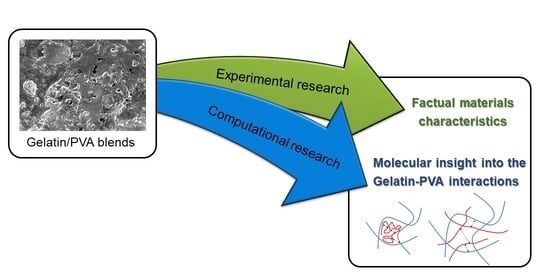

Functional Properties of Two-Component Hydrogel Systems Based on Gelatin and Polyvinyl Alcohol—Experimental Studies Supported by Computational Analysis

Abstract

:1. Introduction

2. Results

2.1. Experimental Studies on Functional Properties of Gelatin and Gelatin/PVA Hydrogels

2.1.1. Structural Properties of Gelatin and Gelatin/PVA Hydrogels

2.1.2. Mechanical Properties of Gelatin and Gelatin/PVA Hydrogels

2.1.3. Water Content in Gelatin and Gelatin/PVA Hydrogels

2.1.4. Sorption Properties of Gelatin and Gelatin/PVA-Based Hydrogels

2.1.5. Application of Gelatin and Gelatin/PVA Hydrogels as Carriers for Enzyme Immobilization

2.2. Computational Studies/Molecular Insight into the Structural Characterization of Gelatin and Gelatin/PVA Hydrogels

2.2.1. Models of Gelatin and Gelatin/PVA Blends

2.2.2. Mechanical Properties of Gelatin and Gelatin/PVA Blends

2.2.3. Porosity and Swelling Properties of the Gelatin and Gelatin/PVA Blends

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Methods

4.2.1. Preparation of Hydrogel Matrices

4.2.2. Determination of Pore Distribution in Hydrogel Materials

4.2.3. Determination of the Mechanical Properties of Hydrogels

4.2.4. Determination of the Water Content in the Hydrogel Structures

4.2.5. Determination of Hydrogel Sorption Properties

4.2.6. Entrapment of Invertase from Saccharomyces Cerevisiae in Hydrogel Matrices

4.2.7. Determination of Protein Concentration

4.2.8. Determination of Glucose Concentration

4.2.9. Determination of the Catalytic Activity of Native and Immobilized Invertase

4.2.10. Determination of the Operational Stability of Invertase Immobilized in Hydrogel Matrices

4.2.11. Preparation of Molecular Models of Hydrogel Structures

4.2.12. Computational Determination of Functional Parameters of Hydrogels

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Slaughter, B.V.; Khurshid, S.S.; Fisher, O.Z.; Khademhosseini, A.; Peppas, N.A. Hydrogels in regenerative medicine. Adv. Mater. 2009, 21, 3307–3329. [Google Scholar] [CrossRef] [Green Version]

- Aswathy, S.H.; Narendrakumar, U.; Manjubala, I. Commercial hydrogels for biomedical applications. Heliyon 2020, 6, e03719. [Google Scholar] [CrossRef]

- Mallick, S.P.; Suman, D.K.; Singh, B.N.; Srivastava, P.; Siddiqui, N.; Yella, V.R.; Madhual, A.; Vemuri, P.K. Strategies toward development of biodegradable hydrogels for biomedical applications. Polym. Technol. Mater. 2020, 59, 911–927. [Google Scholar] [CrossRef]

- Elkhoury, K.; Morsink, M.; Sanchez-Gonzalez, L.; Kahn, C.; Tamayol, A.; Arab-Tehrany, E. Biofabrication of natural hydrogels for cardiac, neural, and bone Tissue engineering Applications. Bioact. Mater. 2021, 6, 3904–3923. [Google Scholar] [CrossRef] [PubMed]

- Kharkar, P.M.; Kiick, K.L.; Kloxin, A.M. Designing degradable hydrogels for orthogonal control of cell microenvironments. Chem. Soc. Rev. 2013, 42, 7335–7372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, H.; Marra, K.G. Injectable, biodegradable hydrogels for tissue engineering applications. Materials 2010, 3, 1746–1767. [Google Scholar] [CrossRef]

- Huang, H.; Qi, X.; Chen, Y.; Wu, Z. Thermo-sensitive hydrogels for delivering biotherapeutic molecules: A review. Saudi Pharm. J. 2019, 27, 990–999. [Google Scholar] [CrossRef] [PubMed]

- Kamath, K.R.; Park, K. Biodegradable hydrogels in drug delivery. Adv. Drug Deliv. Rev. 1993, 11, 59–84. [Google Scholar] [CrossRef]

- Peers, S.; Montembault, A.; Ladavière, C. Chitosan hydrogels for sustained drug delivery. J. Control. Release 2020, 326, 150–163. [Google Scholar] [CrossRef]

- Ahmed, I.; Elsherif, M.; Omar, A.; Saadi, W.; Ali, M.; Alqattan, B.; Salih, A.; Saleh, H.; Al Qutayri, M.; Park, S.; et al. Usage of Hydrogels for Brian Imaging and Diagnostics. Glob. J. Eng. Sci. 2020, 4, 1–7. [Google Scholar]

- Wiraja, C.; Ning, X.; Cui, M.; Xu, C. Hydrogel-Based Technologies for the Diagnosis of Skin Pathology. Technologies 2020, 8, 47. [Google Scholar] [CrossRef]

- Culver, H.R.; Clegg, J.R.; Peppas, N.A. Analyte-Responsive Hydrogels: Intelligent Materials for Biosensing and Drug Delivery. Acc. Chem. Res. 2017, 50, 170–178. [Google Scholar] [CrossRef]

- Klein, M.; Poverenov, E. Natural biopolymer-based hydrogels for use in food and agriculture. J. Sci. Food Agric. 2020, 100, 2337–2347. [Google Scholar] [CrossRef] [PubMed]

- Khalesi, H.; Lu, W.; Nishinari, K.; Fang, Y. New insights into food hydrogels with reinforced mechanical properties: A review on innovative strategies. Adv. Colloid Interface Sci. 2020, 285, 102278. [Google Scholar] [CrossRef]

- Yang, J.; Shen, M.; Luo, Y.; Wu, T.; Chen, X.; Wang, Y.; Xie, J. Advanced applications of chitosan-based hydrogels: From biosensors to intelligent food packaging system. Trends Food Sci. Technol. 2021, 110, 822–832. [Google Scholar] [CrossRef]

- Mitura, S.; Sionkowska, A.; Jaiswal, A. Biopolymers for hydrogels in cosmetics: Review. J. Mater. Sci. Mater. Med. 2020, 31, 1–14. [Google Scholar] [CrossRef]

- Rizwan, M.; Rubina Gilani, S.; Iqbal Durani, A.; Naseem, S. Materials diversity of hydrogel: Synthesis, polymerization process and soil conditioning properties in agricultural field. J. Adv. Res. 2021. In Press, Corrected Proof. [Google Scholar] [CrossRef]

- Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Mironiuk, M.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Controlled release micronutrient fertilizers for precision agriculture—A review. Sci. Total Environ. 2020, 712, 136365. [Google Scholar] [CrossRef]

- Kalossaka, L.M.; Sena, G.; Barter, L.M.C.; Myant, C. Review: 3D printing hydrogels for the fabrication of soilless cultivation substrates. Appl. Mater. Today 2021, 24, 101088. [Google Scholar] [CrossRef]

- Singh, N.; Agarwal, S.; Jain, A.; Khan, S. 3-Dimensional cross linked hydrophilic polymeric network “hydrogels”: An agriculture boom. Agric. Water Manag. 2021, 253, 106939. [Google Scholar] [CrossRef]

- Gyles, D.A.; Castro, L.D.; Silva, J.O.C.; Ribeiro-Costa, R.M. A review of the designs and prominent biomedical advances of natural and synthetic hydrogel formulations. Eur. Polym. J. 2017, 88, 373–392. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Lin, S.; Zhao, X. Hydrogel machines. Mater. Today 2020, 36, 102–124. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Jomeh Farsangi, Z.; Allahverdi, A.; Shakoori, Z. Hydrogels as intelligent materials: A brief review of synthesis, properties and applications. Mater. Today Chem. 2018, 8, 42–55. [Google Scholar] [CrossRef]

- Raghuwanshi, V.S.; Garnier, G. Characterisation of hydrogels: Linking the nano to the microscale. Adv. Colloid Interface Sci. 2019, 274, 102044. [Google Scholar] [CrossRef] [PubMed]

- Bilal, M.; Iqbal, H.M.N. Naturally-derived biopolymers: Potential platforms for enzyme immobilization. Int. J. Biol. Macromol. 2019, 130, 462–482. [Google Scholar] [CrossRef]

- Dreiss, C.A. Hydrogel design strategies for drug delivery. Curr. Opin. Colloid Interface Sci. 2020, 48, 1–17. [Google Scholar] [CrossRef]

- Abaee, A.; Mohammadian, M.; Jafari, S.M. Whey and soy protein-based hydrogels and nano-hydrogels as bioactive delivery systems. Trends Food Sci. Technol. 2017, 70, 69–81. [Google Scholar] [CrossRef]

- Amiri, M.; Khazaeli, P.; Salehabadi, A.; Salavati-Niasari, M. Hydrogel beads-based nanocomposites in novel drug delivery platforms: Recent trends and developments. Adv. Colloid Interface Sci. 2021, 288, 102316. [Google Scholar] [CrossRef] [PubMed]

- Dhand, A.P.; Galarraga, J.H.; Burdick, J.A. Enhancing Biopolymer Hydrogel Functionality through Interpenetrating Networks. Trends Biotechnol. 2021, 39, 519–538. [Google Scholar] [CrossRef]

- Kamoun, E.A.; Chen, X.; Mohy Eldin, M.S.; Kenawy, E.R.S. Crosslinked poly(vinyl alcohol) hydrogels for wound dressing applications: A review of remarkably blended polymers. Arab. J. Chem. 2015, 8, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Qi, X.; Su, T.; Zhang, M.; Tong, X.; Pan, W.; Zeng, Q.; Shen, J. Sustainable, flexible and biocompatible hydrogels derived from microbial polysaccharides with tailorable structures for tissue engineering. Carbohydr. Polym. 2020, 237, 116160. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Tiwari, S. A review on biomacromolecular hydrogel classification and its applications. Int. J. Biol. Macromol. 2020, 162, 737–747. [Google Scholar] [CrossRef] [PubMed]

- Ullah, F.; Othman, M.B.H.; Javed, F.; Ahmad, Z.; Akil, H.M. Classification, processing and application of hydrogels: A review. Mater. Sci. Eng. C 2015, 57, 414–433. [Google Scholar] [CrossRef]

- Srivastava, N.; Choudhury, A.R. Recent advances in composite hydrogels prepared solely from polysaccharides. Colloids Surf. B Biointerfaces 2021, 205, 111891. [Google Scholar] [CrossRef]

- Catoira, M.C.; Fusaro, L.; Di Francesco, D.; Ramella, M.; Boccafoschi, F. Overview of natural hydrogels for regenerative medicine applications. J. Mater. Sci. Mater. Med. 2019, 30, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Radosinski, L.; Labus, K.; Zemojtel, P.; Wojciechowski, J.W. Development and validation of a virtual gelatin model using molecular modeling computational tools. Molecules 2019, 24, 3365. [Google Scholar] [CrossRef] [Green Version]

- Labus, K.; Wolanin, K.; Radosiński, Ł. Comparative Study on Enzyme Immobilization Using Natural Hydrogel Matrices—Experimental Studies Supported by Molecular Models Analysis. Catalysts 2020, 10, 489. [Google Scholar] [CrossRef]

- Manoochehri, H.; Hosseini, N.F.; Saidijam, M.; Taheri, M.; Rezaee, H.; Nouri, F. A review on invertase: Its potentials and applications. Biocatal. Agric. Biotechnol. 2020, 25, 101599. [Google Scholar] [CrossRef]

- Abdullah, Z.W.; Dong, Y.; Davies, I.J.; Barbhuiya, S. PVA, PVA Blends, and Their Nanocomposites for Biodegradable Packaging Application. Polym. Plast. Technol. Eng. 2017, 56, 1307–1344. [Google Scholar] [CrossRef] [Green Version]

- Mahnama, H.; Dadbin, S.; Frounchi, M.; Rajabi, S. Preparation of biodegradable gelatin/PVA porous scaffolds for skin regeneration. Artif. Cells, Nanomed. Biotechnol. 2017, 45, 928–935. [Google Scholar] [CrossRef] [Green Version]

- Djagny, K.B.; Wang, Z.; Xu, S. Gelatin: A valuable protein for food and pharmaceutical industries: Review. Crit. Rev. Food Sci. Nutr. 2001, 41, 481–492. [Google Scholar] [CrossRef]

- Journal, T.E. Opinion of the Scientific Panel on food additives, flavourings, processing aids and materials in contact with food (AFC) related to the use of polyvinyl alcohol as a coating agent for food supplements. EFSA J. 2006, 4, 1–15. [Google Scholar]

- Jain, N.; Singh, V.K.; Chauhan, S. A review on mechanical and water absorption properties of polyvinyl alcohol based composites/films. J. Mech. Behav. Mater. 2017, 26, 213–222. [Google Scholar] [CrossRef]

- Nagarkar, R.; Patel, J. Polyvinyl Alcohol: A Comprehensive Study. Acta Sci. Pharm. Sci. 2019, 3, 34–44. [Google Scholar]

- Hou, Y.; Chen, C.; Liu, K.; Tu, Y.; Zhang, L.; Li, Y. Preparation of PVA hydrogel with high-transparence and investigations of its transparent mechanism. RSC Adv. 2015, 5, 24023–24030. [Google Scholar] [CrossRef]

- Han, J.; Lei, T.; Wu, Q. High-water-content mouldable polyvinyl alcohol-borax hydrogels reinforced by well-dispersed cellulose nanoparticles: Dynamic rheological properties and hydrogel formation mechanism. Carbohydr. Polym. 2014, 102, 306–316. [Google Scholar] [CrossRef]

- Schrieber, R.; Gareis, H. Gelatine Handbook: Theory and Industrial Practice; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007; ISBN 9783527315482. [Google Scholar]

- Alipal, J.; Mohd Pu’ad, N.A.S.; Lee, T.C.; Nayan, N.H.M.; Sahari, N.; Basri, H.; Idris, M.I.; Abdullah, H.Z. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today Proc. 2019, 42, 240–250. [Google Scholar] [CrossRef]

- Liang, H.C.; Chang, W.H.; Liang, H.F.; Lee, M.H.; Sung, H.W. Crosslinking structures of gelatin hydrogels crosslinked with genipin or a water-soluble carbodiimide. J. Appl. Polym. Sci. 2004, 91, 4017–4026. [Google Scholar] [CrossRef]

- Kirchmajer, D.M.; Watson, C.A.; Ranson, M.; Panhuis, M. In Het Gelapin, a degradable genipin cross-linked gelatin hydrogel. RSC Adv. 2013, 3, 1073–1081. [Google Scholar] [CrossRef] [Green Version]

- Yang, G.; Xiao, Z.; Long, H.; Ma, K.; Zhang, J.; Ren, X.; Zhang, J. Assessment of the characteristics and biocompatibility of gelatin sponge scaffolds prepared by various crosslinking methods. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef]

- Haiyan, L.; Kunlong, M.; Zhenghua, X.; Xiaomei, R.; Gang, Y. Preparation and characteristics of gelatin sponges crosslinked by microbial transglutaminase. PeerJ 2017, 2017, 3665. [Google Scholar]

- Yung, C.W.; Wu, L.Q.; Ullman, J.A.; Payne, G.F.; Bentley, W.E.; Barbari, T.A. Transglutaminase crosslinked gelatin as a tissue engineering scaffold. J. Biomed. Mater. Res. A. 2007, 83, 1039–1046. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.; Cai, X.; Guo, Y.; Wang, G.; Guo, Y.; Lei, M.; Song, Y.; Yingfeng, Z.; Wang, Y. Atomic-scale and experimental investigation on the micro-structures and mechanical properties of PLA blending with CMC for additive manufacturing. Mater. Des. 2019, 183, 108158. [Google Scholar] [CrossRef]

- Asma, C.; Meriem, E.; Mahmoud, B.; Djaafer, B. Physicochemical characterization of gelatin-cmc composite edibles films from polyion-complex hydrogels. J. Chil. Chem. Soc. 2014, 59, 2279–2283. [Google Scholar] [CrossRef] [Green Version]

- Zaupa, A.; Neffe, A.T.; Pierce, B.F.; Lendlein, A.; Hofmann, D. A molecular dynamic analysis of gelatin as an amorphous material: Prediction of mechanical properties of gelatin systems. Int. J. Artif. Organs 2011, 34, 139–151. [Google Scholar] [CrossRef] [PubMed]

- Hago, E.E.; Li, X. Interpenetrating polymer network hydrogels based on gelatin and PVA by biocompatible approaches: Synthesis and characterization. Adv. Mater. Sci. Eng. 2013, 2013, 328763. [Google Scholar] [CrossRef] [Green Version]

- Thangprasert, A.; Tansakul, C.; Thuaksubun, N.; Meesane, J. Mimicked hybrid hydrogel based on gelatin/PVA for tissue engineering in subchondral bone interface for osteoarthritis surgery. Mater. Des. 2019, 183, 108113. [Google Scholar] [CrossRef]

- Nguyen, T.-H.; Ventura, R.; Min, Y.-K.; Lee, B.-T. Genipin Cross-Linked Polyvinyl Alcohol-Gelatin Hydrogel for Bone Regeneration. J. Biomed. Sci. Eng. 2016, 09, 419–429. [Google Scholar] [CrossRef] [Green Version]

- You, S.J.; Ahn, W.S.; Jang, H.S.; Kang, M.I.; Chun, H.J.; Lim, Y.M.; Nho, Y.C. Preparation and characterization of gelatin-poly(vinyl alcohol) hydrogels for three-dimensional cell culture. J. Ind. Eng. Chem. 2007, 13, 116–120. [Google Scholar]

- Rodríguez-Rodríguez, R.; Espinosa-Andrews, H.; Velasquillo-Martínez, C.; García-Carvajal, Z.Y. Composite hydrogels based on gelatin, chitosan and polyvinyl alcohol to biomedical applications: A review. Int. J. Polym. Mater. Polym. Biomater. 2020, 69, 1–20. [Google Scholar] [CrossRef]

- Hubner, P.; Marcilio, N.R.; Tessaro, I.C. Gelatin/poly(vinyl alcohol) based hydrogel film—A potential biomaterial for wound dressing: Experimental design and optimization followed by rotatable central composite design. J. Biomater. Appl. 2021. [Google Scholar] [CrossRef]

- Ren, T.; Gan, J.; Zhou, L.; Chen, H. Physically crosslinked hydrogels based on poly (vinyl alcohol) and fish gelatin for wound dressing application: Fabrication and characterization. Polymers 2020, 12, 1729. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lim, H.; Kim, S.; Lee, D.Y. Effect of PVA Concentration on Strength and Cell Growth Behavior of PVA/gelatin Hydrogels for Wound Dressing. J. Biomed. Eng. Res. 2020, 41, 1–7. [Google Scholar]

- Imtiaz, N.; Niazi, M.B.K.; Fasim, F.; Khan, B.A.; Bano, S.A.; Shah, G.M.; Badshah, M.; Menaa, F.; Uzair, B. Fabrication of an original transparent PVA/gelatin hydrogel: In vitro antimicrobial activity against skin pathogens. Int. J. Polym. Sci. 2019, 2019, 7651810. [Google Scholar] [CrossRef] [Green Version]

- Pal, K.; Banthia, A.K.; Majumdar, D.K. Preparation and characterization of polyvinyl alcohol-gelatin hydrogel membranes for biomedical applications. AAPS Pharm. Sci. Tech. 2007, 8, E142–E146. [Google Scholar] [CrossRef]

- Marrella, A.; Lagazzo, A.; Dellacasa, E.; Pasquini, C.; Finocchio, E.; Barberis, F.; Pastorino, L.; Giannoni, P.; Scaglione, S. 3D porous gelatin/PVA hydrogel as meniscus substitute using alginate micro-particles as porogens. Polymers 2018, 10, 380. [Google Scholar] [CrossRef] [Green Version]

- Rizwan, M.; Yao, Y.; Gorbet, M.B.; Tse, J.W.; Anderson, D.E.J.; Hinds, M.T.; Yim, E.K.F. One-Pot Covalent Grafting of Gelatin on Poly(Vinyl Alcohol) Hydrogel to Enhance Endothelialization and Hemocompatibility for Synthetic Vascular Graft Applications. ACS Appl. Bio Mater. 2020, 3, 693–703. [Google Scholar] [CrossRef] [Green Version]

- Hui, B.; Zhang, Y.; Ye, L. Structure of PVA/gelatin hydrogel beads and adsorption mechanism for advanced Pb(II) removal. J. Ind. Eng. Chem. 2015, 21, 868–876. [Google Scholar] [CrossRef]

- Rodriguez-Abetxuko, A.; Sánchez-deAlcázar, D.; Muñumer, P.; Beloqui, A. Tunable Polymeric Scaffolds for Enzyme Immobilization. Front. Bioeng. Biotechnol. 2020, 8, 830. [Google Scholar] [CrossRef] [PubMed]

- Bermejo, J.S.; Ugarte, C.M. Chemical crosslinking of PVA and prediction of material properties by means of fully atomistic MD simulations. Macromol. Theory Simul. 2009, 18, 259–267. [Google Scholar] [CrossRef]

- Wu, R.; Qiu, X.; Yang, X. Molecular dynamics simulations of atomistic hydration structures of poly(vinyl methyl ether). Chinese J. Polym. Sci. 2016, 34, 1396–1410. [Google Scholar] [CrossRef]

- de Arenaza, I.M.; Meaurio, E.; Sarasu, J.-R. Analysis of the Miscibility of Polymer Blends Through Molecular Dynamics Simulations. In Polymerization; De Souza Gomes, A., Ed.; Intech: London, UK, 2012; Chapter 2; pp. 29–46. [Google Scholar]

- Li, J.; Jin, S.; Lan, G.; Chen, S.; Li, L. Molecular dynamics simulations on miscibility, glass transition temperature and mechanical properties of PMMA/DBP binary system. J. Mol. Graph. Model. 2018, 84, 182–188. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, Y.; Che, Y.; Yang, M.; Li, X.; Zhang, Y. Molecular mechanisms in compatibility and mechanical properties of Polyacrylamide/Polyvinyl alcohol blends. J. Mech. Behav. Biomed. Mater. 2017, 65, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Liu, Q.; Cui, L.; Yu, Y.; Zhang, M. Molecular simulation and experimental study on propylene dehumidification through a PVA-PAA blend membrane. J. Mater. Chem. A 2014, 2, 16687–16696. [Google Scholar] [CrossRef]

- Neffe, A.T.; Zaupa, A.; Pierce, B.F.; Hofmann, D.; Lendlein, A. Knowledge-based tailoring of gelatin-based materials by functionalization with tyrosine-derived groups. Macromol. Rapid Commun. 2010, 31, 1534–1539. [Google Scholar] [CrossRef] [Green Version]

- Knani, D.; Barkay-Olami, H.; Alperstein, D.; Zilberman, M. Simulation of novel soy protein-based systems for tissue regeneration applications. Polym. Adv. Technol. 2017, 28, 496–505. [Google Scholar] [CrossRef]

- Labus, K.; Drozd, A.; Trusek-Holownia, A. Preparation and characterisation of gelatine hydrogels predisposed to use as matrices for effective immobilisation of biocatalystst. Chem. Pap. 2016, 70, 523–530. [Google Scholar]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- Abbott, L.J.; Hart, K.E.; Colina, C.M. Polymatic: A generalized simulated polymerization algorithm for amorphous polymers. Theor. Chem. Acc. 2013, 132, 1334. [Google Scholar] [CrossRef]

- Zhao, B. Gelatin. In Polymer Data Handbook; James, M., Ed.; Oxford University Press: Oxford, UK, 1999; pp. 121–129. ISBN 978-0195107890. [Google Scholar]

- Shokuhfar, A.; Arab, B. The effect of cross linking density on the mechanical properties and structure of the epoxy polymers: Molecular dynamics simulation. J. Mol. Model. 2013, 19, 3719–3731. [Google Scholar] [CrossRef] [PubMed]

| Hydrogel Type | Tangent Modulus at Specified Strain (MPa) | |||||

|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | 60% | |

| G/PVA 0% | 0.044 | 0.107 | 0.147 | 0.338 | 0.732 | 2.314 |

| G/PVA 1% | 0.055 | 0.096 | 0.191 | 0.368 | 0.924 | - * |

| G/PVA 2% | 0.071 | 0.113 | 0.211 | 0.437 | 1.104 | - * |

| Hydrogel Type | Failure Strength (MPa) | Standard Deviation | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | Average | ||

| G/PVA 0% | 0.629 | 0.763 | 0.604 | 0.594 | 0.440 | 0.606 | 0.115 |

| G/PVA 1% | 0.250 | 0.254 | 0.265 | 0.272 | 0.269 | 0.262 | 0.009 |

| G/PVA 2% | 0.198 | 0.175 | 0.187 | 0.198 | 0.191 | 0.190 | 0.009 |

| Hydrogel Type | Hydrated Hydrogel (g) | Dried Hydrogel (g) | Water Content in the Hydrogel (%) |

|---|---|---|---|

| G/PVA 0% | 15.022 ± 0.466 | 1.609 ± 0.053 | 89.29 |

| G/PVA 1% | 14.807 ± 0.434 | 1.703 ± 0.046 | 88.50 |

| G/PVA 2% | 14.006 ± 0.364 | 1.677 ± 0.051 | 88.02 |

| Hydrogel Type | Swelling Degree (%) | ||

|---|---|---|---|

| 30 °C | 40 °C | 50 °C | |

| G/PVA 0% | 481.5 ± 11.56 | 514.0 ± 16.45 | 528.5 ± 17.44 |

| G/PVA 1% | 547.7 ± 16.98 | 588.3 ± 25.30 | 637.6 ± 18.49 |

| G/PVA 2% | 626.2 ± 18.16 | 642.0 ± 32.74 | 661.0 ± 25.78 |

| Hydrogel Type | Water Absorption Capacity (%) | ||

|---|---|---|---|

| 30 °C | 40 °C | 50 °C | |

| G/PVA 0% | 789.5 ± 16.58 | 840.5 ± 31.94 | 853.5 ± 34.99 |

| G/PVA 1% | 991.2 ± 35.68 | 1046 ± 25.10 | 1267 ± 41.81 |

| G/PVA 2% | 1018 ± 48.86 | 1093 ± 57.93 | 1348 ± 35.05 |

| Hydrogel Type | Hydrolytic Degradation (%) | ||

|---|---|---|---|

| 30 °C | 40 °C | 50 °C | |

| G/PVA 0% | 39.99 ± 0.9197 | 41.68 ± 1.292 | 42.06 ± 1.052 |

| G/PVA 1% | 34.62 ± 1.004 | 37.81 ± 1.059 | 38.81 ± 1.125 |

| G/PVA 2% | 31.44 ± 1.132 | 32.71 ± 0.850 | 33.36 ± 0.767 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Labus, K.; Radosinski, L.; Kotowski, P. Functional Properties of Two-Component Hydrogel Systems Based on Gelatin and Polyvinyl Alcohol—Experimental Studies Supported by Computational Analysis. Int. J. Mol. Sci. 2021, 22, 9909. https://doi.org/10.3390/ijms22189909

Labus K, Radosinski L, Kotowski P. Functional Properties of Two-Component Hydrogel Systems Based on Gelatin and Polyvinyl Alcohol—Experimental Studies Supported by Computational Analysis. International Journal of Molecular Sciences. 2021; 22(18):9909. https://doi.org/10.3390/ijms22189909

Chicago/Turabian StyleLabus, Karolina, Lukasz Radosinski, and Piotr Kotowski. 2021. "Functional Properties of Two-Component Hydrogel Systems Based on Gelatin and Polyvinyl Alcohol—Experimental Studies Supported by Computational Analysis" International Journal of Molecular Sciences 22, no. 18: 9909. https://doi.org/10.3390/ijms22189909

APA StyleLabus, K., Radosinski, L., & Kotowski, P. (2021). Functional Properties of Two-Component Hydrogel Systems Based on Gelatin and Polyvinyl Alcohol—Experimental Studies Supported by Computational Analysis. International Journal of Molecular Sciences, 22(18), 9909. https://doi.org/10.3390/ijms22189909