suspensions, has been shown to originate from frictional interactions between particles. However, not all dense suspensions shear jam. Dense fumed silica

[...] Read more.

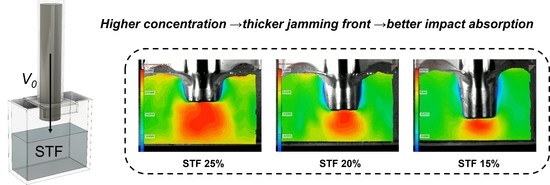

Shear jamming, a relatively new type of phase transition from discontinuous shear thickening into a solid-like state driven by shear in dense suspensions, has been shown to originate from frictional interactions between particles. However, not all dense suspensions shear jam. Dense fumed silica colloidal systems have wide applications in the industry of smart materials from body armor to dynamic dampers due to extremely low bulk density and high colloid stability. In this paper, we provide new evidence of shear jamming in polypropylene glycol/fumed silica suspensions using optical in situ speed recording during low-velocity impact and explain how it contributes to impact absorption. Flow rheology confirmed the presence of discontinuous shear thickening at all studied concentrations. Calculations of the flow during impact reveal that front propagation speed is 3–5 times higher than the speed of the impactor rod, which rules out jamming by densification, showing that the cause of the drastic impact absorption is the shear jamming. The main impact absorption begins when the jamming front reaches the boundary, creating a solid-like plug under the rod that confronts its movement. These results provide important insights into the impact absorption mechanism in fumed silica suspensions with a focus on shear jamming.

Full article

►▼

Show Figures

Open AccessArticle

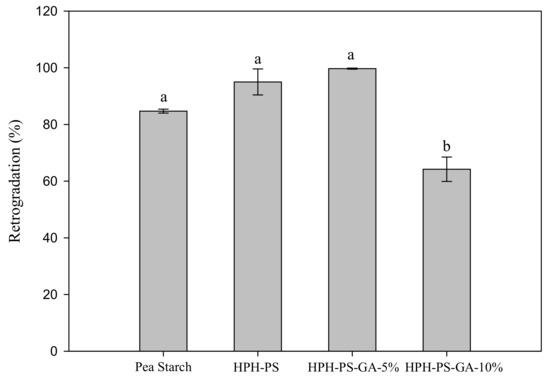

Modification of Pea Starch Digestibility through the Complexation with Gallic Acid via High-Pressure Homogenization

by

Franciene Almeida Villanova and Amy Hui-Mei Lin

Cited by 10 | Viewed by 2723

Abstract

Pea starch and some legume starches are the side streams of plant-based protein production. Structural modification toward moderate digestibility and desirable functionality is a way to increase the economic values of these side-stream starches. We applied an innovative and sustainable technique, high-pressure homogenization,

[...] Read more.

Pea starch and some legume starches are the side streams of plant-based protein production. Structural modification toward moderate digestibility and desirable functionality is a way to increase the economic values of these side-stream starches. We applied an innovative and sustainable technique, high-pressure homogenization, to alter pea starch structure, which resulted in a high level of complexation with the small phenolic acid molecule, gallic acid, to alter starch digestibility. This study showed a great level of disruption of the compact starch structure represented by the decrease in gelatinization temperature, enthalpy change, and relative crystallinity. The addition of a high concentration (10%) of gallic acid contributed to a typical V-type X-ray diffractometry pattern. Data demonstrated a significant decrease (~23%) in the susceptibility to α-amylase and an increase in resistant starch (~13%). In addition, starch functionality was improved with a reduced retrogradation rate. Pea starch responded to the high-pressure homogenization process well. Compared with the rice and maize starch reported in the literature, pea starch required a reduced amount of gallic acid to form a high level of complexation with a significant delay in starch digestion.

Full article

►▼

Show Figures

Open AccessReview

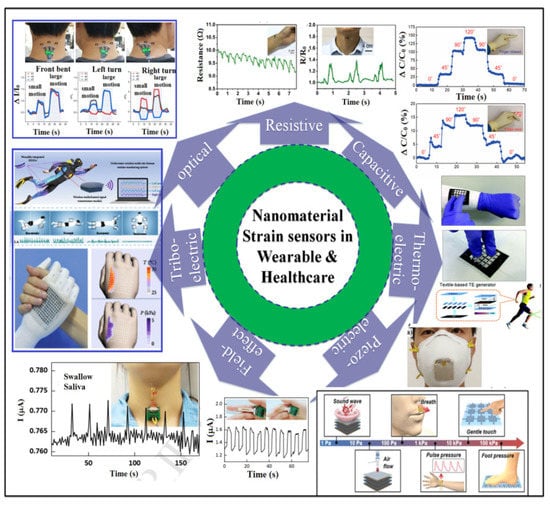

Intelligent Nanomaterials for Wearable and Stretchable Strain Sensor Applications: The Science behind Diverse Mechanisms, Fabrication Methods, and Real-Time Healthcare

by

Veluru Jagadeesh Babu, Merum Anusha, Merum Sireesha, Subramanian Sundarrajan, Syed Sulthan Alaudeen Abdul Haroon Rashid, A. Senthil Kumar and Seeram Ramakrishna

Cited by 5 | Viewed by 3232

Abstract

It has become a scientific obligation to unveil the underlying mechanisms and the fabrication methods behind wearable/stretchable strain sensors based on intelligent nanomaterials in order to explore their possible potential in the field of biomedical and healthcare applications. This report is based on

[...] Read more.

It has become a scientific obligation to unveil the underlying mechanisms and the fabrication methods behind wearable/stretchable strain sensors based on intelligent nanomaterials in order to explore their possible potential in the field of biomedical and healthcare applications. This report is based on an extensive literature survey of fabrication of stretchable strain sensors (SSS) based on nanomaterials in the fields of healthcare, sports, and entertainment. Although the evolution of wearable strain sensors (WSS) is rapidly progressing, it is still at a prototype phase and various challenges need to be addressed in the future in special regard to their fabrication protocols. The biocalamity of COVID-19 has brought a drastic change in humans’ lifestyles and has negatively affected nations in all capacities. Social distancing has become a mandatory rule to practice in common places where humans interact with each other as a basic need. As social distancing cannot be ruled out as a measure to stop the spread of COVID-19 virus, wearable sensors could play a significant role in technologically impacting people’s consciousness. This review article meticulously describes the role of wearable and strain sensors in achieving such objectives.

Full article

►▼

Show Figures

Open AccessArticle

Effect of PMMA Coupling Layer in Enhancing the Ultrasonic Weld Strength of Novel Room Temperature Curable Acrylic Thermoplastic to Epoxy Based Composites

by

Goram Gohel, Chun Zhi Soh, Kah Fai Leong, Pierre Gerard and Somen K. Bhudolia

Cited by 6 | Viewed by 2443

Abstract

The joining of composites can be performed in an extremely short time with more energy-efficient ultrasonic welding techniques. The current research investigated the performance optimization of ultrasonic welding of carbon/Elium

® composite to carbon/epoxy composite using a polymethyl methacrylate (PMMA) coupling interlayer. The

[...] Read more.

The joining of composites can be performed in an extremely short time with more energy-efficient ultrasonic welding techniques. The current research investigated the performance optimization of ultrasonic welding of carbon/Elium

® composite to carbon/epoxy composite using a polymethyl methacrylate (PMMA) coupling interlayer. The weld strength was quantified by static lap shear strength (LSS) testing. A new methodology was used by creating a PMMA coupling layer on the epoxy composite adherend to achieve an improved interphase and thus enhance the weld properties. The LSS of Elium (EL)-Epoxy (EP) _0.25_0.25 was found to be 190% higher compared to that of EL-EP, confirming the effectiveness of the strategy used for creating an interlayer thermoplastic coupling layer. The time required for welding was optimized to be 2s as compared to 10 min required for adhesive bonding. Scanning electron microscopic images of epoxy and PMMA/Elium matrix interphase were observed to have a rough surface and remained largely unaffected by welding. There was an interphase change further away from the interphase to a rougher texture. There was little to no effect on the penultimate layer on the weld strength, as no interphase change could be observed after welding. Fractography investigation revealed shear cusps, matrix plastic deformation, fiber imprints, fiber pull-out, and good adhesion between matrix and fiber, features seen for configuration with maximum LSS. The current research findings present a way to join Elium

® with epoxy composites that could be used in applications that require a selective strengthening, such as in sporting goods and consumer products. Furthermore, a detailed investigation is ongoing to use different filler particles and coupling layers to reach the maximum welding performance.

Full article

►▼

Show Figures