Polymeric Forms of Plant Flavonoids Obtained by Enzymatic Reactions

Abstract

:1. Introduction

2. Results and Discussion

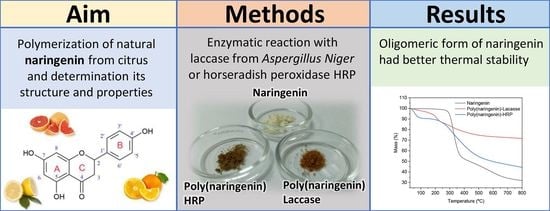

2.1. Analysis of the Structure of Poly(naringenin) Obtained by Reaction with the Enzymes Laccase and Horseradish Peroxidase (HRP)

2.1.1. FTIR and UV-Vis Spectroscopy

2.1.2. Nuclear Magnetic Resonance (NMR) Analysis

2.1.3. Gel Permeation Chromatography (GPC)

2.1.4. Microscopic Analysis

2.2. Analysis of the Properties of Poly(naringenin) Obtained by Reaction with the Enzymes Laccase and Horseradish Peroxidase (HRP)

2.2.1. Antioxidant Capacity

2.2.2. Thermal Analysis

2.2.3. Antimicrobial Properties

3. Materials and Methods

3.1. Polymerization of Naringenin with Laccase and Horseradish Peroxidase (HRP)

3.2. FTIR and UV-Vis Spectroscopy

3.3. Nuclear Magnetic Resonance Characterization (NMR)

3.4. Gel Permeation Chromatography (GPC)

3.5. Microscopic Analysis

3.6. Antioxidant Activity Determined by ABTS, DPPH, FRAP and CUPRAC Methods

3.7. Thermal Analysis (Thermogravimetric TG and Differential Scanning Calorimetry DSC)

3.8. Antimicrobial Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Liu, D.; Meng, S.; Xiang, Z.; He, N.; Yang, G. Antimicrobial mechanism of reaction products of Morus notabilis (mulberry) polyphenol oxidases and chlorogenic acid. Phytochemistry 2019, 163, 1–10. [Google Scholar] [CrossRef]

- Xu, J.-B.; Li, Y.-Z.; Huang, S.; Chen, L.; Luo, Y.-Y.; Gao, F.; Zhou, X.-L. Diterpenoid alkaloids from the whole herb of Delphinium grandiflorum L. Phytochemistry 2021, 190, 112866. [Google Scholar] [CrossRef]

- Rice-Evans, C.A.; Miller, N.J.; Paganga, G. Structure-antioxidant activity relationships of flavonoids and phenolic acids. Free Radic. Biol. Med. 1996, 20, 933–956. [Google Scholar] [CrossRef]

- Rice-Evans, C.A.; Packer, L. Flavonoids in Health and Disease, 2nd ed.; CRC Press: New York, NY, USA, 2003. [Google Scholar]

- Zheng, Y.-Z.; Deng, G.; Chen, D.-F.; Guo, R.; Lai, R.-C. The influence of C2=C3 double bond on the antiradical activity of flavonoid: Different mechanisms analysis. Phytochemistry 2019, 157, 1–7. [Google Scholar] [CrossRef]

- Zheng, Y.-Z.; Deng, G.; Zhang, Y.-C. Multiple free radical scavenging reactions of aurones. Phytochemistry 2021, 190, 112853. [Google Scholar] [CrossRef]

- Burda, S.; Oleszek, W. Antioxidant and antiradical activities of flavonoids. J. Agric. Food Chem. 2001, 49, 2774–2779. [Google Scholar] [CrossRef]

- Heim, K.E.; Tagliaferro, A.R.; Bobilya, D.J. Flavonoid antioxidants: Chemistry, metabolism and structure-activity relationships. J. Nutr. Biochem. 2002, 13, 572–584. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A. Natural Polymeric Compound Based on High Thermal Stability Catechin from Green Tea. Biomolecules 2020, 10, 1191. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A. Structure—Activity relationships analysis of monomeric and polymeric poly-phenols (quercetin, rutin and catechin) obtained by various polymerization methods. Chem. Biodivers. 2019, 16, e1900426. [Google Scholar] [CrossRef]

- Kurisawa, M.; Chung, J.E.; Uyama, H.; Kobayashi, S. Laccase-catalyzed Synthesis and Antioxidant Property of Poly(catechin). Macromol. Biosci. 2003, 3, 758–764. [Google Scholar] [CrossRef]

- Kurisawa, M.; Chung, J.E.; Kim, Y.J.; Uyama, H.; Kobayashi, S. Amplification of Antioxidant Activity and Xanthine Oxidase Inhibition of Catechin by Enzymatic Polymerization. Biomacromolecules 2003, 4, 469–471. [Google Scholar] [CrossRef]

- Hosny, H.; Rosazza, J.P.N. Novel Oxidations of (+)-Catechin by Horseradish Peroxidase and Laccase. J. Agric. Food Chem. 2002, 50, 5539–5545. [Google Scholar] [CrossRef]

- Chebil, L.; Rhouma, G.B.; Chekir-Ghedira, L.; Ghoul, M. Enzymatic Polymerization of Rutin and Esculin and Evaluation of the Antioxidant Capacity of Polyrutin and Polyesculin. In Biotechnology; IntechOpen: London, UK, 2015; pp. 117–133. [Google Scholar]

- Liang, J.-Y.; Wu, J.-Y.; Yang, M.-Y.; Hu, A.; Chen, L.-Y. Photo-catalytic polymerization of catechin molecules in alkaline aqueous. J. Photochem. Photobiol. B 2016, 165, 115–120. [Google Scholar] [CrossRef]

- Chung, J.E.; Kurisawa, M.; Kim, Y.-J.; Uyama, H.; Kobayashi, S. Amplification of Antioxidant Activity of Catechin by Polycondensation with Acetaldehyde. Biomacromolecules 2004, 5, 113–118. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Chung, J.E.; Kurisawa, M.; Uyama, H.; Kobayashi, S. Regioselective Synthesis and Structures of (+)-Catechin-Aldehyde Polycondensates. Macromol. Chem. Phys. 2003, 204, 1863–1868. [Google Scholar] [CrossRef]

- Sahiner, N. One step poly(quercetin) particle preparation as biocolloid and its characterization. Colloids Surf. A Physicochem. Eng. Asp. 2014, 452, 173–180. [Google Scholar] [CrossRef]

- Sahiner, N. One step poly(rutin) particle preparation as biocolloid and its characterization. Mater. Sci. Eng. C 2014, 44, 9–16. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A.; Piotrowska, M. Novel Polymeric Biomaterial Based on Naringenin. Materials 2021, 14, 2142. [Google Scholar] [CrossRef]

- Zaidun, N.H.; Thent, Z.C.; Latiff, A.A. Combating oxidative stress disorders with citrus flavonoid: Naringenin. Life Sci. 2018, 208, 111–122. [Google Scholar] [CrossRef]

- Rani, N.; Bharti, S.; Krishnamurthy, B.; Bhatia, J.; Sharma, C.; Kamal, M.A.; Ojha, S.; Arya, D.S. Pharmacological Properties and Therapeutic Potential of Naringenin: A Citrus Flavonoid of Pharmaceutical Promise. Curr. Pharm. Des. 2016, 22, 4341–4359. [Google Scholar] [CrossRef]

- Kurisawa, M.; Chung, J.E.; Uyama, H.; Kobayashi, S. Enzymatic Synthesis and Antioxidant Properties of Poly(rutin). Biomacromolecules 2003, 4, 1394–1399. [Google Scholar] [CrossRef]

- Anthoni, J.; Lionneton, F.; Wieruszeski, J.-M.; Magdalou, J.; Engasser, J.-M.; Chebil, L.; Humeau, C.; Ghoul, M. Investigation of enzymatic oligomerization of rutin. Rasayan J. Chem. 2008, 1, 718–731. [Google Scholar]

- Desentis-Mendoza, R.M.; Hernandez-Sanchez, H.; Moreno, A.; Rojas del, C.E.; Chel-Guerrero, L.; Tamariz, J.; Jaramillo-Flores, M.E. Enzymatic Polymerization of Phenolic Compounds Using Laccase and Tyrosinase from Ustilago maydis. Biomacromolecules 2006, 7, 1845–1854. [Google Scholar] [CrossRef]

- Hamada, S.; Kontani, M.; Hosono, H.; Ono, H.; Tanaka, T.; Ooshima, T.; Mitsunaga, T.; Abe, I. Peroxidase-catalyzed generation of catechin oligomers that inhibit glucosyltransferase from Streptococcus sobrinus. FEMS Microbiol. Lett. 1996, 143, 35–40. [Google Scholar] [CrossRef]

- Bruno, F.F.; Trotta, A.; Fossey, S.; Nagarajan, S.; Nagarajan, R.; Samuelson, L.A.; Kumar, J. Enzymatic Synthesis and Characterization of PolyQuercetin. J. Macromol. Sci.-Pure Appl. Chem. 2010, 47, 1191–1196. [Google Scholar] [CrossRef]

- Parker, F.S.; Hilger, A. Applications of IR Spectroscopy in Biochemistry, Biology and Medicine; Springer: London, UK, 1971. [Google Scholar]

- Quintanilla-Licea, R.; Vargas-Villarreal, J.; Verde-Star, M.J.; Rivas-Galindo, V.M.; Torres-Hernández, Á.D. Antiprotozoal Activity Against Entamoeba histolytica of Flavonoids Isolated from Lippia graveolens Kunth. Molecules 2020, 25, 2464. [Google Scholar] [CrossRef]

- Sigma-Aldrich. Laccase from Aspergillus sp. Available online: https://www.sigmaaldrich.com/PL/pl/product/sigma/sae0050 (accessed on 4 February 2022).

- Sigma-Aldrich. Peroxidase from Horseradish. Available online: https://www.sigmaaldrich.com/PL/pl/product/sigma/p6782 (accessed on 4 February 2022).

- Rabek, J. Współczesna Wiedza o Polimerach; PWN: Warsaw, Poland, 2008. [Google Scholar]

- Hernández-Aquino, E.; Muriel, P. Beneficial effects of naringenin in liver diseases: Molecular mechanisms. World J. Gastroenterol. 2018, 24, 1679–1707. [Google Scholar] [CrossRef]

- Simon, K.; Janocha, J. Epidemia EHEC (Escherichia coli O 104:H4) w Europie w 2011 roku—Problemy Kliniczne i Terapeutyczne. Przegl. Epidemiol. 2012, 66, 73–77. [Google Scholar]

- Su, Y.; Liu, C.; Fang, H.; Zhang, D. Bacillus subtilis: A universal cell factory for industry, agriculture, biomaterials and medicine. Microb. Cell Fact. 2020, 19, 173. [Google Scholar] [CrossRef]

- Abrahamian, F.M.; Snyder, E.W. Community-associated Methicillinresistant Staphylococcus aureus: Incidence, Clinical Presentation, and Treatment Decisions. Curr. Infect. Dis. Rep. 2007, 9, 391–397. [Google Scholar] [CrossRef]

- Panchal, P.; Pethani, J.; Patel, D.; Rathod, S.; Shah, P. Analysis of various fungal agents in clinically suspected cases of Otomycosis. Indian J. Basic Appl. Med. Res. 2013, 2, 865–869. [Google Scholar]

- Sudbery, P.E. Growth of Candida albicans hyphae. Nat. Rev. Microbiol. 2011, 9, 737–748. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Li, Q.; Bi, K.-S. Bioactive flavonoids in medicinal plants: Structure, activity and biological fate. Asian J. Pharm. Sci. 2018, 13, 12–23. [Google Scholar] [CrossRef]

- De Freitas Araújo, M.G.; Hilário, F.; Vilegas, W.; Dos Santos, L.C.; Brunetti, I.L.; Sotomayor, C.E.; Bauab, T.M. Correlation among Antioxidant, Antimicrobial, Hemolytic, and Antiproliferative Properties of Leiothrix spiralis Leaves Extract. Int. J. Mol. Sci. 2012, 13, 9260–9277. [Google Scholar] [CrossRef]

- El Khomsi, M.; Kara, M.; Hmamou, A.; Assouguem, A.; Al Kamaly, O.; Saleh, A.; Ercisli, S.; Fidan, H.; Hmouni, D. In Vitro Studies on the Antimicrobial and Antioxidant Activities of Total Polyphenol Content of Cynara humilis from Moulay Yacoub Area (Morocco). Plants 2022, 11, 1200. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A.; Piotrowska, M. Thermally Stable and Antimicrobial Active Poly(Catechin) Obtained by Reaction with a Cross-Linking Agent. Biomolecules 2020, 11, 50. [Google Scholar] [CrossRef]

- Zobeiri, M.; Belwal, T.; Parvizi, F.; Naseri, R.; Farzaei, M.H.; Nabavi, S.F.; Sureda, A. Naringenin and its Nano-formulations for Fatty Liver: Cellular Modes of Action and Clinical Perspective. Curr. Pharm. Biotechnol. 2018, 19, 196–205. [Google Scholar] [CrossRef]

- Masek, A.; Chrzescijanska, E.; Latos-Brozio, M.; Zaborski, M. Characteristics of juglone (5-hydroxy-1,4,-naphthoquinone) using voltammetry and spectrophotometric methods. Food Chem. 2019, 301, 125279. [Google Scholar] [CrossRef]

| Sample | Mn (g/mol) | Mw/Mn |

|---|---|---|

| Naringenin | below the measuring range | |

| Poly(naringenin)-laccase | 4.584 × 103 | 1.040 |

| Poly(naringenin)-HRP | 9.972 × 102 | 1.392 |

| Method | Parameter | Naringenin | Poly(Naringenin)-Laccase | Poly(Naringenin)-HRP |

|---|---|---|---|---|

| ABTS | Inhibition ABTS+• (%) | 55.0 ± 0.22 | 85.7 ± 0.28 | 30.4 ± 0.16 |

| TEAC (mmolT/100 g) | 28.4 ± 0.12 | 93.5 ± 0.31 | 33.1 ± 0.17 | |

| DPPH | Inhibition DPPH• (%) | 1.0 ± 0.01 | no activity | 0.2 ± 0.01 |

| TEAC (mmolT/100 g) | 0.9 ± 0.02 | no activity | 0.2 ± 0.02 | |

| FRAP | ΔA (-) | 0.05 ± 0.002 | 0.03 ± 0.002 | 0.02 ± 0.001 |

| CUPRAC | ΔA (-) | 1.9 ± 0.11 | 0.402 ± 0.002 | no activity |

| T10 | T20 | T30 | T50 | T55 | T60 | |

|---|---|---|---|---|---|---|

| Naringenin | 307 | 322 | 337 | 436 | 518 | 591 |

| Poly(naringenin)-laccase | 213 | 356 | 800 | - | - | - |

| Poly(naringenin)-HRP | 173 | 302 | 365 | 593 | 772 | - |

| Sample | Tg (°C) | ΔHm (J/g) | Tm (°C) | ΔHo (J/g) | To (°C) |

|---|---|---|---|---|---|

| Naringenin | - | 164.3 | 252.9 | 88.4 | 281.3 (initial) 330.5 (final) |

| Poly(naringenin)-laccase | 66.6 | 162.4 | 182.9 | 182.2 | 295.0 (initial) 358.7 (final) |

| Poly(naringenin)-HRP | - | 220.7 | 25.3 | 679.5 | 299.7 (initial) 354.1 (final) |

| Sample | Concentration (mg/mL) | Escherichia coli | Staphylococus aureus | Bacillus subtilis | Aspergillus niger | Candida albicans |

|---|---|---|---|---|---|---|

| Growth Inhibition Zone (mm) | ||||||

| Naringenin | 1 | 0.0 ± 0.0 | 18.1 ± 0.6 * | 23.0 ± 2.0 | 30.0 ± 0.6 | 22.3 ± 1.5 |

| 5 | 0.0 ± 0.0 | 22.0 ± 1.0 | 33.0 ± 1.0 | 32.0 ± 1.0 | 24.0 ± 1.7 | |

| 10 | 22.0 ± 1.0 | 30.0 ± 2.0 | 34.0 ± 1.7 | 35.0 ± 1.0 | 24.3 ± 0.6 | |

| Poly(naringenin)-laccase | 1 | 20.0 ± 1.0 * | 0.0 ± 0.0 | 22.0 ± 0.0 * | 28.0 ± 1.0 | 26.3 ± 0.6 |

| 5 | 20.3 ± 0.6 | 0.0 ± 0.0 | 23.3 ± 0.6 | 28.0 ± 0.0 | 26.0 ± 1.0 | |

| 10 | 22.0 ± 1.0 | 18.3 ± 0.6 | 25.0 ± 1.0 | 30.3 ± 0.6 | 27.7 ± 0.6 | |

| Microorganisms | Species | Collection Number | |

|---|---|---|---|

| Bacteria | Escherichia coli | ATCC 10536 | |

| Staphylococcus aureus | ATCC 6538 | ||

| Bacillus subtilis | NCAIM 01644 | ||

| Fungus | Yeast | Candida albicans | ATCC 10231 |

| Molds | Aspergillus niger | ATCC 16404 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latos-Brozio, M.; Masek, A.; Piotrowska, M. Polymeric Forms of Plant Flavonoids Obtained by Enzymatic Reactions. Molecules 2022, 27, 3702. https://doi.org/10.3390/molecules27123702

Latos-Brozio M, Masek A, Piotrowska M. Polymeric Forms of Plant Flavonoids Obtained by Enzymatic Reactions. Molecules. 2022; 27(12):3702. https://doi.org/10.3390/molecules27123702

Chicago/Turabian StyleLatos-Brozio, Malgorzata, Anna Masek, and Małgorzata Piotrowska. 2022. "Polymeric Forms of Plant Flavonoids Obtained by Enzymatic Reactions" Molecules 27, no. 12: 3702. https://doi.org/10.3390/molecules27123702

APA StyleLatos-Brozio, M., Masek, A., & Piotrowska, M. (2022). Polymeric Forms of Plant Flavonoids Obtained by Enzymatic Reactions. Molecules, 27(12), 3702. https://doi.org/10.3390/molecules27123702