Amorphization of Thiamine Mononitrate: A Study of Crystallization Inhibition and Chemical Stability of Thiamine in Thiamine Mononitrate Amorphous Solid Dispersions

Abstract

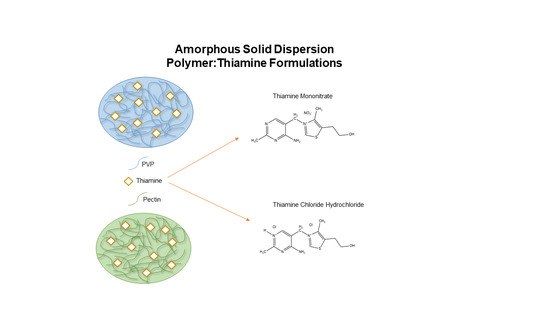

:1. Introduction

2. Results and Discussion

2.1. Physical Stability of Amorphous Thiamine Mononitrate

2.2. Effect of Polymer Type on Amorphization and Physical Stability of TMN Dispersions

2.3. Effect of Physical State on Chemical Stability of Thiamine

2.4. Effect of Glass Transition Temperature on Thiamine Stability

2.5. Effect of Vitamin:Polymer Ratio in Solid Dispersions on Thiamine Stability

2.6. Comparison of Thiamine Stability in TMN and TClHCl Solid Dispersions

2.6.1. Physical Stability

2.6.2. Chemical Stability

3. Materials and Methods

3.1. Materials

3.2. Preparations of TMN Solid Dispersions via Lyophilization

3.3. Storage Treatments

3.4. Powder X-ray Diffraction (PXRD)

3.5. Fourier Transform Infrared Spectroscopy (FTIR)

3.6. Chemical Stability Determination with HPLC

3.7. Moisture Sorption Isotherm Analysis

3.8. Determination of Glass Transition Temperature by Differential Scanning Calorimetry (DSC)

3.9. Reaction Kinetics Calculations

3.10. Statistical Analysis

4. Conclusions

- Thiamine was less stable when present at low proportions in a solid dispersion than when present at higher proportions (a concerning factor when delivering low concentrations of thiamine in solid formulations, and an indicator that the sample Tg is not the main factor in governing thiamine stability in amorphous systems since the thiamine was most labile in the dispersions with the highest Tgs);

- Thiamine was most stable in the crystalline form, less stable in the amorphous form, and degraded most rapidly when present in (concentrated) solutions (such as in the physical mixtures and dispersions of TMN with PVP that were stored at 75% RH and 40 °C);

- Despite the higher solubility of TClHCl compared to TMN, thiamine was more stable in the amorphous vitamin:polymer dispersions made with TClHCl than with TMN. The enhanced stability of thiamine in the TClHCl:polymer dispersions was attributed to not only the increased noncovalent intermolecular interactions between the TClHCl and polymer compared to the TMN-polymer interactions (TClHCl has an additional hydrogen bond donor), but also to the more acidic pHs created by the HCl counterion than the nitrate counterion.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DSC | Differential scanning calorimetry |

| FTIR | Fourier Transform infrared spectroscopy |

| HBA | Hydrogen bond acceptor |

| HBD | Hydrogen bond donor |

| HPLC | High-performance liquid chromatography |

| PEC | Pectin |

| PM | Physical mixture |

| PVP | Poly(vinylpyrrolidone) |

| PXRD | Powder X-ray diffraction |

| RH | Relative humidity |

| SD | Solid dispersion |

| TClHCl | Thiamine chloride hydrochloride |

| TMN | Thiamine mononitrate |

| TFA | Trifluoroacetic acid |

| Tg | Glass transition temperature |

References

- Mulley, E.; Stumbo, C.; Hunting, W. Kinetics of thiamine degradation by heat. Effect of pH and form of the vitamin on its rate of destruction. J. Food Sci. 1975, 40, 989–992. [Google Scholar] [CrossRef]

- Dwivedi, B.K.; Arnold, R.G. Chemistry of thiamine degradation in food products and model systems: A review. J. Agric. Food. Chem. 1973, 21, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Farrer, K. The thermal destruction of vitamin B1 in foods. Adv. Food Res. 1955, 6, 257–311. [Google Scholar] [CrossRef]

- Grosch, W.; Zeiler-Hilgart, G. Formation of Meatlike Flavor Compounds. In Flavor Precursors; American Chemical Society: Washington, DC, USA, 1992; Volume 490, pp. 183–192. [Google Scholar]

- Voelker, A.L.; Miller, J.; Running, C.A.; Taylor, L.S.; Mauer, L.J. Chemical stability and reaction kinetics of two thiamine salts (thiamine mononitrate and thiamine chloride hydrochloride) in solution. Food Res. Int. 2018, 112, 443–456. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dreher, J.G.; Rouseff, R.L.; Naim, M. GC-olfactometric characterization of aroma volatiles from the thermal degradation of thiamin in model orange juice. J. Agric. Food Chem. 2003, 51, 3097–3102. [Google Scholar] [CrossRef] [PubMed]

- Labuza, T.; Kamman, J. Comparison of stability of thiamin salts at high temperature and water activity. J. Food Sci. 1982, 47, 664–665. [Google Scholar] [CrossRef]

- Arioglu-Tuncil, S.; Bhardwaj, V.; Taylor, L.S.; Mauer, L.J. Amorphization of thiamine chloride hydrochloride: A study of the crystallization inhibitor properties of different polymers in thiamine chloride hydrochloride amorphous solid dispersions. Food Res. Int. 2017, 99, 363–374. [Google Scholar] [CrossRef] [PubMed]

- Hancock, B.C.; Zografi, G. Characteristics and significance of the amorphous state in pharmaceutical systems. J. Pharm. Sci. 1997, 86, 1–12. [Google Scholar] [CrossRef]

- Arioglu-Tuncil, S.; Voelker, A.L.; Taylor, L.S.; Mauer, L.J. Amorphization of thiamine chloride hydrochloride: Effects of physical state and polymer type on the chemical stability of thiamine in solid dispersions. Int. J. Mol. Sci. 2020, 21, 5935. [Google Scholar] [CrossRef]

- Christina, B.; Taylor, L.S.; Mauer, L.J. Physical stability of l-ascorbic acid amorphous solid dispersions in different polymers: A study of polymer crystallization inhibitor properties. Food Res. Int. 2015, 76, 867–877. [Google Scholar] [CrossRef]

- Wegiel, L.A.; Zhao, Y.; Mauer, L.J.; Edgar, K.J.; Taylor, L.S. Curcumin amorphous solid dispersions: The influence of intra and intermolecular bonding on physical stability. Pharm. Dev. Technol. 2014, 19, 976–986. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Yoshioka, S.; Aso, Y.; Kojima, S. Ability of polyvinylpyrrolidone and polyacrylic acid to inhibit the crystallization of amorphous acetaminophen. J. Pharm. Sci. 2004, 93, 2710–2717. [Google Scholar] [CrossRef] [PubMed]

- Kestur, U.S.; Van Eerdenbrugh, B.; Taylor, L.S. Influence of polymer chemistry on crystal growth inhibition of two chemically diverse organic molecules. CrystEngComm 2011, 13, 6712–6718. [Google Scholar] [CrossRef]

- Wang, R.; Pellerin, C.; Lebel, O. Role of hydrogen bonding in the formation of glasses by small molecules: A triazine case study. J. Mater. Chem. 2009, 19, 2747–2753. [Google Scholar] [CrossRef]

- Roos, Y.H.; Drusch, S. Reaction kinetics. In Phase Transitions in Foods, 2nd ed.; Academic Press: San Diego, CA, USA, 2016; pp. 275–313. [Google Scholar] [CrossRef]

- Ismail, Y.; Mauer, L.J. Phase transitions of ascorbic acid and sodium ascorbate in a polymer matrix and effects on vitamin degradation. J. Food Process. Eng. 2019, 43, e13073. [Google Scholar] [CrossRef]

- Bell, L.; White, K. Thiamin stability in solids as affected by the glass transition. J. Food Sci. 2000, 65, 498–501. [Google Scholar] [CrossRef]

- Slade, L.; Levine, H. Beyond water activity: Recent advances based on an alternative approach to the assessment of food quality and safety. Crit. Rev. Food Sci. Nutr. 1991, 30, 115–360. [Google Scholar] [CrossRef]

- Beaman, G. Relation between (apparent) second-order transition temperature and melting point. J. Polym. Sci. 1952, 9, 470–472. [Google Scholar] [CrossRef]

- Fox, T.G. Influence of diluent and of copolymer composition on the glass temperature of a polymer system. Bull. Am. Phys. Soc. 1956, 1, 123–135. [Google Scholar]

- Gordon, M.; Taylor, J.S. Ideal copolymers and the second-order transitions of synthetic rubbers. I. Noncrystalline copolymers. Rubber Chem. Technol. 1953, 26, 323–335. [Google Scholar] [CrossRef]

- Bell, L.; Hageman, M.J. Differentiating between the effects of water activity and glass transition dependent mobility on a solid state chemical reaction: Aspartame degradation. J. Agric. Food. Chem. 1994, 42, 2398–2401. [Google Scholar] [CrossRef]

- Sanchez, J.; Ismail, Y.; Christina, B.; Mauer, L.J. Degradation of L-ascorbic acid in the amorphous solid state. J. Food Sci. 2018, 83, 670–681. [Google Scholar] [CrossRef] [PubMed]

- Lai, M.C.; Hageman, M.J.; Schowen, R.L.; Borchardt, R.T.; Topp, E.M. Chemical stability of peptides in polymers. 1. Effect of water on peptide deamidation in poly(vinyl alcohol) and poly(vinyl pyrrolidone) matrixes. J. Pharm. Sci. 1999, 88, 1073–1080. [Google Scholar] [CrossRef]

- Luthra, S.A.; Shalaev, E.Y.; Medek, A.; Hong, J.; Pikal, M.J. Chemical stability of amorphous materials: Specific and general media effects in the role of water in the degradation of freeze-dried zoniporide. J. Pharm. Sci. 2012, 101, 3110–3123. [Google Scholar] [CrossRef] [PubMed]

- Pachapurkar, D.; Bell, L. Kinetics of thiamin degradation in solutions under ambient storage conditions. J. Food Sci. 2006, 70, c423–c426. [Google Scholar] [CrossRef]

- Waterman, K.C.; Gerst, P.; Dai, Z. A generalized relation for solid-state drug stability as a function of excipient dilution: Temperature-independent behavior. J. Pharm. Sci. 2012, 101, 4170–4177. [Google Scholar] [CrossRef] [PubMed]

- David, S.; Timmins, P.; Conway, B. Impact of the counterion on the solubility and physicochemical properties of salts of carboxylic acid drugs. Drug Dev. Ind. Pharm. 2012, 38, 93–103. [Google Scholar] [CrossRef]

- ChemSpider. Thiamine; Royal Society of Chemistry: London, UK, 2015. [Google Scholar]

- Hiatt, A.N.; Ferruzzi, M.G.; Taylor, L.S.; Mauer, L.J. Impact of deliquescence on the chemical stability of vitamins B(1), B(6), and C in powder blends. J. Agric. Food. Chem. 2008, 56, 6471–6479. [Google Scholar] [CrossRef]

- Murase, N.; Franks, F. Salt precipitation during the freeze-concentration of phosphate buffer solutions. Biophys. Chem. 1989, 34, 293. [Google Scholar] [CrossRef]

- Xia, F.; Hong, P.; Alden, B.; Boissel, C.; Swanson, D.; Chambers, E.; Diehl, D.; Iraneta, P.; Mazzeo, J.; Wyndham, K.; et al. Improvements in reversed-phase HPLC columns designed for polar compound retention. In Proceedings of the HPLC, San Francisco, CA, USA, 17–23 June 2006. [Google Scholar]

- Windheuser, J.J.; Higuchi, T. Kinetics of thiamine hydrolysis. J. Pharm. Sci. 1962, 51, 354–364. [Google Scholar] [CrossRef]

| Sample | Storage Condition | Onset Tg (°C) |

|---|---|---|

| 5TMN:95PVP | ‘As is’ following lyophilization | 65 ± 7 B |

| 5TMN:95PVP | 11% RH and 30 °C | 49 ± 1 A |

| 5TMN:95PVP | 11% RH and 60 °C | 52 ± 3 A |

| 10TMN:90PVP | ‘As is’ following lyophilization | 60 ± 4 B |

| Thiamine Salt Form | % PVP | kobs (day−1) | R2 | t90 * (days) |

|---|---|---|---|---|

| TMN | 99 | 0.0055 | 0.7981 | 19.2 |

| 97 | 0.0054 | 0.9217 | 19.5 | |

| 95 | 0.0050 | 0.8637 | 21.1 | |

| 93 | 0.0049 | 0.9371 | 21.5 | |

| 90 | 0.0038 | 0.9155 | 27.7 | |

| 80 | 0.0018 | 0.9464 | 58.5 | |

| TClHCl 1 | 99 | 0.0062 | 0.96 | 17 |

| 97 | 0.0047 | 0.95 | 22 | |

| 95 | 0.0038 | 0.95 | 28 | |

| 93 | 0.0032 | 0.93 | 33 | |

| 90 | 0.0025 | 0.95 | 42 | |

| 80 | 0.0015 | 0.92 | 70 |

| Thiamine Mononitrate | Thiamine Chloride Hydrochloride | |

|---|---|---|

| Structure |  |  |

| Molecular weight 1 | 327.36 g/mol | 337.26 g/mol |

| Melting point 1 | 196–200 °C | 248 °C |

| Tg 2 | 40 °C | 74 °C |

| Deliquescence point (RH0) 3 | 98.5% RH | 88% RH |

| Aqueous solubility 4 | 30 mg/mL | 570 mg/mL |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arioglu-Tuncil, S.; Voelker, A.L.; Taylor, L.S.; Mauer, L.J. Amorphization of Thiamine Mononitrate: A Study of Crystallization Inhibition and Chemical Stability of Thiamine in Thiamine Mononitrate Amorphous Solid Dispersions. Int. J. Mol. Sci. 2020, 21, 9370. https://doi.org/10.3390/ijms21249370

Arioglu-Tuncil S, Voelker AL, Taylor LS, Mauer LJ. Amorphization of Thiamine Mononitrate: A Study of Crystallization Inhibition and Chemical Stability of Thiamine in Thiamine Mononitrate Amorphous Solid Dispersions. International Journal of Molecular Sciences. 2020; 21(24):9370. https://doi.org/10.3390/ijms21249370

Chicago/Turabian StyleArioglu-Tuncil, Seda, Adrienne L. Voelker, Lynne S. Taylor, and Lisa J. Mauer. 2020. "Amorphization of Thiamine Mononitrate: A Study of Crystallization Inhibition and Chemical Stability of Thiamine in Thiamine Mononitrate Amorphous Solid Dispersions" International Journal of Molecular Sciences 21, no. 24: 9370. https://doi.org/10.3390/ijms21249370

APA StyleArioglu-Tuncil, S., Voelker, A. L., Taylor, L. S., & Mauer, L. J. (2020). Amorphization of Thiamine Mononitrate: A Study of Crystallization Inhibition and Chemical Stability of Thiamine in Thiamine Mononitrate Amorphous Solid Dispersions. International Journal of Molecular Sciences, 21(24), 9370. https://doi.org/10.3390/ijms21249370