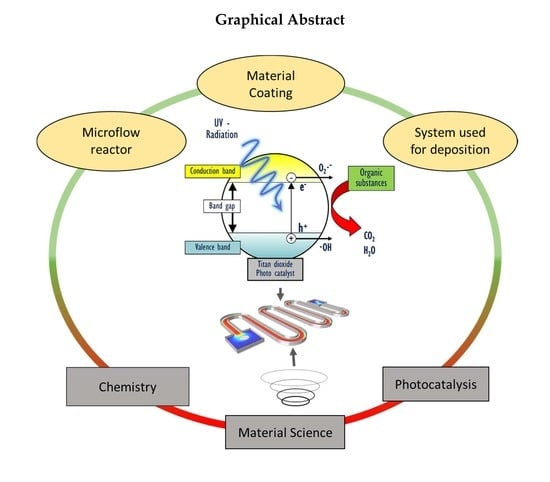

Designing Microflowreactors for Photocatalysis Using Sonochemistry: A Systematic Review Article

Abstract

:1. Introduction

2. Theoretical Background

3. Side-by-Side Comparative Evaluation of Flow System to Batch

- Improved irradiation of the reaction mixture;

- Reliable scale-up;

- Improved reaction selectivity and increased reproducibility;

- Fast mixing;

- Fast heat exchange;

- Multiphase chemistry;

- Multistep reaction sequences;

- Immobilized catalysts;

- Increased safety of operation.

4. Ultrasound: The Useful Tool for Chemists

4.1. Synthesis of Materials

4.2. For Immobilization of Catalyst

4.3. For Photocatalytic Experiments

5. Early Works on Microreactors

6. Immobilization of Nanoparticles Inside the Microtube

7. Photocatalytic Experiment

8. Microreactor with Ultrasound for Photocatalysis: A New Way Forward

9. Future Challenges and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Meng, X.; Zhang, Z.; Li, X. Synergetic photoelectrocatalytic reactors for environmental remediation: A review. J. Photochem. Photobiol. C Photochem. Rev. 2015, 24, 83–101. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Lisowski, P.; Łomot, D. A novel biomass-based support (Starbon) for TiO2 hybrid photocatalysts: A versatile green tool for water purification. RSC Adv. 2013, 3, 20186–20192. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, M.; Lin, C. Photocatalytic activity and scale-up effect in liquid-solid mini-fluidized bed reactor. Chem. Eng. J. 2016, 291, 254–268. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, Y.; Du, L.; Liu, J.; Yao, J. Review of the applications of microreactors. Renew. Sustain. Energy Rev. 2015, 47, 519–539. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Varma, R.S.; Nair, V. Selective photocatalysis of lignin-inspired chemicals by integrating hybrid nanocatalysis in microfluidic reactors. Chem. Soc. Rev. 2017, 46, 6675–6686. [Google Scholar] [CrossRef] [PubMed]

- Aljbour, S.; Tagawa, T.; Yamada, H. Ultrasound-assisted capillary microreactor for aqueous-organic multiphase reactions. J. Ind. Eng. Chem. 2009, 15, 829–834. [Google Scholar] [CrossRef]

- Knowles, J.P.; Elliott, L.D.; Booker-Milburn, K.I. Flow photochemistry: Old light through new windows. Beilstein J. Org. Chem. 2012, 8, 2025–2052. [Google Scholar] [CrossRef] [Green Version]

- Munirathinam, R.; Huskens, J.; Verboom, W. Supported catalysis in continuous-flow microreactors. Adv. Synth. Catal. 2015, 357, 1093–1123. [Google Scholar] [CrossRef]

- Yue, J. Multiphase flow processing in microreactors combined with heterogeneous catalysis for efficient and sustainable chemical synthesis. Catal. Today 2018, 308, 3–19. [Google Scholar] [CrossRef]

- Dimov, S.; Gasenko, O. Catalytic combustion and steam reforming of hydrocarbons in microreactor. MATEC Web Conf. 2017, 115, 03011. [Google Scholar] [CrossRef] [Green Version]

- Licklider, L.; Kuhr, W.G. Optimization of on-line peptide mapping by capillary zone electrophoresis. Anal. Chem. 1994, 66, 4400–4407. [Google Scholar] [CrossRef]

- Nge, P.N.; Rogers, C.I.; Woolley, A.T. Advances in microfluidic materials, functions, integration, and applications. Chem. Rev. 2013, 113, 2550–2583. [Google Scholar] [CrossRef] [PubMed]

- Sohrabi, S.; Keshavarz Moraveji, M.; Iranshahi, D. A review on the design and development of photocatalyst synthesis and application in microfluidic reactors: Challenges and opportunities. Rev. Chem. Eng. 2019, 0, 1–36. [Google Scholar] [CrossRef]

- Aran, H.C.; Salamon, D.; Rijnaarts, T.; Mul, G.; Wessling, M.; Lammertink, R.G.H. Porous photocatalytic membrane microreactor (P2M2): A new reactor concept for photochemistry. J. Photochem. Photobiol. A Chem. 2011, 225, 36–41. [Google Scholar] [CrossRef]

- Worz, O.; Jackel, K.P.; Richter, T.; Wolf, A. Microreactors–A new efficient tool forreactor development. Chem. Eng. Technol. 2001, 24, 138–142. [Google Scholar] [CrossRef]

- Krivec, M.; Žagar, K.; Suhadolnik, L.; Čeh, M.; Dražić, G. Highly efficient TiO2-based microreactor for photocatalytic applications. ACS Appl. Mater. Interfaces 2013, 5, 9088–9094. [Google Scholar] [CrossRef] [PubMed]

- Eskandarloo, H.; Badiei, A.; Behnajady, M.A.; Ziarani, G.M. UV-LEDs assisted preparation of silver deposited TiO2 catalyst bed inside microchannels as a high efficiency microphotoreactor for cleaning polluted water. Chem. Eng. J. 2015, 270, 158–167. [Google Scholar] [CrossRef]

- Fernandez Rivas, D.; Kuhn, S. Synergy of microfluidics and ultrasound: Process intensification challenges and opportunities. Top. Curr. Chem. 2016, 374, 70. [Google Scholar] [CrossRef]

- Fernandez Rivas, D.; Cintas, P.; Gardeniers, H.J.G.E. Merging microfluidics and sonochemistry: Towards greener and more efficient micro-sono-reactors. Chem. Commun. 2012, 48, 10935–10947. [Google Scholar] [CrossRef]

- Wood, R.J.; Lee, J.; Bussemaker, M.J. A parametric review of sonochemistry: Control and augmentation of sonochemical activity in aqueous solutions. Ultrason. Sonochem. 2017, 38, 351–370. [Google Scholar] [CrossRef]

- Cintas, P. Ultrasound and green chemistry–Further comments. Ultrason. Sonochem. 2016, 28, 257–258. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Zhao, S.; Zhang, Y.; Yao, C.; Chen, G.; Yuan, Q. Mixing and residence time distribution in ultrasonic microreactors. AIChE J. 2017, 63, 1404–1418. [Google Scholar] [CrossRef]

- Wang, H.; Nakamura, H.; Uehara, M.; Miyazaki, M.; Maeda, H. Preparation of titania particles utilizing the insoluble phase interface in a microchannel reactor. Chem. Commun. 2002, 2, 1462–1463. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekhar, D.; Borra, S.; Kapure, J.S.; Shivaji, G.S.; Srinivasulu, G.; Maurya, R.A. Visible-light photoredox catalysis: Direct synthesis of fused β-carbolines through an oxidation/[3 + 2] cycloaddition/oxidative aromatization reaction cascade in batch and flow microreactors. Org. Chem. Front. 2015, 2, 1308–1312. [Google Scholar] [CrossRef]

- Matsushita, Y.; Ichimura, T.; Ohba, N.; Kumada, S.; Sakeda, K.; Suzuki, T.; Tanibata, H.; Murata, T. Recent progress on photoreactions in microreactors. Pure Appl. Chem. 2007, 79, 1959–1968. [Google Scholar] [CrossRef]

- Oelgemoeller, M. Highlights of photochemical reactions in microflow reactors. Chem. Eng. Technol. 2012, 35, 1144–1152. [Google Scholar] [CrossRef]

- Pandoli, O.; del Rosso, T.; Santos, V.M.; Rezende, R.D.S.; Marinkovic, B.A. Prototyping of photocatalitic microrreators and photodegradation tests of organic colors prototyping of photocatalytic microreactor and testing of photodegradation of organic. Quim. Nova 2015, 38, 859–863. [Google Scholar]

- Ren, K.; Zhou, J.; Wu, H. Materials for microfluidic chip fabrication. Acc. Chem. Res. 2013, 46, 2396–2406. [Google Scholar] [CrossRef]

- Wang, N.; Lei, L.; Zhang, X.M.; Tsang, Y.H.; Chen, Y.; Chan, H.L.W. A comparative study of preparation methods of nanoporous TiO2 films for microfluidic photocatalysis. Microelectron. Eng. 2011, 88, 2797–2799. [Google Scholar] [CrossRef]

- Cambié, D.; Bottecchia, C.; Straathof, N.J.W.; Hessel, V.; Noël, T. Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment. Chem. Rev. 2016, 116, 10276–10341. [Google Scholar] [CrossRef]

- Noël, T.; Naber, J.R.; Hartman, R.L.; Mcmullen, J.P.; Jensen, K.F.; Buchwald, S.L. Palladium-catalyzed amination reactions in flow: Overcoming the challenges of clogging via acoustic irradiation. Chem. Sci. 2011, 2, 287–290. [Google Scholar] [CrossRef]

- Nair, V.; Colmenares, J.C.; Lisovytskiy, D. Ultrasound assisted ZnO coating in a microflow based photoreactor for selective oxidation of benzyl alcohol to benzaldehyde. Green Chem. 2019, 21, 1241–1246. [Google Scholar] [CrossRef]

- Aljbour, S.; Yamada, H.; Tagawa, T. Ultrasound-assisted phase transfer catalysis in a capillary microreactor. Chem. Eng. Process. Process Intensif. 2009, 48, 1167–1172. [Google Scholar] [CrossRef]

- Hartman, R.L.; Naber, J.R.; Zaborenko, N.; Buchwald, S.L.; Jensen, K.F. Overcoming the challenges of solid bridging and constriction during Pd-catalyzed C-N bond formation in microreactors abstract: We investigate the mechanisms that govern plugging in microreactors. Org. Process Res. Dev. 2010, 14, 1347–1357. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Ouyang, W.; Ojeda, M.; Kuna, E.; Chernyayeva, O.; Lisovytskiy, D.; De, S.; Luque, R.; Balu, A.M. Mild ultrasound-assisted synthesis of TiO2 supported on magnetic nanocomposites for selective photo-oxidation of benzyl alcohol. Appl. Catal. B Environ. 2016, 183, 107–112. [Google Scholar] [CrossRef]

- Pol, V.G.; Grisaru, H.; Gedanken, A. Coating noble metal nanocrystals (Ag, Au, Pd, and Pt) on polystyrene spheres via ultrasound irradiation. Langmuir 2005, 21, 3635–3640. [Google Scholar] [CrossRef]

- Zhong, Z.; Mastai, Y.; Koltypin, Y.; Zhao, Y.; Gedanken, A. Sonochemical coating of nanosized nickel on alumina submicrospheres and the interaction between the nickel and nickel oxide with the substrate. Chem. Mater. 1999, 11, 2350–2359. [Google Scholar] [CrossRef]

- Liu, S.; Guo, Z.; Qian, X.; Zhang, J.; Liu, J.; Lin, J. Sonochemical deposition of ultrafine metallic Pt nanoparticles on CdS for efficient photocatalytic hydrogen evolution. Sustain. Energy Fuels 2019, 3, 1048–1054. [Google Scholar] [CrossRef]

- Qiu, P.; Park, B.; Choi, J.; Thokchom, B.; Pandit, A.B. A review on heterogeneous sonocatalyst for treatment of organic pollutants in aqueous phase based on catalytic mechanism. Ultrason. Sonochem. 2018, 45, 29–49. [Google Scholar] [CrossRef]

- Yang, C.; Yeong, T.; Ching, J. An application of ultrasound technology in synthesis of titania-based photocatalyst for degrading pollutant. Chem. Eng. J. 2017, 317, 586–612. [Google Scholar]

- Yu, J.C.; Zhang, L.; Yu, J. Rapid synthesis of mesoporous TiO2 with high photocatalytic activity by ultrasound-induced agglomeration. New J. Chem. 2002, 26, 416–420. [Google Scholar] [CrossRef]

- Das, S.; Srivastava, V.C. Microfluidic-based photocatalytic microreactor for environmental application: A review of fabrication substrates and techniques, and operating parameters. Photochem. Photobiol. Sci. 2016, 15, 714–730. [Google Scholar] [CrossRef]

- Tao, S.; Yang, M.; Chen, H.; Ren, M.; Chen, G. Microfluidic synthesis of Ag @ Cu2O core-shell nanoparticles with enhanced photocatalytic activity. J. Colloid Interface Sci. 2017, 486, 16–26. [Google Scholar] [CrossRef]

- Sachdev, S.; Maugi, R.; Kirk, C.; Zhou, Z.; Christie, S.D.R.; Platt, M. Synthesis and assembly of gold and iron oxide particles within an emulsion droplet; Facile production of core @ shell particles. Colloid Interface Sci. Commun. 2017, 16, 14–18. [Google Scholar] [CrossRef]

- Jas, G.; Kirschning, A. Continuous flow techniques in organic synthesis. Chem. Eur. J. 2003, 9, 5708–5723. [Google Scholar] [CrossRef]

- Baxendale, I.R.; Schou, S.C.; Sedelmeier, J.; Ley, S.V. Multi-step synthesis by using modular flow reactors: The preparation of yne–ones and their use in heterocycle synthesis. Communication 2010, 16, 89–94. [Google Scholar] [CrossRef]

- Mcmullen, J.P.; Jensen, K.F. Rapid determination of reaction kinetics with an automated microfluidic system. Org. Process Res. Dev. 2011, 15, 398–407. [Google Scholar] [CrossRef]

- Kreutz, J.E.; Shukhaev, A.; Du, W.; Druskin, S.; Daugulis, O.; Ismagilov, R.F. Evolution of catalysts directed by genetic algorithms in a plug-based microfluidic device tested with oxidation of methane by oxygen. J. Am. Chem. Soc. 2010, 132, 128–3132. [Google Scholar] [CrossRef]

- Pastre, J.C.; Browne, D.L.; Ley, S.V. Flow chemistry syntheses of natural products. Chem. Soc. Rev. 2013, 42, 8849–8869. [Google Scholar] [CrossRef]

- Shchukin, D.G.; Sviridov, D.V. Photocatalytic processes in spatially confined micro- and nanoreactors. J. Photochem. Photobiol. C Photochem. Rev. 2006, 7, 23–39. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, Z.; Li, X. Ce Pt T; Elsevier Ireland Ltd.: Shannon, Ireland, 2015; ISBN 2227404701. [Google Scholar]

- Lakerveld, R.; Sturm, G.S.J.; Stankiewicz, A.I.; Stefanidis, G.D. Integrated design of microwave and photocatalytic reactors. Where are we now? Curr. Opin. Chem. Eng. 2014, 5, 37–41. [Google Scholar] [CrossRef]

- Saien, J.; Soleymani, A.R. Feasibility of using a slurry falling film photo-reactor for individual and hybridized AOPs. J. Ind. Eng. Chem. 2012, 18, 1683–1688. [Google Scholar] [CrossRef]

- Leblebici, M.E.; Stefanidis, G.D.; Van Gerven, T. Comparison of photocatalytic space-time yields of 12 reactor designs for wastewater treatment. Chem. Eng. Process. Process Intensif. 2015, 97, 106–111. [Google Scholar] [CrossRef]

- Heggo, D.; Ookawara, S. Multiphase photocatalytic microreactors. Chem. Eng. Sci. 2017, 169, 67–77. [Google Scholar] [CrossRef]

- Shen, C.; Wang, Y.J.; Xu, J.H.; Luo, G.S. Glass capillaries with TiO2 supported on inner wall as microchannel reactors. Chem. Eng. J. 2015, 277, 48–55. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, X.; Chen, R.; Liao, Q.; Feng, H.; Li, L. Catalytic membrane microreactor with Pd/γ-Al2 O3 coated PDMS film modified by dopamine for hydrogenation of nitrobenzene. Chem. Eng. J. 2016, 301, 35–41. [Google Scholar] [CrossRef]

- Stephan, B.; Ludovic, L.; Dominique, W. Modelling of a falling thin film deposited photocatalytic step reactor for water purification: Pesticide treatment. Chem. Eng. J. 2011, 169, 216–225. [Google Scholar] [CrossRef]

- Chen, Y.; Dionysiou, D.D. Effect of calcination temperature on the photocatalytic activity and adhesion of TiO2 films prepared by the P-25 powder-modified sol–gel method. J. Mol. Catal. A Chem. 2006, 244, 73–82. [Google Scholar] [CrossRef]

- Charles, G.; Roques-Carmes, T.; Becheikh, N.; Falk, L.; Commenge, J.; Corbel, S. Determination of kinetic constants of a photocatalytic reaction in micro-channel reactors in the presence of mass-transfer limitation and axial dispersion. J. Photochem. Photobiol. A Chem. 2011, 223, 202–211. [Google Scholar] [CrossRef]

- Corbel, S.; Becheikh, N.; Roques-Carmes, T.; Zahraa, O. Mass transfer measurements and modeling in a microchannel photocatalytic reactor. Chem. Eng. Res. Des. 2013, 92, 657–662. [Google Scholar] [CrossRef]

- Oelgemöller, M.; Shvydkiv, O. Recent advances in microflow photochemistry. Molecules 2011, 16, 7522–7550. [Google Scholar] [CrossRef]

- Ramos, B.; Ookawara, S.; Matsushita, Y.; Yoshikawa, S. Low-cost polymeric photocatalytic microreactors: Catalyst deposition and performance for phenol degradation. J. Environ. Chem. Eng. 2014, 2, 1487–1494. [Google Scholar] [CrossRef]

- Padoin, N.; Andrade, L.; Angelo, J.; Mendes, A.; Moreira, R.D.F.P.M.; Soares, C. Intensification of photocatalytic pollutant abatement in microchannel reactor using TiO2 and TiO2-graphene. AIChE J. 2016, 62, 2794–2802. [Google Scholar] [CrossRef]

- Liao, W.; Wang, N.; Wang, T.; Xu, J.; Han, X. Biomimetic microchannels of planar reactors for optimized photocatalytic efficiency of water purification. Biomicrofluidics 2016, 10, 014123. [Google Scholar] [CrossRef] [Green Version]

- Wilms, D.; Klos, J.; Frey, H. Trends in polymer science microstructured reactors for polymer synthesis: A renaissance of continuous flow processes for tailor-made macromolecules? Macromol. Chem. Phys. 2008, 209, 343–356. [Google Scholar] [CrossRef]

- Kumar, M.; Rao, N.; Khandekar, S.; Kunzru, D. Distributed hydrogen production from ethanol in a microfuel processor: Issues and challenges. Renew. Sustain. Energy Rev. 2011, 15, 524–533. [Google Scholar]

- Hornung, C.H.; Hallmark, B.; Baumann, M.; Baxendale, I.R.; Ley, S.V.; Hester, P.; Clayton, P.; MacKley, M.R. Multiple microcapillary reactor for organic synthesis. Ind. Eng. Chem. Res. 2010, 49, 4576–4582. [Google Scholar] [CrossRef]

- Davis, G. Microfluidics: Its impact on drug discovery. Innov. Pharm. Technol. 2008, 25, 24–27. [Google Scholar]

- Microfluidics, D.; Song, H.; Chen, D.L.; Ismagilov, R.F. Reactions in droplets in microfluidic channels. Angew. Chem. Int. Ed. 2006, 45, 7336–7356. [Google Scholar]

- Mcmullen, J.P.; Stone, M.T.; Buchwald, S.L.; Jensen, K.F. An integrated microreactor system for self-optimization of a heck reaction: From micro- to mesoscale flow systems. Angew. Chem. Int. Ed. 2010, 49, 7076–7080. [Google Scholar] [CrossRef]

- Naber, J.R.; Buchwald, S.L. Packed-bed reactors for continuous-flow C-N cross-coupling. Angew. Chem. Int. Ed. 2010, 49, 9469–9474. [Google Scholar] [CrossRef]

- Okawa, A.; Yoshida, R.; Isozaki, T.; Shigesato, Y.; Matsushita, Y.; Suzuki, T. Photocatalytic oxidation of benzene in a microreactor with immobilized TiO2 thin films deposited by sputtering. Catal. Commun. 2017, 100, 1–4. [Google Scholar] [CrossRef]

- Hawkins, A.R.; Schmidt, H. Handbook of Optofluidics; Taylor and Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar]

- Ohering, M. Materials Science of Thin Films, Deposition and Structure; Academic Press: San Diego, CA, USA, 2002. [Google Scholar]

- Visan, A.; Rafieian, D.; Ogieglo, W.; Lammertink, R.G.H. Modeling intrinsic kinetics in immobilized photocatalytic microreactors. Appl. Catal. B Environ. 2014, 150, 93–100. [Google Scholar] [CrossRef]

- Pierson, H.O. Handbook of Chemical Vapor Deposition: Technology, and Applications; Noyes Publications: Norwich, NY, USA, 2001. [Google Scholar]

- Grosso, D.; Marie, P. How to exploit the full potential of the dip-coating process to better control film formation. J. Mater. Chem. 2011, 21, 17033–17038. [Google Scholar] [CrossRef]

- Taylor, P.; Edler, K.J.; Roser, S.J. Growth and characterization of mesoporous silica films. Int. Rev. Phys. Chem. 2001, 20, 387–466. [Google Scholar]

- Meng, Z.; Zhang, X.; Qin, J. A high efficiency microfluidic-based photocatalytic microreactor using electrospun nanofibrous TiO2 as a photocatalyst. Nanoscale 2013, 4687–4690. [Google Scholar] [CrossRef]

- Ra, D.; Driessen, R.T.; Ogieglo, W.; Lammertink, R.G.H. Intrinsic photocatalytic assessment of reactively sputtered TiO2 films. ACS Appl. Mater. Interfaces 2015, 7, 8727–8732. [Google Scholar]

- Piveteau, L.; Gasser, B.; Schlapbach, L. Evaluating mechanical adhesion of sol-gel titanium dioxide coatings containing calcium phosphate for metal implant application. Biomaterials 2000, 21, 2193–2201. [Google Scholar] [CrossRef]

- Manivannan, A.; Spataru, N.; Arihara, K.; Fujishima, A. Electrochemical deposition of titanium oxide on boron-doped diamond electrodes. Electrochem. Solid Lett. 2005, 8, 138–140. [Google Scholar] [CrossRef]

- Chein, R.; Chen, L.; Chen, Y.; Chung, J.N. Heat transfer effects on the methanol-steam reforming with partially filled catalyst layers. Int. J. Hydrog. Energy 2009, 34, 5398–5408. [Google Scholar] [CrossRef]

- Lopez-Orozco, S.; Inayat, A.; Schwab, A.; Selvam, T.; Schwieger, W. Zeolitic materials with hierarchical porous structures. Adv. Mater. 2011, 23, 2602–2615. [Google Scholar] [CrossRef]

- Tanimu, A.; Jaenicke, S.; Alhooshani, K. Heterogeneous catalysis in continuous flow microreactors: A review of methods and applications. Chem. Eng. J. 2017, 327, 792–821. [Google Scholar] [CrossRef]

- Abramovic, B.F.; Šojic, D.V.; Krstic, J.B.; Finc, N.L.; Banic, N.D.; Boc, I.P. Efficiency of neonicotinoids photocatalytic degradation by using annular slurry reactor. Chem. Eng. J. 2016, 286, 184–190. [Google Scholar]

- Nakamura, H.; Li, X.; Wang, H.; Uehara, M.; Miyazaki, M.; Shimizu, H.; Maeda, H. A simple method of self assembled nano-particles deposition on the micro-capillary inner walls and the reactor application for photo-catalytic and enzyme reactions. Chem. Eng. J. 2004, 101, 261–268. [Google Scholar] [CrossRef]

- Rebrov, E.V.; Berenguer-Murcia, A.; Skelton, H.E.; Johnson, B.F.G.; Wheatley, A.E.H.; Schouten, J.C. Capillary microreactors wall-coated with mesoporous titania thin film catalyst supports. Lab Chip 2009, 9, 503–506. [Google Scholar] [CrossRef]

- Li, L.; Tang, D.; Song, Y.; Jiang, B. Dual-film optofluidic microreactor with enhanced light-harvesting for photocatalytic applications. Chem. Eng. J. 2018, 339, 71–77. [Google Scholar] [CrossRef]

- Suhadolnik, L.; Krivec, M.; Kristina, Ž.; Dra, G.; Ceh, M. A TiO2-nanotubes-based coil-type microreactor for highly efficient photoelectrocatalytic degradation of organic compounds. J. Ind. Eng. Chem. 2017, 47, 384–390. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Nair, V.; Kuna, E.; Łomot, D. Development of photocatalyst coated fluoropolymer based microreactor using ultrasound for water remediation. Ultrason. Sonochem. 2018, 41, 297–302. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Kuna, E.; Lomot, D. Method and the Device for Deposition of Nanoparticles on the Inner Walls of a Polymer Capillary, Using Ultrasonic Waves. Patent PL 231485, 7 November 2018. [Google Scholar]

- Dragone, V.; Sans, V.; Rosnes, M.H.; Kitson, P.J.; Cronin, L. 3D-printed devices for continuous-flow organic chemistry. Beilstein J. Org. Chem. 2013, 9, 951–959. [Google Scholar] [CrossRef]

- Corrêa, A.G.; Zuin, V.G.; Ferreira, V.F.; Vazquez, P.G. Green chemistry in Brazil. Pure Appl. Chem. 2013, 85, 1643–1653. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.; Kuhn, S. Strategies for solids handling in microreactors. Chim. Oggi 2014, 32, 62–67. [Google Scholar]

- Cassano, A.E.; Alfano, O.M. Reaction engineering of suspended solid heterogeneous photocatalytic reactors. Catal. Today 2000, 58, 167–197. [Google Scholar] [CrossRef]

- Kar, A.; Smith, Y.R. Improved photocatalytic degradation of textile dye using titanium dioxide nanotubes formed over titanium wires. Environ. Sci. Technol. 2009, 43, 3260–3265. [Google Scholar] [CrossRef]

- Colina Marquez, J.; Machuca-Martinez, F.; Puma, G.L. Radiation absorption and optimization of solar photocatalytic reactors for environmental applications. Environ. Sci. Technol. 2010, 44, 5112–5120. [Google Scholar] [CrossRef]

- Seeberger, P.H. Highly efficient continuous flow reactions using singlet oxygen as a “green” reagent. Org. Lett. 2011, 13, 5008–5011. [Google Scholar]

- Wang, X.; Cuny, G.D.; Noel, T. A mild, one-pot Stadler–Ziegler synthesis of arylsulfides facilitated by photoredox catalysis in batch and continuous-flow. Angew. Chem. Int. Ed. 2013, 52, 7860–7864. [Google Scholar] [CrossRef]

- Carlos, J. Sonication-induced pathways in the synthesis of light-active catalysts for photocatalytic oxidation of organic contaminants. ChemSusChem 2014, 7, 1512–1527. [Google Scholar]

- Tang, Z.R.; Yin, X.; Zhang, Y.; Xu, Y.J. One-pot, high-yield synthesis of one-dimensional ZnO nanorods with well-defined morphology as a highly selective photocatalyst. RSC Adv. 2013, 3, 5956–5965. [Google Scholar] [CrossRef]

- Chatel, G.; Valange, S.; Behling, R.; Carlos, J. A combined approach using sonochemistry and photocatalysis: How to apply sonophotocatalysis for biomass conversion? ChemCatChem 2017, 9, 2615–2621. [Google Scholar] [CrossRef]

- Xu, H.; Zeiger, B.W.; Suslick, K.S. Sonochemical synthesis of nanomaterials. Chem. Soc. Rev. 2013, 2555–2567. [Google Scholar] [CrossRef]

- Bora, M.; Shusteff, M. Efficient coupling of acoustic modes in microfluidic channel devices. Lab Chip 2015, 15, 3192–3202. [Google Scholar] [CrossRef]

- John, J.J.; Kuhn, S.; Braeken, L.; Van Gerven, T. Ultrasound assisted liquid-liquid extraction in microchannels–A direct contact method. Chem. Eng. Process. Process Intensif. 2016, 102, 37–46. [Google Scholar] [CrossRef]

- Thangavadivel, K.; Konagaya, M.; Okitsu, K.; Ashokkumar, M. Ultrasound-assisted degradation of methyl orange in a micro reactor. J. Environ. Chem. Eng. 2014, 2, 1841–1845. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Viswanathan, R. Review on the recent improvements in sonochemical and combined sonochemical oxidation processes—A powerful tool for destruction of environmental contaminants. Renew. Sustain. Energy Rev. 2016, 55, 426–454. [Google Scholar] [CrossRef]

- Rossi, D.; Jamshidi, R.; Sa, N.; Kuhn, S.; Gavriilidis, A.; Mazzei, L. Continuous-flow sonocrystallization in droplet-based micro fluidics. Cryst. Growth Des. 2015, 15, 5519–5529. [Google Scholar] [CrossRef]

- Jiang, M.; Papageorgiou, C.D.; Waetzig, J.; Hardy, A.; Langston, M.; Braatz, R.D. Indirect ultrasonication in continuous slug-flow crystallization. Cryst. Growth Des. 2015, 15, 2486–2492. [Google Scholar] [CrossRef]

- Rivas, D.F.; Castro-Hernández, E.; Villanueva Perales, A.L.; van der Meer, W. Evaluation method for process intensification alternatives. Chem. Eng. Process. Process Intensif. 2018, 123, 221–232. [Google Scholar] [CrossRef]

- Wang, M.; Rajendran, V. Kinetics for dichlorocyclopropanation of 1,7-octadiene under the influence of ultrasound assisted phase-transfer catalysis conditions. J. Mol. Catal. A Chem. 2007, 273, 5–13. [Google Scholar] [CrossRef]

- Hyun, S.; Hyang, J.; Cho, D. An analysis method for degradation kinetics of lowly concentrated PAH solutions under UV light and ultrasonication. J. Ind. Eng. Chem. 2009, 15, 157–162. [Google Scholar]

- Thompson, L.H.; Doraiswamy, L.K. Sonochemistry: Science and engineering. Ind. Eng. Chem. Res. 1999, 38, 1215–1249. [Google Scholar] [CrossRef]

- Laudadio, G.; Gemoets, H.P.L.; Hessel, V.; Noe, T. Flow synthesis of diaryliodonium triflates. J. Org. Chem. 2017, 82, 11735–11741. [Google Scholar] [CrossRef]

- Joseph, J.; Kuhn, S.; Braeken, L.; Van Gerven, T. Ultrasound assisted liquid-liquid extraction with a novel interval-contact reactor. Chem. Eng. Process. Process Intensif. 2017, 113, 35–41. [Google Scholar]

- Rizkin, B.A.; Popovic, F.G.; Hartman, R.L.; Rizkin, B.A.; Popovic, F.G.; Hartman, R.L. Spectroscopic microreactors for heterogeneous catalysis. J. Vac. Sci. Tehnol. A Vac. Surf. Films 2019, 37, 050801. [Google Scholar] [CrossRef]

| Reference | Type of Microreactor | Method of TiO2 Immobilization | Outcomes from TiO2 Characterization |

|---|---|---|---|

| [17] | metal-titanium foil | Anodization and hydrothermal treatment | Good mechanical properties of titania nanotube film, nanotubes of TiO2 (TEM, SEM) |

| [57] | glass capillaries | Sol-gel | Homogenous dispersion, narrow particle size distribution (SEM, TEM) |

| [18] | stainless steel microreactor | Sol-gel | Uniform distribution of catalyst on surface, crystalline size is 32 nm, the reflectance spectrum of pure TiO2 is 393 nm (HRTEM, XRD, DRS) |

| [74] | self-adhesive fluorine resin (EFEP) channel and switched between two glass plates | Sputtering | Growth of anatase peaks (XRD) |

| [90] | Silica capillary | Wash coating and calcination | The thickness of the deposited layer 88 nm (Field Emission Gun-Scanning Electron Microscopy(FEG-SEM)) |

| [91] | Dual-film optofluidic microreactor | Hydrothermally prepared nanorod growth on fluorine-doped tin oxide (FTO) glass | 2.4 μm thick film of TiO2 nanorods inside glass tube (SEM) |

| [92] | coil-type photoelectrocatalytic microreactor | Anodization | 25 nm thickness and 12 to 15 µm length of titania nanotubes (FESEM) |

| [93,94] | fluorinated ethylene propylene (FEP) microtube | Ultrasound-based deposition | Structural transformation of polymer tube with ultrasound, thickness of catalyst layer was 3– 6µm (confocal microscopy, SEM) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashmi Pradhan, S.; Colmenares-Quintero, R.F.; Colmenares Quintero, J.C. Designing Microflowreactors for Photocatalysis Using Sonochemistry: A Systematic Review Article. Molecules 2019, 24, 3315. https://doi.org/10.3390/molecules24183315

Rashmi Pradhan S, Colmenares-Quintero RF, Colmenares Quintero JC. Designing Microflowreactors for Photocatalysis Using Sonochemistry: A Systematic Review Article. Molecules. 2019; 24(18):3315. https://doi.org/10.3390/molecules24183315

Chicago/Turabian StyleRashmi Pradhan, Swaraj, Ramón Fernando Colmenares-Quintero, and Juan Carlos Colmenares Quintero. 2019. "Designing Microflowreactors for Photocatalysis Using Sonochemistry: A Systematic Review Article" Molecules 24, no. 18: 3315. https://doi.org/10.3390/molecules24183315

APA StyleRashmi Pradhan, S., Colmenares-Quintero, R. F., & Colmenares Quintero, J. C. (2019). Designing Microflowreactors for Photocatalysis Using Sonochemistry: A Systematic Review Article. Molecules, 24(18), 3315. https://doi.org/10.3390/molecules24183315