Developments in the End-of-Life Tire Recycling Process

A special issue of Processes (ISSN 2227-9717). This special issue belongs to the section "Environmental and Green Processes".

Deadline for manuscript submissions: closed (15 October 2023) | Viewed by 803

Special Issue Editors

Interests: waste management; rubber and plastic recycling; polymer characterization; polymerization, polymer processing

Interests: chemical engineering; thermochemical process technologies

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

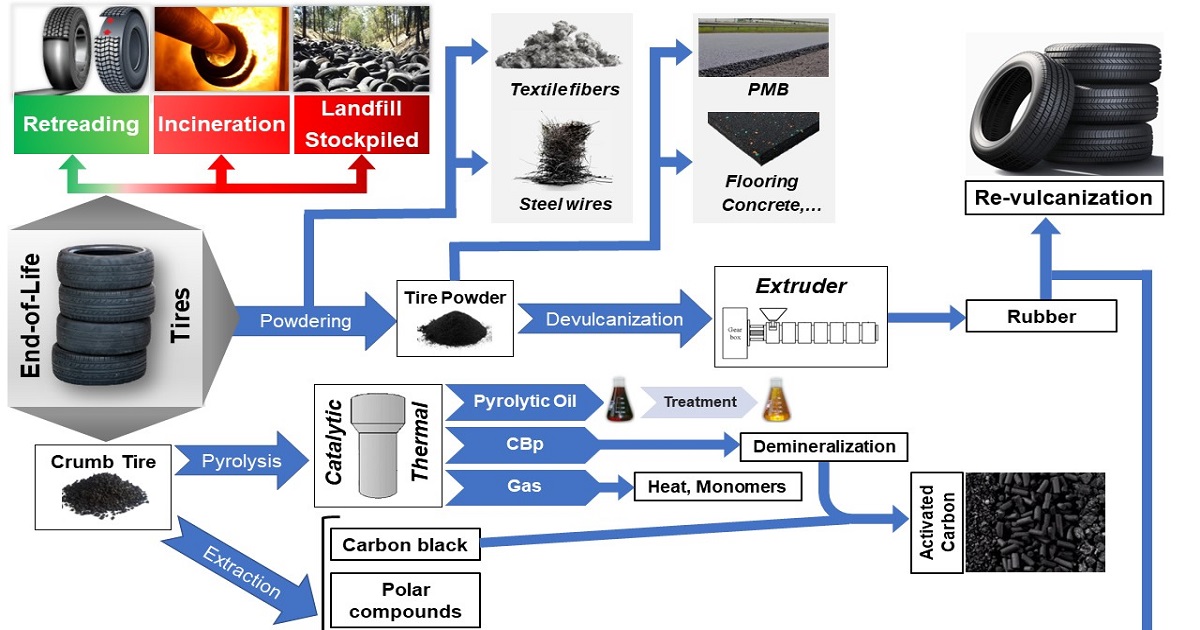

End-of-life tires are discarded on a daily basis, but even at present, limited action has been taken toward boosting their recyclability as most of the tires are either incinerated or landfilled/stockpiled. The complexity of tires has also been drastically increased, with little attention paid to designing them specifically for recycling. The retreading process is currently under intense development, and end-of-life tires have the ability to be retread several times. Furthermore, powdering (pulverization and grinding) the tires and separating the steel and textiles from this stream is a promising route that has found expanding applications. The particle size and surface area of the produced powder, purity, rubber degradation, and cost of equipment and production are the determining factors. In terms of processability, devulcanization has received a lot of attention from the tire recycling industry, and numerous physical, chemical, and microbial processes and combinations are being developed to be industrialized in the near future. Nevertheless, none of these processes are currently at a high enough technological readiness level to be operated at a large scale. In the dissolution extraction process, such as as in physical recycling, the solvent extraction devulcanizes and separates rubber from other tire components at low temperatures in addition to breaking sulfur bonds. In this way, the purity of the extracted products, e.g., rubber, carbon black (CB), and minerals, is much higher than that from other recycling methods.

Since applications of the mentioned recycled products (powder and devulcanized tire) are limited, tire pyrolysis has become extremely important. Process parameters and reactor design play a significant role in the degradation mechanisms and pyrolysis products, e.g., light olefins and dienes, naphthenes, mono-aromatics, tar, polar aromatics, and coke. Catalytic pyrolysis with promoted zeolites leads to larger yields of valuable products at the expense of the formation of tar and polar aromatics, i.e., N/S/O-containing aromatics. In addition, upgrading processes, e.g., hydro-treating, can reduce polar aromatics in the pyrolysis products by up to 90%. Furthermore, the demineralization of pyrolytic carbon black and activated carbon production are promising processes that result in increased tire recovery rates.

Dr. Mehrdad Seifali Abbas-Abadi

Dr. Gartzen Lopez

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- end-of-life tire

- pyrolysis

- oil treatment

- retreading

- devulcanization

- powdering

- tire dissolution

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Further information on MDPI's Special Issue polices can be found here.