Home-Processed Red Beetroot (Beta vulgaris L.) Products: Changes in Antioxidant Properties and Bioaccessibility

Abstract

:1. Introduction

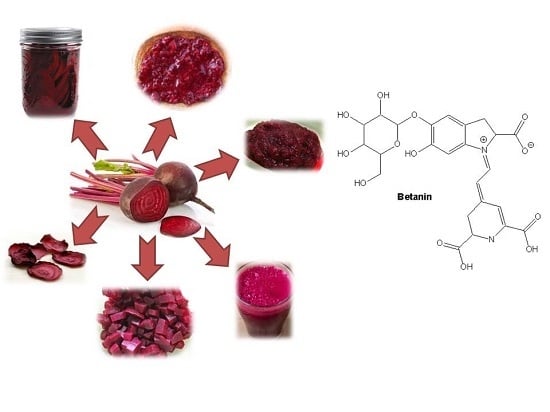

2. Results and Discussion

2.1. Moisture Content

2.2. Total Phenolic Content

2.3. Total Flavonoid Content

2.4. Total Antioxidant Capacity

2.5. Individual Red Beetroot Antioxidants

2.6. Processing Effects on in Vitro Bioaccessibility

3. Materials and Methods

3.1. Red Beetroot Products

3.2. Extract Preparation

3.3. Moisture Content

3.4. Total Phenolic Content Determination

3.5. Total Flavonoid Content Determination

3.6. Total Antioxidant Capacity Determination

3.6.1. ABTS (2,2-Azinobis (3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt) Method

3.6.2. DPPH (1,1-Diphenyl-2-picrylhydrazyl) Method

3.6.3. FRAP (Ferric Reducing Antioxidant Power) Method

3.6.4. CUPRAC (Cupric Ion Reducing Antioxidant Capacity) Method

3.7. HPLC (High-Pressure Liquid Chromatography) Analysis of Betanin

3.8. In Vitro Gastrointestinal Digestion

3.9. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nicoli, M.C.; Anese, M.; Parpinel, M. Influence of processing on the antioxidant properties of fruits and vegetables. Trends Food Sci. Technol. 1999, 10, 94–100. [Google Scholar] [CrossRef]

- Kaur, C.; Kapoor, H.C. Antioxidants in fruits and vegetables—The millenium’s health. Int. J. Food Sci. Technol. 2001, 36, 703–725. [Google Scholar] [CrossRef]

- Motulsky, A.G. Diet and health: Implications for reducing chronic disease risk. In Diet And Heath; National Academies: Washington, DC, USA, 1989. [Google Scholar]

- Frank, T.; Stintzing, F.C.; Carle, R.; Bitsch, I.; Quaas, D.; Straß, G.; Bitsch, R.; Netzel, M. Urinary pharmacokinetics of betalains following consumption of red beet juice in healthy humans. Pharmacol. Res. 2005, 52, 290–297. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, S.J.; von Elbe, J.H. Quantitative determination of individual betacyanin pigments by high-performance liquid chromatography. J. Agric. Food Chem. 1980, 28, 540–543. [Google Scholar] [CrossRef]

- Singh, B.; Hathan, B.S. Chemical composition, functional properties and processing of Beetroot. Int. J. Sci. Eng. Res. 2014, 5, 679–684. [Google Scholar]

- Tesoriere, L.; Allegra, M.; Butera, D.; Livrea, M.A. Absorption, excretion, and distribution of dietary antioxidant betalains in LDLs: Potential health effects of betalains in humans. Am. J. Clin. Nutr. 2004, 80, 941–945. [Google Scholar] [PubMed]

- Delgado-Vargas, F.; Jiménez, A.; Paredes-López, O. Natural pigments: Carotenoids, anthocyanins, and betalains—Characteristics, biosynthesis, processing, and stability. Crit. Rev. Food Sci. Nutr. 2000, 40, 173–289. [Google Scholar] [CrossRef] [PubMed]

- Coles, L.T.; Clifton, P.M. Effect of beetroot juice on lowering blood pressure in free-living, disease-free adults: A randomized, placebo-controlled trial. Nutr. J. 2012, 11. [Google Scholar] [CrossRef] [PubMed]

- Krajka-Kuźniak, V.; Szaefer, H.; Ignatowicz, E.; Adamska, T.; Baer-Dubowska, W. Beetroot juice protects against N-nitrosodiethylamine-induced liver injury in rats. Food Chem. Toxicol. 2012, 50, 2027–2033. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, D.A.; Kaffa, N.; George, T.W.; Methven, L.; Lovegrove, J.A. Blood pressure-lowering effects of beetroot juice and novel beetroot-enriched bread products in normotensive male subjects. Br. J. Nutr. 2012, 108, 2066–2074. [Google Scholar] [CrossRef] [PubMed]

- Wootton-Beard, P.C.; Moran, A.; Ryan, L. Stability of the total antioxidant capacity and total polyphenol content of 23 commercially available vegetable juices before and after in vitro digestion measured by FRAP, DPPH, ABTS and Folin–Ciocalteu methods. Food Res. Int. 2011, 44, 217–224. [Google Scholar] [CrossRef]

- Figiel, A. Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J Food Eng. 2010, 98, 461–470. [Google Scholar] [CrossRef]

- Latorre, M.E.; Narvaiz, P.; Rojas, A.M.; Gerschenson, L.N. Effects of gamma irradiation on bio-chemical and physico-chemical parameters of fresh-cut red beet (Beta vulgaris L. var. conditiva) root. J. Food Eng. 2010, 98, 178–191. [Google Scholar] [CrossRef]

- Czyżowska, A.; Klewicka, E.; Libudzisz, Z. The influence of lactic acid fermentation process of red beet juice on the stability of biologically active colorants. Eur. Food Res. Technol. 2006, 223, 110–116. [Google Scholar] [CrossRef]

- Marfil, P.; Santos, E.; Telis, V. Ascorbic acid degradation kinetics in tomatoes at different drying conditions. LWT-Food Sci. Technol. 2008, 41, 1642–1647. [Google Scholar] [CrossRef]

- Gokhale, S.; Lele, S. Dehydration of red beet root (Beta vulgaris) by hot air drying: Process optimization and mathematical modeling. Food Sci. Biotechnol. 2011, 20, 955–964. [Google Scholar] [CrossRef]

- Böhm, V.; Kühnert, S.; Rohm, H.; Scholze, G. Improving the nutritional quality of microwave-vacuum dried strawberries: A preliminary study. Food Sci. Technol. Int. 2006, 12, 67–75. [Google Scholar]

- Parada, J.; Aguilera, J.M. Food microstructure affects the bioavailability of several nutrients. J. Food Sci. 2007, 72, R21–R32. [Google Scholar] [CrossRef] [PubMed]

- Larrauri, J.A.; Rupérez, P.; Saura-Calixto, F. Effect of drying temperature on the stability of polyphenols and antioxidant activity of red grape pomace peels. J. Agric. Food Chem. 1997, 45, 1390–1393. [Google Scholar] [CrossRef]

- Turkmen, N.; Sari, F.; Velioglu, Y.S. The effect of cooking methods on total phenolics and antioxidant activity of selected green vegetables. Food Chem. 2005, 93, 713–718. [Google Scholar] [CrossRef]

- Stewart, A.J.; Bozonnet, S.; Mullen, W.; Jenkins, G.I.; Lean, M.E.; Crozier, A. Occurrence of flavonols in tomatoes and tomato-based products. J. Agric. Food Chem. 2000, 48, 2663–2669. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Hu, Y.; Liu, D.; Chen, J.; Ye, X. Changes of phenolic acids and antioxidant activities during potherb mustard (Brassica juncea, Coss.) pickling. Food Chem. 2008, 108, 811–817. [Google Scholar] [CrossRef] [PubMed]

- Juan, M.-Y.; Chou, C.-C. Enhancement of antioxidant activity, total phenolic and flavonoid content of black soybeans by solid state fermentation with Bacillus subtilis BCRC 14715. Food Microbiol. 2010, 27, 586–591. [Google Scholar] [CrossRef] [PubMed]

- Lai, L.-R.; Hsieh, S.-C.; Huang, H.-Y.; Chou, C.-C. Effect of lactic fermentation on the total phenolic, saponin and phytic acid contents as well as anti-colon cancer cell proliferation activity of soymilk. J. Biosci. Bioeng. 2013, 115, 552–556. [Google Scholar] [CrossRef] [PubMed]

- Chien, H.-L.; Huang, H.-Y.; Chou, C.-C. Transformation of isoflavone phytoestrogens during the fermentation of soymilk with lactic acid bacteria and bifidobacteria. Food Microbiol. 2006, 23, 772–778. [Google Scholar] [CrossRef] [PubMed]

- Robbins, R.J. Phenolic acids in foods: An overview of analytical methodology. J. Agric. Food Chem. 2003, 51, 2866–2887. [Google Scholar] [CrossRef] [PubMed]

- Kamiloglu, S.; Demirci, M.; Selen, S.; Toydemir, G.; Boyacioglu, D.; Capanoglu, E. Home processing of tomatoes (Solanum lycopersicum): Effects on in vitro bioaccessibility of total lycopene, phenolics, flavonoids, and antioxidant capacity. J. Sci. Food Agric. 2014, 94, 2225–2233. [Google Scholar] [CrossRef] [PubMed]

- Ravichandran, K.; Ahmed, A.R.; Knorr, D.; Smetanska, I. The effect of different processing methods on phenolic acid content and antioxidant activity of red beet. Food Res. Int. 2012, 48, 16–20. [Google Scholar] [CrossRef]

- Crozier, A.; Lean, M.E.; McDonald, M.S.; Black, C. Quantitative analysis of the flavonoid content of commercial tomatoes, onions, lettuce, and celery. J. Agric. Food Chem. 1997, 45, 590–595. [Google Scholar] [CrossRef]

- Stuppner, H.; Egger, R. Application of capillary zone electrophoresis to the analysis of betalains from Beta vulgaris. J. Chromatogr. A 1996, 735, 409–413. [Google Scholar] [CrossRef]

- Stintzing, F.C.; Carle, R. Functional properties of anthocyanins and betalains in plants, food, and in human nutrition. Trends Food Sci. Technol. 2004, 15, 19–38. [Google Scholar] [CrossRef]

- Cardoso-Ugarte, G.A.; Sosa-Morales, M.E.; Ballard, T.; Liceaga, A.; San Martín-González, M.F. Microwave-assisted extraction of betalains from red beet (Beta vulgaris). LWT—Food Sci. Technol. 2014, 59, 276–282. [Google Scholar] [CrossRef]

- Güneşer, O. Pigment and color stability of beetroot betalains in cow milk during thermal treatment. Food Chem. 2016, 196, 220–227. [Google Scholar] [CrossRef] [PubMed]

- Ravichandran, K.; Saw, N.M.M.T.; Mohdaly, A.A.A.; Gabr, A.M.M.; Kastell, A.; Riedel, H.; Cai, Z.; Knorr, D.; Smetanska, I. Impact of processing of red beet on betalain content and antioxidant activity. Food Res. Int. 2013, 50, 670–675. [Google Scholar] [CrossRef]

- Helal, A.; Tagliazucchi, D.; Verzelloni, E.; Conte, A. Bioaccessibility of polyphenols and cinnamaldehyde in cinnamon beverages subjected to in vitro gastro-pancreatic digestion. J. Funct. Foods 2014, 7, 506–516. [Google Scholar] [CrossRef]

- Wootton-Beard, P.C.; Ryan, L. A beetroot juice shot is a significant and convenient source of bioaccessible antioxidants. J. Funct. Foods 2011, 3, 329–334. [Google Scholar] [CrossRef]

- Tagliazucchi, D.; Verzelloni, E.; Bertolini, D.; Conte, A. In vitro bio-accessibility and antioxidant activity of grape polyphenols. Food Chem. 2010, 120, 599–606. [Google Scholar] [CrossRef]

- Gil-Izquierdo, A.; Gil, M.I.; Ferreres, F.; Tomas-Barberan, F.A. In vitro availability of flavonoids and other phenolics in orange juice. J. Agric. Food Chem. 2001, 49, 1035–1041. [Google Scholar] [CrossRef] [PubMed]

- Bouayed, J.; Hoffmann, L.; Bohn, T. Total phenolics, flavonoids, anthocyanins and antioxidant activity following simulated gastro-intestinal digestion and dialysis of apple varieties: Bioaccessibility and potential uptake. Food Chem. 2011, 128, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Apak, R.; Ozyurek, M.; Guclu, K.; Capanoglu, E. Antioxidant activity/capacity measurement. 1. Classification, physicochemical principles, mechanisms, and electron transfer (ET)-based assays. J. Agric. Food Chem. 2016, 64, 997–1027. [Google Scholar] [CrossRef] [PubMed]

- Capanoglu, E.; Beekwilder, J.; Boyacioglu, D.; Hall, R.; de Vos, R. Changes in antioxidant and metabolite profiles during production of tomato paste. J. Agric. Food Chem. 2008, 56, 964–973. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Chidambara Murthy, K.; Jayaprakasha, G. Studies on the antioxidant activity of pomegranate (Punica granatum) peel and seed extracts using in vitro models. J. Agric. Food Chem. 2002, 50, 81–86. [Google Scholar] [CrossRef] [PubMed]

- Čanadanovic´-Brunet, J.M.; Savatovi´, S.S.; C´etkovic´, G.S.; Vulic´, J.J.; Djilas, S.M.; Markov, S.L.; Cvetkovic´, D.D. Antioxidant and antimicrobial activities of beet root pomace extracts. Czech. J. Food Sci. 2011, 29, 575–585. [Google Scholar]

- Miller, N.J.; Rice-Evans, C.A. Factors influencing the antioxidant activity determined by the ABTS.+ radical cation assay. Free Radic. Res. 1997, 26, 195–199. [Google Scholar] [CrossRef] [PubMed]

- Benzie, I.F.; Strain, J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Apak, R.; Güçlü, K.; Özyürek, M.; Karademir, S.E. Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of neocuproine: CUPRAC method. J. Agric. Food Chem. 2004, 52, 7970–7981. [Google Scholar] [CrossRef] [PubMed]

- Toydemir, G.; Capanoglu, E.; Roldan, M.V.G.; de Vos, R.C.; Boyacioglu, D.; Hall, R.D.; Beekwilder, J. Industrial processing effects on phenolic compounds in sour cherry (Prunus cerasus L.) fruit. Food Res. Int. 2013, 53, 218–225. [Google Scholar] [CrossRef]

- McDougall, G.J.; Dobson, P.; Smith, P.; Blake, A.; Stewart, D. Assessing potential bioavailability of raspberry anthocyanins using an in vitro digestion system. J. Agric. Food Chem. 2005, 53, 5896–5904. [Google Scholar] [CrossRef] [PubMed]

| Samples | Total Phenolic Content (TP) | Total Flavonoid Content (TF) | Total Antioxidant Capacity (TAC) | |||

|---|---|---|---|---|---|---|

| DPPH ‡ | ABTS ‡ | FRAP ‡ | CUPRAC ‡ | |||

| Fresh red beetroot | 255 ± 48 b | 260 ± 13 a,b | 137 ± 11 a,b | 190 ± 12 a | 181 ± 8 a | 3889 ± 82 a |

| Boiled red beetroot | 238 ± 15 b | 261 ± 38 a,b | 131 ± 6 a,b | 158 ± 9 b | 126 ± 17 c,d | 3376 ± 377 b |

| Dried red beetroot | 347 ± 24 a | 230 ± 53 b | 143 ± 8 a | 188 ± 0.4 a | 170 ± 25 a,b | 3567 ± 307 a,b |

| Pickled red beetroot | 192 ± 50 c | 173 ± 38 c | 114 ± 15 c | 122 ± 29 c | 66 ± 5 e | 2413 ± 425 d |

| Red beetroot jam | 231 ± 36 b,c | 143 ± 37 c | 127 ± 15 b | 160 ± 26 b | 126 ± 31 c,d | 2931 ± 528 c |

| Red beetroot juice | 225 ± 15 b,c | 126 ± 14 c | 110 ± 9 c | 126 ± 12 c | 112 ± 16 d | 2397 ± 195 d |

| Red beetroot puree | 236 ± 18 b | 290± 53 a | 139 ± 4 a,b | 186 ± 11 a | 148 ± 24 b,c | 3529 ± 243 a,b |

| Sample Names | Initial ‡ | PG ‡ | IN ‡ | OUT ‡ | Recovery (%) ‡ |

|---|---|---|---|---|---|

| Fresh red beetroot | 255 ± 48 b | 55 ± 7 b,c | 17 ± 2 b | 37 ± 5 b | 7 ± 2 b |

| Boiled red beetroot | 238 ± 15 b | 61 ± 6 b | 18 ± 4 b | 34 ± 6 b | 8 ± 0.6 b |

| Dried red beetroot | 347 ± 23 a | 43 ± 8 c,d | 19 ± 4 b | 37 ± 7 b | 5 ± 0.8 b,c |

| Pickled red beetroot | 192± 50 c | 29 ± 6 e | 8 ± 1 d | 16 ± 1 c | 4 ± 1 d |

| Red beetroot jam | 231 ± 36 b,c | 75 ± 19 a | 37 ± 3 a | 59 ± 15 a | 16 ± 2 a |

| Red beetroot juice | 225 ± 15 b,c | 35 ± 8 d,e | 12 ± 2 c | 13 ± 1 c | 5 ± 0.6 b,c |

| Red beetroot puree | 236 ± 18 b | 55 ± 5 b,c | 13 ± 2 c | 30 ± 6 b | 6 ± 1 b,c |

| Sample Names | Initial ‡ | PG ‡ | IN ‡ | OUT ‡ | Recovery (%) ‡ |

|---|---|---|---|---|---|

| Fresh Red Beetroot | 260 ± 13 a,b | 105 ± 5 d | 33 ± 19 b | 100 ± 26 b | 13 ± 5 c |

| Boiled Red Beetroot | 261 ± 38 a,b | 148 ± 17 c | 35 ± 1 b | 82 ± 12 b | 13 ± 2 b |

| Dried Red Beetroot | 230 ± 53 b | 288 ± 39 a | 93 ± 35 a | 255 ± 57 a | 34 ± 8 a |

| Pickled Red Beetroot | 173 ± 38 c | 84 ± 17 d,e | 29 ± 26 b | 26 ± 9 c | 10 ± 3 c |

| Red Beetroot Jam | 143 ± 37 c | 188 ± 20 b | 31 ± 4 b | 78 ± 11 b | 23 ± 5 b |

| Red Beetroot Juice | 126 ± 14 c | 65 ± 8 e | 17 ± 9 b | 72 ± 56 b,c | 10 ± 0.7 c |

| Red Beetroot Puree | 290 ± 53 a | 170 ± 26 b,c | 18 ± 4 b | 73 ± 20 b,c | 7 ± 2 c |

| Assay | Samples | Initial ‡ | PG ‡ | IN ‡ | OUT ‡ | Recovery (%) ‡ |

|---|---|---|---|---|---|---|

| DPPH | Fresh red beetroot | 137 ± 11 a,b | 83 ± 12 a,b | nd † | nd † | nd † |

| Boiled red beetroot | 131 ± 6 a,b | 72.3 ± 4 b | nd † | nd † | nd † | |

| Dried red beetroot | 143 ± 8 a | 76 ± 10 b | nd † | nd † | nd † | |

| Pickled red beetroot | 114 ± 15 c | 44 ± 11 c | nd † | nd † | nd † | |

| Red beetroot jam | 127 ± 15 b | 91 ± 8 a | nd † | nd † | nd † | |

| Red beetroot juice | 110 ± 9 c | 43 ± 11 c | nd † | nd † | nd † | |

| Red beetroot puree | 139 ± 4 a,b | 78 ± 5 b | nd † | nd † | nd † | |

| CUPRAC | Fresh red beetroot | 3889 ± 82 a | 209 ± 32 a | 18 ± 7 b | 96 ± 45 a,b,c | 0.5 ± 0.2 b |

| Boiled red beetroot | 3375 ± 377 b | 216 ± 28 a | 15 ± 16 b | 48 ± 23 d,e | 0.4 ± 0.2 b | |

| Dried red beetroot | 3567 ± 307 a,b | 231 ± 55 a | 15 ± 5 b | 121 ± 46 a | 0.4 ± 0.1 b | |

| Pickled red beetroot | 2413± 425 d | 111 ± 23 b | nd †,c | 12 ± 5 e | nd † | |

| Red beetroot jam | 2931 ± 528 c | 246 ± 20 a | 39 ± 11 a | 108 ± 19 a,b | 1.4 ± 0.6 a | |

| Red beetroot juice | 2397 ± 195 d | 139 ± 14 b | 9 ± 3 b,c | 57 ± 30 c,d | 0.4 ± 0.1 b | |

| Red beetroot puree | 3529 ± 243 a,b | 247 ± 34 a | 18 ± 13 b,c | 74 ± 7 b,c,d | 0.2 ± 0.01 b | |

| ABTS | Fresh red beetroot | 189 ± 12 a | 30 ± 0.0 b | 33 ± 0.1 a | 36 ± 0.4 a,b | 17 ± 6 a |

| Boiled red beetroot | 158 ± 9 b | 30 ± 0.0 b | 33 ± 0.3 a | 37 ± 0.2 a | 21 ± 1 a | |

| Dried red beetroot | 188 ± 0.4 a | 92 ± 71 a | 33 ± 0.2 a | 36 ± 0.6 b | 18 ± 0.1 a | |

| Pickled red beetroot | 122 ± 29 c | 28 ± 0.0 b | 25 ± 5 c | 32 ± 1.4 d | 21 ± 5 a | |

| Red beetroot jam | 160 ± 26 b | 30 ± 0.0 b | 33 ± 0.0 a | 37 ± 0.1 a | 21 ± 4 a | |

| Red beetroot juice | 126 ± 12 c | 28 ± 0.0 b | 30 ± 1.0 b | 33 ± 1.0 c | 24 ± 2 a | |

| Red beetroot puree | 186 ± 11 a | 30 ± 0.1 b | 33 ± 0.0 a | 36 ± 0.4 a,b | 18 ± 0.8 a | |

| FRAP | Fresh red beetroot | 181± 8 a | 50 ± 0.4 b | 19 ± 5 a | 38 ± 4 a | 10 ± 3 a |

| Boiled red beetroot | 126 ± 17 c,d | 50 ± 0.4 b | 11 ± 3 c,d | 25 ± 2 c | 9 ± 2 a | |

| Dried red beetroot | 170 ± 25 a,b | 51 ± 0.3 a | 17 ± 6 a,b | 36 ± 9 a | 10 ± 4 a | |

| Pickled red beetroot | 66 ± 5 e | 48 ± 0.5c | 1 ± 1 e | 9 ± 0.6 e | 3 ± 0.3 b | |

| Red beetroot jam | 126 ± 31 c,d | 48 ± 0.3 c | 14 ± 0.7 b,c | 33 ± 2 a,b | 11 ± 3 a | |

| Red beetroot juice | 112 ± 16 d | 51 ± 0.6 b | 9 ± 1.6 d | 19 ± 4 d | 8 ± 2 a | |

| Red beetroot puree | 148 ± 24 b,c | 50 ± 0.3 b | 12 ± 1 c,d | 29 ± 2 b,c | 8 ± 1 a |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guldiken, B.; Toydemir, G.; Nur Memis, K.; Okur, S.; Boyacioglu, D.; Capanoglu, E. Home-Processed Red Beetroot (Beta vulgaris L.) Products: Changes in Antioxidant Properties and Bioaccessibility. Int. J. Mol. Sci. 2016, 17, 858. https://doi.org/10.3390/ijms17060858

Guldiken B, Toydemir G, Nur Memis K, Okur S, Boyacioglu D, Capanoglu E. Home-Processed Red Beetroot (Beta vulgaris L.) Products: Changes in Antioxidant Properties and Bioaccessibility. International Journal of Molecular Sciences. 2016; 17(6):858. https://doi.org/10.3390/ijms17060858

Chicago/Turabian StyleGuldiken, Burcu, Gamze Toydemir, Kubra Nur Memis, Sena Okur, Dilek Boyacioglu, and Esra Capanoglu. 2016. "Home-Processed Red Beetroot (Beta vulgaris L.) Products: Changes in Antioxidant Properties and Bioaccessibility" International Journal of Molecular Sciences 17, no. 6: 858. https://doi.org/10.3390/ijms17060858

APA StyleGuldiken, B., Toydemir, G., Nur Memis, K., Okur, S., Boyacioglu, D., & Capanoglu, E. (2016). Home-Processed Red Beetroot (Beta vulgaris L.) Products: Changes in Antioxidant Properties and Bioaccessibility. International Journal of Molecular Sciences, 17(6), 858. https://doi.org/10.3390/ijms17060858