Membrane Deformation and Its Effects on Flow and Mass Transfer in the Electromembrane Processes

Abstract

:1. Introduction

2. Results and Discussion

2.1. Mechanical Results

2.1.1. Influence of Pitch to Height Ratio (P/H) and Limiting Values

2.1.2. Membrane and Channel Deformation for the Selected Geometry (P/H = 8)

2.2. CFD Results for P/H = 8

2.2.1. Undeformed Configuration

2.2.2. Deformed Configurations

2.2.3. Global Parameters

3. Materials and Methods

3.1. Simulation Strategy

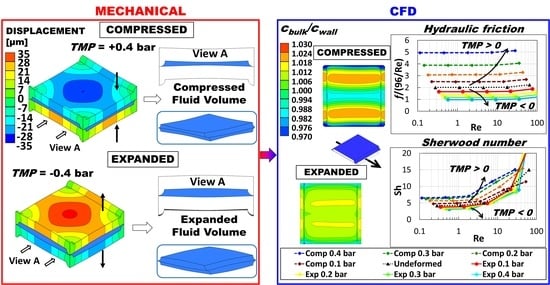

- First, the influence of the pitch-to-height ratio (P/H) was addressed by mechanical simulations. A TMP of 0.8 bar was applied, and the geometry with the largest value of P/H still able to withstand this load without collapsing (i.e., without exhibiting a contact between opposite membranes) was identified. The figure of 0.8 bar was conservatively chosen as a value comfortably larger than the highest TMP actually expected in real RED/ED applications. The search for the largest admissible P/H was motivated by the fact that small values of P/H are associated with large pressure drops: many studies [13,16,30,53,54,55] have highlighted the importance of reducing pressure drop and thus mechanical power losses in the channels, especially in RED applications. It is true that the increase of P/H may also cause a reduction in mass transfer coefficients, but its effect on stack performance is usually less important.

- The geometry thus identified was then investigated under expansion and compression conditions corresponding to TMP varying from −0.4 to +0.4 bar. As discussed in the Introduction, this range encompasses most of the conditions that are likely to occur in actual ED/RED applications. For each load condition, the deformed configuration was computed by mechanical simulations.

- Finally, for each deformed configuration, fluid flow and mass transfer in the expanded or compressed channel were numerically simulated by CFD; in particular, friction coefficients and Sherwood numbers were computed as functions of the Reynolds number.

3.2. The Mechanical Problem

3.2.1. Governing Equations

3.2.2. Computational Domain and Boundary Conditions

- Each of the four segments representing the external vertical edges of the domain (1) was clamped, i.e., zero displacement and rotation were imposed to all points belonging to it.

- Each of the four side faces of the domain (2) was imposed zero displacement in the direction normal to itself, so that a single computational domain is representative of a periodic array of repetitive units.

- The trans-membrane pressure TMP (relative to that of the internal fluid channel) was applied to the whole outer surface of the domain (3). Please note that TMP > 0 for compression conditions, while TMP < 0 for expansion conditions.

3.2.3. FE mesh for Mechanical Simulations

3.2.4. Mechanical Model Validation

3.3. The Fluid Dynamics and Mass Transfer Problem

3.3.1. Computational Approach

3.3.2. Governing Equations and Definitions

- Consider pressure p first. In the fully developed region of a channel, p can be decomposed into a periodic component , whose spatial distribution repeats itself identically in each unit cell, and a large-scale component −Kp(x·s) which decreases linearly along the main flow direction whose unit vector is s (x is the position vector of components xi). By substituting for p in the i-th steady-state Navier-Stokes equation:(where ρ and μ are the fluid’s density and viscosity), it becomesEquation (6) is similar to Equation (5), but (a) the “true” pressure p is replaced by its periodic component , and (b) a body force per unit volume (mean pressure gradient) acting along the main flow direction s appears at the right hand side. If required, the “true” pressure p can always be reconstructed from the simulation results as p = .

- In regard to the concentration c, by definition of fully developed conditions it can be decomposed into a periodic component and a large-scale component Kc(x·s), where Kc can now be either positive (net inflow of electrolyte into the channel) or negative (net outflow of electrolyte from the channel). By substituting for c in the transport equation(where D is the electrolyte diffusivity), after some manipulation one obtains:in which us = u·s is the local velocity component along the main flow direction s. The large-scale gradient Kc can be obtained by an elementary balance as:in which j is the molar salt flux at walls (imposed in the simulation), A is the membrane surface active area in a fluid unit cell (so that jA is the molar flow per unit time, mol/s), V is the cell volume and 〈us〉 is the volume average of us.

3.3.3. Flow Attack Angle, Boundary Conditions and Simulation Settings

3.3.4. FV Mesh for CFD Simulations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| ED | ElectroDialysis |

| FE | Finite Element |

| FV | Finite Volume |

| OCF | Overlapped Crossed Filaments |

| RED | Reverse ElectroDialysis |

References

- Campione, A.; Gurreri, L.; Ciofalo, M.; Micale, G.; Tamburini, A.; Cipollina, A. Electrodialysis for water desalination: A critical assessment of recent developments on process fundamentals, models and applications. Desalination 2018, 434, 121–160. [Google Scholar] [CrossRef]

- Dufton, G.; Mikhaylin, S.; Gaaloul, S.; Bazinet, L. Positive Impact of Pulsed Electric Field on Lactic Acid Removal, Demineralization and Membrane Scaling during Acid Whey Electrodialysis. Int. J. Mol. Sci. 2019, 20, 797. [Google Scholar] [CrossRef] [PubMed]

- Tufa, R.A.; Hnát, J.; Němeček, M.; Kodým, R.; Curcio, E.; Bouzek, K. Hydrogen production from industrial wastewaters: An integrated reverse electrodialysis—Water electrolysis energy system. J. Clean. Prod. 2018, 203, 418–426. [Google Scholar] [CrossRef]

- Strathmann, H. Electrodialysis, a mature technology with a multitude of new applications. Desalination 2010, 264, 268–288. [Google Scholar] [CrossRef]

- Mei, Y.; Tang, C.Y. Recent developments and future perspectives of reverse electrodialysis technology: A review. Desalination 2018, 425, 156–174. [Google Scholar] [CrossRef]

- Pawlowski, S.; Crespo, J.; Velizarov, S. Profiled Ion Exchange Membranes: A Comprehensible Review. Int. J. Mol. Sci. 2019, 20, 165. [Google Scholar] [CrossRef] [PubMed]

- Nikonenko, V.V.; Kovalenko, A.V.; Urtenov, M.K.; Pismenskaya, N.D.; Han, J.; Sistat, P.; Pourcelly, G. Desalination at overlimiting currents: State-of-the-art and perspectives. Desalination 2014, 342, 85–106. [Google Scholar] [CrossRef]

- Pawlowski, S.; Geraldes, V.; Crespo, J.G.; Velizarov, S. Computational fluid dynamics (CFD) assisted analysis of profiled membranes performance in reverse electrodialysis. J. Membr. Sci. 2016, 502, 179–190. [Google Scholar] [CrossRef]

- Tadimeti, J.G.D.; Kurian, V.; Chandra, A.; Chattopadhyay, S. Corrugated membrane surfaces for effective ion transport in electrodialysis. J. Membr. Sci. 2016, 499, 418–428. [Google Scholar] [CrossRef]

- Gurreri, L.; Ciofalo, M.; Cipollina, A.; Tamburini, A.; Van Baak, W.; Micale, G. CFD modelling of profiled-membrane channels for reverse electrodialysis. Desalin. Water Treat. 2015, 55, 3404–3423. [Google Scholar] [CrossRef]

- Larchet, C.; Zabolotsky, V.I.; Pismenskaya, N.; Nikonenko, V.V.; Tskhay, A.; Tastanov, K.; Pourcelly, G. Comparison of different ED stack conceptions when applied for drinking water production from brackish waters. Desalination 2008, 222, 489–496. [Google Scholar] [CrossRef]

- Vermaas, D.A.; Saakes, M.; Nijmeijer, K. Power generation using profiled membranes in reverse electrodialysis. J. Membr. Sci. 2011, 385–386, 234–242. [Google Scholar] [CrossRef]

- Vermaas, D.A.; Saakes, M.; Nijmeijer, K. Enhanced mixing in the diffusive boundary layer for energy generation in reverse electrodialysis. J. Membr. Sci. 2014, 453, 312–319. [Google Scholar] [CrossRef]

- Güler, E.; Elizen, R.; Saakes, M.; Nijmeijer, K. Micro-structured membranes for electricity generation by reverse electrodialysis. J. Membr. Sci. 2014, 458, 136–148. [Google Scholar] [CrossRef]

- Pawlowski, S.; Rijnaarts, T.; Saakes, M.; Nijmeijer, K.; Crespo, J.G.; Velizarov, S. Improved fluid mixing and power density in reverse electrodialysis stacks with chevron-profiled membranes. J. Membr. Sci. 2017, 531, 111–121. [Google Scholar] [CrossRef]

- La Cerva, M.L.; Di Liberto, M.; Gurreri, L.; Tamburini, A.; Cipollina, A.; Micale, G.; Ciofalo, M. Coupling CFD with a one-dimensional model to predict the performance of reverse electrodialysis stacks. J. Membr. Sci. 2017, 541, 595–610. [Google Scholar] [CrossRef]

- She, Q.; Jin, X.; Tang, C.Y. Osmotic power production from salinity gradient resource by pressure retarded osmosis: Effects of operating conditions and reverse solute diffusion. J. Membr. Sci. 2012, 401–402, 262–273. [Google Scholar] [CrossRef]

- She, Q.; Hou, D.; Liu, J.; Tan, K.H.; Tang, C.Y. Effect of feed spacer induced membrane deformation in the performance of pressure retarded osmosis (PRO): Implications for PRO process operation. J. Membr. Sci. 2013, 445, 170–182. [Google Scholar] [CrossRef]

- Karabelas, A.J.; Koutsou, C.P.; Sioutopoulos, D.C. Comprehensive performance assessment of spacers in spiral-wound membrane modules accounting for compressibility effects. J. Membr. Sci. 2018, 549, 602–615. [Google Scholar] [CrossRef]

- Huang, S.M. Laminar flow and heat transfer in plate membrane channels: Effects of the deformation heights. Int. J. Therm. Sci. 2016, 109, 44–53. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, X. A numerical study of flow crossover between adjacent flow channels in a proton exchange membrane fuel cell with serpentine flow field. J. Power Sources 2008, 185, 985–992. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiao, K.; Du, Q.; Yin, Y.; Li, X. Gas diffusion layer deformation and its effect on the transport characteristics and performance of proton exchange membrane fuel cell. Int. J. Hydrog. Energy 2013, 38, 12891–12903. [Google Scholar] [CrossRef]

- Hereijgers, J.; Ottevaere, H.; Breugelmans, T.; De Malsche, W. Membrane deflection in a flat membrane microcontactor: Experimental study of spacer features. J. Membr. Sci. 2016, 504, 153–161. [Google Scholar] [CrossRef]

- Moreno, J.; Slouwerhof, E.; Vermaas, D.A.; Saakes, M.; Nijmeijer, K. The Breathing Cell: Cyclic Intermembrane Distance Variation in Reverse Electrodialysis. Environ. Sci. Technol. 2016, 50, 11386–11393. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y. Pressure distribution, hydrodynamics, mass transport and solution leakage in an ion-exchange membrane electrodialyzer. J. Membr. Sci. 2004, 234, 23–39. [Google Scholar] [CrossRef]

- Tanaka, Y. Overall mass transport and solution leakage in an ion-exchange membrane electrodialyzer. J. Membr. Sci. 2004, 235, 15–24. [Google Scholar] [CrossRef]

- Hong, S.K.; Kim, C.S.; Hwang, K.S.; Han, J.H.; Kim, H.K.; Jeong, N.J.; Choi, K.S. Experimental and numerical studies on pressure drop in reverse electrodialysis: Effect of unit cell configuration. J. Mech. Sci. Technol. 2016, 30, 5287–5292. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Tedesco, M.; Gurreri, L.; Ciofalo, M.; Micale, G. The REAPower Project: Power Production From Saline Waters and Concentrated Brines. In Current Trends and Future Developments on (Bio-) Membranes; Basile, A., Curcio, E., Inamuddin, I., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 407–448. [Google Scholar]

- Tedesco, M.; Cipollina, A.; Tamburini, A.; Micale, G. Towards 1 kW power production in a reverse electrodialysis pilot plant with saline waters and concentrated brines. J. Membr. Sci. 2017, 522, 226–236. [Google Scholar] [CrossRef]

- Wright, N.C.; Shah, S.R.; Amrose, S.E.; Winter, A.G. A robust model of brackish water electrodialysis desalination with experimental comparison at different size scales. Desalination 2018, 443, 27–43. [Google Scholar] [CrossRef]

- Long, R.; Li, B.; Liu, Z.; Liu, W. Performance analysis of reverse electrodialysis stacks: Channel geometry and flow rate optimization. Energy 2018, 158, 427–436. [Google Scholar] [CrossRef]

- Ciofalo, M.; La Cerva, M.; Di Liberto, M.; Gurreri, L.; Cipollina, A.; Micale, G. Optimization of net power density in Reverse Electrodialysis. Energy 2019. under review. [Google Scholar]

- Bdiri, M.; Dammak, L.; Larchet, C.; Hellal, F.; Porozhnyy, M.; Nevakshenova, E.; Pismenskaya, N.; Nikonenko, V. Characterization and cleaning of anion-exchange membranes used in electrodialysis of polyphenol-containing food industry solutions; comparison with cation-exchange membranes. Sep. Purif. Technol. 2019, 210, 636–650. [Google Scholar] [CrossRef]

- Garcia-Vasquez, W.; Dammak, L.; Larchet, C.; Nikonenko, V.; Pismenskaya, N.; Grande, D. Evolution of anion-exchange membrane properties in a full scale electrodialysis stack. J. Membr. Sci. 2013, 446, 255–265. [Google Scholar] [CrossRef]

- Garcia-Vasquez, W.; Ghalloussi, R.; Dammak, L.; Larchet, C.; Nikonenko, V.; Grande, D. Structure and properties of heterogeneous and homogeneous ion-exchange membranes subjected to ageing in sodium hypochlorite. J. Membr. Sci. 2014, 452, 104–116. [Google Scholar] [CrossRef]

- Garcia-Vasquez, W.; Dammak, L.; Larchet, C.; Nikonenko, V.; Grande, D. Effects of acid-base cleaning procedure on structure and properties of anion-exchange membranes used in electrodialysis. J. Membr. Sci. 2016, 507, 12–23. [Google Scholar] [CrossRef]

- Klaysom, C.; Moon, S.H.; Ladewig, B.P.; Lu, G.Q.M.; Wang, L. Preparation of porous ion-exchange membranes (IEMs) and their characterizations. J. Membr. Sci. 2011, 371, 37–44. [Google Scholar] [CrossRef]

- Křivčík, J.; Neděla, D.; Válek, R. Ion-exchange membrane reinforcing. Desalin. Water Treat. 2015, 56, 3214–3219. [Google Scholar] [CrossRef]

- Kusoglu, A.; Karlsson, A.M.; Santare, M.H.; Cleghorn, S.; Johnson, W.B. Mechanical behavior of fuel cell membranes under humidity cycles and effect of swelling anisotropy on the fatigue stresses. J. Power Sources 2007, 170, 345–358. [Google Scholar] [CrossRef]

- Safronova, E.Y.; Golubenko, D.V.; Shevlyakova, N.V.; D’yakova, M.G.; Tverskoi, V.A.; Dammak, L.; Grande, D.; Yaroslavtsev, A.B. New cation-exchange membranes based on cross-linked sulfonated polystyrene and polyethylene for power generation systems. J. Membr. Sci. 2016, 515, 196–203. [Google Scholar] [CrossRef]

- Solasi, R.; Zou, Y.; Huang, X.; Reifsnider, K. A time and hydration dependent viscoplastic model for polyelectrolyte membranes in fuel cells. Mech. Time-Depend. Mater. 2008, 12, 15–30. [Google Scholar] [CrossRef]

- Tang, Y.; Karlsson, A.M.; Santare, M.H.; Gilbert, M.; Cleghorn, S.; Johnson, W.B. An experimental investigation of humidity and temperature effects on the mechanical properties of perfluorosulfonic acid membrane. Mater. Sci. Eng. A 2006, 425, 297–304. [Google Scholar] [CrossRef]

- Vandiver, M.A.; Caire, B.R.; Carver, J.R.; Waldrop, K.; Hibbs, M.R.; Varcoe, J.R.; Herring, A.M.; Liberatore, M.W. Mechanical Characterization of Anion Exchange Membranes by Extensional Rheology under Controlled Hydration. J. Electrochem. Soc. 2014, 161, H677–H683. [Google Scholar] [CrossRef]

- Ghalloussi, R.; Garcia-Vasquez, W.; Bellakhal, N.; Larchet, C.; Dammak, L.; Huguet, P.; Grande, D. Ageing of ion-exchange membranes used in electrodialysis: Investigation of static parameters, electrolyte permeability and tensile strength. Sep. Purif. Technol. 2011, 80, 270–275. [Google Scholar] [CrossRef]

- Narducci, R.; Chailan, J.F.; Fahs, A.; Pasquini, L.; Di Vona, M.L.; Knauth, P. Mechanical properties of anion exchange membranes by combination of tensile stress-strain tests and dynamic mechanical analysis. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1180–1187. [Google Scholar] [CrossRef]

- Nagarale, R.K.; Gohil, G.S.; Shahi, V.K. Recent developments on ion-exchange membranes and electro-membrane processes. Adv. Colloid Interface Sci. 2006, 119, 97–130. [Google Scholar] [CrossRef]

- Ran, J.; Wu, L.; He, Y.; Yang, Z.; Wang, Y.; Jiang, C.; Ge, L.; Bakangura, E.; Xu, T. Ion exchange membranes: New developments and applications. J. Membr. Sci. 2017, 522, 267–291. [Google Scholar] [CrossRef]

- Hong, J.G.; Zhang, B.; Glabman, S.; Uzal, N.; Dou, X.; Zhang, H.; Wei, X.; Chen, Y. Potential ion exchange membranes and system performance in reverse electrodialysis for power generation: A review. J. Membr. Sci. 2015, 486, 71–88. [Google Scholar] [CrossRef]

- Tedesco, M.; Hamelers, H.V.M.; Biesheuvel, P.M. Nernst-Planck transport theory for (reverse) electrodialysis: III. Optimal membrane thickness for enhanced process performance. J. Membr. Sci. 2018, 565, 480–487. [Google Scholar] [CrossRef]

- Gurreri, L.; Tamburini, A.; Cipollina, A.; Micale, G.; Ciofalo, M. Pressure drop at low Reynolds numbers in woven-spacer-filled channels for membrane processes: CFD prediction and experimental validation. Desalin. Water Treat. 2017, 61, 170–182. [Google Scholar] [CrossRef]

- Gurreri, L.; Tamburini, A.; Cipollina, A.; Micale, G.; Ciofalo, M. CFD prediction of concentration polarization phenomena in spacer-filled channels for reverse electrodialysis. J. Membr. Sci. 2014, 468, 133–148. [Google Scholar] [CrossRef]

- Ciofalo, M.; La Cerva, M.; Di Liberto, M.; Tamburini, A. Influence of the boundary conditions on heat and mass transfer in spacer-filled channels. J. Phys. Conf. Ser. 2017, 923, 012053. [Google Scholar] [CrossRef]

- Chiapello, J.-M.; Bernard, M. Improved spacer design and cost reduction in an electrodialysis system. J. Membr. Sci. 1993, 80, 251–256. [Google Scholar] [CrossRef]

- Vermaas, D.A.; Saakes, M.; Nijmeijer, K. Doubled power density from salinity gradients at reduced intermembrane distance. Environ. Sci. Technol. 2011, 45, 7089–7095. [Google Scholar] [CrossRef]

- von Gottberg, A. New High-Performance Spacers in Electro- Dialysis Reversal (EDR) Systems. In Proceedings of the 1998 AWWA Anual Conference, Dallas, TX, USA, 21–25 June 1998. [Google Scholar]

- Timoshenko, S.; Goodier, J.N. Theory of Elasticity; McGraw-Hill: New York, NY, USA, 1951. [Google Scholar]

- Tufa, R.A.; Pawlowski, S.; Veerman, J.; Bouzek, K.; Fontananova, E.; di Profio, G.; Velizarov, S.; Goulão Crespo, J.; Nijmeijer, K.; Curcio, E. Progress and prospects in reverse electrodialysis for salinity gradient energy conversion and storage. Appl. Energy 2018, 225, 290–331. [Google Scholar] [CrossRef]

- Iyengar, K.T.S.R.; Naqvi, M.M. Large deflections of rectangular plates. Int. J. Non-Linear Mech. 1966, 1, 109–122. [Google Scholar] [CrossRef]

- Sonin, A.A.; Probstein, R.F. A hydrodynamic theory of desalination by electrodialysis. Desalination 1968, 5, 293–329. [Google Scholar] [CrossRef]

- Newman, J.; Thomas-Alyea, K. Electrochemical Systems, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004; pp. 277–280. [Google Scholar]

- Nakayama, A.; Sano, Y.; Bai, X.; Tado, K. A boundary layer analysis for determination of the limiting current density in an electrodialysis desalination. Desalination 2017, 404, 41–49. [Google Scholar] [CrossRef]

- La Cerva, M.; Gurreri, L.; Tedesco, M.; Cipollina, A.; Ciofalo, M.; Tamburini, A.; Micale, G. Determination of limiting current density and current efficiency in electrodialysis units. Desalination 2018, 445, 138–148. [Google Scholar] [CrossRef]

| Quantity | Compressed +0.4 Bar | Undeformed | Expanded −0.4 Bar |

|---|---|---|---|

| [cm/s] | ~1.6 | ~4 | ~7.8 |

| 〈k〉, upper wall [m/s] | ~3.72 × 10−5 | ~2.84 × 10−5 | ~2.89 × 10−5 |

| 〈k〉, lower wall [m/s] | ~2.47 × 10−5 | ~1.78 × 10−5 | ~2.00 × 10−5 |

| Quantity | Value | Units |

|---|---|---|

| Membrane Young modulus, E | 150 | MPa |

| Membrane Poisson ratio, ν | 0.4 | - |

| Membrane thickness | 120 | μm |

| Channel thickness, H | 200 | μm |

| Pitch-to-height ratio, P/H | 7–9 | - |

| Angle between filaments | 90 | deg |

| FE Mechanical Mesh | No. Elements (P/H = 8) | Maximum Displacement at Membrane Surface [μm] |

|---|---|---|

| OCF-I | 200 × 103 | 67.04 |

| OCF-II | 500 × 103 | 67.38 |

| OCF-III | 1 million | 67.53 |

| Property | Value | Units |

|---|---|---|

| Density, ρ | 1017 | kg m−3 |

| Viscosity, µ | 0.931 × 10−3 | N s m−2 |

| Salt diffusivity, D | 1.47 × 10−9 | m2 s−1 |

| Schmidt number, (µ/ρ)/D | 622 | - |

| FV CFD Mesh | No. Finite Volumes (P/H = 8, Reτ = 5.2, γ = 0°) | Darcy Friction Coefficient | Sherwood Number (Upper Wall) | Sherwood Number (Lower Wall) |

|---|---|---|---|---|

| OCF-A | 2.252 × 106 | 10.985 | 5.685 | 9.122 |

| OCF-B | 3.833 × 106 | 11.062 | 5.519 | 8.771 |

| OCF-C | 7.502 × 106 | 11.117 | 5.491 | 8.596 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Battaglia, G.; Gurreri, L.; Airò Farulla, G.; Cipollina, A.; Pirrotta, A.; Micale, G.; Ciofalo, M. Membrane Deformation and Its Effects on Flow and Mass Transfer in the Electromembrane Processes. Int. J. Mol. Sci. 2019, 20, 1840. https://doi.org/10.3390/ijms20081840

Battaglia G, Gurreri L, Airò Farulla G, Cipollina A, Pirrotta A, Micale G, Ciofalo M. Membrane Deformation and Its Effects on Flow and Mass Transfer in the Electromembrane Processes. International Journal of Molecular Sciences. 2019; 20(8):1840. https://doi.org/10.3390/ijms20081840

Chicago/Turabian StyleBattaglia, Giuseppe, Luigi Gurreri, Girolama Airò Farulla, Andrea Cipollina, Antonina Pirrotta, Giorgio Micale, and Michele Ciofalo. 2019. "Membrane Deformation and Its Effects on Flow and Mass Transfer in the Electromembrane Processes" International Journal of Molecular Sciences 20, no. 8: 1840. https://doi.org/10.3390/ijms20081840

APA StyleBattaglia, G., Gurreri, L., Airò Farulla, G., Cipollina, A., Pirrotta, A., Micale, G., & Ciofalo, M. (2019). Membrane Deformation and Its Effects on Flow and Mass Transfer in the Electromembrane Processes. International Journal of Molecular Sciences, 20(8), 1840. https://doi.org/10.3390/ijms20081840