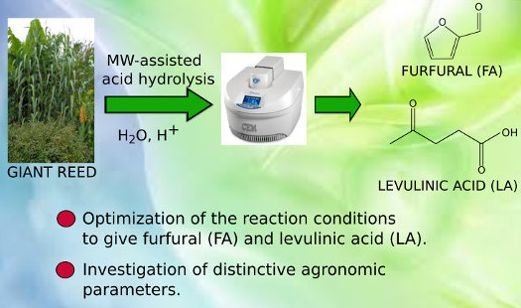

Hydrothermal Conversion of Giant Reed to Furfural and Levulinic Acid: Optimization of the Process under Microwave Irradiation and Investigation of Distinctive Agronomic Parameters

Abstract

:1. Introduction

2. Results and Discussion

2.1. Optimization of the Biomass Hydrolysis Conversion to Give Furfural and Levulinic Acid

| Reaction Time (min) | Temperature (°C) | LA Yield (wt %) |

|---|---|---|

| 20 | 180 | 21.1 |

| 15 | 180 | 20.2 |

| 10 | 180 | 15.2 |

| 20 | 140 | 7.4 |

| 15 | 140 | 5.1 |

| 10 | 140 | Traces |

| Temperature (°C) | Initial pH | Final pH | Δ pH |

|---|---|---|---|

| 120 | 0.67 | 0.41 | 0.26 |

| 130 | 0.61 | 0.40 | 0.21 |

| 140 | 0.62 | 0.32 | 0.30 |

| 150 | 0.66 | 0.32 | 0.34 |

| 160 | 0.68 | 0.29 | 0.39 |

| 170 | 0.67 | 0.27 | 0.40 |

| 180 | 0.68 | 0.26 | 0.42 |

| 190 | 0.68 | 0.26 | 0.42 |

| Catalyst | FA Yield (wt %) | LA Yield (wt %) |

|---|---|---|

| HCl | 8.9 | 19.6 |

| No catalyst | 0.2 | 1.1 |

2.2. Optimization of FA and LA Production as Function of the Harvest Time

2.3. Yield in Solid Residue: Recovery and Exploitation Possibilities

3. Experimental Section

3.1. Field Experiment and Sample Preparation

3.2. Cellulose, Hemicellulose, and Lignin Determination

3.3. Hydrolysis Experiments

3.4. Identification of FA and LA in the Hydrolyzate by GC-MS

3.5. Determination of Furfural by UV-Vis Spectroscopy

3.6. Determination of Levulinic Acid by GC Chromatography

3.7. Simultaneous Determination of Glucose, Xylose, Arabinose, Furfural. and Levulinic Acid by Means of HPLC

3.8. pH Monitoring during the Giant Reed Hydrothermal Conversion

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Raspolli Galletti, A.M.; Antonetti, C.; de Luise, V. Levulinic acid production from waste biomass. BioResources 2012, 7, 1824–1835. [Google Scholar] [CrossRef]

- Corma, A.; Iborra, S.; Velty, A. Chemical routes for the transformation of biomass into chemicals. Chem. Rev. 2007, 107, 2411–2502. [Google Scholar] [CrossRef] [PubMed]

- Rackermann, D.W.; Doherty, W.O.S. The conversion of lignocellulosics to levulinic acid. Biofuel Bioprod. Biorefin. 2011, 5, 115–126. [Google Scholar]

- Eseyin, A.E.; Steele, P.H. An overview of the applications of furfural and its derivatives. Int. J. Adv. Chem. Sci. Appl. 2015, 3, 42–47. [Google Scholar] [CrossRef]

- Cai, C.M.; Zhang, T.; Kumar, R.; Wyman, C.E. Integrated furfural production as a renewable fuel and chemical platform from lignocellulosic biomass. J. Chem. Technol. Biotechnol. 2014, 89, 2–10. [Google Scholar] [CrossRef]

- Bhogeswararao, S.; Srinivas, D. Catalytic conversion of furfural to industrial chemicals over supported Pt and Pd catalysts. J. Catal. 2015, 327, 65–77. [Google Scholar] [CrossRef]

- Yan, K.; Wu, G.; Lafleur, T.; Jarvis, C. Production, properties and catalytic hydrogenation of furfural to fuel additives and value-added chemicals. Renew. Sustain Energy Rev. 2014, 38, 663–676. [Google Scholar] [CrossRef]

- De, S.; Saha, B.; Luque, R. Hydrodeoxygenation processes: Advances on catalytic transformations of biomass-derived platform chemicals into hydrocarbon fuels. Bioresour. Technol. 2015, 178, 108–118. [Google Scholar] [CrossRef] [PubMed]

- Addepally, U.; Thulluri, C. Recent progress in production of fuel range liquid hydrocarbons from biomass-derived furanics via strategic catalytic routes. Fuel 2015, 159, 935–942. [Google Scholar] [CrossRef]

- Kamm, B.; Gerhardt, M.D.; Dautzenberg, G. Catalytic processes of lignocellulosic feedstock conversion for production of furfural, levulinic acid, and formic acid-based fuel components. In New and Future Developments in Catalysis: Catalytic Biomass Conversion; Suib, S.L., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 91–113. [Google Scholar]

- Dias, A.S.; Lima, S.; Pillinger, M.; Valente, A.A. Furfural and furfural-based industrial chemicals. In Ideas in Chemistry and Molecular Sciences: Advances in Synthetic Chemistry; Pignataro, B., Ed.; Wiley-VCH Verlag Gmbh & Co. KGaA: Weinheim, Germany, 2010; pp. 167–186. [Google Scholar]

- Demolis, A.; Essayem, N.; Rataboul, F. Synthesis and applications of alkyl levulinates. ACS Sustain. Chem. Eng. 2014, 2, 1338–1352. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, S.; Li, B.; Zhang, H. Advances in the catalytic production of valuable levulinic acid derivatives. ChemCatChem 2012, 4, 1230–1237. [Google Scholar] [CrossRef]

- Yan, K.; Jarvis, C.; Fafleur, T.; Qiao, Y.; Xie, X. Novel synthesis of Pd nanoparticles for hydrogenation of biomass-derived platform chemicals showing enhanced catalytic performance. RSC Adv. 2013, 3, 25865–25871. [Google Scholar] [CrossRef]

- Yan, K.; Chen, A. Selective hydrogenation of furfural and levulinic acid to biofuels on the ecofriendly Cu-Fe catalyst. Fuel 2014, 115, 101–108. [Google Scholar] [CrossRef]

- Bohre, A.; Dutta, S.; Saha, B.; Abu-Omar, M.M. Upgrading furfurals to drop-in biofuels: An overview. ACS Sustain. Chem. Eng. 2015, 3, 1263–1277. [Google Scholar] [CrossRef]

- Lange, J.P.; van der Heide, E.; van Buijtenen, J.; Price, R. Furfural a promising platform for lignocellulosic biofuels. ChemSusChem 2012, 5, 150–166. [Google Scholar] [CrossRef] [PubMed]

- Yan, K.; Lafleur, T.; Wu, G.; Cheng, C.; Xie, X.M. Highly selective production of value-added γ-valerolactone from biomass-derived levulinic acid using the robust Pd nanoparticles. Appl. Catal. A Gen. 2013, 468, 52–58. [Google Scholar] [CrossRef]

- Yan, K.; Lafleur, T.; Jarvis, C.; Wu, G.S. Clean and selective production of γ-valerolactone from biomass-derived levulinic acid catalyzed by recyclable Pd nanoparticle catalyst. J. Clean. Prod. 2014, 72, 230–232. [Google Scholar] [CrossRef]

- Yan, K.; Jarvis, C.; Gu, J.; Yan, Y. Production and catalytic transformation of levulinic acid: A platform for speciality chemicals and fuels. Renew. Sustain. Energ. Rev. 2015, 51, 986–997. [Google Scholar] [CrossRef]

- Morone, A.; Apte, M.; Pandey, R.A. Levulinic acid production from renewable waste resources: Bottlenecks, potential remedies, advancements and applications. Renew. Sustain. Energ. Rev. 2015, 51, 548–565. [Google Scholar] [CrossRef]

- Raspolli Galletti, A.M.; Antonetti, C.; de Luise, V.; Martinelli, M. A sustainable process for the production of γ-valerolactone by hydrogenation of biomass-derived levulinic acid. Green Chem. 2012, 14, 688–694. [Google Scholar] [CrossRef]

- Werpy, T.; Petersen, G.; Aden, A.; Bozell, J.; Holladay, J.; White, J.; Manheim, A.; Eliot, D.; Lasure, L.; Jones, S. Results of screening for potential candidates from sugars and synthesis gas. In Top Value Added Chemicals from Biomass; Werpy, T., Petersen, G., Eds.; Office of Energy Efficiency and Renewable Energy, US Department of Energy: Washington, DC, USA, 2004; Volume 1, pp. 1–67. [Google Scholar]

- Mamman, A.S.; Lee, J.M.; Kim, Y.C.; Hwang, I.T.; Park, N.J.; Hwang, Y.K.; Chang, J.S.; Hwang, J.S. Furfural: Hemicellulose/xylose derived biochemical. Biofuels Bioprod. Biorefin. 2008, 2, 438–454. [Google Scholar] [CrossRef]

- Dutta, S.; De, S.; Saha, B.; Alam, M.I. Advances in conversion of hemicellulosic biomass to furfural and upgrading to biofuels. Catal. Sci. Technol. 2012, 2, 2025–2036. [Google Scholar] [CrossRef]

- Mukherjee, A.; Dumont, M.J.; Raghavan, V. Review: Sustainable production of hydroxymethylfurfural and levulinic acid: Challenges and opportunities. Biomass Bioenerg. 2015, 72, 143–183. [Google Scholar] [CrossRef]

- Zhou, C.H.; Xia, X.; Lin, C.X.; Tong, D.S.; Beltramini, J. Catalytic conversion of lignocellulosic biomass to fine chemicals and fuels. Chem. Soc. Rev. 2011, 40, 5588–5617. [Google Scholar] [CrossRef] [PubMed]

- Ahlkvist, J.; Mäki-Arvela, P.; Mikkola, J.P. Macro-Molecules as a Source of Levulinic acid. Int. Rev. Chem. Eng. (IRECHE) 2014, 6, 44–58. [Google Scholar]

- Rivas, S.; Raspolli-Galletti, A.M.; Antonetti, C.; Santos, V.; Parajó, J.C. Sustainable conversion of Pinus pinaster wood into biofuel precursors: A biorefinery approach. Fuel 2016, 164, 51–58. [Google Scholar] [CrossRef]

- Saha, B.; Mosier, N.S.; Abu-Omar, M.M. Catalytic dehydration of lignocellulosic derived xylose to furfural. In Plants and Bioenergy; McCann, M.C., Buckeridge, M.S., Carpita, N.C., Eds.; Springer Science + Business Media: New York, NY, USA, 2014; Volume 4, pp. 267–276. [Google Scholar]

- Takeuki, Y.; Jin, F.; Tohji, K.; Enomoto, H. Acid catalytic hydrothermal conversion of carbohydrate biomass into useful substances. J. Mater. Sci. 2008, 43, 2472–2475. [Google Scholar] [CrossRef]

- Adel, A.M.; El-Wahab, Z.H.A.; Ibrahim, A.A.; Al.-Shemv, M.T. Characterization of microcrystalline cellulose prepared from lignocellulosic materials. Part I. Acid catalyzed hydrolysis. Bioresour. Technol. 2010, 101, 4446–4455. [Google Scholar] [CrossRef] [PubMed]

- Horedia-Olea, E.; Perez-Carrillo, E.; Serna-Saldivar, S.O. Effects of different acid hydrolyses on the conversion of sweet sorghum bagasse into C5 and C6 sugars and yeast inhibitors using response surface methodology. Bioresour. Technol. 2012, 119, 216–223. [Google Scholar] [CrossRef] [PubMed]

- Szabolcs, A.; Molnár, M.; Dibó, G.; Mika, L. Microwave assisted conversion of carbohydrates to levulinic acid: An essential step in biomass conversion. Green Chem. 2013, 15, 439–445. [Google Scholar] [CrossRef]

- Nsanganwimana, F.; Marchand, L.; Douay, F.; Mench, M. Arundo donax L. a candidate for phytomanaging water and soils contaminated by trace elements and producing plant-based feedstock. A review. Int. J. Phytoremediation 2014, 16, 982–1017. [Google Scholar] [CrossRef] [PubMed]

- Fagnano, M.; Impagliazzo, A.; Mori, M.; Fiorentino, N. Agronomic and environmental impacts of giant reed (Arundo donax L.): Results from a long-term field experiment in Hilly areas subject to soil erosion. BioEnergy Res. 2015, 8, 415–422. [Google Scholar] [CrossRef]

- Zucaro, A.; Forte, A.; Fagnano, M.; Bastianoni, S.; Basosi, R.; Fierro, A. Comparative attributional life cycle assessment of annual and perennial lignocellulosic feedstocks production under Mediterranean climate for biorefinery framework. Integr. Environ. Assess. Manag. 2015, 11, 397–403. [Google Scholar] [CrossRef] [PubMed]

- Raghu, S.; Anderson, R.C.; Daehler, C.C. Adding biofuels to the invasive species fire? Science 2006, 313, 1742. [Google Scholar] [CrossRef] [PubMed]

- Barney, J.N.; Ditomaso, J.M. Nonnative species and bioenergy: Are we cultivating the next invader? BioScience 2008, 58, 64–70. [Google Scholar] [CrossRef]

- Angelini, L.G.; Ceccarini, L.; Nassi o Di Nasso, N.; Bonari, E. Comparison of Arundo donax L. and Miscanthus x giganteus in a long-term field experiment in Central Italy: Analysis of productive characteristics and energy balance. Biomass Bioenergy 2009, 33, 635–643. [Google Scholar] [CrossRef]

- Nassi o Di Nasso, N.; Roncucci, N.; Bonari, E. Giant reed (Arundo donax L.) as energy crop in Central Italy: A review. Ital. J. Agron. 2013, 8, 10–17. [Google Scholar]

- Dragoni, F.; Nassi, N.; Tozzini, C.; Bonari, E.; Ragaglini, G. Aboveground yield and biomass quality of giant reed (Arundo donax L.) as affected by harvest time and frequency. BioEnergy Res. 2015, 8, 1321–1331. [Google Scholar] [CrossRef] [Green Version]

- Monti, A.; Zanetti, F.; Scordia, D.; Testa, G.; Cosentino, S.L. What to harvest when? Autumn, winter, annual and biennial harvesting of giant reed, miscanthus and switchgrass in northern and southern Mediterranean area. Ind. Crops Prod. 2015, 75, 129–134. [Google Scholar] [CrossRef]

- Raspolli Galletti, A.M.; Antonetti, C.; Ribechini, E.; Colombini, M.P.; Nassi o Di Nasso, N.; Bonari, E. From giant reed (Arundo donax L.) to levulinic acid and gamma-valerolactone: A high-yield catalytic route to valeric biofuels. Appl. Energ. 2013, 102, 157–162. [Google Scholar] [CrossRef]

- Ragaglini, G.; Dragoni, F.; Simone, M.; Bonari, E. Suitability of giant reed (Arundo donax L.) for anaerobic digestion: Effect of harvest time and frequency on the biomethane yield potential. Bioresour. Technol. 2014, 152, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Lemons e Silva, C.F.; Schirmer, M.A.; Maeda, R.N.; Barcelos, C.A.; Pereira, N., Jr. Potential of giant reed (Arundo donax L.) for second generation ethanol production. Electron. J. Biotechnol. 2015, 18, 10–15. [Google Scholar] [CrossRef]

- Scordia, D.; Testa, G.; Cosentino, S.L. Perennial grasses as lignocellulosic feedstock for second-generation bioethanol production in Mediterranean environment. Ital. J. Agron. 2014, 9, 84–92. [Google Scholar] [CrossRef]

- Richel, A.; Laurent, P.; Wathelet, B.; Wathelet, J.-P.; Paquot, M. Microwave-assisted conversion of carbohydrates. State of the art and outlook. C. R. Chim. 2011, 14, 224–234. [Google Scholar] [CrossRef]

- Raspolli Galletti, A.M.; Antonetti, C.; Marracci, M.; Piccinelli, F.; Tellini, B. Novel microwave-synthesis of Cu nanoparticles in the absence of any stabilizing agent and their antibacterial and antistatic applications. Appl. Surf. Sci. 2013, 280, 610–618. [Google Scholar] [CrossRef]

- Raspolli Galletti, A.M.; Antonetti, C.; Bertoldo, M.; Piccinelli, F. Chitosan as biosupport for the MW-assisted synthesis of palladium catalysts and their use in the hydrogenation of ethyl cinnamate. Appl. Catal. A Gen. 2013, 468, 95–101. [Google Scholar] [CrossRef]

- Raspolli Galletti, A.M.; Toniolo, L.; Antonetti, C.; Evangelisti, C.; Forte, C.; Martra, G.; Manzoli, M. New palladium catalysts on polyketone prepared through different smart methodologies and their use in the hydrogenation of cinnamaldehyde. Appl. Catal. A Gen. 2012, 447–448, 49–59. [Google Scholar] [CrossRef]

- Jin, F.; Wang, Y.; Zeng, X.; Shen, Z.; Yao, G. Water under high temperature and pressure conditions and its applications to develop green technologies for biomass conversion. In Application of Hydrothermal Reactions to Biomass Conversion; Jin, F., Ed.; Springer-Verlag: Berlin, Germany, 2014; pp. 3–28. [Google Scholar]

- Akiya, N.; Savage, P.E. Roles of water for chemical reactions in High-Temperature Water. Chem. Rev. 2002, 102, 2725–2750. [Google Scholar] [CrossRef] [PubMed]

- Jin, F.M.; Enomoto, H. Rapid and highly selective conversion of biomass into value added products in hydrothermal conditions: Chemistry of acid/base-catalysed and oxidation reactions. Energ. Environ. Sci. 2011, 4, 382–397. [Google Scholar] [CrossRef]

- Hu, X.; Wang, S.; Westerhof, R.J.M.; Wu, L.; Song, Y.; Dong, D.; Li, C.-Z. Acid-catalyzed conversion of C6 sugar monomer/oligomers to levulinic acid in water, tetrahydrofuran and toluene: Importance of the solvent polarity. Fuel 2015, 141, 56–63. [Google Scholar] [CrossRef]

- Yemis, O.; Mazza, G. Optimization of furfural and 5-hydroxymethylfurfural production from wheat straw by a microwave-assisted process. Bioresour. Technol. 2012, 109, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Raspolli Galletti, A.M.; D’Alessio, A.; Licursi, D.; Antonetti, C.; Valentini, G.; Galia, A.; Nassi o Di Nasso, N. Midinfrared FT–IR as a Tool for Monitoring Herbaceous Biomass Composition and Its Conversion to Furfural. J. Spectrosc. 2015, 2015, 719042. Available online: http://www.hindawi.com/journals/jspec/2015/719042 (accessed on 10 September 2015). [Google Scholar] [CrossRef]

- Gómez Bernal, H.; Bernazzani, L.; Raspolli Galletti, A.M. Furfural from corn stover hemicelluloses. A mineral acid-free approach. Green Chem. 2014, 16, 3734–3740. [Google Scholar] [CrossRef]

- Zhou, K.; Qian, H.; Zhou, H.; Zhu, K. Study on technology of ultrasound-microwave assisted generation of levulinic acid by hydrolysis of cornstarch. Sci. Technol. Food Ind. 2008, 2, 74–76. [Google Scholar]

- Rivas, S.; Raspolli Galletti, A.M.; Antonetti, C.; Santos, V.; Parajo, J.C. Sustainable production of levulinic acid from the cellulosic fraction of Pinus pinaster wood: Operation in aqueous media under microwave irradiation. J. Wood Chem. Technol. 2015, 15, 315–324. [Google Scholar] [CrossRef]

- Tabasso, S.; Montoneri, E.; Carnaroglio, D.; Caporaso, M.; Cravotto, G. Microwave-assisted flash conversion of non-edible polysaccharides and post-harvest tomato plant waste to levulinic acid. Green Chem. 2014, 16, 73–76. [Google Scholar] [CrossRef]

- DIBANET (The Production of Sustainable Diesel Miscible Biofuels from the Residues & Wastes of Europe & Latin America): Research Project Funded under the EU’s Seventh Framework Programme Co-Ordinated by Carbolea at the University of Limerick. Available online: http://www.dibanet.org (accessed on 10 September 2015).

- De Souza, R.O.M.A. Theoretical aspects of microwave irradiation practises. In Production of Biofuels and Chemicals with Microwave; Fang, Z., Smith, R.L., Jr., Qi, X., Eds.; Springer Science: Dordrecht, The Netherlands, 2015; pp. 3–16. [Google Scholar]

- Zeitsch, K.J. Furfural loss reactions. In The Chemistry and Technology of Furfural and Its Many By-Products, 1st ed.; Zeitsch, K.J., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2000; Volume 13, pp. 19–22. [Google Scholar]

- Danon, B.; Marcotullio, G.; de Jong, W. Mechanistic and kinetic aspects of pentose dehydration towards furfural in aqueous media employing homogeneous catalysis. Green Chem. 2014, 16, 39–54. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Wine, R.H. The determination of lignin and cellulose in acid detergent fibre with permanganate. J. Assoc. Off. Anal. Chem. 1968, 51, 780–785. [Google Scholar]

- Fitzpatrick, S.W. Lignocellulose Degradation to Furfural and Levulinic Acid. U.S. Patent 4,897,497, 30 January 1990. [Google Scholar]

- Fitzpatrick, S.W. Production of Levulinic Acid from Carbohydrate-Containing Materials. U.S. Patent 5,608,105, 4 March 1997. [Google Scholar]

- Hayes, D.J.; Ross, J.; Hayes, M.H.B.; Fitzpatrick, S.W. The biofine process: Production of levulinic acid, furfural and formic acid from lignocellulosic feedstocks. In Biorefineries—Industrial Processes and Product; Kamm, B., Gruber, P.R., Kamm, M., Eds.; Wiley-VCH: Weinheim, Germany, 2006; Volume 1, pp. 139–164. [Google Scholar]

- Shatalov, A.A.; Pereira, H. Papermaking fibers from giant reed (Arundo donax L.) by advanced ecologically friendly pulping and bleaching technologies. BioResources 2006, 1, 45–61. [Google Scholar]

- Klaas, M.R.; Shoene, H. Direct, high-yield conversion of cellulose into biofuels and platform chemicals—On the way to a sustainable bio-based economy. ChemSusChem 2009, 2, 127–128. [Google Scholar] [CrossRef] [PubMed]

- Rosatella, A.A.; Simeonov, S.P.; Frade, R.F.M.; Afonso, C.A.M. 5-Hydroxymethylfurfural (HMF) as a building block platform: biological properties, synthesis and synthetic applications. Green Chem. 2011, 13, 754–793. [Google Scholar] [CrossRef]

- Van Zandvoort, I.; Wang, Y.; Rasrendra, C.B.; van Eck, E.R.; Bruijnincx, P.C.; Heeres, H.J.; Weckhuysen, B.M. Formation, molecular structure, and morphology of humins in biomass conversion: Influence of feedstock and processing conditions. ChemSusChem 2013, 6, 1745–1758. [Google Scholar] [CrossRef] [PubMed]

- Sturm, G.S.J.; Verweij, M.D.; van Gerven, T.; Stankiewicz, A.I.; Stefanidis, G.D. On the effect of resonant microwave fields on temperature distribution in time and space. Int. J. Heat Mass Trans. 2012, 55, 3800–3811. [Google Scholar] [CrossRef]

- Ribechini, E.; Zanaboni, M.; Raspolli Galletti, A.M.; Antonetti, C.; Nassi, N.; Bonari, E.; Colombini, M.P. Py-GC/MS characterization of a wild and a selected clone of Arundo donax, and of its residues after catalytic hydrothermal conversion to high added-value products. J. Anal. Appl. Pyrol. 2012, 94, 223–229. [Google Scholar] [CrossRef]

- Licursi, D.; Antonetti, C.; Bernardini, J.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A.; Raspolli Galletti, A.M.; Martinelli, M. Characterization of the Arundo donax L. solid residue from hydrothermal conversion: Comparison with technical lignins and application perspectives. Ind. Crops Prod. 2015, 76, 1008–1024. [Google Scholar] [CrossRef]

- Ondruschka, B.; Bonrath, W.; Stuerga, D. Development and design of laboratory and pilot scale reactors for microwave-assisted chemistry. In Microwaves in Organic Chemistry; Loupy, A., Ed.; WILEY-VCH Verlag Gmbh & Co. KGaA: Weinheim, Germany, 2006; pp. 62–103. [Google Scholar]

- Rinaldi, L.; Carnaroglio, D.; Rotolo, L.; Cravotto, G. A microwave-based chemical factory in the lab: From milligram to multigram preparations. J. Chem. 2015, 2015, 879531. [Google Scholar] [CrossRef]

- Sample Availability: Not available.

© 2015 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antonetti, C.; Bonari, E.; Licursi, D.; Nassi o Di Nasso, N.; Raspolli Galletti, A.M. Hydrothermal Conversion of Giant Reed to Furfural and Levulinic Acid: Optimization of the Process under Microwave Irradiation and Investigation of Distinctive Agronomic Parameters. Molecules 2015, 20, 21232-21253. https://doi.org/10.3390/molecules201219760

Antonetti C, Bonari E, Licursi D, Nassi o Di Nasso N, Raspolli Galletti AM. Hydrothermal Conversion of Giant Reed to Furfural and Levulinic Acid: Optimization of the Process under Microwave Irradiation and Investigation of Distinctive Agronomic Parameters. Molecules. 2015; 20(12):21232-21253. https://doi.org/10.3390/molecules201219760

Chicago/Turabian StyleAntonetti, Claudia, Enrico Bonari, Domenico Licursi, Nicoletta Nassi o Di Nasso, and Anna Maria Raspolli Galletti. 2015. "Hydrothermal Conversion of Giant Reed to Furfural and Levulinic Acid: Optimization of the Process under Microwave Irradiation and Investigation of Distinctive Agronomic Parameters" Molecules 20, no. 12: 21232-21253. https://doi.org/10.3390/molecules201219760

APA StyleAntonetti, C., Bonari, E., Licursi, D., Nassi o Di Nasso, N., & Raspolli Galletti, A. M. (2015). Hydrothermal Conversion of Giant Reed to Furfural and Levulinic Acid: Optimization of the Process under Microwave Irradiation and Investigation of Distinctive Agronomic Parameters. Molecules, 20(12), 21232-21253. https://doi.org/10.3390/molecules201219760