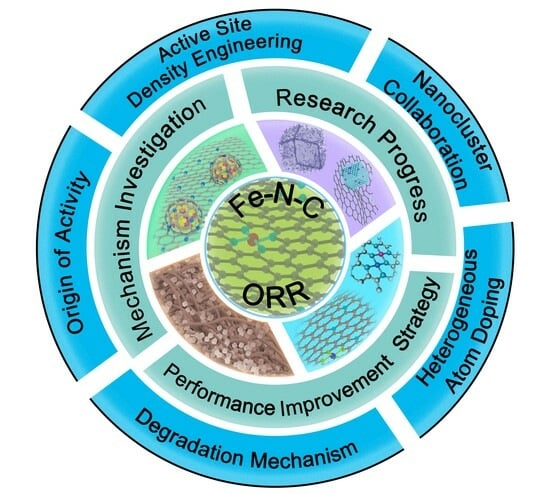

Research Progress on Atomically Dispersed Fe-N-C Catalysts for the Oxygen Reduction Reaction

Abstract

:1. Introduction

2. Mechanism Investigation

2.1. General ORR Mechanism

2.2. Origin of Activity

2.3. Degradation Mechanism

2.4. Resistance to Poisoning

3. Performance Improvement Strategy

3.1. Heterogeneous Atom Doping

3.2. Bimetallic Atom

3.3. Nanocluster Collaboration

3.4. Active Site Density Engineering

4. Conclusions and Outlook

- (1)

- The precise design of the doping sites and the uniform distribution of the separated metal atoms require further research. There is an urgent need to increase the loading of individual metal atoms so that more individual atoms can be anchored to the substrate, resulting in greater activity and durability.

- (2)

- Further research on different substrates in needed for the selection of an ideal, low-cost, stable support to improve the active site exposure and environmental stability of the catalyst. High-surface-area and high-volume porous carbon substrates are excellent substrates for active sites. A good substrate should be able to precisely regulate the physical/chemical environment to provide stronger bonds for isolated iron atoms, thereby maintaining stronger catalytic activity in the electrocatalytic process and ensuring long-term performance during the electrocatalytic process.

- (3)

- In the design and preparation of catalysts, the framework structure and interatomic interactions of the support should be fully considered in order to maximize the dispersion of metal atoms, effectively suppress the aggregation of metal atoms, and reduce the loss of active sites. The scope of research on dopants should be further extended, and the effects of these impurities at different doping sites should be fully and accurately considered.

- (4)

- Theoretical calculations and in situ characterization techniques should be used to further explore the relationship between structure and performance at the atomic level and to promote research into catalytic mechanisms. Advanced systematic testing methods are key factors in the rational evaluation of catalyst performance. With precise control of the coordination environment, Fe-N-C catalysts have broad application prospects in areas such as fuel cells (FCs).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Snitkoff-Sol, R.Z.; Friedman, A.; Honig, H.C.; Yurko, Y.; Kozhushner, A.; Zachman, M.J.; Zelenay, P.; Bond, A.M.; Elbaz, L. Quantifying the electrochemical active site density of precious metal-free catalysts in situ in fuel cells. Nat. Catal. 2022, 5, 163–170. [Google Scholar] [CrossRef]

- Sun, W.; Wang, F.; Zhang, B.; Zhang, M.; Kupers, V.; Ji, X.; Theile, C.; Bieker, P.; Xu, K.; Wang, C.; et al. A rechargeable zinc-air battery based on zinc peroxide chemistry. Science 2021, 371, 46–51. [Google Scholar] [CrossRef] [PubMed]

- Mehmood, A.; Gong, M.; Jaouen, F.; Roy, A.; Zitolo, A.; Khan, A.; Sougrati, M.-T.; Primbs, M.; Bonastre, A.M.; Fongalland, D.; et al. High loading of single atomic iron sites in Fe–NC oxygen reduction catalysts for proton exchange membrane fuel cells. Nat. Catal. 2022, 5, 311–323. [Google Scholar] [CrossRef]

- Zhu, Y.; Yue, K.; Xia, C.; Zaman, S.; Yang, H.; Wang, X.; Yan, Y.; Xia, B.Y. Recent Advances on MOF Derivatives for Non-Noble Metal Oxygen Electrocatalysts in Zinc-Air Batteries. Nano-Micro Lett. 2021, 13, 137. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Li, N.; Xia, J.-W.; Zhou, S.-L.; Qian, X.-Y.; Yin, F.-X.; Dai, G.-H.; He, G.-Y.; Chen, H.-Q. A pH-universal ORR catalyst with atomic Fe-heteroatom (N, S) sites for high-performance Zn-air batteries. Nano Res. 2023, 16, 9416–9425. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Liu, Y.; Liu, M.; Sheng, K.; Wang, Y.; Yang, J.; Li, J.; Li, W. Recent advances in regulating the performance of acid oxygen reduction reaction on carbon-supported non-precious metal single atom catalysts. J. Energy Chem. 2023, 76, 601–616. [Google Scholar] [CrossRef]

- Ren, S.; Duan, X.; Ge, F.; Chen, Z.; Yang, Q.; Zhang, M.; Zheng, H. Novel MOF-derived hollow CoFe alloy coupled with N-doped Ketjen Black as boosted bifunctional oxygen catalysts for Zn–air batteries. Chem. Eng. J. 2022, 427, 131614. [Google Scholar] [CrossRef]

- Yang, Z.; Xiang, M.; Zhu, Y.; Hui, J.; Jiang, Y.; Dong, S.; Yu, C.; Ou, J.; Qin, H. Single-atom platinum or ruthenium on C4N as 2D high-performance electrocatalysts for oxygen reduction reaction. Chem. Eng. J. 2021, 426, 131347. [Google Scholar] [CrossRef]

- Pruchyathamkorn, J.; Yang, M.; Amin, H.M.A.; Batchelor-McAuley, C.; Compton, R.G. Imaging Electrode Heterogeneity Using Chemically Confined Fluorescence Electrochemical Microscopy. J. Phys. Chem. Lett. 2017, 8, 6124–6127. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, T.; Ge, J.; Lin, Y.; Du, Z.; Zhong, C.; Wang, W.; Jiao, Q.; Yuan, R.; Tian, Y.; et al. High-Density Planar-like Fe2N6 Structure Catalyzes Efficient Oxygen Reduction. Matter 2020, 3, 509–521. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Li, Y.; Wang, J.; Kawi, S.; Zhong, Q. FeCo alloy/N, S co-doped carbon aerogel derived from directional-casting cellulose nanofibers for rechargeable liquid flow and flexible Zn-air batteries. Nano Res. 2023, 16, 6870–6880. [Google Scholar] [CrossRef]

- Yang, B.; Li, B.; Xiang, Z. Advanced MOF-based electrode materials for supercapacitors and electrocatalytic oxygen reduction. Nano Res. 2022, 16, 1338–1361. [Google Scholar] [CrossRef]

- Sarapuu, A.; Lilloja, J.; Akula, S.; Zagal, J.H.; Specchia, S.; Tammeveski, K. Recent Advances in Non-Precious Metal Single-Atom Electrocatalysts for Oxygen Reduction Reaction in Low-Temperature Polymer-Electrolyte Fuel Cells. ChemCatChem 2023, 15, e202300849. [Google Scholar] [CrossRef]

- Bai, J.; Ge, W.; Zhou, P.; Xu, P.; Wang, L.; Zhang, J.; Jiang, X.; Li, X.; Zhou, Q.; Deng, Y. Precise constructed atomically dispersed Fe/Ni sites on porous nitrogen-doped carbon for oxygen reduction. J. Colloid Interface Sci. 2022, 616, 433–439. [Google Scholar] [CrossRef] [PubMed]

- Ku, Y.P.; Ehelebe, K.; Hutzler, A.; Bierling, M.; Bohm, T.; Zitolo, A.; Vorokhta, M.; Bibent, N.; Speck, F.D.; Seeberger, D.; et al. Oxygen Reduction Reaction in Alkaline Media Causes Iron Leaching from Fe-N-C Electrocatalysts. J. Am. Chem. Soc. 2022, 144, 9753–9763. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; He, C.; Li, B.; He, Y.; Cullen, D.A.; Wegener, E.C.; Kropf, A.J.; Martinez, U.; Cheng, Y.; Engelhard, M.H.; et al. Performance enhancement and degradation mechanism identification of a single-atom Co–N–C catalyst for proton exchange membrane fuel cells. Nat. Catal. 2020, 3, 1044–1054. [Google Scholar] [CrossRef]

- Zhan, Y.; Zeng, H.; Zhao, T.; Situ, A.; Yang, L.; Zhang, Z. Densely accessible single atom Fe sites dispersed on porous carbon as highly stable and active ORR catalyst for PEMFC. Int. J. Hydrogen Energy 2024, 56, 1049–1056. [Google Scholar] [CrossRef]

- Tian, H.; Song, A.; Zhang, P.; Sun, K.; Wang, J.; Sun, B.; Fan, Q.; Shao, G.; Chen, C.; Liu, H.; et al. High Durability of Fe-N-C Single Atom Catalysts with Carbon Vacancies Towards Oxygen Reduction Reaction in Alkaline Media. Adv. Mater. 2023, 35, e2210714. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, L.; Khan, J.; Wang, X.; Xiao, J.; Zhang, H.; Xie, H.; Li, L.; Wang, S.; Han, L. Decorating Single-Atomic Mn Sites with FeMn Clusters to Boost Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 2023, 62, e202214988. [Google Scholar] [CrossRef]

- Zhuang, Z.; Xia, L.; Huang, J.; Zhu, P.; Li, Y.; Ye, C.; Xia, M.; Yu, R.; Lang, Z.; Zhu, J.; et al. Continuous Modulation of Electrocatalytic Oxygen Reduction Activities of Single-Atom Catalysts through p-n Junction Rectification. Angew. Chem. Int. Ed. 2023, 62, e202212335. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Liu, X.; Wang, X.; Tian, H.; Waterhouse, G.I.N.; Kruger, P.E.; Telfer, S.G.; Ma, S. Large-scale synthesis of N-doped carbon capsules supporting atomically dispersed iron for efficient oxygen reduction reaction electrocatalysis. eScience 2022, 2, 227–234. [Google Scholar] [CrossRef]

- Chen, C.; Wu, Y.; Li, X.; Ye, Y.; Li, Z.; Zhou, Y. Modulating Fe spin state in FeNC catalysts by adjacent Fe atomic clusters to facilitate oxygen reduction reaction in proton exchange membrane fuel cell. Appl. Catal. B-Environ. 2024, 342, 123407. [Google Scholar] [CrossRef]

- Xia, D.; Tang, X.; Dai, S.; Ge, R.; Rykov, A.; Wang, J.; Huang, T.H.; Wang, K.W.; Wei, Y.; Zhang, K.; et al. Ultrastable Fe-N-C Fuel Cell Electrocatalysts by Eliminating Non-Coordinating Nitrogen and Regulating Coordination Structures at High Temperatures. Adv. Mater. 2022, 35, e2204474. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Qin, Y.; Wu, T.; Ding, S.; Su, Y. Insights into local coordination environment of main group metal-nitrogen-carbon catalysts for enhanced oxygen reduction reaction. Appl. Surf. Sci. 2023, 631, 157581. [Google Scholar] [CrossRef]

- Qin, Y.; Li, Y.; Zhao, W.; Chen, S.; Wu, T.; Su, Y. Computational study of transition metal single-atom catalysts supported on nitrogenated carbon nanotubes for electrocatalytic nitrogen reduction. Nano Res. 2022, 16, 325–333. [Google Scholar] [CrossRef]

- Ramaswamy, N.; Tylus, U.; Jia, Q.; Mukerjee, S. Activity descriptor identification for oxygen reduction on nonprecious electrocatalysts: Linking surface science to coordination chemistry. J. Am. Chem. Soc. 2013, 135, 15443–15449. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Wang, Y.; Li, Y. Two-dimensional iron-porphyrin sheet as a promising catalyst for oxygen reduction reaction: A computational study. Sci Bull. 2017, 62, 1337–1343. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Cheng, D.; Cao, D.; Zeng, X.C. A universal principle for a rational design of single-atom electrocatalysts. Nat. Catal. 2018, 1, 339–348. [Google Scholar] [CrossRef]

- Liu, K.; Fu, J.; Lin, Y.; Luo, T.; Ni, G.; Li, H.; Lin, Z.; Liu, M. Insights into the activity of single-atom Fe-N-C catalysts for oxygen reduction reaction. Nat. Commun. 2022, 13, 2075. [Google Scholar] [CrossRef]

- Li, J.; Zhang, H.; Samarakoon, W.; Shan, W.; Cullen, D.A.; Karakalos, S.; Chen, M.; Gu, D.; More, K.L.; Wang, G.; et al. Thermally Driven Structure and Performance Evolution of Atomically Dispersed FeN4 Sites for Oxygen Reduction. Angew. Chem. Int. Ed. 2019, 58, 18971–18980. [Google Scholar] [CrossRef]

- Li, J.; Jiao, L.; Wegener, E.; Richard, L.L.; Liu, E.; Zitolo, A.; Sougrati, M.T.; Mukerjee, S.; Zhao, Z.; Huang, Y.; et al. Evolution Pathway from Iron Compounds to Fe1(II)-N4 Sites through Gas-Phase Iron during Pyrolysis. J. Am. Chem. Soc. 2020, 142, 1417–1423. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Chen, S.; Chen, L.; Tian, Y.; Yao, S.; Lu, Z.; Zhang, X.; Zhou, Z. What is the Real Origin of the Activity of Fe-N-C Electrocatalysts in the O2Reduction Reaction? Critical Roles of Coordinating Pyrrolic N and Axially Adsorbing Species. J. Am. Chem. Soc. 2022, 144, 18144–18152. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Li, C.; Zachman, M.J.; Zeng, Y.; Yu, H.; Li, B.; Wang, M.; Braaten, J.; Liu, J.; Meyer, H.M.; et al. Atomically dispersed iron sites with a nitrogen–carbon coating as highly active and durable oxygen reduction catalysts for fuel cells. Nat. Energy 2022, 7, 652–663. [Google Scholar] [CrossRef]

- Meyer, Q.; Liu, S.; Li, Y.; Zhao, C. Operando detection of oxygen reduction reaction kinetics of Fe-N-C catalysts in proton exchange membrane fuel cells. J. Power Sources 2022, 533, 231058. [Google Scholar] [CrossRef]

- Ma, Q.; Jin, H.; Zhu, J.; Li, Z.; Xu, H.; Liu, B.; Zhang, Z.; Ma, J.; Mu, S. Stabilizing Fe-N-C Catalysts as Model for Oxygen Reduction Reaction. Adv. Sci. 2021, 8, e2102209. [Google Scholar] [CrossRef]

- Liu, S.; Meyer, Q.; Jia, C.; Wang, S.; Rong, C.; Nie, Y.; Zhao, C. Operando deconvolution of the degradation mechanisms of iron–nitrogen–carbon catalysts in proton exchange membrane fuel cells. Energy Environ. Sci. 2023, 16, 3792–3802. [Google Scholar] [CrossRef]

- Li, J.K.; Sougrati, M.T.; Zitolo, A.; Ablett, J.M.; Oguz, I.C.; Mineva, T.; Matanovic, I.; Atanassov, P.; Huang, Y.; Zenyuk, I.; et al. Identification of durable and non-durable FeNx sites in Fe-N-C materials for proton exchange membrane fuel cells. Nat. Catal. 2020, 4, 10–19. [Google Scholar] [CrossRef]

- Bae, G.; Kim, M.M.; Han, M.H.; Cho, J.; Kim, D.H.; Sougrati, M.-T.; Kim, J.; Lee, K.-S.; Joo, S.H.; Goddard, W.A.; et al. Unravelling the complex causality behind Fe–N–C degradation in fuel cells. Nat. Catal. 2023, 6, 1140–1150. [Google Scholar] [CrossRef]

- Yarlagadda, V.; Carpenter, M.K.; Moylan, T.E.; Kukreja, R.S.; Koestner, R.; Gu, W. Boosting Fuel Cell Performance with Accessible Carbon Mesopores. ACS Energy Lett. 2018, 3, 618–621. [Google Scholar] [CrossRef]

- Cheng, Y.; He, S.; Veder, J.P.; De Marco, R.; Yang, S.Z.; Jiang, S.P. Atomically Dispersed Bimetallic FeNi Catalysts as Highly Efficient Bifunctional Catalysts for Reversible Oxygen Evolution and Oxygen Reduction Reactions. ChemElectroChem 2019, 6, 3478–3487. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Y.; Yang, L.; Zhu, K.; Yuan, Y.; Li, G.; Yuan, Y.; Zhang, Q.; Bai, Z. Boosting oxygen reduction reaction kinetics through perturbating electronic structure of single-atom Fe-N3S1 catalyst with sub-nano FeS cluster. J. Colloid Interface Sci. 2023, 650, 924–933. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.; Hao, J.; Zhang, Y.; Kang, X.; Zhang, J.; Fu, X.Z.; Luo, J.L. N and S dual-coordinated Fe single-atoms in hierarchically porous hollow nanocarbon for efficient oxygen reduction. J. Colloid Interface Sci. 2023, 650, 603–612. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Tang, Y.; Fu, T.; Xiang, Y.; Xiong, Z.; Si, Y.; Guo, C.; Jiang, Z. S, N co-doped carbon nanotubes coupled with CoFe nanoparticles as an efficient bifunctional ORR/OER electrocatalyst for rechargeable Zn-air batteries. Chem. Eng. J. 2022, 429, 132174. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, L.; Zhu, Q.; Ke, Z.; Hu, G. Spatial separation strategy to construct N/S co-doped carbon nanobox embedded with asymmetrically coupled Fe-Co pair-site for boosted reversible oxygen electrocatalysis. J. Energy Chem. 2024, 653, 1577–1587. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Zhang, L.; Zhu, X.; Zhu, S.; Min, Y.; Xu, Q.; Li, Q. Trace Mn-doped on highly dispersed Fe/Mn-SNC ultrathin carbon nanosheets for efficient oxygen reduction reaction. Appl. Surf. Sci. 2023, 613, 156087. [Google Scholar] [CrossRef]

- Wang, R.; Liu, J.; Xie, J.; Cai, Z.; Yu, Y.; Zhang, Z.; Meng, X.; Wang, C.; Xu, X.; Zou, J. Hollow nanocage with skeleton Ni-Fe sulfides modified by N-doped carbon quantum dots for enhancing mass transfer for oxygen electrocatalysis in zinc-air battery. Appl. Catal. B-Environ. 2023, 324, 122230. [Google Scholar] [CrossRef]

- Mun, Y.; Lee, S.; Kim, K.; Kim, S.; Lee, S.; Han, J.W.; Lee, J. Versatile Strategy for Tuning ORR Activity of a Single Fe-N4 Site by Controlling Electron-Withdrawing/Donating Properties of a Carbon Plane. J. Am. Chem. Soc. 2019, 141, 6254–6262. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Wang, Y.; Han, J.; Niu, X.; Guan, J. Engineering the electronic structure of isolated manganese sites to improve the oxygen reduction, Zn-air battery and fuel cell performances. Appl. Catal. B-Environ. 2023, 337, 122966. [Google Scholar] [CrossRef]

- Xiao, Z.; Wu, Y.; Cao, S.; Yan, W.; Chen, B.; Xing, T.; Li, Z.; Lu, X.; Chen, Y.; Wang, K.; et al. An active site pre-anchoring and post-exposure strategy in Fe(CN)64−@PPy derived Fe/S/N-doped carbon electrocatalyst for high performance oxygen reduction reaction and zinc-air batteries. Chem. Eng. J. 2021, 413, 127395. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, X.; Sun, P.; Xu, H.; Yang, L.; Zeng, X.; Huang, Y.; Wang, S.; Cao, D. AgNPs@Fe-N-C oxygen reduction catalysts for anion exchange membrane fuel cells. Nano Energy 2022, 100, 107466. [Google Scholar] [CrossRef]

- Li, Y.; Zang, K.; Duan, X.; Luo, J.; Chen, D. Boost oxygen reduction reaction performance by tuning the active sites in Fe-N-P-C catalysts. J. Energy Chem. 2021, 55, 572–579. [Google Scholar] [CrossRef]

- Ma, R.; Cui, X.; Xu, X.; Wang, Y.; Xiang, G.; Gao, L.; Lin, Z.; Yang, Y. Collaborative integration of ultrafine Fe2P nanocrystals into Fe, N, P-codoped carbon nanoshells for highly-efficient oxygen reduction. Nano Energy 2023, 108, 108179. [Google Scholar] [CrossRef]

- An, Q.; Zhang, X.; Yang, C.; Su, H.; Zhou, W.; Liu, M.; Zhang, X.; Sun, X.; Bo, S.; Yu, F.; et al. Engineering Unsymmetrically Coordinated Fe Sites via Heteroatom Pairs Synergetic Contribution for Efficient Oxygen Reduction. Small 2023, 19, e2304303. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Guo, Y.-F.; Liu, X.; Wang, P.-F.; Xie, Y.; Yi, T.-F. Dual MOF-derived Fe/N/P-tridoped carbon nanotube as high-performance oxygen reduction catalysts for zinc-air batteries. Appl. Catal. B-Environ. 2023, 327, 122469. [Google Scholar] [CrossRef]

- Xu, L.-H.; Che, P.-C.; Zhang, X.-J.; Cosnier, S.; Shan, D. FeP nanoparticles highly dispersed on N,P-doped petaloid carbon nanosheet: Interface engineering and boosted intrinsic ORR activity. Appl. Surf. Sci. 2023, 620, 156770. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, L.; Sun, Y.; Khan, J.; Feng, B.; Xiao, J.; Zhang, H.; Xie, H.; Li, L.; Wang, S.; et al. Asymetric N, P-Coordinated Single-Atomic Fe Sites with Fe2P Nanoclusters/Nanoparticles on Porous Carbon Nanosheets for Highly Efficient Oxygen Electroreduction. Adv. Energy Mater. 2023, 13, 2301223. [Google Scholar] [CrossRef]

- Pei, Z.; Zhang, H.; Guo, Y.; Luan, D.; Gu, X.; Lou, X.W.D. Atomically Dispersed Fe Sites Regulated by Adjacent Single Co Atoms Anchored on N-P Co-Doped Carbon Structures for Highly Efficient Oxygen Reduction Reaction. Adv. Mater. 2023, e2306047. [Google Scholar] [CrossRef] [PubMed]

- Xue, W.; Zhou, Q.; Cui, X.; Zhang, J.; Zuo, S.; Mo, F.; Jiang, J.; Zhu, X.; Lin, Z. Atomically Dispersed FeN2P2 Motif with High Activity and Stability for Oxygen Reduction Reaction Over the Entire pH Range. Angew. Chem. Int. Ed. 2023, 62, e202307504. [Google Scholar] [CrossRef]

- Zhang, Q.; Tsai, H.J.; Li, F.; Wei, Z.; He, Q.; Ding, J.; Liu, Y.; Lin, Z.Y.; Yang, X.; Chen, Z.; et al. Boosting the Proton-coupled Electron Transfer via Fe-P Atomic Pair for Enhanced Electrochemical CO2 Reduction. Angew. Chem. Int. Ed. 2023, 135, e202311550. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, R.; Tao, X.; Qiu, Z.; Chen, G.; Yang, J.; Zhao, Y.; Feng, X.; Mullen, K. Boosting Oxygen Electrocatalytic Activity of Fe-N-C Catalysts by Phosphorus Incorporation. J. Am. Chem. Soc. 2023, 145, 3647–3655. [Google Scholar] [CrossRef]

- Roh, J.; Cho, A.; Kim, S.; Lee, K.-S.; Shin, J.; Choi, J.S.; Bak, J.; Lee, S.; Song, D.; Kim, E.-J.; et al. Transformation of the Active Moiety in Phosphorus-Doped Fe–N–C for Highly Efficient Oxygen Reduction Reaction. ACS Catal. 2023, 13, 9427–9441. [Google Scholar] [CrossRef]

- Yin, H.; Yuan, P.; Lu, B.-A.; Xia, H.; Guo, K.; Yang, G.; Qu, G.; Xue, D.; Hu, Y.; Cheng, J.; et al. Phosphorus-Driven Electron Delocalization on Edge-Type FeN4 Active Sites for Oxygen Reduction in Acid Medium. ACS Catal. 2021, 11, 12754–12762. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, S.; Liu, H.; Liu, S.; Yuan, Y.; Meng, Y.; Wang, M.; Shen, C.; Peng, Q.; Chen, J.; et al. Breaking Local Charge Symmetry of Iron Single Atoms for Efficient Electrocatalytic Nitrate Reduction to Ammonia. Angew. Chem. Int. Ed. 2023, 62, e202308044. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Tuo, Y.; Ye, C.; Chen, C.; Lu, Q.; Li, G.; Jiang, P.; Chen, S.; Zhu, P.; Ma, M.; et al. Phosphorus Induced Electron Localization of Single Iron Sites for Boosted CO2 Electroreduction Reaction. Angew. Chem. Int. Ed. 2021, 60, 23614–23618. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Jia, Y.; Yu, B.; Wang, Y.; Li, H.; Liu, Y.; Tan, Q. Heteroatom Coordination Regulates Iron Single-Atom-Catalyst with Superior Oxygen Reduction Reaction Performance for Aqueous Zn-Air Battery. Small 2023, 19, e2206478. [Google Scholar] [CrossRef] [PubMed]

- Zong, L.; Fan, K.; Li, P.; Lu, F.; Li, B.; Wang, L. Promoting Oxygen Reduction Reaction on Atomically Dispersed Fe Sites via Establishing Hydrogen Bonding with the Neighboring P Atoms. Adv. Energy Mater. 2023, 13, 2203611. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Q.-a.; Wang, J.; Wang, J.; Zhang, J.; Zhao, Y. Supported dual-atom catalysts: Preparation, characterization, and potential applications. Chin. J. Catal. 2020, 41, 783–798. [Google Scholar] [CrossRef]

- Zeng, Z.; Gan, L.Y.; Yang, H.B.; Su, X.; Gao, J.; Liu, W. Orbital coupling of hetero-diatomic nickel-iron site for bifunctional electrocatalysis of CO2 reduction and oxygen evolution. Nat. Commun. 2021, 12, 4088. [Google Scholar] [CrossRef]

- Hao, Q.; Zhong, H.-X.; Wang, J.-Z.; Liu, K.-H.; Yan, J.-M.; Ren, Z.-H. Nickel dual-atom sites for electrochemical carbon dioxide reduction. Nat. Synth. 2022, 1, 719–728. [Google Scholar] [CrossRef]

- Tang, T.; Wang, Y.; Han, J.; Zhang, Q.; Bai, X.; Niu, X. Dual-atom Co-Fe catalysts for oxygen reduction reaction. Chin. J Catal. 2023, 46, 48–55. [Google Scholar] [CrossRef]

- Soltani, M.; Amin, H.M.A.; Cebe, A.; Ayata, S.; Baltruschat, H. Metal-Supported Perovskite as an Efficient Bifunctional Electrocatalyst for Oxygen Reduction and Evolution: Substrate Effect. J. Electrochem. Soc. 2021, 168, 034504. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, L.; Libretto, N.J.; Li, X.; Li, C.; Wan, Y. Ensemble Effect in Bimetallic Electrocatalysts for CO2 Reduction. J. Am. Chem. Soc. 2019, 141, 16635–16642. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.; Liu, H.; Cao, Y.; Xi, S.; Li, Z.; He, Z. Mesostructured cellular foam silica supported Au–Pt nanoalloy: Enrichment of d-state electrons for promoting the catalytic synergy. Microporous Mesoporous Mater. 2021, 316, 110982. [Google Scholar] [CrossRef]

- Yin, S.; Shen, Y.; Zhang, J.; Yin, H.-M.; Liu, X.-Z.; Ding, Y. Tuning the electronic structure of nanoporous Ag via alloying effect from Cu to boost the ORR and Zn-air battery performance. Appl. Surf. Sci. 2021, 545, 149042. [Google Scholar] [CrossRef]

- Liu, Y.; Du, L.; Kong, F.; Han, G.; Gao, Y.; Du, C. Sulfur Dioxide-Tolerant Bimetallic PtRu Catalyst toward Oxygen Electroreduction. ACS Sustain. Chem. Eng. 2019, 8, 1295–1301. [Google Scholar] [CrossRef]

- Zhao, K.; Shu, Y.; Li, F.; Peng, G. Bimetallic catalysts as electrocatalytic cathode materials for the oxygen reduction reaction in microbial fuel cell: A review. Green Energy Environ. 2023, 8, 1043–1070. [Google Scholar] [CrossRef]

- Karmodak, N.; Norskov, J.K. Activity and Stability of Single- and Di-Atom Catalysts for the O2 Reduction Reaction. Angew. Chem. Int. Ed. 2023, 22, e202311113. [Google Scholar]

- Guo, D.; Wang, Y.; Lu, P.; Liu, J.; Liu, Y. Flow-through electro-Fenton using nanoconfined Fe-Mn bimetallic oxides: Ionization potential-dependent micropollutants degradation mechanism. Appl. Catal. B-Environ. 2023, 328, 122538. [Google Scholar] [CrossRef]

- Huang, S.; Qiao, Z.; Sun, P.; Qiao, K.; Pei, K.; Yang, L.; Xu, H.; Wang, S.; Huang, Y.; Yan, Y.; et al. The strain induced synergistic catalysis of FeN4 and MnN3 dual-site catalysts for oxygen reduction in proton-/anion-exchange membrane fuel cells. Appl. Catal. B-Environ. 2022, 317, 721770. [Google Scholar] [CrossRef]

- Jiao, Y.; Deng, L.; Liu, D.; Jiao, Y.; Wang, D.; Chen, J.-F. Process intensification for Fe/Mn-nitrogen-doped carbon-based catalysts toward efficient oxygen reduction reaction of Zn-air battery. Chem. Eng. Sci. 2022, 259, 117811. [Google Scholar] [CrossRef]

- Li, J.-K.; Wang, F.-F.; Zhang, Y.; Wang, R.; Zhao, S.-N.; Zang, S.-Q. Engineering the electronic structures of hetero-diatomic iron-manganese sites by d-d orbital hybridization for boosting oxygen reduction. Appl. Catal. B-Environ. 2023, 338, 123090. [Google Scholar] [CrossRef]

- Li, T.; Hu, Y.; Liu, K.; Yin, J.; Li, Y.; Fu, G.; Zhang, Y.; Tang, Y. Hollow yolk-shell nanoboxes assembled by Fe-doped Mn3O4 nanosheets for high-efficiency electrocatalytic oxygen reduction in Zn-Air battery. Chem. Eng. J. 2022, 427, 131992. [Google Scholar] [CrossRef]

- Lin, S.-Y.; Xia, L.-X.; Zhang, L.; Feng, J.-J.; Zhao, Y.; Wang, A.-J. Highly active Fe centered FeM-N-doped carbon (M=Co/Ni/Mn): A general strategy for efficient oxygen conversion in Zn–air battery. Chem. Eng. J. 2021, 424, 131992. [Google Scholar] [CrossRef]

- Song, S.; Wang, Y.; Tian, P.; Zang, J. One-step complexation and self-template strategy to synthesis bimetal Fe/Mn–N doped interconnected hierarchical porous carbon for enhancing catalytic oxygen reduction reaction. Int. J. Hydrogen Energy 2022, 47, 24728–24737. [Google Scholar] [CrossRef]

- Wu, D.H.; Huang, H.; Ul Haq, M.; Zhang, L.; Feng, J.J.; Wang, A.J. Lignin-derived iron carbide/Mn, N, S-codoped carbon nanotubes as a high-efficiency catalyst for synergistically enhanced oxygen reduction reaction and rechargeable zinc-air battery. J. Colloid Interface Sci. 2023, 647, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.X.; Zhang, S.; Huang, H.; Liu, X.; Li, B.; Lee, Y.; Wang, X.; Bai, Y.; Sun, M.; Wu, Y.; et al. General Synthesis of a Diatomic Catalyst Library via a Macrocyclic Precursor-Mediated Approach. J. Am. Chem. Soc. 2023, 145, 4819–4827. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Ma, Z.; Wan, Z.; Li, J.; Wang, X. Noble-Metal-Free FeMn-N-C catalyst for efficient oxygen reduction reaction in both alkaline and acidic media. J. Colloid Interface Sci. 2023, 642, 800–809. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Liao, X.; Sun, C.; Zhao, K.; Ye, D.; Li, J.; Wu, G.; Fang, J.; Zhao, H.; Zhang, J. Enhanced performance of atomically dispersed dual-site Fe-Mn electrocatalysts through cascade reaction mechanism. Appl. Catal. B-Environ. 2021, 288, 120021. [Google Scholar] [CrossRef]

- Wang, N.; Liang, J.; Liu, J.; Cai, Q.; Li, J.; Chen, J.; Huang, T.; Shi, Z. CoFe nanoparticles dispersed in Co/Fe-N-C support with meso- and macroporous structures as the high-performance catalyst boosting the oxygen reduction reaction for Al/Mg-air batteries. J. Power Sources 2022, 517, 230707. [Google Scholar] [CrossRef]

- Yasin, G.; Ali, S.; Ibraheem, S.; Kumar, A.; Tabish, M.; Mushtaq, M.A.; Ajmal, S.; Arif, M.; Khan, M.A.; Saad, A.; et al. Simultaneously Engineering the Synergistic-Effects and Coordination-Environment of Dual-Single-Atomic Iron/Cobalt-sites as a Bifunctional Oxygen Electrocatalyst for Rechargeable Zinc-Air Batteries. ACS Catal. 2023, 13, 2313–2325. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, M.; Yang, Q.; Lai, M.; Zhang, J.; Liu, C.; Xu, X.; Jia, J. Agarose-gel-based self-limiting synthesis of a bimetal (Fe and Co)-doped composite as a bifunctional catalyst for a zinc-air battery. J. Colloid Interface Sci. 2023, 635, 186–196. [Google Scholar] [CrossRef]

- Zhu, W.; Pei, Y.; Douglin, J.C.; Zhang, J.; Zhao, H.; Xue, J.; Wang, Q.; Li, R.; Qin, Y.; Yin, Y.; et al. Multi-scale study on bifunctional Co/Fe–N–C cathode catalyst layers with high active site density for the oxygen reduction reaction. Appl. Catal. B-Environ. 2021, 299, 120656. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, Y.; Li, L.; Wei, L.; Su, J.; Guo, L. Enhanced oxygen reduction activity and stability of double-layer nitrogen-doped carbon catalyst with abundant Fe-Co dual-atom sites. Nano Energy 2023, 117, 108854. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Liao, T.; Ma, C.; Chen, B.; Li, Y.; Fan, X.; Peng, W. Fe doping induced selenium vacancy on cobalt selenide for enhanced hydrogen peroxides production. Appl. Catal. B-Environ. 2024, 341, 123344. [Google Scholar] [CrossRef]

- Xiao, Z.; Sun, P.; Qiao, Z.; Qiao, K.; Xu, H.; Wang, S.; Cao, D. Atomically dispersed Fe-Cu dual-site catalysts synergistically boosting oxygen reduction for hydrogen fuel cells. Chem. Eng. J. 2022, 446, 137112. [Google Scholar] [CrossRef]

- Bu, M.; Liu, Y.; Liao, S.; Liu, W.; Yang, Z.; Jiang, J.; Gao, X.; Yang, Y.; Liu, H. In-site grown carbon nanotubes connecting Fe/Cu-N-C polyhedrons as robust electrocatalysts for Zn-air batteries. Carbon 2023, 214, 137112. [Google Scholar] [CrossRef]

- Nie, Z.; Zhang, L.; Zhu, Q.; Ke, Z.; Zhou, Y.; Wågberg, T.; Hu, G. Reversed charge transfer induced by nickel in Fe-Ni/Mo2C@nitrogen-doped carbon nanobox for promoted reversible oxygen electrocatalysis. J. Energy Chem. 2024, 88, 202–212. [Google Scholar] [CrossRef]

- Tsai, J.-E.; Hong, W.-X.; Pourzolfaghar, H.; Wang, W.-H.; Li, Y.-Y. A Fe-Ni-Zn triple single-atom catalyst for efficient oxygen reduction and oxygen evolution reaction in rechargeable Zn-air batteries. Chem. Eng. J. 2023, 460, 141868. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, B.; Hu, J.; Huang, X.; Ma, W.; Li, N.; Wagberg, T.; Hu, G. Nickel-induced charge redistribution in Ni-Fe/Fe3C@nitrogen-doped carbon nanocage as a robust Mott-Schottky bi-functional oxygen catalyst for rechargeable Zn-air battery. J. Colloid Interface Sci. 2022, 625, 521–531. [Google Scholar] [CrossRef]

- Chen, D.; Li, G.; Chen, X.; Zhang, Q.; Sui, J.; Li, C.; Zhang, Y.; Hu, J.; Yu, J.; Yu, L.; et al. Developing nitrogen and Co/Fe/Ni multi-doped carbon nanotubes as high-performance bifunctional catalyst for rechargeable zinc-air battery. J. Colloid Interface Sci. 2021, 593, 204–213. [Google Scholar] [CrossRef]

- Wang, Z.; Li, C.; Liu, Y.; Wu, Y.; Zhang, S.; Deng, C. Atomically dispersed Fe-Ni dual sites in heteroatom doped carbon tyres for efficient oxygen electrocatalysis in rechargeable Zn-Air battery. J. Energy Chem. 2023, 83, 264–274. [Google Scholar] [CrossRef]

- Yao, B.; Yu, Y.; Wang, Z.; Yang, J.; Zhou, Y.; Dionysiou, D.D. Electro-induced activation of persulfate over N-doped porous carbon decorated with Fe/Ni bimetals for organic pollutants enhanced degradation: Synergism of electro-activation and catalytic activation. Chem. Eng. J. 2023, 476, 146769. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Jiang, M.; Wei, J.; Ding, X.; Zhu, C.; He, H.; Lai, H.; Shi, J. Engineering the coordination environment in atomic Fe/Ni dual-sites for efficient oxygen electrocatalysis in Zn-air and Mg-air batteries. Chem. Eng. J. 2021, 426, 130758. [Google Scholar] [CrossRef]

- Wang, B.; Tang, J.; Zhang, X.; Hong, M.; Yang, H.; Guo, X.; Xue, S.; Du, C.; Liu, Z.; Chen, J. Nitrogen doped porous carbon polyhedral supported Fe and Ni dual-metal single-atomic catalysts: Template-free and metal ligand-free sysnthesis with microwave-assistance and d-band center modulating for boosted ORR catalysis in zinc-air batteries. Chem. Eng. J. 2022, 437, 135295. [Google Scholar] [CrossRef]

- Yang, G.; Zhu, J.; Yuan, P.; Hu, Y.; Qu, G.; Lu, B.A.; Xue, X.; Yin, H.; Cheng, W.; Cheng, J.; et al. Regulating Fe-spin state by atomically dispersed Mn-N in Fe-N-C catalysts with high oxygen reduction activity. Nat. Commun. 2021, 12, 1734. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yang, X.; Li, Y.; Liu, L.; Guo, S.; Shu, C.; Liu, F.; Liu, Y.; Tan, Q.; Wu, G. Atomically Dispersed Fe–Co Dual Metal Sites as Bifunctional Oxygen Electrocatalysts for Rechargeable and Flexible Zn–Air Batteries. ACS Catal. 2022, 12, 1216–1227. [Google Scholar] [CrossRef]

- Zheng, F.-Y.; Li, R.; Xi, S.; Ai, F.; Wang, J. Engineering an iron atom-cluster nanostructure towards efficient and durable electrocatalysis. J. Mater. Chem. A 2023, 11, 8202–8212. [Google Scholar] [CrossRef]

- Bai, J.; Tang, Y.; Lin, C.; Jiang, X.; Zhang, C.; Qin, H.; Zhou, Q.; Xiang, M.; Lian, Y.; Deng, Y. Iron clusters regulate local charge distribution in Fe-N4 sites to boost oxygen electroreduction. J. Colloid Interface Sci. 2023, 648, 440–447. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; He, T.; Liu, Q.; Hu, Y.; Gu, H.; Deng, L.; Liu, H.; Liu, Y.; Liu, Y.-N.; Zhang, Y.; et al. Highly durable iron single-atom catalysts for low-temperature zinc-air batteries by electronic regulation of adjacent iron nanoclusters. Appl. Catal. B-Environ. 2023, 323, 122163. [Google Scholar] [CrossRef]

- Li, J.-C.; Meng, Y.; Zhong, H.; Zhang, L.; Ding, S.; Lyu, Z.; Beckman, S.P.; Hou, P.-X.; Mei, Y.; Cheng, H.-M.; et al. Supramolecular complex derived carbon nanotubes decorated with iron single atoms and nanoclusters as efficient bifunctional oxygen electrocatalysts for rechargeable Zn-air batteries. Carbon 2023, 205, 302–309. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, L.; Li, R.; Qu, K.; Wang, L.; Kang, W.; Li, H.; Xiong, S. Electrocatalytic oxygen reduction of COF-derived porous Fe-Nx nanoclusters/carbon catalyst and application for high performance Zn-air battery. Microporous Mesoporous Mater. 2022, 330, 111609. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.Y.; Wen, Z.; Yang, C.C.; Jiang, Q. Synchronous bi-modulation by nanoclusters and single atoms for high-efficient oxygen reduction electrocatalysis. Chem. Eng. J. 2022, 446, 111609. [Google Scholar] [CrossRef]

- Tan, F.; Li, W.; Wang, J.; Min, C.; Li, Z.; Zhang, B.; Zheng, X.; Li, L.; Zhang, L.; Zhou, L.; et al. Clarifying the critical roles of iron in boosting oxygen reduction: Single Fe atoms anchored on carbon vacancies as efficient active sites. Appl. Catal. B-Environ. 2022, 305, 121035. [Google Scholar] [CrossRef]

- Wu, S.; Jiang, S.; Liu, S.-Q.; Tan, X.; Chen, N.; Luo, J.-L.; Mushrif, S.H.; Cadien, K.; Li, Z. Single Cu–N4 sites enable atomic Fe clusters with high-performance oxygen reduction reactions. Energy Environ. Sci. 2023, 16, 3576–3586. [Google Scholar] [CrossRef]

- Qi, C.; Yang, H.; Sun, Z.; Wang, H.; Xu, N.; Zhu, G.; Wang, L.; Jiang, W.; Yu, X.; Li, X.; et al. Modulating Electronic Structures of Iron Clusters through Orbital Rehybridization by Adjacent Single Copper Sites for Efficient Oxygen Reduction. Angew. Chem. Int. Ed. 2023, 62, e202308344. [Google Scholar] [CrossRef] [PubMed]

- Dong, Q.; Li, G.; Liu, F.; Ren, J.; Wang, H.; Wang, R. Cu nanoclusters activating ultrafine Fe3N nanoparticles via the Mott-Schottky effect for rechargeable zinc-air batteries. Appl. Catal. B-Environ. 2023, 326, 122415. [Google Scholar] [CrossRef]

- Liu, D.; Liu, J.; Wang, L.; Ma, Z.; Xing, J.; Yang, Y.; Xue, B.; Li, F. Enhanced bifunctional electrocatalytic performance of NiFe-layered double hydroxide activated by ultrasonic-assisted loading of Pd nanoclusters. Int. J. Hydrogen Energy 2023, 49, 152–168. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, L.; Liu, M.; Zhang, Q.; Chen, Z.; Zheng, L.; Cui, Z.; Zhang, Z.; Liao, S. Nitrogen and atomic Fe co-doped hollow carbon nanocages supporting RuPd nanoclusters as extraordinary high-performance nanoreactor-like cathode for lithium–oxygen batteries. Energy Storage Mater. 2023, 61, 102874. [Google Scholar] [CrossRef]

- Manjunatha, R.; Dong, L.; Zhai, Z.; Wang, J.; Fu, Q.; Yan, W.; Zhang, J. Pd nanocluster-decorated CoFe composite supported on nitrogen carbon nanotubes as a high-performance trifunctional electrocatalyst. Green Energy Environ. 2022, 7, 933–947. [Google Scholar] [CrossRef]

- Wu, M.; Yang, X.; Cui, X.; Chen, N.; Du, L.; Cherif, M.; Chiang, F.K.; Wen, Y.; Hassanpour, A.; Vidal, F.; et al. Engineering Fe-N4 Electronic Structure with Adjacent Co-N2C2 and Co Nanoclusters on Carbon Nanotubes for Efficient Oxygen Electrocatalysis. Nano-Micro Lett. 2023, 15, 232. [Google Scholar] [CrossRef]

- Ruan, Q.D.; Zhang, L.; Feng, J.J.; You, L.X.; Wang, Z.G.; Wang, A.J. Three-dimensional self-supporting superstructured double-sided nanoneedles arrays of iron carbide nanoclusters embedded in manganese, nitrogen co-doped carbon for highly efficient oxygen reduction reaction. J. Colloid Interface Sci. 2022, 614, 655–665. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Shu, X.; Tong, P.; Zhang, J.; An, P.; Lv, Z.; Tian, H.; Zhang, J.; Xia, H. Fe-Ni Alloy Nanoclusters Anchored on Carbon Aerogels as High-Efficiency Oxygen Electrocatalysts in Rechargeable Zn-Air Batteries. Small 2021, 17, e2102002. [Google Scholar] [CrossRef] [PubMed]

- Meng, H.L.; Lin, S.Y.; Feng, J.J.; Zhang, L.; Wang, A.J. Coordination regulated pyrolysis synthesis of ultrafine FeNi/(FeNi)9S8 nanoclusters/nitrogen, sulfur-codoped graphitic carbon nanosheets as efficient bifunctional oxygen electrocatalysts. J. Colloid Interface Sci. 2022, 610, 573–582. [Google Scholar] [CrossRef] [PubMed]

- Wan, X.; Liu, Q.; Liu, J.; Liu, S.; Liu, X.; Zheng, L.; Shang, J.; Yu, R.; Shui, J. Iron atom-cluster interactions increase activity and improve durability in Fe-N-C fuel cells. Nat. Commun. 2022, 13, 2963. [Google Scholar] [CrossRef] [PubMed]

- Han, A.; Sun, W.; Wan, X.; Cai, D.; Wang, X.; Li, F.; Shui, J.; Wang, D. Construction of Co4 Atomic Clusters to Enable Fe-N4 Motifs with Highly Active and Durable Oxygen Reduction Performance. Angew. Chem. Int. Ed. 2023, 62, e202303185. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Song, S.; Cai, W.; Luo, X.; Jiao, L.; Fang, Q.; Wang, X.; Wu, N.; Luo, Z.; Wang, H.; et al. Tuning the spin state of Fe single atoms by Pd nanoclusters enables robust oxygen reduction with dissociative pathway. Chem 2023, 9, 181–197. [Google Scholar] [CrossRef]

- Lu, X.; Yang, P.; Wan, Y.; Zhang, H.; Xu, H.; Xiao, L. Active site engineering toward atomically dispersed M−N−C catalysts for oxygen reduction reaction. Coord. Chem. Rev. 2023, 495, 215400. [Google Scholar] [CrossRef]

- Liu, F.; Shi, L.; Lin, X.; Yu, D.; Zhang, C.; Xu, R.; Liu, D.; Qiu, J.; Dai, L. Site-density engineering of single-atomic iron catalysts for high-performance proton exchange membrane fuel cells. Appl. Catal. B-Environ. 2022, 302, 120860. [Google Scholar] [CrossRef]

- Xiao, F.; Wang, Y.; Xu, G.L.; Yang, F.; Zhu, S.; Sun, C.J.; Cui, Y.; Xu, Z.; Zhao, Q.; Jang, J.; et al. Fe-N-C Boosts the Stability of Supported Platinum Nanoparticles for Fuel Cells. J. Am. Chem. Soc. 2022, 144, 20372–20384. [Google Scholar] [CrossRef]

- Lu, G.; Men, X.; Tang, R.; Wang, Z.; Cui, H.; Zheng, T.; Wang, M.; Yang, H.; Liu, Z. Bionic Fe-N-C catalyst with abundant exposed Fe-Nx sites and enhanced mass transfer properties for efficient oxygen reduction. J. Colloid Interface Sci. 2023, 655, 90–99. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Huang, A.; Liu, X.; Li, J.; Zhang, Y.; Chen, Z.; Zhuang, Z.; Wu, Y.; Cheong, W.C.; et al. Engineering Molecular Heterostructured Catalyst for Oxygen Reduction Reaction. J. Am. Chem. Soc. 2023, 145, 21273–21283. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, S.; Xia, J.; Li, L.; Qian, X.; Yin, F.; He, G.; Chen, H. g-C3N4 promoted MOF-derived Fe single atoms anchored on N-doped hierarchically porous carbon for high-performance Zn-air batteries. J. Colloid Interface Sci. 2024, 653, 551–560. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Kong, F.; Yao, H.; Chen, Y.; Meng, G.; Chang, Z.; Chen, C.; Tian, H.; Wang, L.; Cui, X.; et al. Dual metal-organic frameworks-derived Fe-atomic sites bounded to fine Fe/Fe C nanoparticles for enhanced oxygen electroreduction. Chem. Eng. J. 2023, 453, 139820. [Google Scholar] [CrossRef]

- da Silva Freitas, W.; D’Epifanio, A.; Lo Vecchio, C.; Gatto, I.; Baglio, V.; Ficca, V.C.A.; Placidi, E.; Mecheri, B. Tailoring MOF structure via iron decoration to enhance ORR in alkaline polymer electrolyte membrane fuel cells. Chem. Eng. J. 2023, 465, 142987. [Google Scholar] [CrossRef]

- Feng, C.; Guo, Y.; Qiao, S.; Xie, Y.; Zhang, L.; Zhang, L.; Wang, W.; Wang, J. 2-Methylimidazole as a nitrogen source assisted synthesis of a nano-rod-shaped Fe/FeN@N-C catalyst with plentiful FeN active sites and enhanced ORR activity. Appl. Surf. Sci. 2020, 533, 147481. [Google Scholar] [CrossRef]

- Hu, X.; Min, Y.; Ma, L.-L.; Lu, J.-Y.; Li, H.-C.; Liu, W.-J.; Chen, J.-J.; Yu, H.-Q. Iron-nitrogen doped carbon with exclusive presence of FexN active sites as an efficient ORR electrocatalyst for Zn-air battery. Appl. Catal. B-Environ. 2020, 268, 118405. [Google Scholar] [CrossRef]

- Liu, Y.; Tu, F.; Zhang, Z.; Zhao, Z.; Guo, P.; Shen, L.; Zhang, Y.; Zhao, L.; Shao, G.; Wang, Z. Molecular scissor tailoring hierarchical architecture of ZIF-derived Fe/N/C catalysts for acidic oxygen reduction reaction. Appl. Catal. B-Environ. 2023, 324, 122209. [Google Scholar] [CrossRef]

- Niu, W.-J.; Yan, Y.-Y.; Li, R.-J.; Zhao, W.-W.; Chen, J.-L.; Liu, M.-J.; Gu, B.; Liu, W.-W.; Chueh, Y.-L. Identifying the impact of Fe nanoparticles encapsulated by nitrogen-doped carbon to Fe single atom sites for boosting oxygen reduction reaction toward Zn-air batteries. Chem. Eng. J. 2023, 456, 140858. [Google Scholar] [CrossRef]

- Wang, W.; Gong, J.; Long, Q.; Wang, H.; Huang, J.; Dang, W.; Chen, L.; Li, G.; Hou, Z.; Xu, W. Fe-Fe3N composite nitrogen-doped carbon framework: Multi-dimensional cross-linked structure boosting performance for the oxygen reduction reaction electrocatalysis and zinc-air batteries. Appl. Surf. Sci. 2023, 639, 158218. [Google Scholar] [CrossRef]

- Zou, Y.; Li, J.; Yu, Y.; Zhang, J.; Fu, Q.; Zhang, L.; Liao, Q.; Zhu, X. Maximizing Fe-N exposure by tuning surface composition via twice acid treatment based on an ultrathin hollow nanocarbon structure for highly efficient oxygen reduction reaction. Chem. Eng. J. 2022, 432, 134362. [Google Scholar] [CrossRef]

- Wei, S.; Li, L.; Li, A.; Zhang, L.; Hu, H.; Pang, D.; Zhang, Q.; Xiao, H.; Chen, W. Atomic defects engineering on Fe-N4 sites for boosting oxygen reduction by in-situ ZnO thermal etching strategy. Chem. Eng. J. 2023, 465, 142820. [Google Scholar] [CrossRef]

- Han, J.; Bao, H.; Wang, J.-Q.; Zheng, L.; Sun, S.; Wang, Z.L.; Sun, C. 3D N-doped ordered mesoporous carbon supported single-atom Fe-N-C catalysts with superior performance for oxygen reduction reaction and zinc-air battery. Appl. Catal. B-Environ. 2021, 280, 119411. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, F.; Yang, F.; He, H.; Yang, J.; Zhang, W.; Luo, J.; Zhang, J.; Fu, C. Rationalization on high-loading iron and cobalt dual metal single atoms and mechanistic insight into the oxygen reduction reaction. Nano Energy 2022, 93, 106793. [Google Scholar] [CrossRef]

- Ma, F.X.; Liu, Z.Q.; Zhang, G.; Xiong, Y.X.; Zhang, M.T.; Zheng, L. Isolating Fe Atoms in N-Doped Carbon Hollow Nanorods through a ZIF-Phase-Transition Strategy for Efficient Oxygen Reduction. Small 2022, 18, e2205033. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Huang, J.; Chen, Z.; Shi, C.; Yang, H.; Tang, Y. Molecular Engineering toward High-Crystallinity Yet High-Surface-Area Porous Carbon Nanosheets for Enhanced Electrocatalytic Oxygen Reduction. Adv. Sci. 2022, 9, e2103477. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yang, J.; Meng, L.; Ma, C.; Peng, L.; Chen, D. Polyaniline-derived carbon nanofibers with a high graphitization degree loading ordered PtNi intermetallic nanoparticles for oxygen reduction reaction. Ind. Chem. Mater. 2023, 1, 458–464. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Huang, C.; Ye, P.; Luo, X.; Ning, J. Trifunctional electrocatalyst of N-doped graphitic carbon nanosheets encapsulated with CoFe alloy nanocrystals: The key roles of bimetal components and high-content graphitic-N. Appl Catal B-Environ. 2021, 298, 120512. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.; Cheng, M.; Feng, Y.; Han, X.; Qian, Q. Arming Ru with Oxygen-Vacancy-Enriched RuO2 Sub-Nanometer Skin Activates Superior Bifunctionality for pH-Universal Overall Water Splitting. Adv. Mater. 2023, 35, e2206351. [Google Scholar] [CrossRef]

- Ye, W.; Chen, S.; Lin, Y.; Yang, L.; Chen, S.; Zheng, X. Precisely Tuning the Number of Fe Atoms in Clusters on N-Doped Carbon toward Acidic Oxygen Reduction Reaction. Chem 2019, 5, 2865–2878. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, W.; Utetiwabo, W.; Lian, Y.M.; Yin, X.; Zhou, L. Revealing of Active Sites and Catalytic Mechanism in N-Coordinated Fe.; Ni Dual-Doped Carbon with Superior Acidic Oxygen Reduction than Single-Atom Catalyst. J. Phys. Chem. Lett. 2020, 11, 1404–1410. [Google Scholar] [CrossRef]

- Yin, S.H.; Yang, J.; Han, Y.; Li, G.; Wan, L.Y.; Chen, Y.H. Construction of Highly Active Metal-Containing Nanoparticles and FeCo-N4 Composite Sites for the Acidic Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 2020, 59, 21976–21979. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Jin, X.; Zhu, C.; Liu, Y.; Tan, H.; Ku, R. Atomically Dispersed Co2 -N6 and Fe-N4 Costructures Boost Oxygen Reduction Reaction in Both Alkaline and Acidic Media. Adv. Mater. 2021, 33, e2104718. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.; Barr, J.A.; Shi, Q.; Zeng, Y.; Tieu, P.; Lyu, Z. Engineering Atomic Single Metal-FeN4Cl Sites with Enhanced Oxygen-Reduction Activity for High-Performance Proton Exchange Membrane Fuel Cells. ACS Nano 2022, 16, 15165–15174. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Wu, M.; Chen, J.; Mo, Z.; Chen, R.; Wang, K. An Fe-N/S-C hybrid electrocatalyst derived from bimetal-organic framework for efficiently electrocatalyzing oxygen reduction reaction in acidic media. J. Energy Chem. 2021, 52, 291–300. [Google Scholar] [CrossRef]

- Jin, H.; Zhou, H.; He, D.; Wang, Z.; Wu, Q.; Liang, Q. MOF-derived 3D Fe-N-S co-doped carbon matrix/nanotube nanocomposites with advanced oxygen reduction activity and stability in both acidic and alkaline media. Appl. Catal. B-Environ. 2019, 250, 143–149. [Google Scholar] [CrossRef]

- Chen, J.; Huang, B.; Cao, R.; Li, L.; Tang, X.; Wu, B. Steering Local Electronic Configuration of Fe–N–C-Based Coupling Catalysts via Ligand Engineering for Efficient Oxygen Electroreduction. Adv. Funct. Mater. 2022, 33, 2209315. [Google Scholar] [CrossRef]

- Xu, C.; Si, Y.; Hu, B.; Xu, X.; Hu, B.; Jiang, Y. Promoting oxygen reduction via crafting bridge-bonded oxygen ligands on a single-atom iron catalyst. Inorg. Chem. Front. 2022, 9, 3306–3318. [Google Scholar] [CrossRef]

- Guo, X.; Shi, J.; Li, M.; Zhang, J.; Zheng, X.; Liu, Y. Modulating Coordination of Iron Atom Clusters on N, P, S Triply-Doped Hollow Carbon Support towards Enhanced Electrocatalytic Oxygen Reduction. Angew. Chem. Int. Ed. 2023, 62, e202314124. [Google Scholar] [CrossRef]

| Catalysts | Electrolyte | Half-Wave (V vs. RHE) | Current Intensity mA cm−2 | Reference |

|---|---|---|---|---|

| Fe2-NC | 0.1 M HClO4 | 0.78 | 5.5 | [149] |

| FeSA/FeAC-NC 900 | 0.1 M HClO4 | 0.80 | 5.5 | [107] |

| FeNi-N6 | 0.1 M HClO4 | 0.79 | 5.2 | [150] |

| M/FeCo-SAs-N-C | 0.1 M HClO4 | 0.851 | 4.7 | [151] |

| Co2/Fe-N@CHC | 0.1 M HClO4 | 0.812 | 5.9 | [152] |

| FeN4Cl SAC | 0.1 M HClO4 | 0.818 | 6.0 | [153] |

| Fe-N/S-C-10% | 0.5 M H2SO4 | 0.81 | 4.9 | [154] |

| Fe-N-S CNN | 0.5 M H2SO4 | 0.78 | 6.0 | [155] |

| FeNCs/FeSAs-NC-Z8@34 | 0.1 M KOH | 0.918 | 5.6 | [108] |

| FeS/FeNSC | 0.1 M KOH | 0.91 | 5.3 | [156] |

| Fe,P-DAS@MPC | 0.1 M KOH | 0.92 | 6.5 | [66] |

| Fe@Fe/N-G-80 | 0.1 M KOH | 0.866 | 6.34 | [157] |

| FeACs/NPS HC | 0.1 M KOH | 0.87 | 6.0 | [158] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lian, Y.; Xu, J.; Zhou, W.; Lin, Y.; Bai, J. Research Progress on Atomically Dispersed Fe-N-C Catalysts for the Oxygen Reduction Reaction. Molecules 2024, 29, 771. https://doi.org/10.3390/molecules29040771

Lian Y, Xu J, Zhou W, Lin Y, Bai J. Research Progress on Atomically Dispersed Fe-N-C Catalysts for the Oxygen Reduction Reaction. Molecules. 2024; 29(4):771. https://doi.org/10.3390/molecules29040771

Chicago/Turabian StyleLian, Yuebin, Jinnan Xu, Wangkai Zhou, Yao Lin, and Jirong Bai. 2024. "Research Progress on Atomically Dispersed Fe-N-C Catalysts for the Oxygen Reduction Reaction" Molecules 29, no. 4: 771. https://doi.org/10.3390/molecules29040771

APA StyleLian, Y., Xu, J., Zhou, W., Lin, Y., & Bai, J. (2024). Research Progress on Atomically Dispersed Fe-N-C Catalysts for the Oxygen Reduction Reaction. Molecules, 29(4), 771. https://doi.org/10.3390/molecules29040771