2.1. Properties of the Catalysts

Metal loadings, BET surface areas (S

BET), pore volumes and average pore sizes, reducibility, and basicity of the catalysts are summarized in

Table 2. Considering the CeO

2-Al

2O

3 support, the desired weight ratio of 1:4 of ceria to alumina was verified by ICP-OES and XRF. ICP-OES showed 20.6 wt.% of ceria and 79.4 wt.% of alumina, whereas XRF demonstrated 21.7 wt.% and 78.3 wt.%, respectively [

27].

In

Figure 1 and

Figure 2, representative HR-TEM images of the prepared monometallic Au/Al and Au/Ce-Al catalysts with particle size distribution (PSD) and examples of energy-dispersive X-ray (EDX) spectra are presented. The HR-TEM results of bimetallic Pt-Au/Al and Pt-Au/Ce-Al can be found in Reference [

28] and the

Supplementary Materials. The PSD in each catalyst was calculated based on Feret’s diameter because of the irregular shape of the particles. Structures resembling needles in the HR-TEM images are side views of alumina 2D plates.

The Au/Al catalyst demonstrated homogeneously dispersed Au particles mainly in sizes smaller than 10 nm (

Figure 1a,b). The majority of measured particles were below 5 nm. An EDX spectrum from the surface of Au/Al catalyst evidenced 1.8 wt.% of Au. The Au particles in the Au/Ce-Al catalyst were much larger when compared to the Au/Al catalyst (

Figure 1c,d), as already discussed in Reference [

27]. These findings were supported by the XRD and H

2-TPR results. In comparison with the Au/Al catalyst, the PSD data of the Au/Ce-Al catalyst in

Figure 1c show a low number of distinguishable particles (

n = 22) that could be accurately measured and, therefore, do not represent a satisfactory population for PSD. The Au/Ce-Al catalyst contained unevenly dispersed particles in smaller sizes similarly to the Au/Al catalyst but, also, large agglomerates of fused particles in sizes of hundreds of nanometers likely due to sintering (

Figure 1d). Islands of smaller particles that were close to fusing together were observed as well, which supports the occurrence of sintering. These particles were difficult to distinguish from each other and, therefore, could not be included in the PSD data. The EDX spectrum from the agglomerate in

Figure 1c demonstrates intense Au peaks. Due to the very poor Au distribution, a representative bulk loading using EDX was not possible.

Figure 2a–d presents typical HR-TEM images of the Pt/Al and Pt/Ce-Al catalysts. Pt particles were not distinguished clearly from the surface due to contrast similarity, but the EDX spectra (

Figure 2a,c) show evidence of Pt. The Pt particle size is below 10 nm based on

Figure 2a–d and other interpreted images.

The Pt-Au/Al catalyst contained quite evenly dispersed particles, mostly in sizes between 10 to 30 nm (88%,

n = 253), but some larger agglomerates were also observed. The Pt-Au/Ce-Al catalyst contained homogenously dispersed particles mostly in sizes between 10 to 30 nm (77%,

n = 112) but, also, in sizes of 30–40 nm (11%). In addition, some larger isolated islands of agglomerated particles were observed. See Reference [

28] for detailed information.

The total acidity of the catalysts was analyzed by NH

3-TPD experiments. The temperature range of up to 600 °C is especially interesting, since it corresponds to the maximum temperature used in the light-off experiments and in the calcination step of catalyst preparation. The obtained NH

3-TPD profiles are shown in

Figure 3. In this study, the strengths of the acid sites are determined as weak and medium/strong in the sites retaining NH

3 at lower than 300 °C and at higher than 300 °C, respectively. The shapes of the profiles and positions of the peaks indicate the presence of acid sites of different strengths, but one main band for all the catalysts centered at 210–250 °C corresponding to the weak acid sites can be seen in

Figure 3. The Pt/Al, Au/Ce-Al, and Pt/Ce-Al catalysts show the highest amounts of weak acid sites, while the Pt-Au/Al, Au/Al, and Pt-Au/Ce-Al catalysts possess the lowest amounts. The amounts of strong acid sites are rather comparable between the catalysts, except in the case of Pt-Au/Ce-Al (see

Figure 3b), which can, overall, be considered as the least acidic catalyst.

The basicity of the catalysts was measured to find out if it could explain the results related to CO

2 formation during DCM oxidation. The total basicity of the catalysts was analyzed by CO

2-TPD experiments; all results and, also, the new ones for monometallic catalysts, are summarized in

Table 2. The CO

2 uptake of the Al

2O

3-supported catalysts was between 100 to 135 μmol g

−1 and the CeO

2-Al

2O

3-supported catalysts between 85 to 160 μmol g

−1. Au containing catalysts had higher total basicity than the corresponding Pt catalysts. The basicity of the catalysts was at a low level based on the CO

2-TPD [

29], which should be advantageous for the desorption of formed CO

2 from the catalyst surface during DCM oxidation. The basic sites can be assigned low, medium, and high according to different CO

2 desorption ranges at 80–140 °C, 160–240 °C, and >300 °C, respectively [

30]. Based on our results, the Pt and Pt-Au catalysts lacked medium-strength basic sites, whereas the Au/Al and Au/Ce-Al catalysts had low, medium, and high-strength basic sites.

The reducibility of the catalysts was analyzed by H

2-TPR, and the total hydrogen uptakes between 35 °C and 400 °C from References [

27,

28] are summarized in

Table 2. Based on the H

2 consumption, the Pt-Au/Al catalyst showed the lowest and Pt/Ce-Al the highest reducibility. Au/Al and Au/Ce-Al did not show significant reduction in the used temperature range, and the H

2 consumption remained at a level of less than 50 μmol g

−1. The Pt-Au/Al and Pt/Al catalysts demonstrated both H

2 uptakes at a low temperature window of 50–70 °C and within a broad temperature range of 150–300 °C, both being caused likely by the reduction of adsorbed oxygen species and/or platinum oxychloride complexes. The TPR profiles of Pt-Au/Ce-Al and Pt/Ce-Al catalysts showed the H

2 uptake maxima at 255 °C and at 205 °C, which can be assigned to the reduction of Pt species and surface ceria due to a hydrogen spillover enhanced by Pt particles [

31]. The addition of Au in Pt catalysts decreased the reducibility, while the addition of ceria in the support improved the reducibility. Au might block the H

2 spillover on Pt due to the preparation method used.

XPS measurements were done to identify the oxidation state of Au in the Au/Al and Au/Ce-Al catalysts. A typical accuracy of the XPS measurements was 0.1 to 0.2 eV. The XPS results for the bimetallic catalysts (Pt-Au/Al and Pt-Au/Ce-Al) were presented in Reference [

28]. A theoretical intensity ratio of I(Au 4f

7/2):I(Au 4f

5/2) = 4:3 for Au

0 was used as one of the constraints in the fitting of the data [

32].

Figure 4 shows the binding energy of the Au 4f spectra for the Au/Al and Au/Ce-Al catalysts. Usually, the oxidation states of Au are determined from the Au 4f

7/2 at roughly 83.9–84.0 eV [

33,

34,

35]. The characteristic peaks for different Au oxidation states are as follows: Au

0 at 84.0 eV, Au

1+ at 84.6 eV, and Au

3+ at 85.9 eV [

36,

37]. Metallic Au

0 is evidenced here based on the main peaks of Au 4f

7/2 at 83.0 and 83.4 eV and Au 4f

5/2 at 86.6 and 87.2. The binding energy values were lower than those of the bulk metallic Au, i.e., Au 4f

7/2 = 84.0 eV and Au 4f

5/2 = 87.7 eV. Similar results were reported earlier for Au

0 on the surfaces of different catalysts. [

37,

38,

39,

40] These differences can be caused by the size-dependent peak shifts, the presence of hydroxides or oxides [

37], and the metal-support and/or metal-metal interactions [

37,

38,

39]. In addition, the Au/Al catalyst evidenced the presence of Au

1+ based on the peak at 83.6 eV, which is supported by the known peak difference of 0.6 eV between the Au

0 and Au

+1 oxidation states [

36,

37]. In our case, the differences in peak positions of Au between mono- and bimetallic catalyst counterparts were relatively small. The peak shapes were similar, and the binding energy did not differ much. Au was in the metallic state in all Au-containing catalysts, except in the Au/Al catalyst that contained also Au

1+.

Table 3 shows the surface composition and surface metal loading of the catalysts. Pt and Au contents close to the surface were higher compared to the bulk metal loadings analyzed by ICP-OES, which could be explained by the very low Au loading and the accuracy of the measurements. In the case of the Au/Al catalyst, the surface Au loading was 1.6 wt.% based on XPS, which is in accordance with the EDX result evidenced in HR-TEM (1.8 wt.%). Considering the CeO

2-Al

2O

3 support, the bulk Al/Ce weight ratio was about 2.5 in comparison to the surface Al/Ce weight ratio of 7.4 and 10.9 for the Au/Ce-Al and Pt-Au/Ce-Al catalysts, respectively. Since the concentration of ceria on the surface is higher than in the bulk Au, it can interact with ceria more easily [

41].

2.2. Catalytic Performance in DCM Oxidation

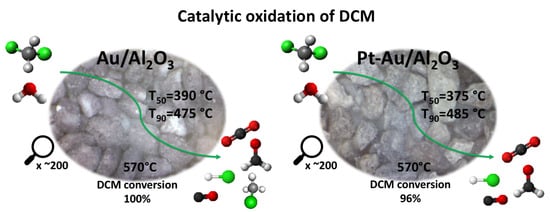

The conversion curves of all the studied catalysts in DCM oxidation are presented in

Figure 5a,b. The T

50 (temperature at which 50% DCM conversion is observed) and T

90 (temperature at which 90% DCM conversion is observed) values, together with the HCl and CO

2 yields at T

90 and at the maximum, are listed in

Table 4. The results show that the bimetallic Pt-Au/Al and monometallic Au/Al catalysts were the most active catalysts among the tested catalysts (

Figure 5a) based on their T

50 and T

90. The addition of Au resulted in a noticeable improvement in the performance by lowering the T

50 by 65 °C and 85 °C in comparison to the γ-Al

2O

3 support and Pt/Al catalyst, respectively. When considering the catalysts supported on CeO

2-Al

2O

3 (

Figure 5b), similar results can be seen, i.e., gold in the catalyst improving the performance in DCM oxidation. The T

50 was lowered by 35 °C and 40 °C in comparison to the CeO

2-Al

2O

3 support and Pt/Ce-Al catalyst, respectively. It is noticeable that the active metal loadings in the Au/Al and Au/Ce-Al catalysts were 0.7 wt.% and 0.5 wt.%, respectively, which are much lower when compared to the Pt/Al catalyst with 1.1 wt.% and Pt/Ce-Al with 1.2 wt.% (see

Table 2). In addition, the BET surface areas were quite comparable, being from 95 to 105 m

2 g

−1 for the Al

2O

3-supported catalysts and from 75 to 85 m

2 g

−1 for the CeO

2-Al

2O

3-supported catalysts. Therefore, the better performance of Au-containing catalysts cannot be explained by the differences in these physical properties.

In this study, the presence of Au, alone or together with Pt, enhanced the performance of the catalyst compared to the catalyst containing only Pt. The addition of Pt improved the selectivity towards the total oxidation products but not the conversion, which is in agreement with the previous literature.

According to Maupin et al. [

19], Pt/Al

2O

3 catalysts oxidize DCM completely at 380 °C, and the rate-limiting step takes place on alumina, since neither the loading of Pt nor the dispersion (particle size) have an effect on the conversion rates and selectivity. Similar observations were seen in our previous study [

12]. The addition of Pt and/or ceria to the catalyst enhanced the selectivity towards CO

2, but DCM conversion was not influenced significantly [

12].

The activity of Au in oxidation reactions is known to be dependent on the particle size and shape [

42,

43]. The activation of oxygen by Pt occurs faster on larger particles [

44]. The Au/Al catalyst contained well-dispersed nanoparticles in sizes below 10 nm, whereas, in the Pt-Au/Al catalyst, the particles were mainly in sizes between 10 to 30 nm. In addition, the Pt-Au/Ce-Al catalyst had mostly particles in sizes between 10 to 40 nm, although a few examples of larger agglomerates were found. The Pt/Al and Pt/Ce-Al catalysts seemed to contain also relatively small particles, but that did not result in better performance. The good performance of Au/Al and Pt-Au/Al catalysts could be at least partly related to the particle size distribution.

Based on the literature, both high acidity [

11,

12,

25,

45,

46,

47,

48,

49] and reducibility [

12,

25,

49] contribute to enhanced activity in DCM oxidation. The reducibility of the catalysts had a substantial effect on the performance also in this study but in the opposite way. The catalysts with the lowest H

2 consumption, i.e., Pt-Au/Al and Au/Al (see

Table 2), demonstrated the best performance, whereas a high reducibility correlated with a poorer performance. Overall, the catalysts that demonstrated reducibility below 300 °C due to the presence of ceria (Pt/Ce-Al and Pt-Au/Ce-Al), except the Au/Ce-Al catalyst, likely because of the large Au particles that are unable to dissociate hydrogen, showed poorer performance compared to the less reducible catalysts.

Three least-acidic catalysts were among the three most active catalysts in DCM oxidation. When a weak acidity was considered, the acidity order of the catalysts from the lowest to highest was Pt-Au/Ce-Al that had the lowest acidity overall < Au/Al followed by the Pt-Au/Al catalyst < Au/Ce-Al < Pt/Ce-Al < Pt/Al. The Au/Al catalyst also had the highest amount of strong acid sites, which correlates with the performance in respect to the previous literature. It is possible that, in our case, the deposition of Au and/or Pt on ceria-alumina supports compensates the acidity loss to some extent by the introduction of Cl− species from the chloride precursors used in the catalyst preparation. In addition, these acid sites could have different characteristics (Brønsted/Lewis acid sites) in different proportions as a result of the deposition, thus influencing the catalyst performance. The total basicity of the catalysts varied between 85 to 160 μmol g−1, but a direct correlation with the performance could not be seen. However, it is worth mentioning that the addition of Au in the Pt catalysts increased the basicity, and the DCM conversion was always higher in comparison to the monometallic Pt catalysts.

By considering the catalytic performance of the studied catalysts on previous findings, Chen et al. reported T

50 and T

90 values of approximately 220 °C and 250 °C, respectively, for a 5%Au/Co

3O

4 catalyst in DCM oxidation (DCM 500 ppm, 0.6 wt.% H

2O, GHSV 15,000 h

−1) [

24]. In a study by Matêjová et al., a 0.3-Au/CeZr catalyst showed T

50 and T

90 values of 417 °C and 487 °C, respectively, in DCM oxidation (DCM 1000 ppm, 1.5 vol.% H

2O, space velocity (SV) 71 m

3 kg

−1 h

−1), with a maximum HCl yield of 77% [

25]. Redina et al. showed that an Au-Rh/TiO

2 catalyst reached a DCM conversion of 99% and HCl selectivity of 90% at 400 °C in DCM oxidation (DCM 510 ppm, H

2O 0.25 vol.%, 40,000 h

−1) [

26].

2.3. Selectivity in DCM Oxidation

In addition to good catalytic performance, high selectivity is also essential in CVOC oxidation in order to avoid the formation of highly toxic by-products. An analysis of the reaction products confirmed that the main reaction products detected during DCM oxidation in this study were CO

2, CO, and HCl. The formation of methyl chloride (CH

3Cl) and formaldehyde (CH

2O) were detected during the tests over certain catalysts at temperatures above 300 °C. The HCl yields of the studied catalysts are shown in

Figure 6a,b and

Table 4. The by-product formation for each catalyst is presented in

Figure 7a–f.

The by-product formation for each catalyst is presented in

Figure 7a–f. Amongst all the tested catalysts, Pt-Au/Al and Au/Al catalysts were the most active and HCl selective, both reaching close to 100% HCl yields at around 550 °C. At the same time, the other catalysts were able to reach HCl yields up to 70–80% during the tests. Even though the monometallic Au/Al and Au/Ce-Al catalysts were noticeably more active than the Pt catalysts, the formation of CO and other intermediates were observed to be substantial (

Figure 7c,d). The Pt-Au/Al catalyst yielded mostly CO

2 and HCl, but a slight formation of CO and formaldehyde was observed. No Cl-containing intermediates were observed during the experiment with the Pt-Au/Ce-Al catalyst. The catalysts in this study were synthesized from chloride-containing precursors and, therefore, may contain residual chlorine as prepared. Calcination in dry air is ineffective to eliminate residual chlorine as HCl. [

50,

51] Chlorine stays on alumina-based catalysts and, further, has an effect on hydrocarbon oxidation as an inhibitor. Residual chlorine is removed during oxidation when water is present, forming HCl, restores the catalytic activity, and may even increase the activity, because the initial Cl in contact with the active phase is eliminated completely [

50].

The formation of carbon monoxide (CO) was observed in every case between concentrations of a few ppm up to over 200 ppm, depending on the catalyst. The Pt/Al and Pt/Ce-Al catalysts showed always the lowest CO formation, the maximum being 27 ppm at 555 °C and 30 ppm 530 °C, respectively. Over the Pt-Au/Al and Pt-Au/Ce-Al catalysts, the highest measured CO concentrations were 78 ppm at 560 °C and 62 ppm at 570 °C, respectively. The highest concentrations of CO amongst the studied catalysts were measured with the Au/Al and Au/Ce-Al catalysts, being over 200 ppm at temperatures higher than 520 °C. The CO formation started always at the same temperature levels as the HCl formation.

The Pt catalysts were the most selective towards the total oxidation product, i.e., carbon dioxide (CO

2) (

Figure 7a,b). The reason might be simply the well-known efficiency of Pt in complete oxidation and relatively low tendency to catalyze partial oxidation [

52,

53]. The bimetallic Pt-Au/Al and Pt-Au/Ce-Al catalysts were able to oxidize carbon intermediates better in comparison to monometallic Au catalysts (

Figure 7e,f), which is probably due to the presence of Pt.

The selectivities towards HCl were rather high with all the catalysts, as evidenced by the methyl chloride concentrations, i.e., intermediate of the DCM oxidation reaction, that were relatively low, varying from zero up to 31 ppm. The highest methyl chloride concentrations were detected with the Pt-Au/Al catalyst, the maximum being 31 ppm at 405 °C followed by the Au/Al catalyst producing 27 ppm at the highest at 390 °C. The methyl chloride formation was not detected with the Pt-Au/Ce-Al catalyst at all, and with the other Ce-Al-supported catalysts and the Pt/Al catalyst, the concentrations were below 8 ppm. Methyl chloride formation was reported over alumina-supported catalysts in oxidative conditions earlier in several studies [

10,

11,

17,

18,

19,

45,

46]. The presence of ceria seems to decrease the formation of methyl chloride.

Formaldehyde (CH2O) formation was observed with all the catalysts, and the maximum concentrations were from 6 ppm up to 108 ppm. The highest formaldehyde concentrations were observed over the Au/Al catalyst (>100 ppm between 440–505 °C) and the Pt-Au/Al catalyst (74 ppm at 430 °C). The lowest concentrations were seen over the Pt/Ce-Al (6 ppm at 495 °C), Pt-Au/Ce-Al (21 ppm at 445 °C), Au/Ce-Al (35 ppm at 470 °C), and Pt/Al (36 pp at 510 °C) catalysts. In this case, also, the presence of ceria decreased the formation of the intermediate.

Alumina support alone converted DCM selectively into HCl, reaching yields higher than 90% at temperatures above 555 °C (

Table 4). However, methyl chloride (CH

3Cl) formation up to 60 ppm was observed during oxidation, and carbon was detected as partial oxidation products (CO and formaldehyde) up to 530 °C, after which, CO

2 formation started. The ceria-alumina support alone was also selective to HCl; the detected concentrations of other Cl-containing products were less than 7 ppm during the light-off test. In addition, the final carbon products were mainly CO

2 and CO. In this case, also, the beneficial effect of ceria was visible. The formaldehyde formation was negligible. However, both supports demonstrated low DCM conversion. The alumina support did not reach T

90, whereas with the ceria-alumina support T

90 was 585 °C, as shown in

Table 4.

The formation of methyl chloride in oxidative conditions over Al

2O

3-supported catalysts has been reported previously by several authors [

11,

12,

18,

19,

45]. It has also been suggested that methyl chloride is formed in the presence of Lewis acid sites that are typical for Al

2O

3. Formaldehyde is reported to be formed on the Brønsted acid sites, which amounts could be increased in the presence of water [

11,

48]. The largest differences were seen in the case of CO formation, since both the Au/Al and Au/Ce-Al catalysts produced relatively high amounts of CO, i.e., over 200 ppm, in addition to the alumina support that produced CO over 340 ppm. The Pt-containing catalysts demonstrated the most beneficial product distributions in terms of the intermediate yields. The monometallic Au catalysts showed the lowest CO

2 yields.

Oxygen activation is known to be easier on ceria and noble metals compared to alumina [

54], which enables a faster delivery of reactive oxygen and, thus, accelerates total oxidation. In addition, surface diffusion and the strength of chemisorption on the catalyst influence the ability of the surface intermediates to move closer to each other for further reactions [

12]. The oxygen activation (

18O

2-TPIE), which was discussed in detail for monometallic catalysts in Reference [

27] and for bimetallic catalysts in Reference [

28], correlates well with the DCM oxidation in the case of the Au/Al and Pt/Al catalysts. Oxygen exchange starts at around 310 °C with the Au/Al catalyst, i.e., at the same temperature as the formation of HCl and partial oxidation products (7 ppm of HCl and 10 ppm of CH

2O at 300 °C). A low formation of

18O

16O (0–0.1 mbar) was seen already from the beginning of the experiment between 200–310 °C, after which, it rapidly increased. The Pt/Al catalyst activated oxygen based on the formation of

18O

16O at around 370 °C (first observations of

18O

16O, i.e., 0–0.1 mbar, already at around 340 °C) and during DCM oxidation; 6 ppm of HCl and 5 ppm of CH

2O were observed at 340 °C. Although the oxygen activation with the Pt-Au/Al catalyst started at a higher temperature of roughly 380 °C, oxidation products during DCM oxidation were observed already at around 290 °C (4 ppm of HCl and 11 ppm of CH

2O), i.e., at the same temperature where the low formation of

16O

16O (0–0.1 mbar) was seen in the

18O

2-TPIE experiment. The Au/Ce-Al catalyst started oxygen activation progressively at 380 °C, but a low formation of

18O

16O (0–0.1 mbar) was observed already between 250 to 380 °C. During DCM oxidation, the formation of HCl and oxidation products were seen at 305 °C (5 ppm of HCl and 6 ppm of CH

2O). In the case of the Pt/Ce-Al catalyst, the oxygen activation began gradually at 340 °C, and a low formation of

18O

16O was observed at above 250 °C, approximately. During DCM oxidation, the formation of HCl and CO

2 was seen at the same temperature (345 °C). The oxygen activation seems to have a connection to the initiation of the DCM oxidation reaction with alumina-supported catalysts. With the Pt-Au/Ce-Al catalyst, the oxygen activation started at around 390 °C, but during DCM oxidation, the formation of HCl, CH

2O, and CO

2 was seen already at 315 °C, which cannot be explained by the

18O

2-TPIE experiment. This could be related to the reduction of Pt-Au/Ce-Al, which demonstrated an H

2 uptake between 150–300 °C. The behavior of the ceria-alumina catalyst could be connected to the reducibility of ceria, i.e., ability to gain electrons that provide the available lattice oxygen already at lower temperatures before the oxygen activation starts to increase progressively. Au was in the metallic state in all the Au containing catalysts, except in the Au/Al catalyst, and no significant differences were evidenced based on the XPS results. Thus, the oxidation state of Au does not seem to explain the differences in the catalytic performance of Au/Al and Pt-Au/Al catalysts in comparison to the Au/Ce-Al and Pt-Au/Ce-Al catalysts.

Carbon balances for the best performing catalysts during the light-off experiments are shown in

Figure 8a,b. In the case of the Au/Al catalyst, the CO

2 formation started at 450 °C, which did not directly have an effect on the CO formation, but formaldehyde formation began simultaneously to decline. The carbon balance nearly enclosed at the end of the experiment. The Pt-Au/Al catalyst showed clearly a better performance towards total oxidation, as seen in

Figure 8b, compared to the Au/Al catalyst in

Figure 8a. CO

2 formation started at around 340 °C, increasing towards the higher temperature area at the end of the experiment. In addition, CO and formaldehyde formation was seen during the whole temperature range of the reaction, but both yields were below 16%. Carbon balance enclosed at the end of the experiment.

2.4. Stability of Pt-Au/Al Catalyst

The durability of a catalyst is of great importance, especially in oxidation of chlorinated compounds. The most active and selective catalyst in this study, i.e., Pt-Au/Al, was chosen for a 100-h stability test. The experimental conditions were selected based on the T90 temperature, but in isothermal conditions, 90% DCM conversion was reached at a lower temperature. The conditions were as follows: DCM 500 ppm and a constant temperature of 395 °C in moist conditions (1.5 vol.% water). During every refill of the DCM and water syringes, the temperature increased roughly by 10 °C, because no gas was fed into the reactor (by-pass) but stabilized down to 395 °C in a few minutes after the gas stream was fed back into the reactor.

Based on the results shown in

Figure 9, the performance of Pt-Au/Al was stable throughout the 100-h test. The DCM conversion remained between roughly 85% and 93%. Only a slight decline in the DCM conversion was observed after 50 h. At the same time, the HCl yield seemed to increase by a few percent units on average. The HCl yield fluctuated from 68% to 91% and the CO

2 yield from 13% to 33%. Considering by-products, the CO and formaldehyde yields were from 14% to 30% and 12% to 20%, respectively. Methyl chloride (CH

3Cl) formation seemed to decline by a few percent.

The light-off experiments performed before and after the stability test (

Figure 10a,b) indicated a slight sintering of active sites and/or support material based on the shape of the curves in

Figure 10a [

55]. The T

50 and T

90 values did not change substantially as the values increased by 5 °C and 20 °C after the stability test, respectively. The high-resolution transmission electron microscope (HR-TEM) and high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM) analyses done after the 100-h stability test provided evidence for the sintering of bimetallic Pt-Au particles. Based on

Figure 9, the CO

2 and CO formation showed a minor increase during the 100-h stability test, but the light-off experiment performed after the stability test (

Figure 10b) showed a lower CO

2 formation. This might be due to the differences between experiments conducted at constant and increasing temperatures.

Carbon balances for the Pt-Au/Al catalyst during the light-off tests before and after the 100-h stability test are shown in

Figure 11a,b. Signs of deactivation can be seen based on the yields of CO

2 and CO. The CO

2 yield is slightly lower and, in turn, the CO yield higher in

Figure 11b. In this regard, the stability test might cause changes in the catalyst structure, affecting the oxidation ability of the Pt-Au/Al catalyst. Yet, the methyl chloride (CH

3Cl) formation was a bit lower, and this was also seen during the stability test (

Figure 9), as mentioned earlier. The carbon balance enclosed in both light-off experiments.

Chen et al. [

24] studied the stability of a catalyst loaded with 5% of Au on Co

3O

4 in DCM oxidation (DCM 100 ppm, H

2O 0.6 wt.%, balance air, GHSV 90,000 h

−1, 350 °C). During 130 h on stream, the Au/Co

3O

4 catalyst did not show serious signs of deactivation at a DCM conversion level of around 90% to 95%, although a small decline could be observed similarly to our experiment. It is good to note that, in their study, the DCM concentration was five times lower and the Au loading five times higher compared to our experiments. Aida et al. [

22] investigated the stability of Au/Al

2O

3 (5 wt.% of Au) in methyl chloride oxidation (catalyst 1 g, CH

3Cl 1000 ppm, H

2O 2 vol.%, balance air, weight/flow (W/F) 13.4 kg s mol

−1, 300 °C). At a constant temperature of 300 °C, the catalyst lost its activity completely from around 100% conversion to 5% in 5 h, but it could be regenerated when raising the temperature above 427 °C. Based on thermogravimetric analysis done after the reaction, HCl did not desorb from the surface at temperatures below 327 °C, even after the addition of water, and the active sites suffered from deactivation. Once the temperature was increased above 400 °C, the catalyst activity recovered. The reaction of Cl and water, followed by the formation and further desorption of HCl, closed the catalytic cycle [

22]. It is known that, in the catalytic oxidation of CVOC, it is essential to prevent the strong interaction of HCl with the catalyst surface, leading to deactivation [

53], but at higher temperatures, another problem arises, since HCl attacks the alumina support [

24]. Bond and Rosa [

10] suggested that the reaction mechanism involves the disruption of the chlorinated reactant at a Lewis acid site, followed by the formation of metal-chloride bonds. After that, the chemisorption of water at a similar Lewis acid site and its reaction with the metal-chloride bond to form HCl takes place. Water and the reactant compete for the same sites, the water molecule more effectively. If the rate of formation of the Cl-M bonds is too high and the water vapor pressure too low, species such as Cl

2M and Cl

3M are formed, and these may react further to give gaseous metal chloride [

10].

Legawiec-Jarzyna et al. [

56] studied the catalytic activity of Pt-Au/Al

2O

3 catalysts in the hydrodechlorination of CCl

4 and suggested that the introduction of Au onto Pt without a noticeable change in metal particle size decreases the affinity to the chloride species. A direct comparison of free energy of the formation for AuCl

3 and PtCl

3 (at the temperature range of 27–227 °C) evidence a much lower metal-Cl bond strength for gold. A higher activation energy for the monometallic (56 vs. ~30 kJ/mol for the bimetallics) indicates that the Cl removal from Pt surface is more difficult than for the bimetallic Pt-Au surface. Pt particles are very prone to excessive chloriding and, in effect, to a drastic deactivation in the hydrodechlorination of CCl

4 [

56].

Figure 12a shows a characteristic HR-TEM image with the corresponding PSD data that gave information on the structural changes in the catalyst after long-term testing. The bright-field STEM image shown in

Figure 12b evidences the sintering of the active phases. The Feret’s diameter of the biggest agglomerates in that image were 150 to 175 nm. Even though the image provided proof of substantial sintering, the PSD data (

n = 450) indicated the contrary. The amounts of particles in sizes between 0 to 10 nm and 10 to 20 nm increased by 2% and 9%, respectively, whereas the amounts in sizes between 20–30 nm decreased by 20% after the stability test. Although, the amounts of larger particles (i.e., between 30 to 40 nm, 40 to 50 nm, and >50 nm) increased all by a few percent units, the distribution indicated a larger number of smaller particles, mainly between 10–20 nm (52%) in comparison to the fresh Pt-Au/Al catalyst with 43% for the same size range. These findings might be a result of the removal of the residual chlorine. There might not be enough chlorine present on the catalyst surface to induce severe sintering of the particles. Au having resistance against highly electronegative elements and the reduced amount of Cl in the catalyst during the reaction might be one reason to maintain the catalytic performance in the stability test.

2.5. The Role of Au in the Reaction Mechanism on Alumina-Supported Catalyst

The alumina-supported catalysts were chosen for further consideration regarding the reaction mechanism, since these were better than ceria-containing analogs. The main reaction products observed during DCM oxidation in this study were CO

2, CO, and HCl (see

Figure 7). The formation of methyl chloride (CH

3Cl) and formaldehyde (CH

2O) were detected during the tests over the Au/Al and Pt-Au/Al catalysts. In the case of Pt/Al, only formaldehyde was observed. To understand better the role of gold in DCM oxidation, measured gaseous products for the Pt/Al, Au/Al, and Au-Pt/Al catalysts are shown in

Table 5. With the Pt/Al, Au/Al, and Pt-Au/Al catalysts, the formation of formaldehyde was seen already at about 40 °C lower temperature compared to HCl. This could mean that, at lower temperatures, direct DCM hydrolysis into formaldehyde takes place. Furthermore, methyl chloride was not observed in the case of Pt/Al, which could mean that the direct hydrolysis reaction rate is high, with Pt/Al also at a higher temperature. The DCM oxidation over the Pt/Al, Au/Al, and Pt-Au/Al catalysts in excess hydrogen originating from the water feed can advance via the cleavage of all chlorines from the carbon atom, thus following the lowest bond energy. Formaldehyde formation is expected to occur on Brønsted acid sites [

48]. According to van den Brink et al. [

11], the first step in DCM oxidation over γ-Al

2O

3 is the reaction of the adsorbed DCM molecule with a surface OH group that produces a chloromethoxyl species, which further reacts to the chemisorbed formaldehyde analog. The adsorbed formate species decomposes to CO or CO

2. The chloride displaced after the formation of the chemisorbed formaldehyde species can react with surface Al

3+ to form an aluminum chloride species or attach to a proton to form HCl. Water is able to regenerate the Al-Cl entities. [

11].

Haber et al. and van den Brink et al. focused on the role of Lewis acid sites in DCM oxidation. Haber et al. suggested that the activity of alumina in DCM oxidation is related to the distribution of Lewis acid sites, whereas the formation and selectivity to methyl chloride is dependent on the concentration of Lewis acid sites [

45,

46]. In the mechanism proposed by van den Brink et al. [

11], both chlorines of DCM are cleaved, and instead of forming HCl or aluminum chloride, Cl can also re-enter a surface methoxy species by nucleophilic displacement. The formaldehyde species, which was formed at a lower temperature range, can also disproportionate to form methoxy and formate groups. The methoxy species can react with HCl to form methyl chloride, which was observed in our case, at a slightly higher temperature. At higher temperatures, formaldehyde species can decompose rapidly and desorb more easily, making disproportionation less likely, and if methyl chloride is still formed, it will be decomposed on γ-Al

2O

3 [

11].

Maupin et al. [

19] suggested a slightly different mechanism for methyl chloride formation compared to that of van den Brink et al. [

11]. Firstly, one chlorine atom from DCM is substituted by an alumina hydroxyl group (step 1), leading to the formation of chloromethoxy species. Secondly, the last species is transformed into a hemiacetal species (step 2). [

19] These steps are in accordance with van den Brink et al. [

11], with the exception that, in the mechanism by van den Brink et al., both chlorines of DCM are removed and then Cl re-enters on a surface methoxy species. However, the methyl chloride formation is explained differently. Maupin et al. [

19] suggested that two chloromethoxy species react, via hemiacetal species, to form a formate species and methyl chloride (step 3), as discussed also by van den Brink et al., in which the hydride is transferred from the hemiacetal species rather than from the surface, as suggested by Haber et al. [

45]. The chloromethoxy disproportionation is accompanied by the formation of Al-O-Al bridges that cause a decrease in the number of available hydroxyl groups. Then, the formed formate species decompose to CO or CO

2, and finally, water regenerates the hydroxyl groups (step 4). [

19]

Pinard et al. studied DCM oxidation over pure NaY and PtNaY catalysts [

57], NaX and NaY zeolites [

58], and PtHFAU [

48] and PtFAU catalysts [

59]. They reported that DCM transformation occurs bifunctionally via DCM hydrolysis on the Brønsted acid sites of the support, resulting in formaldehyde and HCl, followed by formaldehyde oxidation into CO

2 and H

2O on the Pt sites. Water is required for the formation of formaldehyde. Formation of CO may result from formaldehyde oxidation or by decomposition of formate species. The main reactions were suggested as:

A methyl chloride intermediate was formed at higher temperatures via the Lewis acid sites [

48]. The CO formation could result from the direct oxidation of formaldehyde [

48], in addition to the proposed decomposition of formate species on Lewis acid sites, as discussed by van den Brink et al. [

11] and Maupin et al. [

19]. According to Maupin et al. [

19], Pt/Al

2O

3 catalysts oxidize DCM completely at 380 °C. The DCM reaction rate limiting step occurs on alumina, since neither the Pt content nor the dispersion (particle size) influence the conversion rates and selectivity [

19]. Similar observations were seen in our previous study [

12]. The addition of Pt and/or ceria to the catalyst improved the selectivity towards CO

2, but the oxidation rates were not affected that much [

12]. In our experiments, the addition of Au on alumina resulted in a significant decrease in the light-off temperature, and the addition Au on Pt/Al

2O

3 enhanced both DCM conversion and selectivity towards the total oxidation products.

Au catalysts are known to be effective in selective partial oxidation [

42,

43,

60,

61,

62], often succeeding where other metals fail due to a weaker adsorption of the reactants (such as hydrocarbons) on the catalyst surface [

63]. The too-weak adsorption of reaction intermediates might be one reason for the lower total oxidation result observed in our experiments with the monometallic Au catalysts. According to Haruta et al. [

42], the surface adsorption and reactivity of Au can be modified by generating surface structures via downsizing or scratching. Due to the moderate bonding strength on the defect sites of Au, which is weaker than that on Pd and Pt, it often occurs that Au catalysts are better than other noble metal catalysts at low temperatures [

42]. This can also be seen in our case, since reaction products are observed at lower temperatures with the Au-containing catalysts than with the Pt/Al.

In the presence of water, alumina is strongly hydrated, which facilitates the reaction between DCM and hydroxyl groups from alumina [

19]. It is worth noting that alumina is also hydrophilic and, thus, attracts water on its surface [

64]. In addition, the Pt/Al

2O

3 catalyst is hydrophilic [

53], and Au has a hydrophilic nature [

42]. Water is weakly adsorbed on Au [

65]. The adsorption of water is followed by water dissociation into protons and OH groups, which are the sites for DCM adsorption, and, thus, the adsorption is enhanced. We could speculate that the relatively high amounts of formaldehyde produced by the Au/Al catalyst might result from a high amount of Brønsted acid sites. Costello et al. [

66,

67] studied an Au/γ-Al

2O

3 catalyst in CO oxidation and proposed that water forms Au

+-OH

- via adsorption on Au clusters. Chemisorbed oxygen on Au has a Brønsted base character [

42,

65]. On the Au surface, atomic oxygen reacts like a Brønsted base by abstracting a hydrogen atom from acidic molecules. Furthermore, oxygen atoms on the Au(110) surface were observed to react like a nucleophilic base towards formaldehyde. [

65] This might explain the product distributions in the case of the Au-containing alumina catalysts. Further oxidation of an adsorbed compound (in this case, formaldehyde) is suppressed when the activation energy for desorption is lower than that for oxidation. Ceria-containing catalysts, however, are able to oxidize carbon products, further resulting in the formation of CO and CO

2 due to its high oxygen storage capacity and good redox property [

68]. The different product distribution might be also a consequence of different reaction routes: on alumina, direct DCM hydrolysis into formaldehyde appears, and, on ceria, the Mars-van Krevelen mechanism prevails.

The role of Au is evident, since formaldehyde, methyl chloride, and CO are formed in comparison to Pt/Al, which produces mainly CO2. Au enhances the DCM conversion and HCl yield but results in partial oxidation products. The results suggest that DCM decomposition over the Au-containing alumina-supported catalysts proceeds via a bifunctional reaction in which hydrolysis is the first step, followed by oxidation.