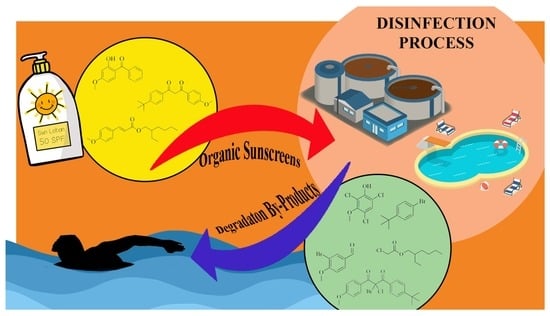

Environmental Fate of Organic Sunscreens during Water Disinfection Processes: The Formation of Degradation By-Products and Their Toxicological Profiles

Abstract

:1. Introduction

2. Discussion

2.1. UVA Chemical Filters: Benzophenone Derivatives

2.1.1. 2-Benzoyl-5-methoxyphenol (BP-3)

2.1.2. 5-Benzoyl-4-hydroxy-2-methoxybenzenesulfonic Acid (PB-4)

2.1.3. 4-Methoxy-2,2′-dihydroxy-benzophenone (PB-8)

2.1.4. Hexyl 2-(4-diethylamino-2-hydroxybenzoyl)benzoate (DHHB)

2.1.5. 2-Ethylhexyl-2-cyano-3,3-diphenylacrylate (OC)

2.2. UVA Chemical Filters: Dibenzoylmethane Derivatives

4-Tert-butyl-4′-methoxy-dibenzoylmethane (AVO)

2.3. UVB Chemical Filters: Derivatives of p-Aminobenzoic Acid

2.3.1. 2-Ethylhexyl 4-(Dimethylamino)benzoate (EHPABA)

2.3.2. 2-Ethylhexyl 4-Methoxybenzoate (EHMB)

2.4. UVB Chemical Filters: Derivatives of Salicylic Acid

2-Ethylhexyl Salicylate (ES)

2.5. UVB Chemical Filters: Derivatives of Cinnamic Acid

2.5.1. 4-Methoxycinnamic Acid (MCA)

2.5.2. 2-Ethylhexyl Methoxycinnamate (EHMC)

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Butt, S.T.; Christensen, T. Toxicity and phototoxicity of chemical sun filters. Radiat. Prot. Dosim. 2000, 91, 283–286. [Google Scholar] [CrossRef]

- Krause, M.; Klit, A.; Jensen, M.B.; Søeborg, T.; Frederiksen, H.; Schlumpf, M.; Lichtensteiger, W.; Skakkebaek, N.E.; Drzewiecki, K.T. Sunscreens: Are they beneficial for health? An overview of endocrine disrupting properties of UV-filters. Int. J. Androl. 2012, 35, 424–436. [Google Scholar] [CrossRef] [PubMed]

- Krause, M.; Frederiksen, H.; Sundberg, K.; Jørgensen, F.S.; Jensen, L.N.; Nørgaard, P.; Jørgensen, C.; Ertberg, P.; Petersen, J.H.; Feldt-Rasmussen, U.; et al. Maternal exposure to UV filters: Associations with maternal thyroid hormones, IGF-I/IGFBP3 and birth outcomes. Endocr. Connect. 2018, 7, 334–346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schlumpf, M.; Schmid, P.; Durrer, S.; Conscience, M.; Maerkel, K.; Henseler, M.; Gruetter, M.; Herzog, I.; Reolon, S.; Ceccatelli, R.; et al. Endocrine activity and developmental toxicity of cosmetic UV filters-an update. Toxicology 2004, 205, 113–122. [Google Scholar] [CrossRef]

- Rodil, R.; Moeder, M. Development of a method for the determination of UV filters in water samples using stir bar sorptive extraction and thermal desorption–gas chromatography–mass spectrometry. J. Chromatogr. A 2008, 1179, 81–88. [Google Scholar] [CrossRef]

- Agrapidis-Paloympis, L.E.; Nash, R.A.; Shaath, N.A. The effect of solvents on the ultraviolet absorbance of sunscreens. J. Soc. Cosmet. Chem. 1987, 38, 209–221. [Google Scholar]

- Onoue, S.; Yamauchi, Y.; Kojima, T.; Igarashi, N.; Tsuda, Y. Analytical studies on photochemical behavior of phototoxic substances; effect of detergent additives on singlet oxygen generation. Pharm. Res. 2008, 5, 861–868. [Google Scholar] [CrossRef]

- Grbović, G.; Malev, O.; Dolenk, D.; Klobucar, R.S.; Cvetkovic, Z.; Cvetkovic, B.; Jovanclevic, B.; Trebse, P. Synthesis, characterization and aquatic ecotoxicity of the UV filter hexyl 2-(4-diethylamino-2-hydroxybenzoyl) benzoate (DHHB) and its chlorinated by-products. Environ. Chem. 2016, 13, 119–126. [Google Scholar] [CrossRef] [Green Version]

- Moreira, S.A.J.; da Silva, J.C.G.E. Degradation studies of UV filter hexyl 2-4-(diethylamino)-2-hydroxybenzoyl.-benzoate (DHHB) in aqueous solution. J. Contam. Hydrol. 2020, 236, 103740. [Google Scholar] [CrossRef]

- Bachelot, M.; Zhi, L.; Munaron, D.; Le Gall, P.; Casellasd, C.; Fenet, H.; Gomez, E. Organic UV filter concentrations in marine mussels from French coastal regions. Sci. Total Environ. 2012, 420, 273–279. [Google Scholar] [CrossRef]

- Matsumoto, S.; Kumasaka, R.; Yagi, M.; Kikuchi, A. Triplet–triplet energy transfer between UV absorbers in solutions at room temperature. J. Photochem. Photobiol. A Chem. 2017, 346, 396–400. [Google Scholar] [CrossRef]

- Oliveira, H.M.; Segundo, M.; Lima, J.; Mirò, M.; Cerdà, V. On-line renewable solid-phase extraction hyphenated to liquid chromatography for the determination of UV filters using bead injection and multisyringe-lab-on-valve approach. J. Chromatogr. A 2010, 1217, 3575–3582. [Google Scholar] [CrossRef] [PubMed]

- Zawadiak, J.; Mrzyczek, M. Influence of substituent on UV absorption and keto–enol tautomerism equilibrium of dibenzoylmethane derivatives. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 96, 815–819. [Google Scholar] [CrossRef]

- Nakajima, M.; Kawakami, T.; Niino, T.; Takahasahi, Y.; Onodera, S. Aquatic fate of sunscreen agents octyl-4-methoxycinnamate and octyl-4-dimethylaminobenzoate in model swimming pools and the mutagenic assays of their chlorination byproducts. J. Health Sci. 2009, 55, 363–372. [Google Scholar] [CrossRef] [Green Version]

- Bestak, R.; St Barnetson, R.C.; Nearn, M.R.; Halliday, G.M. Sunscreen protection of contact hypersensitivity responses from chronic solar-simulated ultraviolet irradiation correlates with the absorption spectrum of the sunscreen. J. Investig. Dermatol. 1995, 105, 345–351. [Google Scholar] [CrossRef] [Green Version]

- Krishnan, R.; Carr, A.; Blair, E.; Nordlund, T.M. Optical spectroscopy of hydrophobic sunscreen molecules adsorbed to dielectric nanospheres. Photochem. Photobiol. 2004, 79, 531–539. [Google Scholar] [CrossRef] [PubMed]

- Krishnan-2, R.; Elmets, C.A.; Nordlund, T.M. A new method to test the effectiveness of sunscreen ingredients in a novel nano-surface skin cell mimic. Photochem. Photobiol. 2006, 82, 1549–1556. [Google Scholar] [CrossRef]

- Johns, N. Synthesis and characterisation of acyl coenzyme A derivatives of aromatic carboxylic acids. Z. Nat. C 1974, 29, 469–474. [Google Scholar] [CrossRef]

- Richardson, S.D. Water analysis: Emerging contaminants and current issues. Anal. Chem. 2009, 81, 4645–4677. [Google Scholar] [CrossRef]

- Balmer, M.E.; Buser, H.R.; Müller, M.D.; Poiger, T. Occurrence of some organic UV filters in wastewater, in surface waters, and in fish from Swiss lakes. Environ. Sci. Technol. 2005, 39, 953–962. [Google Scholar] [CrossRef]

- Gago-Ferrero, P.; Alonso, M.B.; Bertozzi, C.P.; Marigo, J.; Barbosa, L.; Cremer, M.; Secchi, E.R.; Azevedo, A.; Lailson-Brito, J.; Torres, J.P.M.; et al. First determination of UV filters in marine mammals. Octocrylene levels in Franciscana dolphins. Environ. Sci. Technol. 2013, 47, 5619–5625. [Google Scholar] [CrossRef] [PubMed]

- Tsui, M.M.P.; Leung, H.W.; Lam, P.K.S.; Murphy, M.B. Seasonal occurrence, removal efficiencies and preliminary risk assessment of multiple classes of organic UV filters in wastewater treatment plants. Water Res. 2014, 53, 58–67. [Google Scholar] [CrossRef] [PubMed]

- Tsui, M.M.; Leung, H.W.; Wai, T.C.; Yamashita, N.; Taniyasu, S.; Liu, W.; Lam, P.K.; Murphy, M.B. Occurrence, distribution and ecological risk assessment of multiple classes of UV filters in surface waters from different countries. Water Res. 2014, 15, 55–65. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.P.; Shi, Z.G.; Yu, Q.W.; Feng, Y.Q. A new device for magnetic stirring-assisted dispersive liquid–liquid microextraction of UV filters in environmental water samples. Talanta 2011, 83, 1711–1715. [Google Scholar] [CrossRef]

- Jurado, A.; Gago-Ferrero, P.; Vàzquez-Suñé, E.; Carrera, J.; Pujades, E.; Díaz-Cruz, M.S.; Barceló, D. Urban groundwater contamination by residues of UV filters. J. Hazard. Mater. 2014, 271, 141–149. [Google Scholar] [CrossRef]

- Kim, S.; Choi, K. Occurrences, toxicities, and ecological risks of benzophenone-3, a common component of organic sunscreen products: A mini-review. Environ. Int. 2014, 70, 143–157. [Google Scholar] [CrossRef]

- Rodil, R.; Quintana, J.B.; Concha-Graña, E.; López-Mahía, P.; Muniategui-Lorenzo, S.; Prada-Rodríguez, D. Emerging pollutants in sewage, surface and drinking water in Galicia (NW Spain). Chemosphere 2012, 86, 1040–1049. [Google Scholar] [CrossRef]

- Renegar, A.; Dudley, D.K. Interpreting Risk from Sunscreens in the Marine Environment. Chall. Sun Prot. 2021, 55, 259–265. [Google Scholar] [CrossRef]

- Barón, E.; Gago-Ferrero, P.; Gorga, M.; Rudolph, I.; Mendoza, G.; Zapata, A.M.; Díaz-Cruz, S.; Barra, R.; Ocampo-Duque, W.; Páez, M.; et al. Occurrence of hydrophobic organic pollutants (BFRs and UV-filters) in sediments from South America. Chemosphere 2013, 2, 309–316. [Google Scholar] [CrossRef]

- Tovar-Sánchez, A.; Sánchez-Quiles, D.; Basterretxea, G.; Benedé, J.L.; Chisvert, A.; Salvador, A.; Moreno-Garrido, I.; Blasco, J. Sunscreen products as emerging pollutants to coastal waters. PLoS ONE 2013, 8, e65451. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Quiles, D.; Tovar-Sánchez, A. Are sunscreens a new environmental risk associated with coastal tourism? Environ. Int. 2015, 83, 158–170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Negreira, N.; Canosa, I.; Rodrìguez, I.; Ramil, M.; Rubì, E.; Cela, R. Study of some UV filters stability in chlorinated water and identification of halogenated by-products by gas chromatography–mass spectrometry. J. Chromatogr. A 2008, 1178, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Manasfi, T.; Storck, V.; Ravier, S.; Demelas, C.; Coulomb, B.; Boudenne, J.L. Degradation products of benzophenone-3 in chlorinated seawater swimming pools. Environ. Sci. Technol. 2015, 49, 9308–9316. [Google Scholar] [CrossRef] [PubMed]

- Shujuan, Z.; Xiaomao, W.; Hongwei, Y.; Yufeng, F.X. Chlorination of oxybenzone: Kinetics, transformation, disinfection byproducts formation, and genotoxicity changes. Chemosphere 2016, 154, 521–527. [Google Scholar] [CrossRef]

- Young-Min, L.; Moon-Kyung, K.; Kiung-Duk, Z.; Gowoon, L. Kinetics and degradation mechanism of Benzophenone-3 in chlorination and UV/chlorination reactions. Chem. Eng. J. 2020, 393, 124780. [Google Scholar] [CrossRef]

- Yang, F.; Wei, D.; Xiao, M.; Sun, X.; Guo, Q.; Liu, Y.; Du, Y. The chlorination transformation characteristics of benzophenone-4 in the presence of iodide ions. J. Environ. Sci. 2017, 58, 93–101. [Google Scholar] [CrossRef]

- Negreira, N.; Rodriguez, I.; Rodil, R.; Cela, R. Assessment of benzophenone-4 reactivity with free chlorine by liquid chromatography quadrupole time-of-flight mass spectrometry. Anal. Chim. Acta 2012, 743, 101–110. [Google Scholar] [CrossRef]

- Manasfi, T.; Coulomb, B.; Ravier, S.; Boudenne, J.L. Degradation of organic UV filters in chlorinated seawater swimming pools: Transformation pathways and bromoform formation. Environ. Sci. Technol. 2017, 51, 13580–13591. [Google Scholar] [CrossRef] [Green Version]

- Crista, D.M.A.; Margarida, S.M.; da Silva, J.C.G.E. Degradation in chlorinated water of the UV filter 4-tert-butyl-4′-methoxydibenzoylmethane present in commercial sunscreens. Environ. Technol. 2015, 36, 1319–1326. [Google Scholar] [CrossRef]

- Chai, Q.; Zhang, S.; Wang, X.; Yang, H.; Xie, I.F. Effect of bromide on the transformation and genotoxicity of octyl-dimethyl-p-aminobenzoic acid during chlorination. J. Hazard. Mater. 2017, 324, 626–633. [Google Scholar] [CrossRef]

- Kalister, K.; Dolenc, S.; Sarakha, M.; Polyakova, O.V.; Lebedev, A.T.; Trebse, P. A chromatography-mass spectrometry study of aquatic chlorination of UV-filter avobenzone. J. Anal. Chem. 2016, 71, 1289–1293. [Google Scholar] [CrossRef]

- Trebše, P.; Polyakova, O.V.; Baranova, M.; Kralj, M.B.; Dolenc, D.; Sarakha, M.; Kutin, A.; Lebedev, A.T. Transformation of avobenzone in conditions of aquatic chlorination and UV-irradiation. Water Res. 2016, 101, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Detenchuk, E.A.; Chen, J.; Polyakova, O.; Trebse, P.; Pokryshkin, S.; Lebedev, A. Study of the aquatic chlorination of UV filter avobenzone in the presence of inorganic salts by Gas Chromatography–High-Resolution Mass Spectrometry. J. Anal. Chem. 2019, 74, 1271–1276. [Google Scholar] [CrossRef]

- Lebedev, A.T.; Kralj, M.B.; Polyakova, O.V.; Detenchuk, E.A.; Pokryshkin, S.A.; Trebse, P. Identification of avobenzone by-products formed by various disinfectants in different types of swimming pool waters. Environ. Int. 2020, 137, 105495. [Google Scholar] [CrossRef]

- Chugunova, A.A. Study of the chlorination of avobenzone in sea water by gas chromatography–high resolution mass spectrometry. J. Anal. Chem. 2017, 72, 1369–1374. [Google Scholar] [CrossRef]

- Gackowska, A.; Przybylek, M.; Studzinski, W.; Gaca, J. Formation of chlorinated breakdown products during degradation of sunscreen agent, 2-ethylhexyl-4-methoxycinnamate in the presence of sodium hypochlorite. Environ. Sci. Pollut. Res. 2016, 23, 1886–1897. [Google Scholar] [CrossRef] [Green Version]

- Kosaka, K.; Nakai, T.; Hishida, Y.; Asami, M.; Ohkubo, K.; Akiba, M. Formation of 2,6-dichloro-1, 4-benzoquinone from aromatic compounds after chlorination. Water Res. 2017, 110, 48–55. [Google Scholar] [CrossRef]

- Available online: http://www.aipras.org/ (accessed on 10 June 2022).

| Abbreviation | Name | Commercial Names | CAS Number |

|---|---|---|---|

| BP-3; OXY | 2-Benzoyl-5-methoxyphenol | Benzophenone-3; Eusolex 4360; Escalol 567; Uvinul 3040 | 131-57-7 |

| BP-4 | 5-Benzoyl-4-hydroxy-2-methoxybenzenesulfonic acid | Benzophenone-4; Escalol 577; Uvasorb S 5; Uvinul D 5030 | 4065-45-6 |

| BP-8; DIOXY; DMB | 4-Methoxy-2,2′-dihydroxy-benzophenone | Benzophenone-8; Dioxibenzone; Evesorb 52; Cyasorb UV 24 | 131-53-3 |

| DHHB | Hexyl 2-(4-diethylamino-2-hydroxybenzoyl)benzoate | Uvinocamphor l Plus A; Uvinul A+ | 302776-68-7 |

| OC | 2-Ethylhexyl-2-cyano-3,3-diphenylacrylate | Octocrylene; Escalol 597; Uvinul 3039; Uvinul N 539 | 6197-30-4 |

| AVO; BMDM | 4-tert-Butyl-4′-methoxy-dibenzoylmethane | Avobenzone; Parsol 1789; Eusolex 9020 | 70356-09-1 |

| EHPABA; EHDAB; ODPABA | 2-Ethylhexyl 4-(dimethylamino)benzoate | Ethylhexyl dimethyl paba; Padimate O; Chemcure EHA; Escalol 507 | 21245-02-3 |

| PABA | 2-Ethylhexyl 4-aminobenzoate | Vitamin Bx | 26218-04-2 |

| EHMB | 2-Ethylhexyl 4-methoxybenzoate | - | 16451-27-7 |

| ES | 2-Ethylhexyl salicylate | Soct; Sunobe OS | 118-60-5 |

| MCA | 4-Methoxycinnamic acid | NSC 5303 | 830-09-1 |

| EHMC | 2-Ethylhexyl methoycinnamate | Escalol 557; Parsol MCX; Uvinul 3088; Octinoxate | 5466-77-3 |

| Abbreviation | MS | Formula | ε (L mol−1 cm−1) | Octanol–Water Partition Coefficient (Log Kow) | Solubility (g L−1 at 25 °C and pH 6–7) | Refs. |

|---|---|---|---|---|---|---|

| BP-3 | 228.24 | C14H12O3 | 9300 at λ = 321 nm | 3.79 | [5,6] | |

| BP-4 | 308.31 | C14H12O6S | 6700 at λ = 319 nm | 6.3 | [7] | |

| BP-8 | 224.24 | C14H12O4 | 9400 at λ = 326 nm | 4.31 | [6] | |

| DHHB | 397.51 | C24H31NO4 | 35,900 at λ = 355 nm | 6.93 | 9.5 × 10−4 | [8,9] |

| OC | 361.48 | C24H27NO2 | 1300 at λ = 355 nm | 6.88 | 3.81 × 10−6 | [5,10,11] |

| AVO | 310.39 | C20H22O3 | 33,756 at λ = 360 nm | 4.51 | [5,12,13] | |

| EHPABA | 277.40 | C17H27NO2 | 28,400 at λ = 316 nm | 5.76 | 5.3 × 10−6 | [5,6,10,14] |

| PABA | 249.35 | C15H23NO2 | 19,300 at λ = 282 nm | 4.22 | [15,16] | |

| EHMB | 290.40 | C18H26O3 | 24,200 at λ = 312 nm | 5.80 | 1.55 × 10−4 | [5,6,10] |

| ES | 250.33 | C15H22O3 | 5200 at λ = 260 nm | 5.97 | [5,17] | |

| MCA | 178.18 | C10H10O3 | 18,800 at λ = 329 nm | [18] | ||

| EHMC | 290.40 | C18H26O3 | 24,200 at λ = 312 nm | 5.80 | [6,14] |

| AVO/ | Common Name | NaOCl | Refs. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | Br− | I− | Cu2+ | Fe3+ | SPW | SW | DOM | hν | |||

| 1 | Anisole | ✓ | [45] | ||||||||

| 2 | Anisole, 2-chloro | ✓ | [42] | ||||||||

| 3 | Anisole, 2,4-dichloro | ✓ | ✓ | [42,43] | |||||||

| 4 | Anisole, 2,4,6-trichloro | ✓ | [42] | ||||||||

| 5 | Anisole, 4-acetyl | ✓ | ✓ | ✓ | [43,45] | ||||||

| 6 | Anisole, 4-bromo | ✓ | ✓ | ✓ | [43,44,45] | ||||||

| 7 | Anisole, 4-chloro | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,45] | ||||

| 8 | Anisole, 2,4-dibromo | ✓ | ✓ | [43,45] | |||||||

| 10 | Hydroquinone | ✓ | [44,45] | ||||||||

| 12 | Acetophenone, 4-hydroxy | ✓ | [45] | ||||||||

| 13 | Benzoic acid, 4-hydroxy | ✓ | [45] | ||||||||

| 14 | Phenol, 4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||||

| 15 | Phenol, 3-bromo-4-methoxy | ✓ | [44,45] | ||||||||

| 16 | Phenol, 3-chloro-4-methoxy | ✓ | [42] | ||||||||

| 17 | Phenol, 4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||

| 18 | Phenol, 2-bromo-4-tert-butyl | ✓ | [45] | ||||||||

| 20 | Phenol, 3,5-dibromo-4-tert-butyl | ✓ | [44] | ||||||||

| 21 | Phenol, 4-bromo | ✓ | [44,45] | ||||||||

| 24 | Benzaldehyde, 4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | |

| 25 | Benzaldehyde, 3-bromo-4-methoxy | ✓ | [37,45] | ||||||||

| 26 | Benzoic acid, 4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||

| 27 | Benzoic acid, 3-chloro-4-methoxy | ✓ | [42] | ||||||||

| 28 | Benzoyl bromide, 4-methoxy | ✓ | [45] | ||||||||

| 29 | Benzoyl chloride, 4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||

| 31 | Benzoyl acetic acid, 4-methoxy | ✓ | ✓ | ✓ | ✓ | [43,44] | |||||

| 32 | Acetophenone, 4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [43,44] | |||

| 33 | Acetophenone, α-bromo-4-methoxy | ✓ | ✓ | ✓ | [43,44,45] | ||||||

| 34 | Acetophenone, α,α-dibromo-4-methoxy | ✓ | [45] | ||||||||

| 35 | Acetophenone, α-chloro-4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | [41,42,43] | ||||

| 36 | Acetophenone, α,α-dichloro-4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43] | |||

| 37 | Acetophenone, α,α,α-trichloro-4-methoxy | ✓ | [42] | ||||||||

| 38 | Acetophenone, α-hydroxy-4-methoxy | ✓ | ✓ | ✓ | ✓ | ✓ | [42,45] | ||||

| 39 | Acetophenone, α-iodo-4-methoxy | ✓ | ✓ | [42] | |||||||

| 40 | Acetophenone, 3-bromo-4-methoxy | ✓ | [44,45] | ||||||||

| 41 | Acetophenone, 3-chloro-4-methoxy | ✓ | [45] | ||||||||

| 42 | Acetophenone, α,α-dibromo, α-chloro-4-methoxy | ✓ | [45] | ||||||||

| 43 | Benzene, tert-butyl | ✓ | [44,45] | ||||||||

| 44 | Benzene, 1-bromo-4-tert-butyl | ✓ | [44,45] | ||||||||

| 45 | Benzene, 1-chloro-4-tert-butyl | ✓ | [42] | ||||||||

| 46 | Benzaldehyde, 4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||

| 47 | Benzoic acid, 4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | |

| 48 | Benzoyl bromide, 4-tert-butyl | ✓ | [45] | ||||||||

| 49 | Benzoyl chloride, 4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,45] | ||

| 51 | Benzoyl acetic acid, 4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [43] | ||

| 52 | Acetophenone, 4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [43,44,45] | ||

| 53 | Acetophenone, 2-chloro-4-tert-butyl | ✓ | ✓ | [45] | |||||||

| 54 | Acetophenone, α-bromo-4-tert-butyl | ✓ | ✓ | ✓ | [43,44,45] | ||||||

| 55 | Acetophenone, α,α-dibromo-4-tert-butyl | ✓ | [45] | ||||||||

| 56 | Acetophenone, α-bromo,α- carboxy-4-tert-butyl | ✓ | [45] | ||||||||

| 57 | Acetophenone, α-chloro-4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,45] | |||

| 58 | Acetophenone, α,α-dichloro-4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,45] | |

| 59 | Acetophenone, α,α,α-trichloro-4-tert-butyl | ✓ | ✓ | [42] | |||||||

| 60 | Acetophenone, α-hydroxy-2-bromo -4-tert-butyl | ✓ | ✓ | ✓ | ✓ | ✓ | [43] | ||||

| 61 | Acetophenone, α-iodo-2-chloro-4-tert-butyl | ✓ | ✓ | [43] | |||||||

| 62 | Chloroavobenzone | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||

| 63 | Dichloroavobenzone | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [42,43,44,45] | ||

| 64 | Bromoavobenzone | ✓ | ✓ | ✓ | [40,43,44,45] | ||||||

| 65 | Dibromoavobenzone | ✓ | ✓ | ✓ | [40,43] | ||||||

| 66 | Bromo-chloroavobenzone | ✓ | ✓ | [43] | |||||||

| 68 | 1-(4-tert-Butyl)phenyl-3-(4-methoxy)- Phenyl propantrione-1,2,3 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [43,44,45] | |||

| 69 | 1-(4-tert-Butyl)phenyl-2-(4-methoxy)- phenylethandione-1,2 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | [43,44,45] | |||

| 70 | 4-tert-Butyl-3′-chloro-4′- methoxydibenzoylmethane | ✓ | [39] | ||||||||

| 71 | 4-tert-Butyl-3′,5′-dichloro-4′- methoxydibenzoylmethane | ✓ | [39] | ||||||||

| Bromoform (4) | ✓ | [40] | |||||||||

| No. | Common Name | Treatment | Refs. | |

|---|---|---|---|---|

| hν | NaOBr | |||

| 1 | Anisole | ✓ | [45] | |

| 9 | Anisole, 2,6-dibromo | ✓ | [44] | |

| 10 | Hydroquinone | ✓ | [44,45] | |

| 11 | Hydroquinone, 2-bromo | ✓ | [44] | |

| 14 | Phenol, 4-methoxy | ✓ | ✓ | [42,43,44,45] |

| 15 | Phenol, 3-bromo-4-methoxy | ✓ | [44,45] | |

| 17 | Phenol, 4-tert-butyl | ✓ | ✓ | [42,43,44,45] |

| 19 | Phenol, 2,6-dichloro-4-tert-butyl | ✓ | [42] | |

| 22 | Phenol, 2,6-dibromo | ✓ | [44] | |

| 23 | Phenol, 2,4,6-trichloro | ✓ | [42] | |

| 24 | Benzaldehyde, 4-methoxy | ✓ | ✓ | [42,43,44,45] |

| 25 | Benzaldehyde, 3-bromo-4-methoxy | ✓ | [44,45] | |

| 26 | Benzoic acid, 4-methoxy | ✓ | ✓ | [42,43,44,45] |

| 30 | Benzoyl formic acid, 4-methoxy | ✓ | [44] | |

| 31 | Benzoyl acetic acid, 4-methoxy | ✓ | [43,44] | |

| 32 | Acetophenone, 4-methoxy | ✓ | [44] | |

| 33 | Acetophenone, α-bromo-4-methoxy | ✓ | [43,44,45] | |

| 40 | Acetophenone, 3-bromo-4-methoxy | ✓ | [44,45] | |

| 43 | Benzene, tert-butyl | ✓ | [44,45] | |

| 44 | Benzene, 1-bromo-4-tert-butyl | ✓ | [44,45] | |

| 46 | Benzaldehyde, 4-tert-butyl | ✓ | ✓ | [42,43,44,45] |

| 47 | Benzoic acid, 4-tert-butyl | ✓ | ✓ | [42,43,44,45] |

| 50 | Benzoyl formaldehyde, 4-tert-butyl | ✓ | [44] | |

| 52 | Acetophenone, 4-tert-butyl | ✓ | [43,44,45] | |

| 53 | Acetophenone, 2-chloro-4-tert-butyl | ✓ | [45] | |

| 54 | Acetophenone, α-bromo-4-tert-butyl | ✓ | [43,44,45] | |

| 64 | Bromoavobenzone | ✓ | [40,43,44,45] | |

| 67 | Hydroxyavobenzone | ✓ | [44] | |

| 68 | ArCOCOCOAr’ | ✓ | [43,44,45] | |

| 69 | ArCOCOAr’ | ✓ | [43,44,45,46] | |

| 72 | AVO-8 | ✓ | [44] | |

| 73 | AVO-9 | ✓ | [44] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medici, A.; Luongo, G.; Di Fabio, G.; Zarrelli, A. Environmental Fate of Organic Sunscreens during Water Disinfection Processes: The Formation of Degradation By-Products and Their Toxicological Profiles. Molecules 2022, 27, 4467. https://doi.org/10.3390/molecules27144467

Medici A, Luongo G, Di Fabio G, Zarrelli A. Environmental Fate of Organic Sunscreens during Water Disinfection Processes: The Formation of Degradation By-Products and Their Toxicological Profiles. Molecules. 2022; 27(14):4467. https://doi.org/10.3390/molecules27144467

Chicago/Turabian StyleMedici, Antonio, Giovanni Luongo, Giovanni Di Fabio, and Armando Zarrelli. 2022. "Environmental Fate of Organic Sunscreens during Water Disinfection Processes: The Formation of Degradation By-Products and Their Toxicological Profiles" Molecules 27, no. 14: 4467. https://doi.org/10.3390/molecules27144467

APA StyleMedici, A., Luongo, G., Di Fabio, G., & Zarrelli, A. (2022). Environmental Fate of Organic Sunscreens during Water Disinfection Processes: The Formation of Degradation By-Products and Their Toxicological Profiles. Molecules, 27(14), 4467. https://doi.org/10.3390/molecules27144467