Fiber-Reinforced Polymer Composites in Structural Engineering

Share This Topical Collection

Editors

Prof. Dr. Alper Ilki

Prof. Dr. Alper Ilki

Prof. Dr. Alper Ilki

Prof. Dr. Alper Ilki

E-Mail

Website

Collection Editor

Structural and Earthquake Engineering Laboratory, Civil Engineering Faculty, Istanbul Technical University, 34469 Maslak Istanbul, Turkey

Interests: structural engineering; reinforced concrete structures; masonry structures; seismic retrofit with advanced materials; seismic performance assessment

Special Issues, Collections and Topics in MDPI journals

Prof. Dr. Masoud Motavalli

Prof. Dr. Masoud Motavalli

Prof. Dr. Masoud Motavalli

Prof. Dr. Masoud Motavalli

E-Mail

Website

Collection Editor

Structural Engineering Laboratory, Empa Swiss Federal Laboratories for Materials Science and Technology, Überlandstrasse 129, 8600 Dübendorf, Switzerland

Interests: application of advanced materials (such as fiber-reinforced polymer composites and shape memory alloys in civil engineering); structural rehabilitation and repair; seismic retrofitting; large and full scale laboratory and field experiments

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

A Special Issue named “Fiber-Reinforced Polymer (FRP) Composites in Structural Engineering” was successfully closed on 30 April 2014 with 16 papers published in Polymers. Many papers have received impressive page reviews. To publish more excellent works on this topic, we reopen this issue as a Topical Collection. This Collection will open for submission in recent three years, authors are welcome to contribute excellent works anytime during this period.

We are expecting to receive papers dealing with cutting-edge issues on the research and application of FRP composites in structural engineering. The topics of the Topical Collection include, but are not limited to: Seismic Retrofitting using FRP composites, Confinement of concrete columns using FRP composites, Strengthening of masonry and historical structures using FRP composites, External strengthening of concrete, timber, and steel structures using FRP composites, Near surface mounting reinforcement using FRP composites, Durability issues of FRP strengthened structures, Fire protection systems for FRP strengthened structures, Practical applications and case studies, Internally reinforced concrete (with FRP rebars), All composite structures using FRP profiles, plates, and shells, Testing and characterization of FRP elements for structural engineering, and Health monitoring of FRP structures.

Prof. Dr. Alper Ilki

Prof. Dr. Masoud Motavalli

Collection Editors

Keywords

- FRP composites

- seismic retrofitting

- external strengthening

- structural rehabilitation

- durability

- fire protection systems

- NSMR using FRP

- FRP reinforced concrete

- FRP profiles

- testing

- structural health monitoring

Published Papers (21 papers)

Open AccessArticle

Transient Thermal Tensile Behaviour of Novel Pitch-Based Ultra-High Modulus CFRP Tendons

by

Giovanni Pietro Terrasi, Emma R. E. McIntyre, Luke A. Bisby, Tobias D. Lämmlein and Pietro Lura

Cited by 8 | Viewed by 6494

Abstract

A novel ultra-high modulus carbon fibre reinforced polymer (CFRP) prestressing tendon made from coal tar pitch-based carbon fibres was characterized in terms of high temperature tensile strength (up to 570 °C) with a series of transient thermal and steady state temperature tensile tests.

[...] Read more.

A novel ultra-high modulus carbon fibre reinforced polymer (CFRP) prestressing tendon made from coal tar pitch-based carbon fibres was characterized in terms of high temperature tensile strength (up to 570 °C) with a series of transient thermal and steady state temperature tensile tests. Digital image correlation was used to capture the high temperature strain development during thermal and mechanical loading. Complementary thermogravimetric (TGA) and dynamic mechanical thermal (DMTA) experiments were performed on the tendons to elucidate their high temperature thermal and mechanical behaviour. The novel CFRP tendons investigated in the present study showed an ambient temperature design tensile strength of 1400 MPa. Their failure temperature at a sustained prestress level of 50% of the design tensile strength was 409 °C, which is higher than the failure temperature of most fibre reinforced polymer rebars used in civil engineering applications at similar utilisation levels. This high-temperature tensile strength shows that there is potential to use the novel high modulus CFRP tendons in CFRP pretensioned concrete elements for building applications that fulfill the fire resistance criteria typically applied within the construction industry.

Full article

►▼

Show Figures

Open AccessArticle

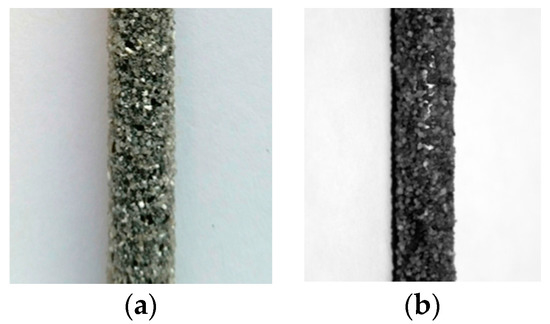

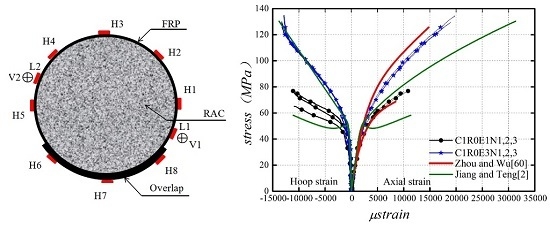

FRP-Confined Recycled Coarse Aggregate Concrete: Experimental Investigation and Model Comparison

by

Yingwu Zhou, Jingjing Hu, Mali Li, Lili Sui and Feng Xing

Cited by 48 | Viewed by 7781

Abstract

The in situ application of recycled aggregate concrete (RAC) is of great significance in environmental protection and construction resources sustainability. However, it has been limited to nonstructural purposes due to its poor mechanical performance. External confinement using steel tubes and fiber-reinforced polymer (FRP)

[...] Read more.

The in situ application of recycled aggregate concrete (RAC) is of great significance in environmental protection and construction resources sustainability. However, it has been limited to nonstructural purposes due to its poor mechanical performance. External confinement using steel tubes and fiber-reinforced polymer (FRP) can significantly improve the mechanical performance of RAC and thus the first-ever study on the axial compressive behavior of glass FRP (GFRP)-confined RAC was recently reported. To have a full understanding of FRP-confined RAC, this paper has extended the type of FRP and presents a systematic experimental study on the axial compressive performance of carbon FRP (CFRP)-confined RAC. The mechanical properties of CFRP-confined RAC from the perspective of the failure mode, ultimate strength and strain, and stress–strain relationship responses were analyzed. Integrated with existing experimental data of FRP-confined RAC, the paper compiles a database for the mechanical properties of FRP-confined RAC. Based on the database, the effects of FRP type (i.e., GFRP and CFRP) and the replacement ratio of recycled coarse aggregate were investigated. The results indicated that the stress–stain behavior of FRP-confined RAC depended heavily on the unconfined concrete strength and the FRP confining pressure instead of the replacement ratio. Therefore, this study adopted eleven high-performance ultimate strength and strain models developed for FRP-confined normal aggregate concrete (NAC) to predict the mechanical properties of FRP-confined RAC. All the predictions had good agreement with the test results, which further confirmed similar roles played by FRP confinement in improving the mechanical properties of RAC and improving those of NAC. On this basis, this paper finally recommended a stress–strain relationship model for FRP-confined RAC.

Full article

►▼

Show Figures

Open AccessArticle

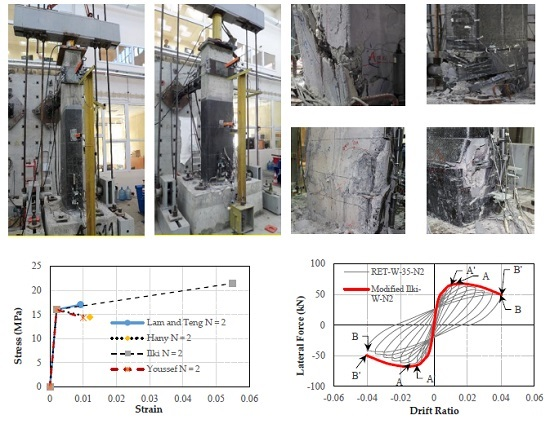

Evaluation of FRP Confinement Models for Substandard Rectangular RC Columns Based on Full-Scale Reversed Cyclic Lateral Loading Tests in Strong and Weak Directions

by

Hamid Farrokh Ghatte, Mustafa Comert, Cem Demir and Alper Ilki

Cited by 24 | Viewed by 7684

Abstract

Although many theoretical and experimental studies are available on external confinement of columns using fiber-reinforced polymer (FRP) jackets, as well as numerous models proposed for the axial stress-axial strain relation of concrete confined with FRP jackets, they have not been validated with a

[...] Read more.

Although many theoretical and experimental studies are available on external confinement of columns using fiber-reinforced polymer (FRP) jackets, as well as numerous models proposed for the axial stress-axial strain relation of concrete confined with FRP jackets, they have not been validated with a sufficient amount and variety of experimental data obtained through full-scale tests of reinforced concrete (RC) columns with different geometrical and mechanical characteristics. Particularly, no systematical experimental data have been presented on full-scale rectangular substandard RC columns subjected to reversed cyclic lateral loads along either their strong or weak axes. In this study, firstly, test results of five full-scale rectangular substandard RC columns with a cross-sectional aspect ratio of two (300 mm × 600 mm) are briefly summarized. The columns were tested under constant axial load and reversed cyclic lateral loads along their strong or weak axes before and after retrofitting with external FRP jackets. In the second stage, inelastic lateral force-displacement relationships of the columns are obtained analytically, making use of the plastic hinge assumption and different FRP confinement models available in the literature. Finally, the analytical findings are compared with the test results for both strong and weak directions of the columns. Comparisons showed that use of different models for the stress-strain relationship of FRP-confined concrete can yield significantly non-conservative or too conservative retrofit designs, particularly in terms of deformation capacity.

Full article

►▼

Show Figures

Open AccessArticle

Moisture Absorption/Desorption Effects on Flexural Property of Glass-Fiber-Reinforced Polyester Laminates: Three-Point Bending Test and Coupled Hygro-Mechanical Finite Element Analysis

by

Xu Jiang, Jie Song, Xuhong Qiang, Henk Kolstein and Frans Bijlaard

Cited by 30 | Viewed by 8669

Abstract

Influence of moisture absorption/desorption on the flexural properties of Glass-fibre-reinforced polymer (GFRP) laminates was experimentally investigated under hot/wet aging environments. To characterize mechanical degradation, three-point bending tests were performed following the ASTM test standard (ASTM D790-10A). The flexural properties of dry (0%

M

[...] Read more.

Influence of moisture absorption/desorption on the flexural properties of Glass-fibre-reinforced polymer (GFRP) laminates was experimentally investigated under hot/wet aging environments. To characterize mechanical degradation, three-point bending tests were performed following the ASTM test standard (ASTM D790-10A). The flexural properties of dry (0%

Mt/

M∞), moisture unsaturated (30%

Mt/

M∞ and 50%

Mt/

M∞) and moisture saturated (100%

Mt/

M∞) specimens at both 20 and 40 °C test temperatures were compared. One cycle of moisture absorption-desorption process was considered in this study to investigate the mechanical degradation scale and the permanent damage of GFRP laminates induced by moisture diffusion. Experimental results confirm that the combination of moisture and temperature effects sincerely deteriorates the flexural properties of GFRP laminates, on both strength and stiffness. Furthermore, the reducing percentage of flexural strength is found much larger than that of E-modulus. Unrecoverable losses of E-modulus (15.0%) and flexural strength (16.4%) for the GFRP laminates experiencing one cycle of moisture absorption/desorption process are evident at the test temperature of 40 °C, but not for the case of 20 °C test temperature. Moreover, a coupled hygro-mechanical Finite Element (FE) model was developed to characterize the mechanical behaviors of GFRP laminates at different moisture absorption/desorption stages, and the modeling method was subsequently validated with flexural test results.

Full article

►▼

Show Figures

Open AccessArticle

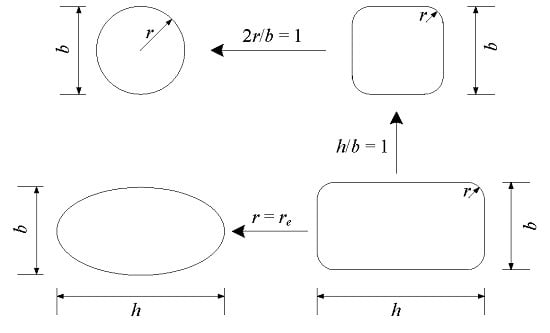

Cross-Sectional Unification on the Stress-Strain Model of Concrete Subjected to High Passive Confinement by Fiber-Reinforced Polymer

by

Yu-Gui Cao, Cheng Jiang and Yu-Fei Wu

Cited by 79 | Viewed by 6944

Abstract

The stress-strain behavior of concrete can be improved by providing a lateral passive confining pressure, such as fiber-reinforced polymer (FRP) wrapping. Many axial stress-strain models have been proposed for FRP-confined concrete columns. However, few models can predict the stress-strain behavior of confined concrete

[...] Read more.

The stress-strain behavior of concrete can be improved by providing a lateral passive confining pressure, such as fiber-reinforced polymer (FRP) wrapping. Many axial stress-strain models have been proposed for FRP-confined concrete columns. However, few models can predict the stress-strain behavior of confined concrete columns with more than two specified cross-sections. A stress-strain model of FRP-confined concrete columns with cross-sectional unification was developed in this paper based on a database from the existing literature that includes circular, square, rectangular and elliptical concrete columns that are highly confined by FRP jackets. Using the database, the existing theoretical models were evaluated. In addition, the ultimate stress and strain models with cross-sectional unification were proposed using two parameters: the cross-sectional aspect ratio and corner radius ratio. The elliptical cross-section can be considered as a rectangular one with a special corner radius for the model calculations. A simple and accurate model of the equivalent corner radius ratio for elliptical columns was proposed. Compared to the other existing models and experimental data, the proposed models show good performance.

Full article

►▼

Show Figures

Open AccessArticle

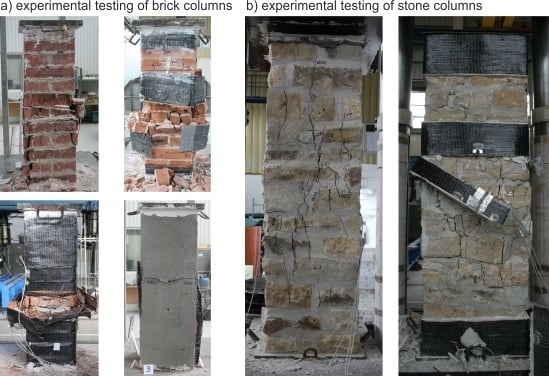

Stress State Analysis and Failure Mechanisms of Masonry Columns Reinforced with FRP under Concentric Compressive Load

by

Jiří Witzany and Radek Zigler

Cited by 29 | Viewed by 8963

Abstract

The strengthening and stabilization of damaged compressed masonry columns with composites based on fabrics of high-strength fibers and epoxy resin, or polymer-modified cement mixtures, belongs to novel, partially non-invasive and reversible progressive methods. The stabilizing and reinforcing effect of these fabrics significantly applies

[...] Read more.

The strengthening and stabilization of damaged compressed masonry columns with composites based on fabrics of high-strength fibers and epoxy resin, or polymer-modified cement mixtures, belongs to novel, partially non-invasive and reversible progressive methods. The stabilizing and reinforcing effect of these fabrics significantly applies to masonry structures under concentric compressive loading whose failure mechanism is characterized by the appearance and development of vertical tensile cracks accompanied by an increase in horizontal masonry strain. During the appearance of micro and hairline cracks (10

−3 to 10

−1 mm), the effect of non-pre-stressed wrapping composite is very small. The favorable effect of passive wrapping is only intensively manifested after the appearance of cracks (10

−1 mm and bigger) at higher loading levels. In the case of “optimum” reinforcement of a masonry column, the experimental research showed an increase in vertical displacements δ

y (up to 247%), horizontal displacements δ

x (up to 742%) and ultimate load-bearing capacity (up to 136%) compared to the values reached in unreinforced masonry columns. In the case of masonry structures in which no intensive “bed joint filler–masonry unit” interaction occurs, e.g., in regular coursed masonry with little differences in the mechanical characteristics of masonry units and the binder, the reinforcing effect of the fabric applies only partially.

Full article

►▼

Show Figures

Open AccessArticle

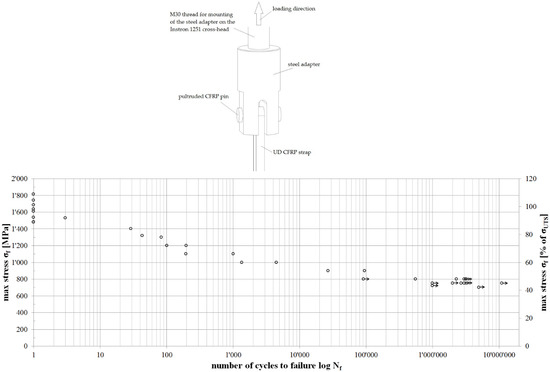

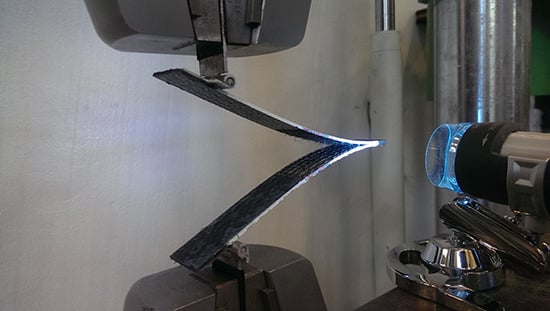

Fretting Fatigue Behaviour of Pin-Loaded Thermoset Carbon-Fibre-Reinforced Polymer (CFRP) Straps

by

Fabio Baschnagel, Vanessa Rohr and Giovanni Pietro Terrasi

Cited by 15 | Viewed by 7122

Abstract

This paper focuses on the fretting fatigue behaviour of pin-loaded carbon-fibre-reinforced polymer (CFRP) straps studied as models for rigging systems in sailing yachts, for suspenders of arch bridges and for pendent cables in cranes. Eight straps were subjected to an ultimate tensile strength

[...] Read more.

This paper focuses on the fretting fatigue behaviour of pin-loaded carbon-fibre-reinforced polymer (CFRP) straps studied as models for rigging systems in sailing yachts, for suspenders of arch bridges and for pendent cables in cranes. Eight straps were subjected to an ultimate tensile strength test. In total, 26 straps were subjected to a fretting fatigue test, of which ten did not fail. An S–N curve was generated for a load ratio

R of 0.1 and a frequency

f of 10 Hz, showing a fatigue limit stress of the straps around the matrix fatigue limit, corresponding to 46% of the straps’ ultimate tensile strength (σ

UTS). The fatigue limit was defined as 3 million load cycles (

N = 3 × 10

6), but tests were even conducted up to

N = 11.09 × 10

6. Catastrophic failure of the straps was initiated in their vertex areas. Investigations on the residual strength and stiffness properties of straps tested around the fatigue limit stress (for

N ≥ 1 × 10

6) showed little influence of the fatigue loading on these properties. Quasi-static finite element analyses (FEA) were conducted. The results obtained from the FEA are in good agreement with the experiments and demonstrate a fibre parallel stress concentration in the vertex area of factor 1.3, under the realistic assumption of a coefficient of friction (

cof) between pin and strap of 0.5.

Full article

►▼

Show Figures

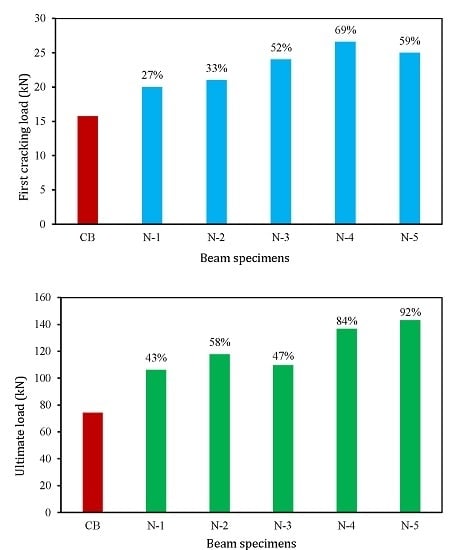

Open AccessArticle

Near Surface Mounted Composites for Flexural Strengthening of Reinforced Concrete Beams

by

Md. Akter Hosen, Mohd Zamin Jumaat, Ubagaram Johnson Alengaram, A. B. M. Saiful Islam and Huzaifa Bin Hashim

Cited by 32 | Viewed by 10657

Abstract

Existing structural components require strengthening after a certain period of time due to increases in service loads, errors in design, mechanical damage, and the need to extend the service period. Externally-bonded reinforcement (EBR) and near-surface mounted (NSM) reinforcement are two preferred strengthening approach.

[...] Read more.

Existing structural components require strengthening after a certain period of time due to increases in service loads, errors in design, mechanical damage, and the need to extend the service period. Externally-bonded reinforcement (EBR) and near-surface mounted (NSM) reinforcement are two preferred strengthening approach. This paper presents a NSM technique incorporating NSM composites, namely steel and carbon fiber-reinforced polymer (CFRP) bars, as reinforcement. Experimental and analytical studies carried out to explore the performance of reinforced concrete (RC) members strengthened with the NSM composites. Analytical models were developed in predicting the maximum crack spacing and width, concrete cover separation failure loads, and deflection. A four-point bending test was applied on beams strengthened with different types and ratios of NSM reinforcement. The failure characteristics, yield, and ultimate capacities, deflection, strain, and cracking behavior of the beams were evaluated based on the experimental output. The test results indicate an increase in the cracking load of 69% and an increase in the ultimate load of 92% compared with the control beam. The predicted result from the analytical model shows good agreement with the experimental result, which ensures the competent implementation of the present NSM-steel and CFRP technique.

Full article

►▼

Show Figures

Open AccessArticle

The Application of Carbon Composites in the Rehabilitation of Historic Baroque Vaults

by

Jiří Witzany, Jiří Brožovský, Tomáš Čejka, Klára Kroftová, Jan Kubát, Daniel Makovička and Radek Zigler

Cited by 13 | Viewed by 7095

Abstract

The stabilization and reinforcement of damaged barrel vaults with lunettes over an arcaded walk, applying composite strips based on high-strength carbon fibers and epoxy resin, was performed during the restoration of a historic monastery. The application of reinforcing composite strips in the soffit

[...] Read more.

The stabilization and reinforcement of damaged barrel vaults with lunettes over an arcaded walk, applying composite strips based on high-strength carbon fibers and epoxy resin, was performed during the restoration of a historic monastery. The application of reinforcing composite strips in the soffit of damaged barrel vaults was preceded by relatively extensive experimental research and theoretical analyses. This method significantly reduces the interventions into and the degradation of the original historic structure (surface application) and is reversible.

Full article

►▼

Show Figures

Open AccessArticle

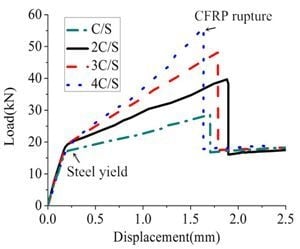

Study of the Tensile Properties of CFRP Strengthened Steel Plates

by

Yiyan Lu, Weijie Li, Shan Li, Xiaojin Li and Tao Zhu

Cited by 29 | Viewed by 6881

Abstract

This paper presents the experimental results of steel plates strengthened with carbon fiber reinforced polymer (CFRP) sheets under tensile load. The number of CFRP layers (ranging from one to four), strengthening schemes (single-sided and double-sided bonding), and temperatures (ranging from 25 to 120

[...] Read more.

This paper presents the experimental results of steel plates strengthened with carbon fiber reinforced polymer (CFRP) sheets under tensile load. The number of CFRP layers (ranging from one to four), strengthening schemes (single-sided and double-sided bonding), and temperatures (ranging from 25 to 120 °C) were investigated. Results showed that the number of CFRP layers and strengthening schemes had insignificant effects on failure modes of specimens. The failure modes were dominated by the degradation of resin matrix at temperatures lower than

Tg + 10 or 20 °C, where

Tg is the glass transition temperature, and were dominated by the volume decrease of resin matrix at temperatures above that. Through bonding CFRP sheets, the ultimate load and post-elastic stiffness of specimens were significantly increased. However, the increase in the number of CFRP layers also led to the decrease in strengthening and stiffening efficiency. The double-sided strengthened specimens showed more preferable mechanical properties than the single-sided strengthened specimens. As temperature increased, significant decreases in ultimate load and post-elastic stiffness were observed. Analytical modeling to predict the mechanical properties at ambient and elevated temperatures were conducted, respectively. The modeling results were verified by the test data.

Full article

►▼

Show Figures

Open AccessFeature PaperArticle

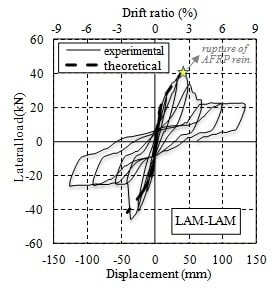

Seismic Behavior of Substandard RC Columns Retrofitted with Embedded Aramid Fiber Reinforced Polymer (AFRP) Reinforcement

by

Engin C. Seyhan, Caglar Goksu, Ahmet Uzunhasanoglu and Alper Ilki

Cited by 32 | Viewed by 10611

Abstract

Many existing reinforced concrete structures were constructed with substandard characteristics. Low quality concrete, poor transverse reinforcement details and insufficient flexural strength are among the most common deficiencies. While substandard structures are in need of retrofitting, particularly in seismic areas, problems such as high

[...] Read more.

Many existing reinforced concrete structures were constructed with substandard characteristics. Low quality concrete, poor transverse reinforcement details and insufficient flexural strength are among the most common deficiencies. While substandard structures are in need of retrofitting, particularly in seismic areas, problems such as high costs and disturbance to occupants are major obstacles for retrofit interventions. Fiber reinforced polymers can provide feasible retrofit solutions with minimum disturbance to occupants. In this study, the basic aim is to investigate the flexural seismic performance of substandard reinforced concrete columns retrofitted with embedded longitudinal fiber reinforced polymer reinforcement without increasing the original dimensions of the columns. In the experimental study, the reference and retrofitted columns were tested under constant vertical and reversed cyclic lateral loads. Three different connection methods of aramid fiber reinforced polymer reinforcement to the footing were investigated experimentally. A significant enhancement was obtained in lateral flexural strength through the proposed retrofitting method. Furthermore, it was observed that the cyclic lateral drift capacities of the retrofitted columns were as high as 3%, which can be deemed as quite satisfactory against seismic actions. The comparison of the experimental data with analytical calculations revealed that a conventional design approach assuming composite action between concrete and fiber reinforced polymer reinforcement can be used for flexural retrofit design. Experimental results also demonstrated that strain limit for longitudinal fiber reinforced polymer (FRP) reinforcement should be remarkably lower in case of reversed cyclic loading conditions.

Full article

►▼

Show Figures

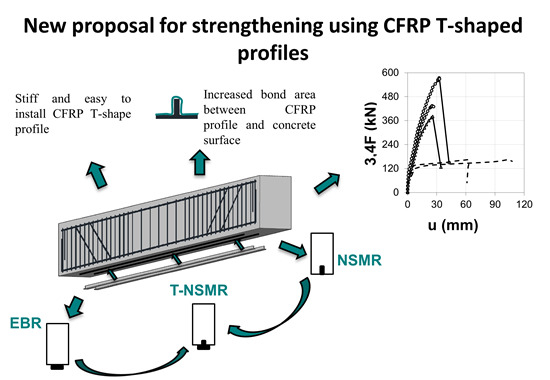

Open AccessFeature PaperArticle

New Proposal for Flexural Strengthening of Reinforced Concrete Beams Using CFRP T-Shaped Profiles

by

Renata Kotynia and Szymon Cholostiakow

Cited by 22 | Viewed by 8512

Abstract

The purpose of this study was to evaluate the performance of a novel strengthening system using T-shaped carbon fiber reinforced polymer (CFRP) profiles. The proposed system successfully combines the advantages of two established strengthening techniques, namely the near surface mounted (NSM) and externally

[...] Read more.

The purpose of this study was to evaluate the performance of a novel strengthening system using T-shaped carbon fiber reinforced polymer (CFRP) profiles. The proposed system successfully combines the advantages of two established strengthening techniques, namely the near surface mounted (NSM) and externally bonded (EB) methods. The paper presents the experimental results of structural tests carried out on seven flexurally-strengthened and two non-strengthened full-scale reinforced concrete (RC) members. Two T-shaped profiles having heights of 15 and 30 mm were applied. The main parameters of concrete strength and composite strengthening ratio were investigated to evaluate the efficiency of the proposed flexural strengthening system. All specimens were tested under a quasi-static six-point bending configuration. The test results showed a significant increase in the load bearing capacity and the stiffness of the RC beams with strengthening and also a notable reduction in maximum deflections. The high tensile strength utilization of the CFRP profiles places this strengthening technique as a promising alternative to other, less structurally-efficient systems.

Full article

►▼

Show Figures

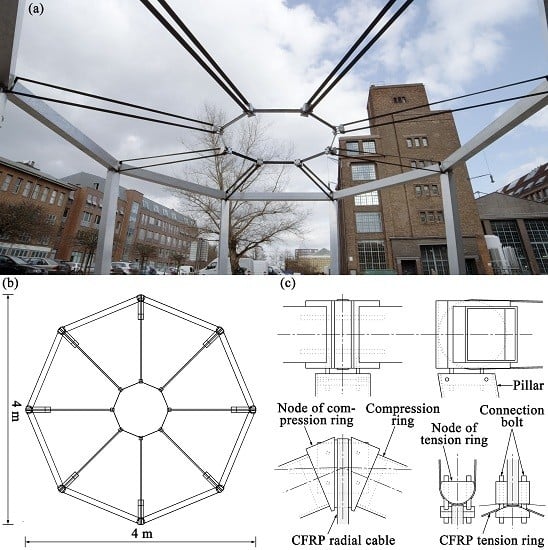

Open AccessReview

Carbon Fiber Reinforced Polymer for Cable Structures—A Review

by

Yue Liu, Bernd Zwingmann and Mike Schlaich

Cited by 235 | Viewed by 63880

Abstract

Carbon Fiber Reinforced Polymer (CFRP) is an advanced composite material with the advantages of high strength, lightweight, no corrosion and excellent fatigue resistance. Therefore, unidirectional CFRP has great potential for cables and to replace steel cables in cable structures. However, CFRP is a

[...] Read more.

Carbon Fiber Reinforced Polymer (CFRP) is an advanced composite material with the advantages of high strength, lightweight, no corrosion and excellent fatigue resistance. Therefore, unidirectional CFRP has great potential for cables and to replace steel cables in cable structures. However, CFRP is a typical orthotropic material and its strength and modulus perpendicular to the fiber direction are much lower than those in the fiber direction, which brings a challenge for anchoring CFRP cables. This paper presents an overview of application of CFRP cables in cable structures, including historical review, state of the art and prospects for the future. After introducing properties of carbon fibers, mechanical characteristics and structural forms of CFRP cables, existing CFRP cable structures in the world (all of them are cable bridges) are reviewed. Especially, their CFRP cable anchorages are presented in detail. New applications for CFRP cables, i.e., cable roofs and cable facades, are also presented, including the introduction of a prototype CFRP cable roof and the conceptual design of a novel structure—CFRP Continuous Band Winding System. In addition, other challenges that impede widespread application of CFRP cable structures are briefly introduced.

Full article

►▼

Show Figures

Open AccessArticle

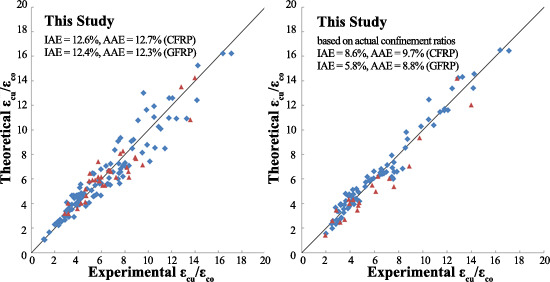

A Design-Oriented Combined Model (7 MPa to 190 MPa) for FRP-Confined Circular Short Columns

by

Zehra Canan Girgin and Konuralp Girgin

Cited by 20 | Viewed by 8526

Abstract

This study addresses a design oriented combined model to predict the ultimate strengths and ultimate strains in an extensive range of unconfined strength (7 to 190 MPa) for the axially loaded fiber-reinforced polymer (FRP)-wrapped circular short columns. Modified Hoek-Brown strength criterion, which was

[...] Read more.

This study addresses a design oriented combined model to predict the ultimate strengths and ultimate strains in an extensive range of unconfined strength (7 to 190 MPa) for the axially loaded fiber-reinforced polymer (FRP)-wrapped circular short columns. Modified Hoek-Brown strength criterion, which was previously extended to FRP-confined concrete from 7 to 108 MPa, is revisited and verified. An empirical strength model beyond 108 MPa encompassing ultra-high strength concrete (UHSC) and ultra-high performance concrete (UHPC) data, as well as empirical strain models, are defined to accomplish the design oriented combined model. This article especially focuses on the verification of the proposed strain models. The assessment performances of those models for carbon FRP (CFRP) and glass FRP (GFRP) confinement are compared with specific models in the current literature. Strength and strain predictions for UHSC and UHPC are integrated into the design oriented combined model as well. The assessments on this model agree with the experimental results in high accuracy.

Full article

►▼

Show Figures

Open AccessArticle

Simplified Model for Strengthening Design of Beam–Column Internal Joints in Reinforced Concrete Frames

by

Antonio Bossio, Francesco Fabbrocino, Gian Piero Lignola, Andrea Prota and Gaetano Manfredi

Cited by 48 | Viewed by 10357

Abstract

The beam-column joints are very restricted areas in which the internal forces, generated by boundary elements, act on the concrete core and reinforcing bars with a very high gradient. They are the link between horizontal and vertical structural elements, and therefore, they are

[...] Read more.

The beam-column joints are very restricted areas in which the internal forces, generated by boundary elements, act on the concrete core and reinforcing bars with a very high gradient. They are the link between horizontal and vertical structural elements, and therefore, they are directly involved in the transfer of seismic forces. Thus, they are crucial to study the seismic behavior of reinforced concrete (RC) structures. To fully understand the seismic performances and failure modes of beam-column joints in RC buildings, a simplified analytical model of joint behavior is proposed and theoretical simulations are performed. The aim of the model, focusing on internal perimetric joints, is to identify the strength hierarchy in terms of capacity for different failure modes (namely failure of cracked joint, bond failure of passing through bars, flexural/shear failures of columns or beams). It could represent a tool for the designers of new joints to quantify the performance of new structures, but also as a tool for the designers of external strengthening of existing joints in order to calculate the benefits of the retrofit and pushing the initial failure to a more desirable failure mode. Further, some experimental results of tests available in the scientific literature are reported, analyzed and compared.

Full article

►▼

Show Figures

Open AccessArticle

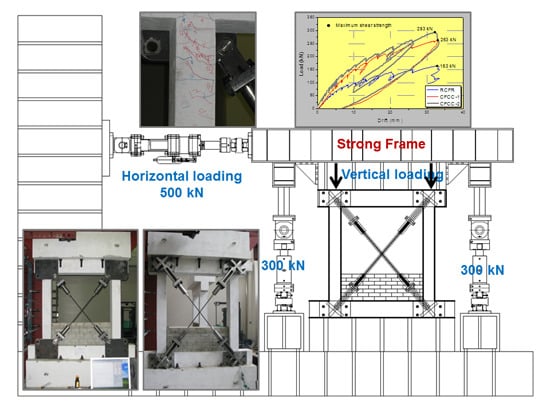

An Experimental Study on Non-Compression X-Bracing Systems Using Carbon Fiber Composite Cable for Seismic Strengthening of RC Buildings

by

Kang Seok Lee

Cited by 12 | Viewed by 8773

Abstract

Cross-bracing (X-bracing) is one of the most popular methods of seismic retrofitting, and has been shown to significantly increase the structural stiffness and strength of buildings. Conventional steel X-bracing methods typically exhibit brittle failure at the connection between the brace and the building,

[...] Read more.

Cross-bracing (X-bracing) is one of the most popular methods of seismic retrofitting, and has been shown to significantly increase the structural stiffness and strength of buildings. Conventional steel X-bracing methods typically exhibit brittle failure at the connection between the brace and the building, or buckling failure of the braces. This study investigated the structural properties of a new type of non-compression X-bracing system using carbon fiber composite cable (CFCC). This non-compression X-bracing system uses CFCC bracing and bolt connections between structural members and the terminal fixer of the CFCC, instead of conventional steel bracing. The aim is to overcome the brittle and buckling failures that can occur at the connection and bracings with conventional steel X-bracing methods. We carried out cyclic loading tests, and the maximum load carrying capacity and deformation were investigated, as well as hysteresis in the lateral load–drift relations. The test results revealed that the CFCC X-bracing system installed in reinforced concrete frames enhanced the strength markedly, and buckling failure of the bracing was not observed.

Full article

►▼

Show Figures

Open AccessArticle

Fatigue Behaviour of CFRP Strengthened Out-of-Plane Gusset Welded Joints with Double Cracks

by

Qian-Qian Yu, Tao Chen, Xiang-Lin Gu and Ning-Xi Zhang

Cited by 11 | Viewed by 6929

Abstract

This paper investigates the fatigue behaviour of out-of-plane gusset welded joints strengthened with carbon fibre reinforced polymer (CFRP) laminates. Two notches were introduced at the weld toes adjacent to longitudinal plate ends to simulate the initial damage. Variables including the stress range, single-

[...] Read more.

This paper investigates the fatigue behaviour of out-of-plane gusset welded joints strengthened with carbon fibre reinforced polymer (CFRP) laminates. Two notches were introduced at the weld toes adjacent to longitudinal plate ends to simulate the initial damage. Variables including the stress range, single- or double-sided strengthening and modulus of CFRP materials were considered. It was found that both cracks propagated under fatigue loading. All the specimens fractured along one predefined notch when the fatigue crack reached a certain length while the other crack also grew to some extent. Test results showed that the addition of composite materials significantly prolonged the fatigue life of specimens by as much as 1.28 to 8.17 times. Double-sided bond and ultra-high modulus CFRP materials led to a better strengthening efficiency. Thereafter, a series of numerical analyses were performed to study the stress intensity factor (SIF) and crack opening displacement (COD). Local debonding around the crack tip at the adhesive-steel interface was taken into consideration. Finally, the fatigue life of all the specimens was evaluated based on the linear elastic fracture mechanism (LEFM) theory and the predicted results agreed well with the experimental data.

Full article

►▼

Show Figures

Open AccessArticle

Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes

by

Elisa Borowski, Eslam Soliman, Usama F. Kandil and Mahmoud Reda Taha

Cited by 104 | Viewed by 12643

Abstract

Carbon fiber reinforced polymer (CFRP) laminates exhibit limited fracture toughness due to characteristic interlaminar fiber-matrix cracking and delamination. In this article, we demonstrate that the fracture toughness of CFRP laminates can be improved by the addition of multi-walled carbon nanotubes (MWCNTs). Experimental investigations

[...] Read more.

Carbon fiber reinforced polymer (CFRP) laminates exhibit limited fracture toughness due to characteristic interlaminar fiber-matrix cracking and delamination. In this article, we demonstrate that the fracture toughness of CFRP laminates can be improved by the addition of multi-walled carbon nanotubes (MWCNTs). Experimental investigations and numerical modeling were performed to determine the effects of using MWCNTs in CFRP laminates. The CFRP specimens were produced using an epoxy nanocomposite matrix reinforced with carboxyl functionalized multi-walled carbon nanotubes (COOH–MWCNTs). Four MWCNTs contents of 0.0%, 0.5%, 1.0%, and 1.5% per weight of the epoxy resin/hardener mixture were examined. Double cantilever beam (DCB) tests were performed to determine the mode I interlaminar fracture toughness of the unidirectional CFRP composites. This composite material property was quantified using the critical energy release rate,

GIC. The experimental results show a 25%, 20%, and 17% increase in the maximum interlaminar fracture toughness of the CFRP composites with the addition of 0.5, 1.0, and 1.5 wt% MWCNTs, respectively. Microstructural investigations using Fourier transform infrared (FTIR) spectroscopy and X-ray photoelectron spectroscopy (XPS) verify that chemical reactions took place between the COOH–MWCNTs and the epoxy resin, supporting the improvements experimentally observed in the interlaminar fracture toughness of the CFRP specimens containing MWCNTs. Finite element (FE) simulations show good agreement with the experimental results and confirm the significant effect of MWCNTs on the interlaminar fracture toughness of CFRP.

Full article

►▼

Show Figures

Open AccessArticle

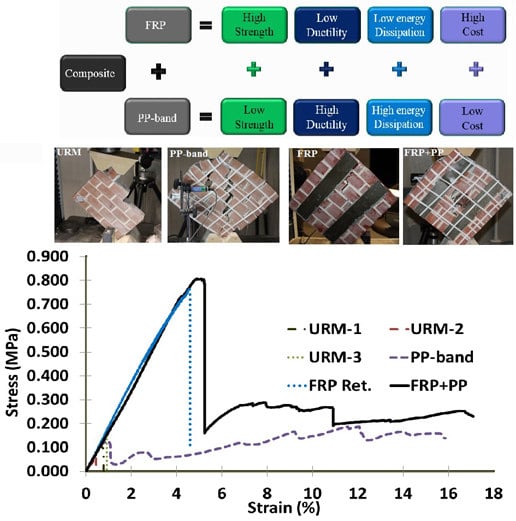

Fiber Reinforced Polymer and Polypropylene Composite Retrofitting Technique for Masonry Structures

by

Saleem Muhammad Umair, Muneyoshi Numada, Muhammad Nasir Amin and Kimiro Meguro

Cited by 38 | Viewed by 13357

Abstract

In the current research work, an attempt is made to increase the seismic capacity of unreinforced masonry (URM) structures by proposing a new composite material which can improve shear strength and deformation capacity of URM wall systems. Fiber Reinforced Polymer (FRP) having high

[...] Read more.

In the current research work, an attempt is made to increase the seismic capacity of unreinforced masonry (URM) structures by proposing a new composite material which can improve shear strength and deformation capacity of URM wall systems. Fiber Reinforced Polymer (FRP) having high tensile and shear stiffness can significantly increase in-plane and out-of-plane strength of masonry walls, but, inherently, FRP strengthened wall systems exhibit brittle failure under extreme seismic loading. Polypropylene (PP-band) is a low cost material with sufficient ductility and deformation capacity. Keeping in view the behavior of FRP and PP-band, a composite of FRP and PP-band is proposed for retrofitting of URM walls. Mechanical behavior of the proposed composite material is assessed by carrying out an in-plane diagonal compression test and an out-of-plane bending test on twenty-five 1/4-scaled masonry wall panels. Experimental plan for each panel, URM, PP-band retrofitted, FRP retrofitted and FRP + PP-band retrofitted masonry, is diagonal compression test and three-point bending test. Experimental results have determined that FRP + PP-band composite increased, not only the initial peak strength, but also the ductility, deformation capacity and residual strength of URM wall systems.

Full article

►▼

Show Figures

Open AccessArticle

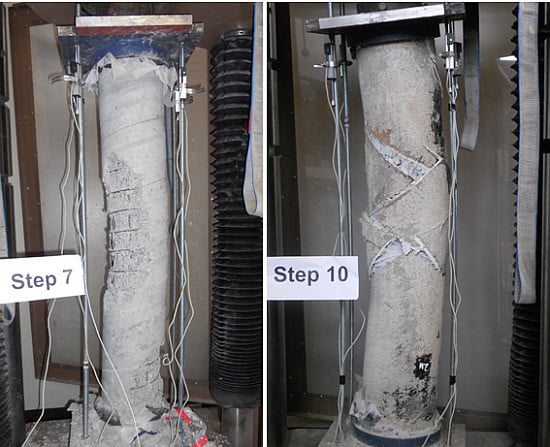

Residual Axial Capacity Comparison of CFFT and RC Bridge Columns after Fire

by

Alicia Echevarria, Arash E. Zaghi, Richard Christenson and Rachel Plank

Cited by 12 | Viewed by 8918

Abstract

The fire performance of protected concrete-filled fiber reinforced polymer (FRP) tube (CFFT) and conventional reinforced concrete (RC) bridge columns is studied through two phases of experimental research comprised of fire exposure and residual axial capacity tests. Two one-fifth scale CFFT columns and two

[...] Read more.

The fire performance of protected concrete-filled fiber reinforced polymer (FRP) tube (CFFT) and conventional reinforced concrete (RC) bridge columns is studied through two phases of experimental research comprised of fire exposure and residual axial capacity tests. Two one-fifth scale CFFT columns and two one-fifth scale conventional RC columns having similar axial and flexural capacities were subjected to two durations of extreme temperature exposure. The CFFT columns were protected by the Tyfo

® CFP fire protection system during the experiments. Subsequently, the post-fire robustness of the columns was quantified by measuring the residual axial capacity characteristics of each column. The protected CFFT columns exhibited superior axial strength and stiffness retention compared to the RC columns after fire exposure.

Full article

►▼

Show Figures

Open AccessArticle

Compressive Behavior of Concrete Confined with GFRP Tubes and Steel Spirals

by

Liang Huang, Xiaoxun Sun, Libo Yan and Deju Zhu

Cited by 44 | Viewed by 8767

Abstract

This paper presents the experimental results and analytical modeling of the axial compressive behavior of concrete cylinders confined by both glass fiber-reinforced polymer (GFRP) tube and inner steel spiral reinforcement (SR). The concrete structure is termed as GFRP–SR confined concrete. The number of

[...] Read more.

This paper presents the experimental results and analytical modeling of the axial compressive behavior of concrete cylinders confined by both glass fiber-reinforced polymer (GFRP) tube and inner steel spiral reinforcement (SR). The concrete structure is termed as GFRP–SR confined concrete. The number of GFRP layers (1, 2, and 3 layers) and volumetric ratios of SR (1.5% and 3%) were the experimental variables. Test results indicate that both GFRP tube and SR confinement remarkably increase the ultimate compressive strength, energy dissipation capacity, and ductility of concrete. The volumetric ratio of SR has a more pronounced influence on the energy dissipation capacity of confined concrete with more GFRP layers. In addition, a stress–strain model is presented to predict the axial compressive behavior of GFRP–SR confined concrete. Comparisons between the analytical results obtained using the proposed model and experimental results are also presented.

Full article

►▼

Show Figures