Exploring Effects of Protease Choice and Protease Combinations in Enzymatic Protein Hydrolysis of Poultry By-Products

Abstract

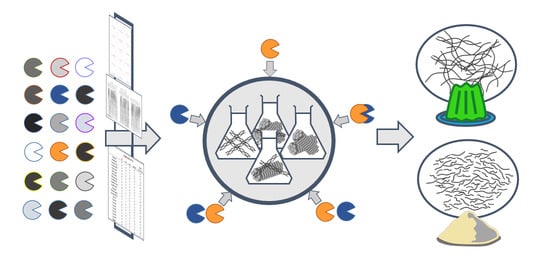

:1. Introduction

2. Results and Discussion

2.1. Protease Activity Screening

2.1.1. Activity Determination with Azo-Casein Assay

2.1.2. Screening of 16 Proteases on Different Poultry Raw Materials

2.2. Proteolysis of Poultry Substrates Using Bromelain and Endocut-02

2.3. Combination of Proteases in EPH of MDCR

2.4. General Discussion and Industrial Relevance

3. Materials and Methods

3.1. Materials and By-Products

3.2. Activity Determination Using the Azo-Casein Assay

3.3. Screening of 18 Proteases on Different Poultry Raw Materials

3.4. Lab-Scale Enzymatic Hydrolysis

3.5. Chemical Composition and Hyp Content in Hydrolysates

3.6. Nitrogen Recovery and Protein Content

3.7. SEC

3.8. SDS-PAGE

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Aspevik, T.; Oterhals, Å.; Rønning, S.B.; Altintzoglou, T.; Wubshet, S.G.; Gildberg, A.; Afseth, N.K.; Whitaker, R.D.; Lindberg, D. Valorization of Proteins from Co- and By-Products from the Fish and Meat Industry. Top. Curr. Chem. 2017, 375, 53. [Google Scholar] [CrossRef]

- Alao, B.O.; Falowo, A.B.; Chulayo, A.; Muchenje, V. The Potential of Animal By-Products in Food Systems: Production, Prospects and Challenges. Sustainability 2017, 9, 1089. [Google Scholar] [CrossRef] [Green Version]

- Aspevik, T.; Egede-Nissen, H.; Oterhals, Å. A Systematic Approach to the Comparison of Cost Efficiency of Endopeptidases for the Hydrolysis of Atlantic Salmon (Salmo salar) By-Products. Food Technol. Biotechnol. 2016, 54, 421–431. [Google Scholar] [CrossRef]

- Lindberg, D.; Kristoffersen, K.A.; de Vogel-van den Bosch, H.; Wubshet, S.G.; Böcker, U.; Rieder, A.; Fricke, E.; Afseth, N.K. Effects of poultry raw material variation and choice of protease on protein hydrolysate quality. Process Biochem. 2021, 110, 85–93. [Google Scholar] [CrossRef]

- Thoresen, P.P.; Álvarez, R.G.; Vaka, M.R.; Rustad, T.; Sone, I.; Fernández, E.N. Potential of innovative pre-treatment technologies for the revalorisation of residual materials from the chicken industry through enzymatic hydrolysis. Innov. Food Sci. Emerg. Technol. 2020, 64, 102377. [Google Scholar] [CrossRef]

- Lasekan, A.; Abu Bakar, F.; Hashim, D. Potential of chicken by-products as sources of useful biological resources. Waste Manag. 2013, 33, 552–565. [Google Scholar] [CrossRef]

- Fu, Y.; Therkildsen, M.; Aluko, R.E.; Lametsch, R. Exploration of collagen recovered from animal by-products as a precursor of bioactive peptides: Successes and challenges. Crit. Rev. Food Sci. Nutr. 2019, 59, 2011–2027. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, T.; Ismail, A.; Ahmad, S.A.; Khalil, K.A.; Kumar, Y.; Adeyemi, K.D.; Sazili, A.Q. Recent advances on the role of process variables affecting gelatin yield and characteristics with special reference to enzymatic extraction: A review. Food Hydrocoll. 2017, 63, 85–96. [Google Scholar] [CrossRef]

- Lapeña, D.; Vuoristo, K.S.; Kosa, G.; Horn, S.J.; Eijsink, V.G.H. Comparative Assessment of Enzymatic Hydrolysis for Valorization of Different Protein-Rich Industrial Byproducts. J. Agric. Food Chem. 2018, 66, 9738–9749. [Google Scholar] [CrossRef] [PubMed]

- Rossi, D.M.; Flôres, S.H.; Heck, J.X.; Ayub, M.A.Z. Production of High-protein Hydrolysate from Poultry Industry Residue and their Molecular Profiles. Food Biotechnol. 2009, 23, 229–242. [Google Scholar] [CrossRef]

- Wang, D.; Shahidi, F. Protein hydrolysate from turkey meat and optimization of its antioxidant potential by response surface methodology. Poult. Sci. 2018, 97, 1824–1831. [Google Scholar] [CrossRef] [PubMed]

- Nikolaev, I.V.; Sforza, S.; Lambertini, F.; Ismailova, D.Y.; Khotchenkov, V.P.; Volik, V.G.; Dossena, A.; Popov, V.O.; Koroleva, O.V. Biocatalytic conversion of poultry processing leftovers: Optimization of hydrolytic conditions and peptide hydrolysate characterization. Food Chem. 2016, 197, 611–621. [Google Scholar] [CrossRef] [PubMed]

- Offengenden, M.; Chakrabarti, S.; Wu, J. Chicken collagen hydrolysates differentially mediate anti-inflammatory activity and type I collagen synthesis on human dermal fibroblasts. Food Sci. Hum. Wellness 2018, 7, 138–147. [Google Scholar] [CrossRef]

- Kristinsson, H.G.; Rasco, B.A. Fish Protein Hydrolysates: Production, Biochemical, and Functional Properties. Crit. Rev. Food Sci. Nutr. 2000, 40, 43–81. [Google Scholar] [CrossRef] [PubMed]

- Wubshet, S.G.; Lindberg, D.; Veiseth-Kent, E.; Kristoffersen, K.A.; Böcker, U.; Washburn, K.E.; Afseth, N.K. Chapter 8—Bioanalytical Aspects in Enzymatic Protein Hydrolysis of By-Products. In Proteins: Sustainable Source, Processing and Applications; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 225–258. [Google Scholar] [CrossRef]

- Di Cera, E. Serine proteases. IUBMB Life 2009, 61, 510–515. [Google Scholar] [CrossRef] [PubMed]

- Gupta, P.; Maqbool, T.; Saleemuddin, M. Oriented immobilization of stem bromelain via the lone histidine on a metal affinity support. J. Mol. Catal. B Enzym. 2007, 45, 78–83. [Google Scholar] [CrossRef]

- Norziah, M.H.; Kee, H.Y.; Norita, M. Response surface optimization of bromelain-assisted gelatin extraction from surimi processing wastes. Food Biosci. 2014, 5, 9–18. [Google Scholar] [CrossRef]

- Hale, L.P.; Greer, P.K.; Trinh, C.T.; James, C.L. Proteinase activity and stability of natural bromelain preparations. Int. Immunopharmacol. 2005, 5, 783–793. [Google Scholar] [CrossRef] [PubMed]

- Johanning, K.; Juliano, M.A.; Juliano, L.; Lazure, C.; Lamango, N.S.; Steiner, D.F.; Lindberg, I. Specificity of Prohormone Convertase 2 on Proenkephalin and Proenkephalin-related Substrates. J. Biol. Chem. 1998, 273, 22672–22680. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, Y.; Liu, J.; Hansen, E.T.; Bredie, W.L.P.; Lametsch, R. Structural characteristics of low bitter and high umami protein hydrolysates prepared from bovine muscle and porcine plasma. Food Chem. 2018, 257, 163–171. [Google Scholar] [CrossRef]

- Wubshet, S.G.; Wold, J.P.; Afseth, N.K.; Böcker, U.; Lindberg, D.; Ihunegbo, F.N.; Måge, I. Feed-Forward Prediction of Product Qualities in Enzymatic Protein Hydrolysis of Poultry By-products: A Spectroscopic Approach. Food Bioprocess Technol. 2018, 11, 2032–2043. [Google Scholar] [CrossRef]

- Cissell, D.D.; Link, J.M.; Hu, J.C.; Athanasiou, K.A. A Modified Hydroxyproline Assay Based on Hydrochloric Acid in Ehrlich’s Solution Accurately Measures Tissue Collagen Content. Tissue Eng. Part C Methods 2017, 23, 243–250. [Google Scholar] [CrossRef]

- Stoilov, I.; Starcher, B.C.; Mecham, R.P.; Broekelmann, T.J. Chapter 7—Measurement of elastin, collagen, and total protein levels in tissues. In Methods in Cell Biology; Mecham, R.P., Ed.; Academic Press: Cambridge, MA, USA, 2018; Volume 143, pp. 133–146. [Google Scholar]

- Benedict, R.C. Determination of Nitrogen and Protein Content of Meat and Meat Products. J. Assoc. Off. Anal. Chem. 1987, 70, 69–74. [Google Scholar] [CrossRef]

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting Nitrogen into Protein—Beyond 6.25 and Jones’ Factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- Han, L.; Zhang, Z.-w.; Wang, B.-h.; Wen, Z.-k. Construction and biocompatibility of a thin type I/II collagen composite scaffold. Cell Tissue Bank. 2018, 19, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Rabotyagova, O.S.; Cebe, P.; Kaplan, D.L. Collagen structural hierarchy and susceptibility to degradation by ultraviolet radiation. Mater. Sci. Eng. C 2008, 28, 1420–1429. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shikh Alsook, M.K.; Gabriel, A.; Salouci, M.; Piret, J.; Alzamel, N.; Moula, N.; Denoix, J.M.; Antoine, N.; Baise, E. Characterization of collagen fibrils after equine suspensory ligament injury: An ultrastructural and biochemical approach. Vet. J. 2015, 204, 117–122. [Google Scholar] [CrossRef]

- Zhang, G.; Young, B.B.; Ezura, Y.; Favata, M.; Soslowsky, L.J.; Chakravarti, S.; Birk, D.E. Development of tendon structure and function: Regulation of collagen fibrillogenesis. J. Musculoskelet. Neuronal Interact. 2005, 5, 5–21. [Google Scholar]

- Grønlien, K.G.; Pedersen, M.E.; Sanden, K.W.; Høst, V.; Karlsen, J.; Tønnesen, H.H. Collagen from Turkey (Meleagris gallopavo) tendon: A promising sustainable biomaterial for pharmaceutical use. Sustain. Chem. Pharm. 2019, 13, 100166. [Google Scholar] [CrossRef]

- Du, L.; Khiari, Z.; Pietrasik, Z.; Betti, M. Physicochemical and functional properties of gelatins extracted from turkey and chicken heads. Poult. Sci. 2013, 92, 2463–2474. [Google Scholar] [CrossRef]

- Shoulders, M.D.; Raines, R.T. Collagen Structure and Stability. Annu. Rev. Biochem. 2009, 78, 929–958. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ha, M.; Bekhit, A.E.-D.A.; Carne, A.; Hopkins, D.L. Characterisation of commercial papain, bromelain, actinidin and zingibain protease preparations and their activities toward meat proteins. Food Chem. 2012, 134, 95–105. [Google Scholar] [CrossRef]

- Zhang, Y.; Dutilleul, P.; Orsat, V.; Simpson, B.K. Alcalase assisted production of novel high alpha-chain gelatin and the functional stability of its hydrogel as influenced by thermal treatment. Int. J. Biol. Macromol. 2018, 118, 2278–2286. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, V.d.M.; Assis, C.R.D.; Costa, B.d.A.M.; Neri, R.C.d.A.; Monte, F.T.D.; Freitas, H.M.S.d.C.V.; França, R.C.P.; Santos, J.F.; Bezerra, R.d.S.; Porto, A.L.F. Physical, biochemical, densitometric and spectroscopic techniques for characterization collagen from alternative sources: A review based on the sustainable valorization of aquatic by-products. J. Mol. Struct. 2021, 1224, 129023. [Google Scholar] [CrossRef]

- Whitaker, R.D.; Altintzoglou, T.; Lian, K.; Fernandez, E.N. Marine bioactive peptides in supplements and functional Foods—A commercial perspective. Curr. Pharm. Des. 2021, 27, 1353–1364. [Google Scholar] [CrossRef]

- Wubshet, S.G.; Måge, I.; Böcker, U.; Lindberg, D.; Knutsen, S.H.; Rieder, A.; Rodriguez, D.A.; Afseth, N.K. FTIR as a rapid tool for monitoring molecular weight distribution during enzymatic protein hydrolysis of food processing by-products. Anal. Methods 2017, 9, 4247–4254. [Google Scholar] [CrossRef]

- Rieder, A.; Afseth, N.K.; Böcker, U.; Knutsen, S.H.; Kirkhus, B.; Mæhre, H.K.; Ballance, S.; Wubshet, S.G. Improved estimation of in vitro protein digestibility of different foods using size exclusion chromatography. Food Chem. 2021, 358, 129830. [Google Scholar] [CrossRef] [PubMed]

| Weight Yield (g/100 g) | |||||

|---|---|---|---|---|---|

| TT | CB | CM | MDCR | Ratio TT/CM (%) | |

| Alcalase | 43 | 11 | 50 | 41 | 86 |

| Bromelain | 46 | 28 | 55 | 37 | 83 |

| Corolase 2TS | 63 | 28 | 74 | 42 | 85 |

| Corolase 7090 | 59 | 22 | 52 | 29 | 114 |

| Endocut-01 | 50 | 32 | 49 | 36 | 103 |

| Endocut-02 | 45 | 35 | 33 | 37 | 136 |

| Endocut-03 | 51 | 20 | 41 | 29 | 124 |

| Flavourzyme | 36 | 13 | 38 | 25 | 94 |

| FoodPro 30L | 45 | 23 | 44 | 35 | 102 |

| FoodPro 51 FP | 48 | 17 | 64 | 31 | 74 |

| FoodPro PNL | 50 | 16 | 45 | 37 | 109 |

| Protamex | 63 | 7 | 56 | 34 | 114 |

| Promod 144GL | 48 | 17 | 50 | 44 | 96 |

| Promod P950 L | 37 | 17 | 42 | 31 | 88 |

| Tail-10 | 45 | 31 | 47 | 41 | 95 |

| Veron L | 48 | 23 | 51 | 34 | 95 |

| Element | CM (g/100 g) | TCT (g/100 g) | MDCR (g/100 g) |

|---|---|---|---|

| Protein | 22 ± 0.2 | 31 ± 1 | 20 ± 1 |

| Ash | 1.2 ± 0 | 5.1 ± 0.8 | 1.8 ± 0.3 |

| Fat | 2.6 ± 0.07 | 4.6 ± 0.3 | 20 ± 0 |

| Water | 74 ± 0.2 | 59 ± 3 | 59 ± 0.4 |

| Hyp | 0.06 ± 0.01 | 3.05 ± 0.03 | 1.02 ± 0.01 |

| Collagen * | 0.44 ± 0.07 | 22.6 ± 0.2 | 7.6 ± 0.07 |

| Protein Recovery (%) | ||||

|---|---|---|---|---|

| Protease | TCT | CM | TCT+CM | MDCR |

| Endocut-02 | 40.1 ± 4.2 | 36.7 ± 2.3 | 38.0 ± 2.1 | 52.6 ± 1.5 |

| Bromelain | 53.9 ± 4.7 | 48.4 ± 3.8 | 51.1 ± 3.0 | 55.1 ± 1.5 |

| CM (g/100 g) | TCT (g/100 g) | TCM+CM (g/100 g) | MDCR (g/100 g) | |||||

|---|---|---|---|---|---|---|---|---|

| Time (min) | B | E | B | E | B | E | B | E |

| 40 | 90 | 87 | 73 | 75 | 85 | 78 | 79 | 73 |

| 50 | 89 | 86 | 76 | 69 | 85 | 79 | 81 | 74 |

| 60 | 88 | 89 | 97 | 93 | 92 | 88 | 91 | 90 |

| Δ (60–50) | −1 | 3 | 21 | 24 | 7 | 9 | 10 | 16 |

| Protein Yield (%) | [Protein], 60 min Sample (g/100 g Dry Matter) | [Protein], End Product (g/100 g Dry Matter) | Δ [Protein] (g/100 g) | |

|---|---|---|---|---|

| Endocut-02 | 54.5 ± 1.0 | 80.8 ± 3.2 | 97.7 ± 0.3 | 16.9 |

| Bromelain | 50.8 ± 3.6 | 75.1 ± 1.5 | 94.3 ± 1.8 | 19.2 |

| BE | 64.3 ± 4.3 | 85.0 ± 0.9 | 95.3 ± 0.2 | 10.3 |

| B+E | 69.3 ± 1.1 | 84.0 ± 0.8 | 95.5 ± 1.3 | 11.5 |

| E+B | 70.7 ± 5.3 | 85.1 ± 2.3 | 96.0 ± 0.3 | 10.9 |

| Protease | Vendor | Activity | Vendor Enzyme Description | pH | Temp |

|---|---|---|---|---|---|

| Alcalase | Novozymes | Endo/exo | Serine endopeptidase (mainly Subtilisin A) | 7.0–10 | 30–70 |

| Bromelain BR 1200 | Bromelain Enzyme | Endo | Cysteine protease | 4.0–9.0 | 40–65 |

| Corolase 2TS | AB Enzymes | Endo | Thermolysin, extracellular neutral metalloprotease | 6.0–9.0 | up to 70 |

| Corolase 7090 | AB Enzymes | Endo | Bacillolysin metallo endopeptidase | 6.5–7.5 | 45–70 |

| Endocut-01 | Tailorzyme | Endo | Neutral endo-protease | 6.0–8.0 | 45–55 |

| Endocut-02 | Tailorzyme | Endo | Alkali endoprotease | (6)7.0–10 | 55–65 |

| Endocut-03 | Tailorzyme | Endo | Alkali endoprotease | 7–10 | 55–70 |

| Flavourzyme | Novozymes | Exo | Mix of different exopeptidases | 5.0–7.0 | 35–65 |

| FoodPro 30L | DuPont/Danisco | Endo | Alkaline serine endopeptidase | 6.0–7.5 | 45–65 |

| FoodPro 51 FP | DuPont/Danisco | Endo/exo | Mix of exo- and endopeptidases | 8.0–10.0 | 45–60 |

| FoodPro PNL | DuPont/Danisco | Endo | Neutral metallo endopeptidase | 6.0–7.5 | 50–70 |

| Protamex | Novozymes | Endo | Trypsin, bacillolysin, subtilisin | 7.0–10 | 35–60 |

| MaxiPro NPU | DSM | Endo | Neutral endo-protease | 5.5–7.5 | 25–55 |

| Neutrase | Novozymes | Endo | Neutral, zinc metallo endo-protease | 5.5–7.5 | 45–55 |

| PROMOD 144GL | Biocatalysts | Endo | Ultralow sulphite papain | 5.0–7.5 | 50–70 |

| PROMOD P950L | Biocatalysts | Endo | Microbial alternative to papain | 5.0–7.0 | 50–60 |

| TAIL-10 | Tailorzyme | Endo | Alkaline serine endopeptidase, ficin, papain, pepsin | 7.0–9.0 | 30–70 |

| VERON L | AB Enzymes | Endo | Proteolytic enzyme preparation based on papain | 5.0–7.5 | 50–70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindberg, D.; Kristoffersen, K.A.; Wubshet, S.G.; Hunnes, L.M.G.; Dalsnes, M.; Dankel, K.R.; Høst, V.; Afseth, N.K. Exploring Effects of Protease Choice and Protease Combinations in Enzymatic Protein Hydrolysis of Poultry By-Products. Molecules 2021, 26, 5280. https://doi.org/10.3390/molecules26175280

Lindberg D, Kristoffersen KA, Wubshet SG, Hunnes LMG, Dalsnes M, Dankel KR, Høst V, Afseth NK. Exploring Effects of Protease Choice and Protease Combinations in Enzymatic Protein Hydrolysis of Poultry By-Products. Molecules. 2021; 26(17):5280. https://doi.org/10.3390/molecules26175280

Chicago/Turabian StyleLindberg, Diana, Kenneth Aase Kristoffersen, Sileshi Gizachew Wubshet, Linn Maria Gundersen Hunnes, Marte Dalsnes, Katinka Riiser Dankel, Vibeke Høst, and Nils Kristian Afseth. 2021. "Exploring Effects of Protease Choice and Protease Combinations in Enzymatic Protein Hydrolysis of Poultry By-Products" Molecules 26, no. 17: 5280. https://doi.org/10.3390/molecules26175280

APA StyleLindberg, D., Kristoffersen, K. A., Wubshet, S. G., Hunnes, L. M. G., Dalsnes, M., Dankel, K. R., Høst, V., & Afseth, N. K. (2021). Exploring Effects of Protease Choice and Protease Combinations in Enzymatic Protein Hydrolysis of Poultry By-Products. Molecules, 26(17), 5280. https://doi.org/10.3390/molecules26175280