Recent Advances in the Synthesis of Inorganic Materials Using Environmentally Friendly Media

Abstract

:1. Introduction

2. Brief Description of Deep Eutectic Solvents

3. DES in Nanoparticle Synthesis from Their Birth to 2020

4. Research on DES Blooms: From 2020 up to Now

| Solvent | Reagents/Path | Product | References |

|---|---|---|---|

| ChCl:urea 1:2 | Preparation of separate solutions of HAuCl4⋅4 H2O (0.015 g) and L-ascorbic acid (LA, 0.05 g) in DES. Addition of LA solution to HAuCl4 at 30 °C under magnetic stirring until the color changes from yellow to dark purple | Au nanoparticles Star, snowflake, or nano-thorn-shaped depending on water content | [49] (Figure 2) |

| Direct electrodeposition on GC substrate in 19.3 mM H2PtCl6/DESs solution at 80 °C | Tetrahexahedral (THH) concave Pt NCs | [52] | |

| Triambic Icosahedral Pt NCs | [54] | ||

| Mixing CuCl2·2H2O (5.0013 g, 0.0293 mol) and Cu powder (1.6935 g, 0.0265 mol) with DES, gentle stirring at 20 °C for 5 h, rinsing with diluted HCl | CuCl nanocrystal powder | [56] | |

| Addition of 2.2232 g of CuCl2 2H2O and 1.3754 g of ascorbic acid to 14 mL DES in the presence of PVP, mild stirring at 25 °C for 1 h, rinsing with 50 mL HCl (0.1 M) | Spherical CuCl nanoparticles | [57] | |

| Addition of 2.164 g (8 mmol) FeCl3·6H2O and 1.194 g (6 mmol) FeCl2·4H2O to 15.585 g DES, stirring at ca. 600 rpm and 80 °C for 20 min, subsequent addition of 2.613 g (46.7 mmol) KOH, and stirring for another 1.5 h at 80 °C. Alternatively, see Figure 5 and last paragraph | Spherical, magnetic Fe3O4 nanoparticles | [58]; Figure 5 and last paragraph | |

| Solvent: 35.70 g of DES (30 mL at 37 °C) and 6 mL of water. Dissolution of thioacetamide (TH, 12 mmol, 0.9134 g) mL into 12 mL of solvent and lead (IV) acetate (LAC, 12 mmol, 5.3206 g) into the remaining liquid, stirring of both solutions at 80 °C. Injection of TH into LAC changes the solution from pale yellow to opaque dark brown. Rinsing with water, followed by dialysis, centrifugation, and drying in furnace at T ≤ 80 °C | Hyperbranched PbS Nano/microcrystals | [59] | |

| Heating of NiCl2·6H2O in DES (0.1 M solution) at 150 °C for 40 min; then addition of 10 mL of water and further stirring for 20 min, cooling in ice bath; drying of precursor overnight at 90 °C and further annealing in air (300 °C) for 4 h | Mesoporous NiO | [60] | |

| NiCl2·6H2O in DES ionothermal reactions at different temperatures and conditions | Ni(NH3)6Cl2, NiCl2 and nanoflower-like α-Ni(OH)2 and NiO | [61] | |

| Dissolution of 5.94 g of Ni(H2PO2)2·6H2O (0.02 mol) and 1.66 g of NH4H2PO2 (0.02 mol) in 27.92 g (0.2 mol) of choline chloride and 24.02 g (0.4 mol) of urea, stirring at 323 K under N2 for 30 min, reduction of product with H2 at 673 K for 3 h | Ni2P supported on amorphous/mesoporous Ni3(PO4)2-Ni2P2O7 | [62] | |

| Emulsion of 2.25 g SnCl2·2H2O in 100 mL DES. Variable reaction times (1 to 60 min) | Nano-sized SnO particles (20–30 nm) | [63] | |

| Heating of 40 mL of 0.1 M FeCl3·6H2O/DES solution at 200 °C, after 10 min. addition of 40 mL of water and further reaction for 10 min. Washing of precipitate with ethanol and dried at 80 °C overnight | Fe2O3 nanospindles | [64] | |

| Dissolving CoCl2·6H2O into ChCl to obtain a 0.1 M CoCl2:ChCl solution, addition of 100 mL of water after heating for 40 min at different temperatures. Subsequent ice bath cooling, rinsing of product with water and methanol, and drying at 70 °C under vacuum | Mesoporous Co3O4 sheets or nanoparticles | [65] | |

| DES solution of bulk ZnO. Precipitation with water (anti-solvent approach) | ZnO nanocrystals doped with Cu(II) ions | [67] | |

| Dissolution of SnCl2·2H2O in DES, stirring in pre-heated water bath (50, 80, 98 °C), precipitation with ethanol, and drying at 230 °C | SnO2 nanoparticles | [68] | |

| Mixing of y mmol NiCl2 6H2O and 20-y mmol CoCl2 6H2O (y = 0, 2.5, 5, 10) in 10 mL DES. Addition of 1 mmol SDS and 20 mL water, heating for 12 h at 100 °C, washing of precipitate with water and ethanol | NixCo2-x(OH)3Cl | [91] | |

| Stirring of 1.668 g (0.006 mol) FeSO4·7H2O and 0.584 g (0.010 mol) of KOH 0.408 g in DES for 30 min, addition of 0.408 g (0.0012 mol) tetrabutyl titanate (TBOT) and 0.420 g (0.008 mol) of KOH, stirring first at 80 °C (30 min) and then at 110 °C (4 h), washing of precipitate with water and ethanol | Fe2.5Ti0.5O4-DES nanoparticles | [93] | |

| ChCl:urea 1:2 ChCl:urea:water 1:2:10 | Hydrothermal treatment of Fe(NO3)3·9H2O/DES mixtures (dry and hydrated DES) for 3–8 h at 90 °C before particles are dried at 60 °C from ethanol after dialysis | FeO | [88] |

| Dissolution of Ce(NO3)3·6 H2O in DES and stirring at 250 rpm for 40 min, reaction in pressurized continuous microreactor at 100–160 °C, washing of the solid product with water and ethanol and drying at 80 °C | CeO2 | [89] | |

| (CH3)NH2 HCl:urea 1:1.5 | Mixture of Sn (0.119 g, 1.0 mmol), Se (0.211 g, 2.67 mmol), dimethylamine hydrochloride (0.58 g, 7.1 mmol), urea (0.64 g, 10.67 mmol), and 0.3 mL of N2H4·H2O (98%) (∼6.17 mmol), hydrothermal synthesis at 160 °C (3 h), rinsing with water | Silver and selenido-stannates [NH4]3AgSn3Se8 [NH4]2Sn4Se9 [NH3C2H5]2Sn3Se7 | [82] |

| ChCl:oxalic acid 1:1 | Dissolution of 30 mg of commercial Fe3O4 in 1 mL ChCl/OA DES at 50 °C by ultrasonic treatment, microwave heating for 10 s at 100 W, further thermal treatment at 300 °C for 2 h | Fe3O4 nanosheets | [117] |

| Addition of MgO and α-Fe2O3 to DES molar ratio 1:1 (0.5 wt% melt in the overall amount of metal oxides), stirring for 1 h, then calcination of melts at 500 °C for 1 h (5 °C min–1 heating rate) | MgFe2O4 nanoparticles | [115] | |

| ChCl:acrylic acid | Stirring of ChCl and MAA in the molar ratio 1:2 at 80 °C; mixing with a porogen (MeOH), initiator (AIBN), crosslinking agent (EGDMA), and template (levofloxacin); heating at 60 °C for 12 h; removal of template by Soxhlet extraction with methanol | Levofloxacin-imprinted Pd nanoparticles | [75] |

| ChCl:oxalic acid:water 1:1:1 | Mixing of cellulose pulp (0.5 g) with DES (10 g) and water (10 g), heating at 110 °C for 2 h in a Teflon-lined reactor to obtain carboxylic cellulose (CNF). Addition of 10 mL of PdCl2 (17.7 mg) in HCl and aqueous NaBH4 (10 mg, 1 mL) to a diluted CNF suspension (20 mL, 0.4 wt%), reaction at 4 °C for 4 h, separation of Pd NPs by dialysis | Pd nanoparticles confined in nanocellulose | [116] |

| ChCl:ethylene glycol 1:2 | Mixing of NiSO4·6H2O (0.1 M), Na2S2O3·5H2O (0.1 M), EDTA (0.06 M), and DES in a beaker at different temperatures (80 °C, 100 °C, 110 °C, 120 °C, 160 °C); stirring of the mixtures for 3 h; washing of the solids with water and ethanol; and drying at 60 °C | NiS2 nanospheres | [101] |

| Dissolution of 4.0 mg of Pt(acac)2, 40 mg PVP, and 25 mg of SDS in 8 mL DES; heating in oil bath at 130 °C for 2 h; washing of the black precipitate with ethanol | Pt hollow-opened structures | [105] | |

| ChCl:glycerol 1:2 | Hydrothermal heating of ZrCl4, BDC (1,4 benzene dicarboxylate), H2O, and DES at a molar ratio of 1:1:1:500 at 120 °C for 48 h; washing of the solid with water | Nanoparticles containing ZrCl4 | [107] |

| Mixing 2.19 g of Zn(CH3COO)2·2H2O and 0.2 g of graphene in 50 mL DES, precipitation with 0.8 g NaOH | ZnO in situ on graphene sheets | [109] | |

| ChCl:CaCl2 1:2 | CO2 capture from air of CaCl2·6H2O and choline chloride DES at 50 °C under stirring at 400 rpm, formation of CaCO3 sediment after 6 h, washing of the sediment with water, drying at 60 °C for 12 h, reuse of the filtrate for further CO2 capture | CaCO3 NPs | [78] |

| ChCl:glucose/fructose/sucrose/maltose/raffinose | Liquid-phase exfoliation of MoS2 in glucose, fructose, sucrose, raffinose, maltose, choline chloride, and water DES at various ratios (5 mg MoS2 per mL of DES); separation of exfoliated material in ethanol/water | MoS2 nanosheets | [77] |

| CHCl:glucose | DASH: Dopamine hydrochloride (DA), N-Hydroxysuccinimide (NHS), 1-ethyl-3-(3-(dimethylamino)propyl) carbodiimide (EDC), sodium hyaluronate (SH) in 2-(N-morpholino) ethanesulfonic acid-buffered solution (MES buffer). Addition of AgNO3 to DES-DASH 4:175 mixture | Na hyaluronate/dopamine/Ag NPs hydrogels | [111] |

| ChCl:xylitol 1:1 | Mixing 0.2 g Fe3O4@TiO2 nanoparticles and 3.0 mL [ChCl][Xyl] by ultrasonication for 2 h, separation by external magnet, rinsing with water | Fe3O4@TiO2@DES | [112] |

| ChCl:gluconic acid | Mixing 2 g choline chloride, 4 g urea, and 0.4 g Co(NO3)2·6H2O in 5.62 mL of 50% gluconic acid solution; calcination in N2 at 700–900 °C after freeze-drying | Co@NPC | [113] |

| CHCl:citric acid 2:1 | Addition of 3.9813 g FeCl2 4H2O (20 mM) and 8.1091 g of FeCl3.6H2O (30 mM) at the molar ratio 1:1.5 to DES, stirring at 80 °C (600 rpm) for 20 min, addition of 40 g (712.94 mM) KOH, stirring for another 1 h, washing with ethanol and water | Fe3O4 nanocubes | [122] |

| Betaine-urea 1:2 | DES: betaine (2.343 g) and urea (2.4 g), heating for 15 min at 125 °C, addition of 1.5 mL water, dissolution of 0.111 g FeSO4·7H2O (0.4 mmol) and 0.216 g FeCl3·6H2O (0.8 mmol) in DES at RT under stirring (10 min), precipitation by the addition of 0.2 g of KOH (3.5 mmol), separation with external magnet, and washing with water | Nano-Fe3O4 Nano-Fe3O4@SiO2–NH2 | [121] |

| BTAB/BTBAC/TBAC:lactic acid | [BTBAC][Lac]-DES: Mixing 3.12 g BTBAC and 1.80 g Lac at a molar ratio 1:2 under heating at 80 °C in oil bath for 1 h. Addition of 2.0 mL DES to a phosphate buffer (20 mM, pH = 7.0) containing 0.24 g of NHS and 0.16 g of EDC·HCl to activate the carboxyl group of DES; subsequently, the addition of 0.20 g MUiO-66-NH2, stirring for 12 h, washing of particles with water, and freeze-drying | Fe3O4-MUiO-66-NH2 | [124] |

| TBAB:imidazole | Condensation of TFPT (main building block) and hydrazine (comonomer) in BuN4Im/Br at 90 °C for 12 h, subsequent impregnation with Pd(oAC)2 under reflux | Pd@MOF | [125] |

| CTAB:acetic acid 1:1 | Mixing cetyltrimethylammonium and acetic acid at 70 °C for 3 h. Addition of 1 g ammonium cerium (IV) nitrate to 0.5 g of DES and hydrothermal treatment of the solution at 130 °C for 7 h. For N-doping, a urea solution (10 g/30 mL of water) is added, followed by the separation of particles by centrifugation and washing with ethanol and acetone | Plain and N-doped CeO2 | [126,127] |

| dl-menthol:oleyl alcohol 1:1.2 | Mixing 1 mol D,L-menthol and oleyl alcohol at 343.15 K under stirring for 12–24 h. Addition of h-BN nanoparticles at different weight percentages, shaking, and sonication for 2 h | BN nanoparticle nanofluid | [128] |

| Acetic acid:menthol 1:2 pyruvic acid:menthol 1:1 lactic acid:menthol 1:2 lauric acid:menthol 2:1 | Mixing of D,L-menthol with PA, AA, LacA, or LauA at 50 °C for 15 min before drying under vacuum (10−1 Pa). Preparation of high-internal-phase emulsions (HIPEs) by dropping DES into a continuous phase of AAm:BAAm (acrylamide:N,N′-Methylenebis(acrylmide), polymerization with potassium persulfate (KPS), and coating with γ-Fe2O3 | Polyacrylamide γ-maghemite composites | [120] |

| Acrylic acid:mentho 1:2 | Mixing AA and menthol at 70 °C in a water bath for 5 min, polymerization of DES via a thermal frontal method usingFe3O4 NPs-AA as a cross-linker and thermal initiator into a magnetic poly (AA-menthol DES) hydrogel | Acrylic acid:Fe3O4 composites | [119] |

| Choline:Na2SO3 2:1 | Heating of 7.0 g of choline chloride and ∼4.0 g NaS2O3 in 2:1 molar ratio at 40 °C for 3 h. Addition of 16 mL DES to a GO solution in the presence of hydrazine as a reducing agent, co-precipitation of reduced GO and sulfur | Sulfur-functionalized graphene oxide NPs | [118] |

| Dimethylammonium nitrate:triethylene/ethylene glycol, or glycerol 1:1 | HBA: Addition of 119.4 mL of 5.0 N HNO3 solution (0.597 mol) to aqueous dimethylamine (40 wt% in H2O, 0.597 mol). HBD: triethylene glycol, ethylene glycol, or glycerol. Addition of HAuCl4 or AgNO3 and oleylamine (OAm) (reducing agent) in each DES under stirring (150 rpm); heating at different temperatures (12 h at 60 °C for Ag, 19 min. 140–170 °C for Au) | Ag or Au colloidal nanocrystals | [81] |

5. Lewis Acid DES (LADES)

| Solvent | Reagents/Path | Product | References |

|---|---|---|---|

| Lanthanide nitrate hydrate:urea 1:3.5 | Mixing of cerium (III) nitrate hexahydrate, neodymium(III) nitrate hexahydrate, or praseodymium(III) nitrate with urea at various ratios; preferred ratio is 1:3.5 | Lanthanide oxides CeO2, Pr6O11, NdO3 + mixed carbonates | [140] |

| UNH(UO2(NO3)2·6H2O):urea at various ratios | Mixing of UNH:urea at ratios 0.9:0.1, 0.8:0.2, 0.75:0.25, 0.6:0.4, 0.5:0.5, 0.33:0.67, 0.2:0.8, 0.1:0.9. Melting point of −5.2 °C for the 0.8:0.2 mixture | UO2 NPs | [141] |

| ZnCl2:urea 1:4 | DES: Urea (20.0 mmol, 1.200 g) and zinc chloride (5.0 mmol, 0.680 g). Covalent bonding of TiO2 to DES through 2,4-toluene diisocyanate (TDI). Dispersion of 0.5 g of TiO2@TDI NPs in DES with stirring at 100 °C for 18 h; washing with ethanol and drying at 60 °C under reduced pressure for 6 h | Ti@DES nanocatalyst | [136,137] |

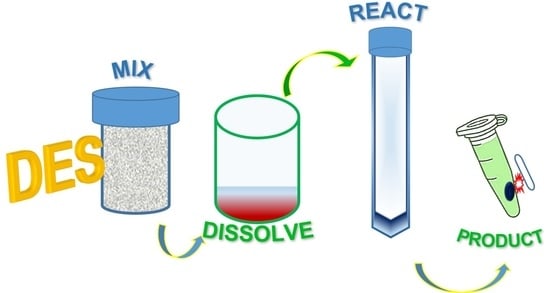

6. A Prototypical Synthesis

- (a)

- Preparation of DES

- (b)

- Preparation of the solution

- (c)

- Precipitation

- (d) Drying

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ealia, S.A.M.; Saravanakumar, M.P. A Review on the Classification, Characterisation, Synthesis of Nanoparticles and Their Application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032019. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on Nanoparticles and Nanostructured Materials: History, Sources, Toxicity and Regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Z.; Wang, X.; Zhao, N.; He, J.; Wang, S.; Wu, G.; Cheng, Y. The Desirable Dielectric Properties and High Thermal Conductivity of Epoxy Composites with the Cobweb-Structured SiCnw–SiO2–NH2 Hybrids. J. Mater. Sci. Mater. Electron. 2021, 32, 20973–20984. [Google Scholar] [CrossRef]

- Wang, Z.; Meng, G.; Wang, L.; Tian, L.; Chen, S.; Wu, G.; Kong, B.; Cheng, Y. Simultaneously Enhanced Dielectric Properties and Through-Plane Thermal Conductivity of Epoxy Composites with Alumina and Boron Nitride Nanosheets. Sci. Rep. 2021, 11, 2495. [Google Scholar] [CrossRef] [PubMed]

- Carbone, M.; Briancesco, R.; Bonadonna, L. Antimicrobial Power of Cu/Zn Mixed Oxide Nanoparticles to Escherichia Coli. Environ. Nanotechnol. Monit. Manag. 2017, 7, 97–102. [Google Scholar] [CrossRef]

- Carbone, M. Cu Zn Co Nanosized Mixed Oxides Prepared from Hydroxycarbonate Precursors. J. Alloys Compd. 2016, 688, 202–209. [Google Scholar] [CrossRef]

- Carbone, M. CQDs@NiO: An Efficient Tool for CH4 Sensing. Appl. Sci. 2020, 10, 6251. [Google Scholar] [CrossRef]

- Carbone, M.; Tagliatesta, P. NiO Grained-Flowers and Nanoparticles for Ethanol Sensing. Materials 2020, 13, 1880. [Google Scholar] [CrossRef] [Green Version]

- Carbone, M.; Aneggi, E.; Figueredo, F.; Susmel, S. NiO-Nanoflowers Decorating a Plastic Electrode for the Non-Enzymatic Amperometric Detection of H2O2 in Milk: Old Issue, New Challenge. Food Control 2022, 132, 108549. [Google Scholar] [CrossRef]

- Carbone, M.; Nesticò, A.; Bellucci, N.; Micheli, L.; Palleschi, G. Enhanced Performances of Sensors Based on Screen Printed Electrodes Modified with Nanosized NiO Particles. Electrochim. Acta 2017, 246, 580–587. [Google Scholar] [CrossRef]

- Carbone, M.; Missori, M.; Micheli, L.; Tagliatesta, P.; Bauer, E.M. NiO Pseudocapacitance and Optical Properties: Does the Shape Win? Materials 2020, 13, 1417. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carbone, M.; Maria Bauer, E.; Micheli, L.; Missori, M. NiO Morphology Dependent Optical and Electrochemical Properties. Colloids Surf. A Physicochem. Eng. Asp. 2017, 532, 178–182. [Google Scholar] [CrossRef]

- Tan, S.; Ebrahimi, A.; Liu, X.; Langrish, T. Role of Templating Agents in the Spray Drying and Postcrystallization of Lactose for the Production of Highly Porous Powders. Dry. Technol. 2018, 36, 1882–1891. [Google Scholar] [CrossRef]

- Li, Y.; Khuu, N.; Prince, E.; Alizadehgiashi, M.; Galati, E.; Lavrentovich, O.D.; Kumacheva, E. Nanoparticle-Laden Droplets of Liquid Crystals: Interactive Morphogenesis and Dynamic Assembly. Sci. Adv. 2019, 5, eaav1035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Holmberg, K. Surfactant-Templated Nanomaterials Synthesis. J. Colloid Interface Sci. 2004, 274, 355–364. [Google Scholar] [CrossRef]

- Xie, H.; Gu, Y.; Ploehn, H.J. Dendrimer-Mediated Synthesis of Platinum Nanoparticles: New Insights from Dialysis and Atomic Force Microscopy Measurements. Nanotechnology 2005, 16, S492–S501. [Google Scholar] [CrossRef] [PubMed]

- Wagle, D.V.; Zhao, H.; Baker, G.A. Deep Eutectic Solvents: Sustainable Media for Nanoscale and Functional Materials. Acc. Chem. Res. 2014, 47, 2299–2308. [Google Scholar] [CrossRef]

- Hansen, B.B.; Spittle, S.; Chen, B.; Poe, D.; Zhang, Y.; Klein, J.M.; Horton, A.; Adhikari, L.; Zelovich, T.; Doherty, B.W.; et al. Deep Eutectic Solvents: A Review of Fundamentals and Applications. Chem. Rev. 2021, 121, 1232–1285. [Google Scholar] [CrossRef]

- Abo-Hamad, A.; Hayyan, M.; AlSaadi, M.A.; Hashim, M.A. Potential Applications of Deep Eutectic Solvents in Nanotechnology. Chem. Eng. J. 2015, 273, 551–567. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef] [Green Version]

- Abbott, A.P.; Capper, G.; Davies, D.L.; Rasheed, R.K.; Tambyrajah, V. Novel Solvent Properties of Choline Chloride/Urea Mixtures. Chem. Commun. 2003, 39, 70–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meng, X.; Ballerat-Busserolles, K.; Husson, P.; Andanson, J.-M. Impact of Water on the Melting Temperature of Urea + Choline Chloride Deep Eutectic Solvent. New J. Chem. 2016, 40, 4492–4499. [Google Scholar] [CrossRef] [Green Version]

- Arkawaz, A.F.; Abdullah, B.A.; Mustafa Ha, S. Physical, Thermal and Structural Properties of 1 Choline Chloride: 2 Urea Based Ionic Liquids. Singap. J. Sci. Res. 2020, 10, 417–424. [Google Scholar] [CrossRef]

- Lapeña, D.; Bergua, F.; Lomba, L.; Giner, B.; Lafuente, C. A Comprehensive Study of the Thermophysical Properties of Reline and Hydrated Reline. J. Mol. Liq. 2020, 303, 112679. [Google Scholar] [CrossRef]

- Ribeiro, B.D.; Florindo, C.; Iff, L.C.; Coelho, M.A.Z.; Marrucho, I.M. Menthol-Based Eutectic Mixtures: Hydrophobic Low Viscosity Solvents. ACS Sustain. Chem. Eng. 2015, 3, 2469–2477. [Google Scholar] [CrossRef]

- Liu, Y.; Friesen, J.B.; McAlpine, J.B.; Lankin, D.C.; Chen, S.-N.; Pauli, G.F. Natural Deep Eutectic Solvents: Properties, Applications, and Perspectives. J. Nat. Prod. 2018, 81, 679–690. [Google Scholar] [CrossRef]

- Paiva, A.; Craveiro, R.; Aroso, I.; Martins, M.; Reis, R.L.; Duarte, A.R.C. Natural Deep Eutectic Solvents–Solvents for the 21st Century. ACS Sustain. Chem. Eng. 2014, 2, 1063–1071. [Google Scholar] [CrossRef]

- Gontrani, L.; Plechkova, N.V.; Bonomo, M. In-Depth Physico-Chemical and Structural Investigation of a Dicarboxylic Acid/Choline Chloride Natural Deep Eutectic Solvent (NADES): A Spotlight on the Importance of a Rigorous Preparation Procedure. ACS Sustain. Chem. Eng. 2019, 7, 12536–12543. [Google Scholar] [CrossRef]

- Jafari, K.; Fatemi, M.H.; Estellé, P. Deep Eutectic Solvents (DESs): A Short Overview of the Thermophysical Properties and Current Use as Base Fluid for Heat Transfer Nanofluids. J. Mol. Liq. 2021, 321, 114752. [Google Scholar] [CrossRef]

- Kanzaki, R.; Uchida, K.; Song, X.; Umebayashi, Y.; Ishiguro, S. Acidity and Basicity of Aqueous Mixtures of a Protic Ionic Liquid, Ethylammonium Nitrate. Anal. Sci. 2008, 24, 1347–1349. [Google Scholar] [CrossRef] [Green Version]

- Mariani, A.; Bonomo, M.; Gao, X.; Centrella, B.; Nucara, A.; Buscaino, R.; Barge, A.; Barbero, N.; Gontrani, L.; Passerini, S. The Unseen Evidence of Reduced Ionicity: The Elephant in (the) Room Temperature Ionic Liquids. J. Mol. Liq. 2021, 324, 115069. [Google Scholar] [CrossRef]

- Abbott, A.P.; Capper, G.; Davies, D.L.; McKenzie, K.J.; Obi, S.U. Solubility of Metal Oxides in Deep Eutectic Solvents Based on Choline Chloride. J. Chem. Eng. Data 2006, 51, 1280–1282. [Google Scholar] [CrossRef]

- Carriazo, D.; Gutiérrez, M.C.; Ferrer, M.L.; del Monte, F. Resorcinol-Based Deep Eutectic Solvents as Both Carbonaceous Precursors and Templating Agents in the Synthesis of Hierarchical Porous Carbon Monoliths. Chem. Mater. 2010, 22, 6146–6152. [Google Scholar] [CrossRef]

- Raghuwanshi, V.S.; Ochmann, M.; Hoell, A.; Polzer, F.; Rademann, K. Deep Eutectic Solvents for the Self-Assembly of Gold Nanoparticles: A SAXS, UV–Vis, and TEM Investigation. Langmuir 2014, 30, 6038–6046. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, V.; Geller, D.; Malberg, F.; Sánchez, P.B.; Padua, A.; Kirchner, B. Strong Microheterogeneity in Novel Deep Eutectic Solvents. ChemPhysChem 2019, 20, 1786–1792. [Google Scholar] [CrossRef] [PubMed]

- Parnham, E.R.; Drylie, E.A.; Wheatley, P.S.; Slawin, A.M.Z.; Morris, R.E. Ionothermal Materials Synthesis Using Unstable Deep-Eutectic Solvents as Template-Delivery Agents. Angew. Chem. 2006, 118, 5084–5088. [Google Scholar] [CrossRef]

- Chen, J.; Ali, M.C.; Liu, R.; Munyemana, J.C.; Li, Z.; Zhai, H.; Qiu, H. Basic Deep Eutectic Solvents as Reactant, Template and Solvents for Ultra-Fast Preparation of Transition Metal Oxide Nanomaterials. Chin. Chem. Lett. 2020, 31, 1584–1587. [Google Scholar] [CrossRef]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. Liquid Structure of the Choline Chloride-Urea Deep Eutectic Solvent (Reline) from Neutron Diffraction and Atomistic Modelling. Green Chem. 2016, 18, 2736–2744. [Google Scholar] [CrossRef] [Green Version]

- McDonald, S.; Murphy, T.; Imberti, S.; Warr, G.G.; Atkin, R. Amphiphilically Nanostructured Deep Eutectic Solvents. J. Phys. Chem. Lett. 2018, 9, 3922–3927. [Google Scholar] [CrossRef]

- Cui, Y.; Rushing, J.C.; Seifert, S.; Bedford, N.M.; Kuroda, D.G. Molecularly Heterogeneous Structure of a Nonionic Deep Eutectic Solvent Composed of N-Methylacetamide and Lauric Acid. J. Phys. Chem. B 2019, 123, 3984–3993. [Google Scholar] [CrossRef]

- Sahu, S.; Banu, S.; Sahu, A.K.; Phani Kumar, B.V.N.; Mishra, A.K. Molecular-Level Insights into Inherent Heterogeneity of Maline Deep Eutectic System. J. Mol. Liq. 2022, 350, 118478. [Google Scholar] [CrossRef]

- Karimi, M.; Rastegar Ramsheh, M.; Mohammad Ahmadi, S.; Reza Madani, M. One-Step and Low-Temperature Synthesis of Monetite Nanoparticles in an All-in-One System (Reactant, Solvent, and Template) Based on Calcium Chloride-Choline Chloride Deep Eutectic Medium. Ceram. Int. 2017, 43, 2046–2050. [Google Scholar] [CrossRef]

- Jhang, P.-C.; Chuang, N.-T.; Wang, S.-L. Layered Zinc Phosphates with Photoluminescence and Photochromism: Chemistry in Deep Eutectic Solvents. Angew. Chem. 2010, 122, 4296–4300. [Google Scholar] [CrossRef]

- Di Carmine, G.; Abbott, A.P.; D’Agostino, C. Deep eutectic solvents: Alternative reaction media for organic oxidation reactions. React. Chem. Eng. 2021, 6, 582–598. [Google Scholar] [CrossRef]

- Wei, X.; Chen, J.; Ali, M.C.; Munyemana, J.C.; Qiu, H. Cadmium Cobaltite Nanosheets Synthesized in Basic Deep Eutectic Solvents with Oxidase-like, Peroxidase-like, and Catalase-like Activities and Application in the Colorimetric Assay of Glucose. Microchim. Acta 2020, 187, 314. [Google Scholar] [CrossRef] [PubMed]

- Bonomo, M.; Gontrani, L.; Capocefalo, A.; Sarra, A.; Nucara, A.; Carbone, M.; Postorino, P.; Dini, D. A Combined Electrochemical, Infrared and EDXD Tool to Disclose Deep Eutectic Solvents Formation When One Precursor Is Liquid: Glyceline as Case Study. J. Mol. Liq. 2020, 319, 114292. [Google Scholar] [CrossRef]

- Hammond, O.S.; Li, H.; Westermann, C.; Al-Murshedi, A.Y.M.; Endres, F.; Abbott, A.P.; Warr, G.G.; Edler, K.J.; Atkin, R. Nanostructure of the Deep Eutectic Solvent/Platinum Electrode Interface as a Function of Potential and Water Content. Nanoscale Horiz. 2019, 4, 158–168. [Google Scholar] [CrossRef]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. The Effect of Water upon Deep Eutectic Solvent Nanostructure: An Unusual Transition from Ionic Mixture to Aqueous Solution. Angew. Chem. 2017, 129, 9914–9917. [Google Scholar] [CrossRef]

- Liao, H.-G.; Jiang, Y.-X.; Zhou, Z.-Y.; Chen, S.-P.; Sun, S.-G. Shape-Controlled Synthesis of Gold Nanoparticles in Deep Eutectic Solvents for Studies of Structure-Functionality Relationships in Electrocatalysis. Angew. Chem. Int. Ed. 2008, 47, 9100–9103. [Google Scholar] [CrossRef] [Green Version]

- Sales, V.; Paternoster, C.; Mantovani, D.; Kolliopoulos, G. Fe–Mn Alloys Electroforming Process Using Choline Chloride Based Deep Eutectic Solvents. Mater. Proc. 2021, 5, 40. [Google Scholar] [CrossRef]

- Maciej, A.; Łatanik, N.; Sowa, M.; Matuła, I.; Simka, W. Electrodeposition of Copper and Brass Coatings with Olive-Like Structure. Materials 2021, 14, 1762. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Fan, Y.-J.; Tian, N.; Zhou, Z.-Y.; Zhao, X.-Q.; Mao, B.-W.; Sun, S.-G. Electrochemically Shape-Controlled Synthesis in Deep Eutectic Solvents—A New Route to Prepare Pt Nanocrystals Enclosed by High-Index Facets with High Catalytic Activity. J. Phys. Chem. C 2012, 116, 2040–2044. [Google Scholar] [CrossRef]

- Hammons, J.A.; Muselle, T.; Ustarroz, J.; Tzedaki, M.; Raes, M.; Hubin, A.; Terryn, H. Stability, Assembly, and Particle/Solvent Interactions of Pd Nanoparticles Electrodeposited from a Deep Eutectic Solvent. J. Phys. Chem. C 2013, 117, 14381–14389. [Google Scholar] [CrossRef]

- Wei, L.; Zhou, Z.-Y.; Chen, S.-P.; Xu, C.-D.; Su, D.; Schuster, M.E.; Sun, S.-G. Electrochemically Shape-Controlled Synthesis in Deep Eutectic Solvents: Triambic Icosahedral Platinum Nanocrystals with High-Index Facets and Their Enhanced Catalytic Activity. Chem. Commun. 2013, 49, 11152. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Das, N.; Kumar, A.; Rayavarapu, R.G. The Role of Deep Eutectic Solvents and Carrageenan in Synthesizing Biocompatible Anisotropic Metal Nanoparticles. Beilstein J. Nanotechnol. 2021, 12, 924–938. [Google Scholar] [CrossRef]

- Zhang, F.; Lai, J.; Huang, Y.; Li, F.; Luo, G.; Chu, G. A Green Method for Preparing CuCl Nanocrystal in Deep Eutectic Solvent. Aust. J. Chem. 2013, 66, 237. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, F.; La, J.; Luo, G.; Lai, J.; Liu, C.; Chu, G. Synthesis and Characterization of CuCl Nanoparticles in Deep Eutectic Solvents. Part. Sci. Technol. 2013, 31, 81–84. [Google Scholar] [CrossRef]

- Chen, F.; Xie, S.; Zhang, J.; Liu, R. Synthesis of Spherical Fe3O4 Magnetic Nanoparticles by Co-Precipitation in Choline Chloride/Urea Deep Eutectic Solvent. Mater. Lett. 2013, 112, 177–179. [Google Scholar] [CrossRef]

- Querejeta-Fernández, A.; Hernández-Garrido, J.C.; Yang, H.; Zhou, Y.; Varela, A.; Parras, M.; Calvino-Gámez, J.J.; González-Calbet, J.M.; Green, P.F.; Kotov, N.A. Unknown Aspects of Self-Assembly of PbS Microscale Superstructures. ACS Nano 2012, 6, 3800–3812. [Google Scholar] [CrossRef]

- Gu, C.D.; Huang, M.L.; Ge, X.; Zheng, H.; Wang, X.L.; Tu, J.P. NiO Electrode for Methanol Electro-Oxidation: Mesoporous vs. Nanoparticulate. Int. J. Hydrogen Energy 2014, 39, 10892–10901. [Google Scholar] [CrossRef]

- Ge, X.; Gu, C.D.; Lu, Y.; Wang, X.L.; Tu, J.P. A Versatile Protocol for the Ionothermal Synthesis of Nanostructured Nickel Compounds as Energy Storage Materials from a Choline Chloride-Based Ionic Liquid. J. Mater. Chem. A 2013, 1, 13454. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Y.; Feng, H.; Shen, J. Synthesis of Nickel Phosphide Nano-Particles in a Eutectic Mixture for Hydrotreating Reactions. J. Mater. Chem. 2011, 21, 8137. [Google Scholar] [CrossRef]

- Zheng, H.; Gu, C.-D.; Wang, X.-L.; Tu, J.-P. Fast Synthesis and Optical Property of SnO Nanoparticles from Choline Chloride-Based Ionic Liquid. J. Nanopart. Res. 2014, 16, 2288. [Google Scholar] [CrossRef]

- Xiong, Q.Q.; Tu, J.P.; Ge, X.; Wang, X.L.; Gu, C.D. One-Step Synthesis of Hematite Nanospindles from Choline Chloride/Urea Deep Eutectic Solvent with Highly Powerful Storage versus Lithium. J. Power Sources 2015, 274, 1–7. [Google Scholar] [CrossRef]

- Ge, X.; Gu, C.D.; Wang, X.L.; Tu, J.P. Correlation between Microstructure and Electrochemical Behavior of the Mesoporous Co3O4 Sheet and Its Ionothermal Synthesized Hydrotalcite-like α-Co(OH)2 Precursor. J. Phys. Chem. C 2014, 118, 911–923. [Google Scholar] [CrossRef]

- Ge, X.; Gu, C.D.; Wang, X.L.; Tu, J.P. Endowing Manganese Oxide with Fast Adsorption Ability through Controlling the Manganese Carbonate Precursor Assembled in Ionic Liquid. J. Colloid Interface Sci. 2015, 438, 149–158. [Google Scholar] [CrossRef]

- Lu, Y.-H.; Lin, W.-H.; Yang, C.-Y.; Chiu, Y.-H.; Pu, Y.-C.; Lee, M.-H.; Tseng, Y.-C.; Hsu, Y.-J. A Facile Green Antisolvent Approach to Cu2+-Doped ZnO Nanocrystals with Visible-Light-Responsive Photoactivities. Nanoscale 2014, 6, 8796. [Google Scholar] [CrossRef]

- Gu, C.; Zhang, H.; Wang, X.; Tu, J. One-Pot Synthesis of SnO2/Reduced Graphene Oxide Nanocomposite in Ionic Liquid-Based Solution and Its Application for Lithium Ion Batteries. Mater. Res. Bull. 2013, 48, 4112–4117. [Google Scholar] [CrossRef]

- Gu, C.D.; Xu, X.J.; Tu, J.P. Fabrication and Wettability of Nanoporous Silver Film on Copper from Choline Chloride-Based Deep Eutectic Solvents. J. Phys. Chem. C 2010, 114, 13614–13619. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, Y.; Gu, C.-D.; Wang, X.-L.; Tu, J.-P. Ionothermal Synthesis and Lithium Storage Performance of Core/Shell Structured Amorphous@crystalline Ni–P Nanoparticles. CrystEngComm 2012, 14, 7942. [Google Scholar] [CrossRef]

- Abbott, A.P.; El Ttaib, K.; Ryder, K.S.; Smith, E.L. Electrodeposition of Nickel Using Eutectic Based Ionic Liquids. Trans. IMF 2008, 86, 234–240. [Google Scholar] [CrossRef]

- Hou, Y.; Peng, Z.; Liang, J.; Fu, S. Ni–Ti Nanocomposite Coatings Electro-Codeposited from Deep Eutectic Solvent Containing Ti Nanoparticles. J. Electrochem. Soc. 2020, 167, 042502. [Google Scholar] [CrossRef]

- Abbott, A.P.; Ttaib, K.E.; Frisch, G.; Ryder, K.S.; Weston, D. The Electrodeposition of Silver Composites Using Deep Eutectic Solvents. Phys. Chem. Chem. Phys. 2012, 14, 2443. [Google Scholar] [CrossRef]

- Mota-Morales, J.D.; Gutiérrez, M.C.; Ferrer, M.L.; Jiménez, R.; Santiago, P.; Sanchez, I.C.; Terrones, M.; del Monte, F.; Luna-Bárcenas, G. Synthesis of Macroporous Poly(Acrylic Acid)–Carbon Nanotube Composites by Frontal Polymerization in Deep-Eutectic Solvents. J. Mater. Chem. A 2013, 1, 3970. [Google Scholar] [CrossRef]

- Li, X.; Row, K.H. Preparation of Levofloxacin-Imprinted Nanoparticles Using Designed Deep Eutectic Solvents for the Selective Removal of Levofloxacin Pollutants from Environmental Waste Water. Analyst 2020, 145, 2958–2965. [Google Scholar] [CrossRef]

- Zainal-Abidin, M.H.; Hayyan, M.; Ngoh, G.C.; Wong, W.F. From Nanoengineering to Nanomedicine: A Facile Route to Enhance Biocompatibility of Graphene as a Potential Nano-Carrier for Targeted Drug Delivery Using Natural Deep Eutectic Solvents. Chem. Eng. Sci. 2019, 195, 95–106. [Google Scholar] [CrossRef]

- Mohammadpour, Z.; Abdollahi, S.H.; Safavi, A. Sugar-Based Natural Deep Eutectic Mixtures as Green Intercalating Solvents for High-Yield Preparation of Stable MoS2 Nanosheets: Application to Electrocatalysis of Hydrogen Evolution Reaction. ACS Appl. Energy Mater. 2018, 1, 5896–5906. [Google Scholar] [CrossRef]

- Karimi, M.; Jodaei, A.; Khajvandi, A.; Sadeghinik, A.; Jahandideh, R. In-Situ Capture and Conversion of Atmospheric CO2 into Nano-CaCO3 Using a Novel Pathway Based on Deep Eutectic Choline Chloride-Calcium Chloride. J. Environ. Manag. 2018, 206, 516–522. [Google Scholar] [CrossRef]

- Adhikari, L.; Larm, N.E.; Bhawawet, N.; Baker, G.A. Rapid Microwave-Assisted Synthesis of Silver Nanoparticles in a Halide-Free Deep Eutectic Solvent. ACS Sustain. Chem. Eng. 2018, 6, 5725–5731. [Google Scholar] [CrossRef]

- Adhikari, L.; Larm, N.E.; Baker, G.A. Argentous Deep Eutectic Solvent Approach for Scaling Up the Production of Colloidal Silver Nanocrystals. ACS Sustain. Chem. Eng. 2019, 7, 11036–11043. [Google Scholar] [CrossRef]

- Adhikari, L.; Larm, N.E.; Baker, G.A. Batch and Flow Nanomanufacturing of Large Quantities of Colloidal Silver and Gold Nanocrystals Using Deep Eutectic Solvents. ACS Sustain. Chem. Eng. 2020, 8, 14679–14689. [Google Scholar] [CrossRef]

- Wang, K.-Y.; Liu, H.-W.; Zhang, S.; Ding, D.; Cheng, L.; Wang, C. Selenidostannates and a Silver Selenidostannate Synthesized in Deep Eutectic Solvents: Crystal Structures and Thermochromic Study. Inorg. Chem. 2019, 58, 2942–2953. [Google Scholar] [CrossRef]

- Antenucci, A.; Bonomo, M.; Ghigo, G.; Gontrani, L.; Barolo, C.; Dughera, S. How Do Arenediazonium Salts Behave in Deep Eutectic Solvents? A Combined Experimental and Computational Approach. J. Mol. Liq. 2021, 339, 116743. [Google Scholar] [CrossRef]

- Li, X.; Row, K.H. Preparation of Deep Eutectic Solvent-Based Hexagonal Boron Nitride-Molecularly Imprinted Polymer Nanoparticles for Solid Phase Extraction of Flavonoids. Microchim. Acta 2019, 186, 753. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, S.; Mao, Z.; Lin, Z.; Ren, X.; Yu, Z. High Electrochemical Activity of a Ti/SnO2–Sb Electrode Electrodeposited Using Deep Eutectic Solvent. Chemosphere 2020, 239, 124715. [Google Scholar] [CrossRef]

- Douglas, F.J.; MacLaren, D.A.; Murrie, M. A Study of the Role of the Solvent during Magnetite Nanoparticle Synthesis: Tuning Size, Shape and Self-Assembly. RSC Adv. 2012, 2, 8027. [Google Scholar] [CrossRef]

- Das, L.; Koonathan, L.D.; Kunwar, A.; Neogy, S.; Debnath, A.K.; Adhikari, S. Nontoxic Photoluminescent Tin Oxide Nanoparticles for Cell Imaging: Deep Eutectic Solvent Mediated Synthesis, Tuning and Mechanism. Mater. Adv. 2021, 2, 4303–4315. [Google Scholar] [CrossRef]

- Hammond, O.S.; Atri, R.S.; Bowron, D.T.; de Campo, L.; Diaz-Moreno, S.; Keenan, L.L.; Doutch, J.; Eslava, S.; Edler, K.J. Structural Evolution of Iron Forming Iron Oxide in a Deep Eutectic-Solvothermal Reaction. Nanoscale 2021, 13, 1723–1737. [Google Scholar] [CrossRef]

- Exposito, A.J.; Barrie, P.J.; Torrente-Murciano, L. Fast Synthesis of CeO2 Nanoparticles in a Continuous Microreactor Using Deep Eutectic Reline as Solvent. ACS Sustain. Chem. Eng. 2020, 8, 18297–18302. [Google Scholar] [CrossRef]

- Mehrabi, N.; Abdul Haq, U.F.; Reza, M.T.; Aich, N. Application of Deep Eutectic Solvent for Conjugation of Magnetic Nanoparticles onto Graphene Oxide for Lead(II) and Methylene Blue Removal. J. Environ. Chem. Eng. 2020, 8, 104222. [Google Scholar] [CrossRef]

- Chen, R.; Chen, J.; Ma, T.; Pan, C.; Kang, J.; Zou, H.; Yang, W.; Chen, S. Porous NixCo2−x(OH)3Cl Nanoparticles as Cathode Materials for Hybrid Supercapacitor. J. Energy Storage 2021, 47, 103655. [Google Scholar] [CrossRef]

- Nazari, F.; Tabaraki, R. Sensitive Fluorescence Detection of Atorvastatin by Doped Carbon Dots Synthesized in Deep Eutectic Media. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 236, 118341. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Chen, R.; Chen, F. New Soft Chemistry Route to Titanomagnetite Magnetic Nanoparticles with Enhanced Peroxidase-like Activity. Powder Technol. 2020, 373, 39–45. [Google Scholar] [CrossRef]

- Morales Betancourt, A.L.; Smith, C.; Minor, K.; Christodoulou, A.; Naranjo, J.; Tek, S.; Nash, K. Synthesis of Colloidal SeTe Nanoalloy by Pulsed Laser Ablation in Deep Eutectic Solvents to Be Used as Anticancer Treatment. In Proceedings of the Colloidal Nanoparticles for Biomedical Applications XVI, San Antonio, TX, USA, 12 March 2021. [Google Scholar] [CrossRef]

- Jia, H.; Sun, J.; Dong, M.; Dong, H.; Zhang, H.; Xie, X. Deep Eutectic Solvent Electrolysis for Preparing Water-Soluble Magnetic Iron Oxide Nanoparticles. Nanoscale 2021, 13, 19004–19011. [Google Scholar] [CrossRef]

- Edison, T.N.J.I.; Atchudan, R.; Karthik, N.; Chandrasekaran, S.; Perumal, S.; Raja, P.B.; Perumal, V.; Lee, Y.R. Deep Eutectic Solvent Assisted Electrosynthesis of Ruthenium Nanoparticles on Stainless Steel Mesh for Electrocatalytic Hydrogen Evolution Reaction. Fuel 2021, 297, 120786. [Google Scholar] [CrossRef]

- Juárez-Marmolejo, L.; Maldonado-Teodocio, B.; de Oca-Yemha, M.G.M.; Romero-Romo, M.; Arce-Estrada, E.M.; Ezeta-Mejía, A.; Ramírez-Silva, M.T.; Mostany, J.; Palomar-Pardavé, M. Electrocatalytic Oxidation of Formic Acid by Palladium Nanoparticles Electrochemically Synthesized from a Deep Eutectic Solvent. Catal. Today 2021. [CrossRef]

- Dang, T.K.; van Toan, N.; Hung, C.M.; van Duy, N.; Viet, N.N.; Thong, L.V.; Son, N.T.; van Hieu, N.; le Manh, T. Investigation of Zinc Electronucleation and Growth Mechanisms onto Platinum Electrode from a Deep Eutectic Solvent for Gas Sensing Applications. J. Appl. Electrochem. 2022, 52, 299–309. [Google Scholar] [CrossRef]

- Phuong, T.D.V.; Phi, T.-L.; Phi, B.H.; van Hieu, N.; Tang Nguyen, S.; le Manh, T. Electrochemical Behavior and Electronucleation of Copper Nanoparticles from CuCl2·2H2O Using a Choline Chloride-Urea Eutectic Mixture. J. Nanomater. 2021, 2021, 9619256. [Google Scholar] [CrossRef]

- El-Hallag, I.; Elsharkawy, S.; Hammad, S. Electrodeposition of Ni Nanoparticles from Deep Eutectic Solvent and Aqueous Solution as Electrocatalyst for Methanol Oxidation in Acidic Media. Int. J. Hydrogen Energy 2021, 46, 15442–15453. [Google Scholar] [CrossRef]

- Zhang, Y.; Ru, J.; Hua, Y.; Huang, P.; Bu, J.; Wang, Z. Facile and Controllable Synthesis of NiS2 Nanospheres in Deep Eutectic Solvent. Mater. Lett. 2021, 283, 128742. [Google Scholar] [CrossRef]

- da Silva, W.; Queiroz, A.C.; Brett, C.M.A. Nanostructured Poly(Phenazine)/Fe2O3 Nanoparticle Film Modified Electrodes Formed by Electropolymerization in Ethaline-Deep Eutectic Solvent. Microscopic and Electrochemical Characterization. Electrochim. Acta 2020, 347, 136284. [Google Scholar] [CrossRef]

- Rastbood, S.; Hadjmohammadi, M.R.; Majidi, S.M. Development of a Magnetic Dispersive Micro-Solid-Phase Extraction Method Based on a Deep Eutectic Solvent as a Carrier for the Rapid Determination of Meloxicam in Biological Samples. Anal. Methods 2020, 12, 2331–2337. [Google Scholar] [CrossRef]

- Hou, Y.; Peng, Z.; Liang, J.; Liu, M. Ni-Al Nanocomposite Coating Electrodeposited from Deep Eutectic Solvent. Surf. Coat. Technol. 2021, 405, 126587. [Google Scholar] [CrossRef]

- Wang, X.; Sun, M.; Xiang, S.; Waqas, M.; Fan, Y.; Zhong, J.; Huang, K.; Chen, W.; Liu, L.; Yang, J. Template-Free Synthesis of Platinum Hollow-Opened Structures in Deep-Eutectic Solvents and Their Enhanced Performance for Methanol Electrooxidation. Electrochim. Acta 2020, 337, 135742. [Google Scholar] [CrossRef]

- Lei, H.; Singh Siwal, S.; Zhang, X.; Zhang, Q. Compositional and Morphological Engineering of In-Situ-grown Ag Nanoparticles on Cu Substrate for Enhancing Oxygen Reduction Reaction Activity: A Novel Electrochemical Redox Tuning Approach. J. Colloid Interface Sci. 2020, 571, 1–12. [Google Scholar] [CrossRef]

- Albayati, N.; Kadhom, M. Preparation of Functionalised UiO-66 Metal–Organic Frameworks (MOFs) Nanoparticles Using Deep Eutectic Solvents as a Benign Medium. Micro Nano Lett. 2020, 15, 1075–1078. [Google Scholar] [CrossRef]

- Leal-Duaso, A.; Mayoral, J.A.; Pires, E. Steps Forward toward the Substitution of Conventional Solvents in the Heck–Mizoroki Coupling Reaction: Glycerol-Derived Ethers and Deep Eutectic Solvents as Reaction Media. ACS Sustain. Chem. Eng. 2020, 8, 13076–13084. [Google Scholar] [CrossRef]

- Jin, X.; Ma, Z.; Liu, G.; Hu, D.; Song, C.; Huang, Q. In-Situ Ionothermal Precipitation of Well-Dispersed ZnO Nanoparticles onto 2-Dimension Neat Graphene Sheets with Excellent Photocatalytic Activity. J. Environ. Chem. Eng. 2020, 8, 104030. [Google Scholar] [CrossRef]

- Mitar, A.; Prlić Kardum, J. Intensification of Mass Transfer in the Extraction Process with a Nanofluid Prepared in a Natural Deep Eutectic Solvent. Chem. Eng. Technol. 2020, 43, 2286–2294. [Google Scholar] [CrossRef]

- Li, W.; Zhao, X.; Huang, T.; Ren, Y.; Gong, W.; Guo, Y.; Wang, J.; Tu, Q. Preparation of Sodium Hyaluronate/Dopamine/AgNPs Hydrogel Based on the Natural Eutetic Solvent as an Antibaterial Wound Dressing. Int. J. Biol. Macromol. 2021, 191, 60–70. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; He, X.; Chen, J.; Xu, F.; Liu, Z.; Zhou, Y. A Green Deep Eutectic Solvent Modified Magnetic Titanium Dioxide Nanoparticles for the Solid-Phase Extraction of Chymotrypsin. Talanta 2021, 230, 122341. [Google Scholar] [CrossRef]

- Li, D.; Huang, Y.; Li, Z.; Zhong, L.; Liu, C.; Peng, X. Deep Eutectic Solvents Derived Carbon-Based Efficient Electrocatalyst for Boosting H2 Production Coupled with Glucose Oxidation. Chem. Eng. J. 2022, 430, 132783. [Google Scholar] [CrossRef]

- Iwanow, M.; Seidler, J.; Vieira, L.; Kaiser, M.; van Opdenbosch, D.; Zollfrank, C.; Gärtner, T.; Richter, M.; König, B.; Sieber, V. Enhanced C2 and C3 Product Selectivity in Electrochemical CO2 Reduction on Carbon-Doped Copper Oxide Catalysts Prepared by Deep Eutectic Solvent Calcination. Catalysts 2021, 11, 542. [Google Scholar] [CrossRef]

- Baby, J.N.; Sriram, B.; Wang, S.-F.; George, M. Effect of Various Deep Eutectic Solvents on the Sustainable Synthesis of MgFe2O4 Nanoparticles for Simultaneous Electrochemical Determination of Nitrofurantoin and 4-Nitrophenol. ACS Sustain. Chem. Eng. 2020, 8, 1479–1486. [Google Scholar] [CrossRef]

- Meng, J.; Liu, Y.; Shi, X.; Chen, W.; Zhang, X.; Yu, H. Recyclable Nanocellulose-Confined Palladium Nanoparticles with Enhanced Room-Temperature Catalytic Activity and Chemoselectivity. Sci. China Mater. 2021, 64, 621–630. [Google Scholar] [CrossRef]

- Ying, H.; Chen, T.; Zhang, C.; Bi, J.; Li, Z.; Hao, J. Regeneration of Porous Fe3O4 Nanosheets from Deep Eutectic Solvent for High-Performance Electrocatalytic Nitrogen Reduction. J. Colloid Interface Sci. 2021, 602, 64–72. [Google Scholar] [CrossRef]

- Wadekar, P.H.; Ghosh, A.; Khose, R.V.; Pethsangave, D.A.; Mitra, S.; Some, S. A Novel Chemical Reduction/Co-Precipitation Method to Prepare Sulfur Functionalized Reduced Graphene Oxide for Lithium-Sulfur Batteries. Electrochim. Acta 2020, 344, 136147. [Google Scholar] [CrossRef]

- Jamshidi, F.; Nouri, N.; Sereshti, H.; Shojaee Aliabadi, M.H. Synthesis of Magnetic Poly (Acrylic Acid-Menthol Deep Eutectic Solvent) Hydrogel: Application for Extraction of Pesticides. J. Mol. Liq. 2020, 318, 114073. [Google Scholar] [CrossRef]

- Vallejo-Macías, M.T.; Recio-Colmenares, C.L.; Pelayo-Vázquez, J.B.; Gómez-Salazar, S.; Carvajal-Ramos, F.; Soltero-Martínez, J.F.; Vázquez-Lepe, M.; Mota-Morales, J.D.; Pérez-García, M.G. Macroporous Polyacrylamide γ-Fe2O3 Nanoparticle Composites as Methylene Blue Dye Adsorbents. ACS Appl. Nano Mater. 2020, 3, 5794–5806. [Google Scholar] [CrossRef]

- Deng, Y.; Ouyang, J.; Wang, H.; Yang, C.; Zhu, Y.; Wang, J.; Li, D.; Ma, K. Magnetic Nanoparticles Prepared in Natural Deep Eutectic Solvent for Enzyme Immobilisation. Biocatal. Biotransform. 2021, 1–11. [Google Scholar] [CrossRef]

- Sakthi Sri, S.P.; Taj, J.; George, M. Facile Synthesis of Magnetite Nanocubes Using Deep Eutectic Solvent: An Insight to Anticancer and Photo-Fenton Efficacy. Surf. Interfaces 2020, 20, 100609. [Google Scholar] [CrossRef]

- Bide, Y.; Shokrollahzadeh, S. Toward Tailoring of a New Draw Solute for Forward Osmosis Process: Branched Poly (Deep Eutectic Solvent)-Decorated Magnetic Nanoparticles. J. Mol. Liq. 2020, 320, 114409. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Y.; Chen, J.; Xu, F.; Liu, Z.; He, X.; Li, H.; Zhou, Y. Adsorption of Pharmaceuticals and Personal Care Products by Deep Eutectic Solvents-Regulated Magnetic Metal-Organic Framework Adsorbents: Performance and Mechanism. Chem. Eng. J. 2020, 392, 124808. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, S.; Xue, Y.; Mo, L.; Zhang, Z. Palladium Anchored on a Covalent Organic Framework as a Heterogeneous Catalyst for Phosphorylation of Aryl Bromides. Appl. Organomet. Chem. 2022, 36, e6480. [Google Scholar] [CrossRef]

- Iqbal, J.; Shah, N.S.; Sayed, M.; Muhammad, N.; Rehman, S.; Khan, J.A.; Haq Khan, Z.U.; Howari, F.M.; Nazzal, Y.; Xavier, C.; et al. Deep Eutectic Solvent-Mediated Synthesis of Ceria Nanoparticles with the Enhanced Yield for Photocatalytic Degradation of Flumequine under UV-C. J. Water Process Eng. 2020, 33, 101012. [Google Scholar] [CrossRef]

- Iqbal, J.; Shah, N.S.; Sayed, M.; Ali Khan, J.; Muhammad, N.; Khan, Z.U.H.; Rehman, S.U.; Naseem, M.; Howari, F.M.; Nazzal, Y.; et al. Synthesis of Nitrogen-Doped Ceria Nanoparticles in Deep Eutectic Solvent for the Degradation of Sulfamethaxazole under Solar Irradiation and Additional Antibacterial Activities. Chem. Eng. J. 2020, 394, 124869. [Google Scholar] [CrossRef]

- Dehury, P.; Mahanta, U.; Banerjee, T. Comprehensive Assessment on the Use of Boron Nitride-Based Nanofluids Comprising Eutectic Mixtures of Diphenyl Ether and Menthol for Enhanced Thermal Media. ACS Sustain. Chem. Eng. 2020, 8, 14595–14604. [Google Scholar] [CrossRef]

- Qin, H.; Hu, X.; Wang, J.; Cheng, H.; Chen, L.; Qi, Z. Overview of Acidic Deep Eutectic Solvents on Synthesis, Properties and Applications. Green Energy Environ. 2020, 5, 8–21. [Google Scholar] [CrossRef]

- Eweka, E.I.; Kerridge, D.H. Solution Chemistry of Molten Amide-Nitrate Eutectics. Chem. Pap. 1999, 53, 11–15. [Google Scholar]

- Mackowiak, A.; Galek, P.; Fic, K. Deep Eutectic Solvents for High-Temperature Electrochemical Capacitors. ChemElectroChem 2021, 8, 4028–4037. [Google Scholar] [CrossRef]

- Taghavi, S.; Amoozadeh, A.; Nemati, F. Deep Eutectic Solvent-assisted Synthesis of Highly Efficient Nanocatalyst (N-TiO2@TDI@DES (ZnCl2:Urea)) for Chemoselective Oxidation of Sulfides to Sulfoxides. Appl. Organomet. Chem. 2021, 35, e6127. [Google Scholar] [CrossRef]

- Taghavi, S.; Amoozadeh, A.; Nemati, F. The First Report of Deep Eutectic Solvent (DES) Nano-photocatalyst (N-TiO2-P25@TDI@DES (Urea: ZnCl2)) and Its Application on Selective Oxidation of Benzyl Alcohols to Benzaldehydes. J. Chem. Technol. Biotechnol. 2021, 96, 384–393. [Google Scholar] [CrossRef]

- Riadi, Y.; Geesi, M.H.; Ouerghi, O.; Dehbi, O.; Elsanousi, A.; Azzallou, R. Synergistic Catalytic Effect of the Combination of Deep Eutectic Solvents and Hierarchical H-TiO2 Nanoparticles toward the Synthesis of Benzimidazole-Linked Pyrrolidin-2-One Heterocycles: Boosting Reaction Yield. Polycycl. Aromat. Compd. 2021, 1–15. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Tran, P.H. One-Pot Multicomponent Synthesis of Thieno [2,3-b]Indoles Catalyzed by a Magnetic Nanoparticle-Supported [Urea]4 [ZnCl2] Deep Eutectic Solvent. RSC Adv. 2020, 10, 9663–9671. [Google Scholar] [CrossRef] [Green Version]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. Structure and Properties of “Type IV” Lanthanide Nitrate Hydrate:Urea Deep Eutectic Solvents. ACS Sustain. Chem. Eng. 2019, 7, 4932–4940. [Google Scholar] [CrossRef]

- Gupta, R.; Gamare, J.; Sahu, M.; Pandey, K.; Gupta, S.K. Electrochemical and Thermodynamic Insights on Actinide Type (IV) Deep Eutectic Solvent. J. Mol. Liq. 2021, 329, 115550. [Google Scholar] [CrossRef]

- Xu, L.-H.; Ma, C.-Y.; Zhang, C.; Liu, J.; Peng, X.-P.; Yao, S.-Q.; Min, D.-Y.; Yuan, T.-Q.; Wen, J.-L. Ultrafast Fractionation of Wild-Type and CSE down-Regulated Poplars by Microwave-Assisted Deep Eutectic Solvents (DES) for Cellulose Bioconversion Enhancement and Lignin Nanoparticles Fabrication. Ind. Crops Prod. 2022, 176, 114275. [Google Scholar] [CrossRef]

- Luo, T.; Wang, C.; Ji, X.; Yang, G.; Chen, J.; Yoo, C.G.; Janaswamy, S.; Lyu, G. Innovative Production of Lignin Nanoparticles Using Deep Eutectic Solvents for Multifunctional Nanocomposites. Int. J. Biol. Macromol. 2021, 183, 781–789. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, L.; Shen, F.; Hu, J.; Huang, M.; He, J.; Zhang, Y.; Deng, S.; Li, Q.; Tian, D. Insights into Lignocellulosic Waste Fractionation for Lignin Nanospheres Fabrication Using Acidic/Alkaline Deep Eutectic Solvents. Chemosphere 2022, 286, 131798. [Google Scholar] [CrossRef]

- Luo, T.; Wang, C.; Ji, X.; Yang, G.; Chen, J.; Janaswamy, S.; Lyu, G. Preparation and Characterization of Size-Controlled Lignin Nanoparticles with Deep Eutectic Solvents by Nanoprecipitation. Molecules 2021, 26, 218. [Google Scholar] [CrossRef]

- Tian, D.; Guo, Y.; Huang, M.; Zhao, L.; Deng, S.; Deng, O.; Zhou, W.; Hu, J.; Shen, F. Bacterial Cellulose/Lignin Nanoparticles Composite Films with Retarded Biodegradability. Carbohydr. Polym. 2021, 274, 118656. [Google Scholar] [CrossRef] [PubMed]

- Bryant, S.J.; da Silva, M.A.; Hossain, K.M.Z.; Calabrese, V.; Scott, J.L.; Edler, K.J. Deep Eutectic Solvent in Water Pickering Emulsions Stabilised by Cellulose Nanofibrils. RSC Adv. 2020, 10, 37023–37027. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gontrani, L.; Tagliatesta, P.; Donia, D.T.; Bauer, E.M.; Bonomo, M.; Carbone, M. Recent Advances in the Synthesis of Inorganic Materials Using Environmentally Friendly Media. Molecules 2022, 27, 2045. https://doi.org/10.3390/molecules27072045

Gontrani L, Tagliatesta P, Donia DT, Bauer EM, Bonomo M, Carbone M. Recent Advances in the Synthesis of Inorganic Materials Using Environmentally Friendly Media. Molecules. 2022; 27(7):2045. https://doi.org/10.3390/molecules27072045

Chicago/Turabian StyleGontrani, Lorenzo, Pietro Tagliatesta, Domenica Tommasa Donia, Elvira Maria Bauer, Matteo Bonomo, and Marilena Carbone. 2022. "Recent Advances in the Synthesis of Inorganic Materials Using Environmentally Friendly Media" Molecules 27, no. 7: 2045. https://doi.org/10.3390/molecules27072045

APA StyleGontrani, L., Tagliatesta, P., Donia, D. T., Bauer, E. M., Bonomo, M., & Carbone, M. (2022). Recent Advances in the Synthesis of Inorganic Materials Using Environmentally Friendly Media. Molecules, 27(7), 2045. https://doi.org/10.3390/molecules27072045