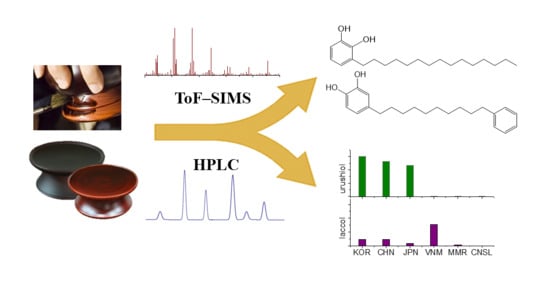

HPLC and ToF‒SIMS Analyses of Toxicodendron vernicifluum Tree Sap Mixed with Other Natural Lacquers

Abstract

:1. Introduction

2. Results and Discussion

2.1. ToF–SIMS Compositional Analysis of Mixed Lacquers

2.2. HPLC Quantitative Analysis of Mixed Lacquers

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Time-of-Flight Secondary Ion Mass Spectrometry

3.2.2. High-Performance Liquid Chromatography

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability: Not available. |

References

- Marianne, W. Lacquer: Technology and Conservation: A Comprehensive Guide to the Technology and Conservation of Asian and European Lacquer; Butterworth–Heinemann: Oxford, UK, 2000. [Google Scholar]

- Kidder, E.J. Japan Before Buddhism, Ancient Peoples and Places, 1st ed.; Thames & Hudson: London, UK, 1959. [Google Scholar]

- Lu, R.; Miyakoshi, T. Lacquer Chemistry and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Brommelle, N.S.; Smith, P. (Eds.) Urushi Proceedings of the Urushi Study Group; Getty Conservation Institute: California, CA, USA, 1988. [Google Scholar]

- Niimura, N.; Miyakoshi, T. Structural characterization of a modified cashew nut shell oil coating film for industrial use. Int. J. Polym. Anal. Char. 2005, 10, 141–151. [Google Scholar] [CrossRef]

- Sung, M.; Lu, R.; Miyakoshi, T. Analysis and characterization of Korean lacquer. Int. J. Polym. Anal. Char. 2015, 20, 150–159. [Google Scholar] [CrossRef]

- Lu, R.; Yoshida, T.; Miyakoshi, T. Oriental lacquer: A natural polymer. Polym. Rev. 2013, 53, 153–191. [Google Scholar] [CrossRef]

- Lee, J.; Jung, S.B.; Terlier, T.; Lee, K.B.; Lee, Y. Molecular identification of Asian lacquers from different trees using Py-GC/MS and ToF-SIMS. Surf. Interface Anal. 2018, 50, 696–704. [Google Scholar] [CrossRef]

- Qin, M.; Mitchell, J.D.; Vogl, O. Oriental lacquer. 10. The South East Asian lacquer. J. Macromol. Sci. A 1996, 33, 1791–1803. [Google Scholar] [CrossRef]

- Kumanotani, J. Urushi (Oriental lacquer)—A natural aesthetic durable and future-promising coating. Prog. Org. Coat. 1995, 26, 163–195. [Google Scholar] [CrossRef]

- Trevisan, M.T.S.; Pfundstein, B.; Haubner, R.; Würtele, G.; Spiegelhalder, B.; Bartsch, H.; Owen, R.W. Characterization of alkyl phenols in cashew (Anacardium occidentale) products and assay of their antioxidant capacity. Food Chem. Toxicol. 2006, 44, 188–197. [Google Scholar] [CrossRef] [PubMed]

- Amorati, R.; Pedulli, G.F.; Valgimigli, L.; Attanasi, O.A.; Filippone, P.; Fiorucci, C.; Saladino, R. Absolute rate constants for the reaction of peroxyl radicals with cardanol derivatives. J. Chem. Soc. Perkin Trans. 2001, 2, 2142–2146. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Cure characteristics of alkali catalysed cashew nut shell liquid-formaldehyde resin. J. Mater. Sci. 2001, 36, 3693–3698. [Google Scholar] [CrossRef]

- Anzai, K.; Lu, R.; Phuc, B.T.; Miyakoshi, T. Development and characterization of laccol lacquer blended with urushiol lacquer. Int. J. Polym. Anal. Chem. 2014, 19, 130–140. [Google Scholar] [CrossRef]

- Lu, R.; Yoshida, T. Structure and molecular weight of Asian lacquer polysaccharides. Carbohydr. Polym. 2003, 54, 419–424. [Google Scholar] [CrossRef]

- Niimura, N.; Miyakoshi, T. Characterization of synthesized lacquer analogue films using X-ray photoelectron spectroscopy. Surf. Interface Anal. 2000, 29, 381–385. [Google Scholar] [CrossRef]

- Xia, J.; Lin, J.; Xu, Y.; Chen, Q. On the UV-induced polymeric behavior of Chinese lacquer. ACS Appl. Mater. Interfaces 2011, 3, 482–489. [Google Scholar] [CrossRef]

- Kimura, M.; Rodriguez-Amaya, D.B. A scheme for obtaining standards and HPLC quantification of leafy vegetable carotenoids. Food Chem. 2002, 78, 389–398. [Google Scholar] [CrossRef]

- Van Vaeck, L.V.; Adriaens, A.; Gijbels, R. Static secondary ion mass spectrometry (S-SIMS) Part 1: Methodology and structural interpretation. Mass Spectrom. Rev. 1999, 18, 1–47. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, J.; Kim, Y.; Choi, S.; Ham, S.W.; Kim, K.J. Investigation of natural dyes and ancient textiles from Korea using TOF-SIMS. Appl. Surf. Sci. 2008, 255, 1033–1036. [Google Scholar] [CrossRef]

- Lee, J.; Kim, M.J.; Kim, M.-H.; Doh, J.-M.; Hahn, H.-G.; Lee, Y. Characterization of traditional Korean lacquers using surface analytical techniques. Surf. Interface Anal. 2015, 47, 1180–1186. [Google Scholar] [CrossRef]

- Dubey, M.; Emoto, K.; Cheng, F.; Gamble, L.J.; Takahashi, H.; Grainger, D.W.; Castner, D.G. Surface analysis of photolithographic patterns using ToF-SIMS and PCA. Surf. Interface Anal. 2009, 41, 645–652. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, H.H.; Lim, J.-A.; Ham, S.W.; Lee, K.-B.; Lee, Y. Quantitative Analysis of Blended Asian Lacquers Using ToF–SIMS, Py–GC/MS and HPLC. Polymers 2021, 13, 97. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-B. Analysis of the Urushiol in Korean Lacquer. Korean J. Food Nutr. 2006, 19, 267–270. [Google Scholar]

| Compound | Retention Time (Rt, min) | Response Factor (Rf*10−3) | LOD (μg/mL) | LOQ (μg/mL) |

|---|---|---|---|---|

| urushiol 15:3 | 8.92, 9.30 | 1.06 | 0.55 | 1.86 |

| urushiol 15:2 | 11.95, 12.48 | 1.23 | 0.57 | 1.90 |

| urushiol 15:1 | 17.63, 18.38 | 1.77 | 0.52 | 1.73 |

| laccol 17:0 | 25.76 | 2.78 | 0.08 | 0.26 |

| cardol 15:3 | 8.30 | 2.62 | 0.08 | 0.25 |

| Korean‒CNSL | CNSL Composition (wt%) [±SD] | ||

| Urushiol 15:3 | Urushiol 15:1 | Used Contents (wt%) | |

| Unknown A0 | 93.3 (±1.4) | 93.9 (±1.0) | 90.0 |

| Unknown B0 | 8.8 (±1.3) | 10.0 (±1.0) | 10.0 |

| ChineseII‒Myanmarese | Myanmarese Composition (wt%) [±SD] | ||

| Urushiol 15:3 | Urushiol 15:2 | Used Contents (wt%) | |

| Unknown A1 | 89.9 (±0.8) | 86.2 (±4.8) | 90.0 |

| Unknown B1 | 33.0 (±0.4) | 31.7 (±2.2) | 30.0 |

| Blend | Korean (wt%) | Vietnamese (wt%) | Blend | Korean (wt%) | CNSL (wt%) | Blend | Chinese II (wt%) | Myanmarese (wt%) |

|---|---|---|---|---|---|---|---|---|

| KV01 | 0 | 100 | KC01 | 0 | 100 | CM01 | 0 | 100 |

| KV02 | 25 | 75 | KC02 | 20 | 80 | CM02 | 20 | 80 |

| KV03 | 50 | 50 | KC03 | 50 | 50 | CM03 | 50 | 50 |

| KV04 | 75 | 25 | KC04 | 80 | 20 | CM04 | 80 | 20 |

| KV05 | 100 | 0 | KC05 | 100 | 0 | CM05 | 100 | 0 |

| urushiol 15:3 | 3-[(8ZE,11Z,14E)-pentadeca-8,11,14-trienyl])- 1,2-benzenediol C21H30O2 M.W. 314.47 |  |

| urushiol 15:2 | 3-(8Z,11Z-Pentadecadienyl)-1,2-benzenediol C21H32O2 M.W. 316.49 |  |

| urushiol 15:1 | 3-(8Z-Pentadecenyl)- 1,2-benzenediol C21H34O2 M.W. 318.49 |  |

| laccol 17:0 | 3-heptadecylbenzene-1,2-diol C23H40O2 M.W. 348.57 |  |

| cardol 15:3 | 5-(8Z,11Z)-8,11,14-Pentadecatrien-1-yl-1,3-benzenediol C21H30O2 M.W. 314.47 |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.H.; Ham, S.W.; Lee, Y. HPLC and ToF‒SIMS Analyses of Toxicodendron vernicifluum Tree Sap Mixed with Other Natural Lacquers. Molecules 2021, 26, 434. https://doi.org/10.3390/molecules26020434

Yu HH, Ham SW, Lee Y. HPLC and ToF‒SIMS Analyses of Toxicodendron vernicifluum Tree Sap Mixed with Other Natural Lacquers. Molecules. 2021; 26(2):434. https://doi.org/10.3390/molecules26020434

Chicago/Turabian StyleYu, Hye Hyun, Seung Wook Ham, and Yeonhee Lee. 2021. "HPLC and ToF‒SIMS Analyses of Toxicodendron vernicifluum Tree Sap Mixed with Other Natural Lacquers" Molecules 26, no. 2: 434. https://doi.org/10.3390/molecules26020434

APA StyleYu, H. H., Ham, S. W., & Lee, Y. (2021). HPLC and ToF‒SIMS Analyses of Toxicodendron vernicifluum Tree Sap Mixed with Other Natural Lacquers. Molecules, 26(2), 434. https://doi.org/10.3390/molecules26020434