3.1. Determination of Actuator Requirements

This is the first step in the design process,

i.e., identifying which are the output parameters that the linear actuator has to meet. In the design of electrical rotating machines, the first specification is generally the rated torque, which allows us to determine the active volume once electrical and magnetic loading are specified [

18]. For conventional rotating machines, loading characteristics are available in the references, such as [

18], based on extensive empirical data available or resultant from heat transfer analysis. However, in linear machines with unconventional topologies and complex heat transfer systems, scarce information is available, especially about the compromise between electrical loading and heat exchange ability depending on the temperature constraints of the materials.

In the case of linear machines, similar to rotating ones, the rated effective axial force that the actuator has to produce in continuous operation must be specified. It is important to highlight that short-stroke linear actuators hardly operate with constant speed, different from rotating machines; therefore, the axial force they produce may also vary. In this sense, it is important to point out that effective force must be set as rated, once it is directly proportional to the effective current density, to which the main source of losses is quadratically proportional, i.e., Joule losses, imposing a performance limited by temperature.

Another essential output parameter that must be specified is the stroke of the actuator, which is required to determine the axial length of armature LzW and the total length of the actuator LzT.

In this paper, the techniques for specification of force and stroke will not be discussed; instead, an actuator will be designed for a general application that requires a rated effective axial force Fr of 120 N and stroke S of 80 mm.

3.3. Building and Simulation of Quasi-Static Parametric 2D FEM for One Pole Pitch

The parameterization of the model is essential, once it enables variation of the dimensional parameters that define the topology of the electromagnetic actuator. By means of this geometric model and the results of numerical parametric simulation, it is possible to analyze the behavior of the various figures of merit for the device performance in terms of interdependency and sensitivity of variables.

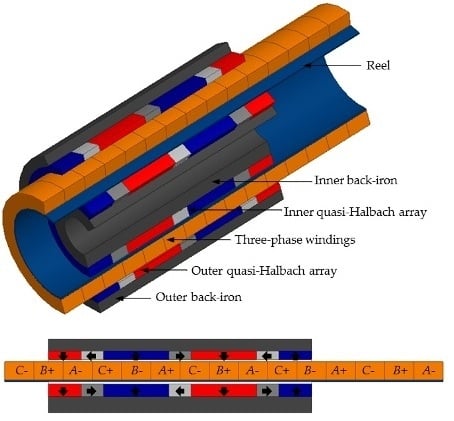

The first step in building this model is the identification of the geometric variables that define the topology, as shown by

Figure 1. The active volume of one pole pitch is delimited by

RiPMi,

RoPMo (the inner and the outer radii, respectively), and

τp. Some variables have dimensional constraints related to manufacturing issues of the parts or to limitation of space in a specific application. Ring-shaped PMs have a limitation for both

RiPMi and

RoPMo, due to the need for radial magnetization and the dimensional limitations of the magnetizer. Even though techniques of segmentation of the rings and parallel magnetization are employed [

10], in this particular case there is a need for a gas mass flow channel for cooling the device, which also requires

RiPMi >

0. The thermal heat transfer mechanism is discussed in

Section 3.8.

The axial length of the PMs with radial magnetization,

τr, may be normalized according to the pole pitch

τp,

i.e.,

τr/

τp; therefore, the axial length of the PMs with axial magnetization,

τz, is

In a cylindrical device of finite length, it is possible to observe a relationship between the axial length and the diameter. This relation can be named as form factor, and, in this case, it is given by the ratio of the pole pitch to the external radius of outer PMs, according to

Due to the aspects previously mentioned, it is interesting to design the actuator using a hollow shaft. Therefore, the form factor must be set to allow devices with annular cross sections. The cylindrical case results when

RiPMi =

0, which excludes the possibility of radial magnetization and cooling air flow. To maintain consistency in the definition of the form factor, volumetric comparison is required between the cylindrical and ring cases, which results in an equivalent radius and provides a proper definition for the form factor given by

The result of the expression is dimensionless and provides a comparison of devices with different scales. The form factor is suitable for the use as a parametric variable because it condenses all the dimensional variables that define the active volume for one pole pitch of the device.

A parametric variable that is defined as the ratio between the radial length of the coil

LrCoil and the radial active space,

i.e.,

Another parametric variable is defined as the ratio between the radial length of the inner PMs and the total radial length of PMs:

where

LrPMi = (

RoPMi −

RiPMi), and

LrPMo is the radial length of the outer PMs,

i.e., (

RoPMo −

RiPMo).

A parametric variable that affects only the radial length of the back-irons is given by

This variable relates the cross section area of the back-irons with half of the cylindrical surface area of PMs with radial magnetization in contact with the back-irons. If nBI = 1, the areas mentioned are equal to each other.

The

nBI factor can be initially estimated by magnetic properties of materials. For devices with coreless armatures and quasi-Halbach arrays, a good rule is

where

Br is the remanent maximum flux density of the PMs and

Bsat is the saturation flux density of back-iron soft ferromagnetic material. Because the topology uses quasi-Halbach arrays, the influence of back-irons in the device performance is less significant in comparison to actuators with non-Halbach arrays. Simulation results of flux density in the back-iron regions must be analyzed and the radial length adjusted in order to avoid saturation.

Considering a position-dependent synchronous electric drive, e.g., with pulse width modulation, the sinusoidal currents of excitation in the sections of the windings are defined according to

where

Jrms is the effective current density through the copper conduction area,

Acond =

τpLrCoil/

3 is the geometric conduction area of one coil in the model,

Ff is the fill factor of the windings, and

θe is the position-dependent electrical angle in radians. By means of these equations, the current density applied to a FEM produces the same magnetomotive force that would be observed in the experimental case.

Considering a study in the quasi-static domain, it is possible to study the behavior of the electromagnetic force depending on the relative position between the stator and the translator,

pz, which can be defined in terms of the electrical angle according to

By means of Equations (8) and (9), the initial relative position pz(0) corresponds to the electrical angle at which the current in phase A is zero, but the currents in phases B and C are identical, so the coil must be positioned with alignment of the phases B and C with the pole faces of the PMs with radial magnetization and axial length τr. Therefore, the generated fields are in quadrature, producing the maximum force in relation to the applied current.

Using equations presented in this subsection, it is possible to build parametric models of the geometry in 2D or 3D spaces. The geometry is axisymmetric, so 2D models satisfactorily represent the behavior of the spatial distribution of the fields, even if the technique of segmenting the rings into a minimum of eight sections with parallel magnetization is applied [

10]. However, if the number of segments is lower than eight, and the asymmetry in the circumferential direction becomes relevant, the 2D model must be replaced by a 3D model. Thus, the model would be more complex and simulation would become time consuming, but the main structure of the proposed methodology would still be applicable.

In order to create and simulate the 2D FEM for one pole pitch, the commercial package Ansys Maxwell® V16.2.0 was employed. The boundary conditions at the axial boundaries of the model were set as symmetric Master/Slave, i.e., Bslave = −Bmaster. Thus, the spatial distribution of the field in these regions behaves as if they had infinite neighboring poles. This approach neglects end effects, however; at this stage, the number of poles of the device to be designed is not known, so adverse effects should be avoided.

The number of poles needed to meet the force requirement in continuous operation is computed in

Section 3.6 and

Section 3.17. The magnetic end poles are set as radial magnetized PMs with half the axial length,

i.e., the end poles present radial length

τr/2 in order to minimize back-iron flux.

Table 1 presents the design variables, and

Figure 3 shows the influence of the four parametric variables with variation between its lower and upper limits, according to the evaluated values.

In

Figure 3, the geometric dimensions affected by the parametric variables highlighted in bold below its respective figure are indicated. The parametric variable

NCPMs affects the radial length of the coils

LrCoil and the radial length of the inner and outer arrays of PMs,

LrPMi and

LrPMo, respectively. The radial lengths of the PMs are also altered by

NPMi. The parametric variable given by the ratio

τr/

τp has effect over the radial length of the inner back-iron

LrPMi, the radial length of the outer back-iron

LrPMo, the axial length of the radially magnetized PMs

τr, and of the axially magnetized PMs

τa. The radial lengths of the back-irons are also a function of

nform. In addition,

τp is also affected by

nform.

3.3.1. Electromagnetic Material Properties

The electromagnetic material properties should correspond to the properties of materials employed in the construction of the actuator, if such data are available. In this case study, the properties were defined as default by Ansys Maxwell® library, with values at a temperature of 25 °C, once the main scope of this paper is about the design methodology itself, and not the comparison with experimental results at this stage.

The main material properties are as follows: PMs made of sintered NdFeB with nominal maximum energy product of 278 kJ/m3, Br(T0) = 1.23 T, Hc(T0) = −890 kA/m, where T0 is the temperature of 25 °C, and µr = 1.099; back-iron pieces were set with nonlinear B-H curve of steel 1010 with Bsat = 2.0 T; coil made of annealed copper with bulk conductivity S/m and µr = 0.999991; and the reel was set to use a high-temperature polymeric material, named Teflon®, with µr = 1 and zero conductivity.

3.3.2. Electrical Loading

The initial electrical loading should be an estimation of what effective current density could be applicable in continuous operation mode. For conventional rotating machines, this is available in the references, e.g., [

18], but for linear actuators with more complex heat transfer systems this is hardly known, if no appropriate study were carried out. In this case, it was assumed that the effective current density is similar to the one used in electrical machines with natural convection,

i.e.,

Jrms = 3 A/mm

2.

3.3.3. Geometrical Constraints

The geometrical constraints applied to this specific case study are summarized in

Table 2.

Ring-shaped PMs have limitations applied to the inner radius of the internal array RiPMi and to the outer radius of external array RoPMo. By assigning a constant value to these variables, the active region to be analyzed is limited radially.

The limitation applied to the RoPMo can be justified due to restrictions of physical space where the actuator must be installed or due to magnetizer restriction. In this work, it was set considering the limitation imposed by the magnetizer fixture available, i.e., model X-Series from Magnet Physik®, which presents a maximum outer radius of approximately 38 mm.

The limitation imposed on

RiPMi is justified by the need for radial magnetization and to enable air flow for cooling of the actuator. The radial magnetization on ring-shaped PMs would be physically impractical on a cylinder if

RiPMi is zero; therefore, a limitation imposed by the magnetizer fixture available, if ideal radial magnetization is desired, may apply. On the other hand, to enable air flow passing through a hollow shaft in the inner back-iron, discussed in

Section 3.8, with a transversal area with the same order of magnitude of the transversal area of the mechanical air-gaps, requires

RiPMi to be estimated accordingly. In this case study, it is considered that radially magnetized PMs are active with segmentation and parallel magnetization [

10], so that no restriction by magnetizer fixture is directly applicable. Thus, considering the

RoPMo dimension, and the needed air flow,

RiPMi was initially set as 18 mm; however, if necessary,

RiPMi could be reconsidered during the project.

It should be noted that even if segmentation and parallel magnetization are also applied to the PMs of the outer array, restriction of RoPMo imposed by the magnetizer is still applicable in order to manufacture the axially magnetized PMs in a ring shape without segmentation.

The mechanical gaps depend on many factors, such as bearing backlash, manufacturing tolerances, thermal expansion of materials, etc. In this paper, inner and outer gaps were set as constant with a value that is typically found in the literature and in datasheets of manufactures and suppliers of linear actuators; however, such value might be minimized, if an in-depth study about the factors that affects mechanical gaps were performed.

The radial length of the reel should be as short as possible, once its presence increases the magnetic gap. In this topology, the reel is necessary to provide more stiffness to the moving coils, and its radial length was defined based on simulation of mechanical stress.

The constraints applied to the radial lengths of the PMs are discussed in detail in

Section 3.7.

The back-iron factor was set in order to satisfy the condition given by Equation (7); thus, all simulations considered nBI = 0.4. If desired, after defining all other variables, nBI could be optimized in order to possibly reduce some of ferromagnetic material of the inner and outer back-iron pieces.

Observing the flowchart presented in

Figure 2, it is possible to see that if some conditions, addressed in

Section 3.7, are not met, new geometrical constraints must be applied. These new geometrical constraints may apply especially to

RoPMo or to

RiPMi, depending on how flexible each one of those is.

3.4. Electromagnetic Uncoupled Parametric Analysis

Analysis of simulation results using 2D or 3D graphics of a space defined by the four parametric variables presented in

Table 1, plus force density and force ripple, can be a difficult and extensive task. An approach that was adopted in this work to analyze results in five dimensions is illustrated in

Figure 4. This figure condenses five variables (four parametric variables, which are independent variables, and one objective function variable, which is a dependent variable) on a single graph. It represents a top-oriented view of a combination of 40 3D graphs, in a way that the color map indicates the dependent variable, which, in the case of

Figure 4, is force density. The vertical axis holds two independent variables:

τr/

τp, which is indicated, and

NCPMs on the minor vertical grid of each rectangle, which is not indicated in

Figure 4 so that this figure is not visually overloaded. The horizontal axis also holds two independent variables,

i.e.,

NPMi, as indicated, and

nform on the minor horizontal grid of each rectangle. Therefore, each of the rectangles in

Figure 4 represents a variation of the parametric variables

nform, on the horizontal axis, and

NCPMs on the vertical axis. As an example, a 3D view of one of the rectangles of

Figure 4, the one with

τr/

τp = 0.75 and

NPMi = 0.60, is shown in

Figure 5. The form of presentation of five variables in a single figure allows one to compare results for the entire domain, which represent the combination of all parametric variables according to

Table 1, in a comprehensive way.

The force density

Fd of

Figure 4 and

Figure 5 is given by

where

Fz1P is the axial force produced by one pole pitch. In the actuator with Halbach arrays, back-irons do not have a significant effect, in fact less than 10% if they are not used at all [

11]. Yet, in this work it was decided to keep them to increase performance and for mechanical support. However, they were not taken into account for computation of force density, because

nBI was not considered in the parametric analysis; therefore, there would be no guarantee that force density is maximized if it were computed considering the back-irons.

It should be noted that the shape, or color map, as presented, of force density would not be affected by its initial electrical loading of the uncoupled model, because effective current density is constant; however, its absolute value would be linearly proportional.

From

Figure 4, it can be seen that the variable

τr/

τp has a greater influence on force density in relation to

NPMi. This can be explained by the increased volume of PMs with radial magnetization as

τr/

τp increases, since it leads to higher levels of the radial component of induction in the magnetic gap, while

NPMi slightly alters the total volume of PMs and the distribution of this volume between internal and external PMs. Consequently, the mean radius of the coil is shifted and so its volume is altered; however, this effect is more significantly observed with

NCPMs.

From

Figure 4, and with more detail in

Figure 5, it is possible to infer that the parametric variable

NCPMs has a higher influence over force density than

nform. This can be explained by a compromise between electrical and magnetic loading, which is directly related to

NCPMs. On the other hand,

nform is related to the interpolar leakage flux, which is more significant for lower values of this parametric variable. A maximum force density of 2.92 × 10

5 N/m

3 is obtained with

NCPMs = 0.4 and

nform ≥ 1.2, with a difference of approximately −30% relative to the minimum simulated results observed.

The minimization of force ripple is a desirable feature with regard to the system linearity, reducing problems related to the positioning control and minimizing the inclusion of oscillations by the actuator when the speed is not zero. Depending on the electric drive technique, there are time-dependent induced harmonics that may generate force ripple during dynamic operation; however, these harmonics are not taken into account in this study, once force ripple is computed based on a magnetostatic model.

The force ripple can be estimated statically calculating the difference between the forces obtained with current in 2-phase and 3-phase, corresponding to, e.g.,

θe = 0 and

θe = π/6, respectively, in relation to the average value between these two cases, according to the following equation:

Figure 6 shows an evaluation of force

F(

θe) normalized in relation to its mean value computed using its maximum and minimum,

i.e., 2

F(

θe)/(

F3 +

F2). Force results were obtained over a

θe range of 60 degrees for four

τr/

τp variations with

NCPMs = 0.4,

NPMi = 0.6,

nform = 1.2 and

Jrms = 3 A/mm

2. From

Figure 6, it is possible to infer that maximum and minimum values of force occur at two particular electrical angles as discussed in the previous paragraph; thus, a fair estimation of the variation of force can be carried out by evaluating

F2 and

F3 and computing the force ripple according to Equation (11).

Figure 6 also shows that for

τr/

τp = 0.75 the force ripple observed significantly decreased; in fact it is 0.44%, whereas for

τr/

τp = 0.55 it is 4.87%,

i.e., more than 10% higher for the former case.

Parametric simulation results of

F3 and

F2 applied to Equation (11) are shown in

Figure 7, where the results of absolute value of static force ripple are presented. The results suggest that

τr/

τp is closely related to force ripple, and with

τr/

τp = 0.75 produces approximately zero force ripple regardless of the values of the other variables.

3.6. Computation of Axial Active Length, Total Length, and Number of Poles of the Uncoupled Design

The active volume of the actuator that is able to cope with effective force specifications can be obtained by dividing the rated force

Fr (

Section 3.1) by the force density

Fd obtained for one pole pitch (

Section 3.4). The axial active length of the actuator

Lz is then calculated by relating it with its active volume, so that

The axial length of armature

LzW is simply the sum of

Lz and the specified stroke

S (

Section 3.1), whereas the total axial length

LzT must be at least the sum of

Lz with twice

S:

The number of poles

P of the actuator can also be determined based on previous results. It was defined that

P must be an integer even number, and that each of the inner and outer magnets of the extremities count as one pole, even though they present radial length of

τr/

2. Therefore,

P is given by

where the operator “ceil” rounds the element to the nearest even integer towards positive infinity [

19]. In order to obey the condition imposed by Equation (14),

Lz or

nform must be recalculated. In this case, it can be observed from

Figure 5 that

nform slightly affects

Fd over a range of 0.8 up to 1.4. That means it could be adjusted without having a significant effect on the overall results.

nform can be recalculated according to

It is important to observe that as nform was recalculated, so must τp be, according to Equation (3). If the choice was to adjust Lz, this could lead to an unnecessary increase in the active volume of the device. If nform, calculated by Equation (15), returns a value outside of the range 0.8–1.4, e.g., it results from the fact that P was adjusted to the nearest even number towards positive infinity, but it was very close to an even number towards zero. In this situation, P should be set as the closest even number to zero, if the dimensional design conditions verified in the next subsection are met, and the final nform calculated with Equation (15).

For the case study, values for Lz, LzW, and LzT were 116.8 mm, 196.8 mm, and 276.8 mm, respectively. P was found to be 4 with a final nform of 1.1633.

3.7. Validity of Parameters of the Uncoupled Design

This step in the designing process verifies whether the results obtained so far are consistent in the sense that the final shape of the actuator presents acceptable dimensions and parameters, which are defined by the following inequalities:

The first inequality, which is the ratio between the axial active length and the windings axial length, is set so that at least half of the total length of the windings is active during operation. This ratio is related to the efficiency of the actuator, once there are Joule losses along the total length of the windings, but only the portion that is placed within the active length produces force.

On the other hand, the second inequality in Equation (16) requires that the minimum number of poles of the actuator is four. This criterion is established in order to limit the way that end effect affects the overall performance of the actuator. End effect is intrinsic to linear machines and is more significant if the device has a low number of poles.

The third and fourth inequalities of Equation (16) limit the radial length of the permanent magnets to a minimum, which are imposed to prevent the PMs from breaking during assembly, which would easily happen if the radial length of the PMs is too small. The shaded area in

Figure 8 indicates a domain of the parametric variables

NPMi and

NCPMs in which radial length of both inner and outer PMs are bigger than 3 mm, whereas the areas that are not shaded indicate whether inner or outer magnets present a radial length smaller than specified.

For the case under study, it was found that

P = 4 and

Lz/

LzW = 0.59; thus, both criteria were simultaneously met in the first place and no change in the geometrical constraints was required. If, for example, the resultant

Lz/

LzW were lower than 0.5, then geometrical constraints ought to be reviewed, as the first inequality of Equation (16) would not be complied with. In this case whether

RoPMo should be decreased or

RiPMi increased, so that the active axial length of the actuator would become larger. The radial length of the inner and outer PMs is also higher than 3 mm, once in

Section 3.4 NPMi and

NCPMs were defined as 0.6 and 0.4, respectively, which, according to

Figure 8, lies within the allowed domain. If the former discussed conditions were not attained, it would be suggested to alter

NPMi, which presents very little sensitivity in relation to design objective, instead of changing

NCPMs.

The inequalities given by Equation (16) could be different from the ones that were set; they are basically criteria imposed by the designer.

3.8. Definition of Thermal Topology

The heat sources associated with losses of an actuator can be of many kinds; however, in this particular actuator, the main source of losses is Joule losses at the conductors. Very low levels of induced current appear in the PMs, which can be neglected. This specific topology presents an intrinsic low level of iron losses because there is no relative movement between back-irons and PMs and it presents a coreless armature. Still, there may be induced current in the back-irons by variation of the flux produced by the armature, but in lower levels than would be observed within actuators with cored armature and low compared to Joule losses, so it can be neglected. Friction losses at bearings are also not considered.

In order to achieve higher force and power density, the device must present an improved capacity of heat exchange. In the proposed methodology, thermal analysis plays an important role, since it allows for determining absolute force density and, thereafter, active volume for a given specification.

In this work, it was considered that a forced air flow was imposed to a hollow shaft, which insufflates the actuator with air at ambient temperature. In order to improve heat exchange in this topology, a forced inlet flow with a speed of 0.5 m/s enters the hollow shaft from the bottom, passes through the inner gap, then passes through the outer gap and outflows at the top of the actuator with a higher temperature. This characterizes a forced convection at the hollow shaft and at the inner and outer gaps, which significantly improves heat transfer.

It must be clear that the decision about whether forced or natural heat transfer is applied must be made in accordance with the mechanical characteristics of the actuator. Depending on the operation conditions, the actuator may be completely sealed, or, in a different situation, it might be open and its own movement produces an air flow that characterizes forced convection. In any case, it must be defined at this step because this significantly affects the designing process.

3.15. Electromagnetic Coupled Analysis

A similar approach to the one presented in

Section 3.4 is carried out at this step,

i.e., first, the results for force density are evaluated as a function of the parametric variables

τr/

τp,

NPMi,

NCPMs, and

nform. After considering the ripple of force, the ratio

τr/

τp is chosen and, considering the geometrical constraints,

NPMi is defined. A 3D graph of force density for the chosen

τr/

τp and

NPMi is presented detailing results as a function of the parametric variables

NCPMs and

nform.

It is important to reinforce that, at this stage, effective force density is corrected in a post-process routine using Matlab

® script for the reasons discussed in the previous subsection. Each design evaluated presents a maximum effective current density, resulting in the maximum allowable temperature at the windings. This means that the force density values presented in

Figure 12 are the absolute maximum considering energy drop at the PMs and thermal constraint.

The results presented in

Figure 12 are significantly different from those presented in

Figure 4, especially because of the parametric variable

NCPMs, which is directly related to the volume of the windings. It is important to emphasize that in

Figure 4 the force density for the uncoupled model is obtained with constant effective current density; on the other hand, in

Figure 12, in the coupled model, the effective current density is adjusted according to Equation (20). This becomes even more evident when comparing

Figure 5 and

Figure 13, where the independent parametric variables are clearly identified, and the force density dependency shows that there is a shift in the maximum point in relation to

NCPMs, from 0.4 for the uncoupled model to 0.25 for the coupled model. The parametric variable

NCPMs directly affects the volume

Vw and external surface area

As of the windings, and these are used to calculate

JrmsMax.

Moreover, the absolute maximum force density has also changed from 2.92 × 105 N/m3 for the uncoupled model to 2.56 × 105 N/m3 for the coupled model. This will directly affect the total active volume of the actuator and, consequently, its dimensional parameters. Even though the figures of maximum force density are close to each other, in this case, they result from a good estimation of the maximum electrical loading. The results could significantly differ, e.g., if: the initial effective current density were set as 5 A/mm2 for the uncoupled model, which is often employed in conventional electrical machines; if the maximum allowable temperature at the windings were set as 120 °C, which in general is acceptable because of its insulation class; or if the NdFeB PMs operation temperature were higher.

The absolute force ripple presented in

Figure 14 shows behavior similar to that in

Figure 7,

i.e., for

τr/

τp = 0.75, the percentage ripple of force is approximately zero. These results were expected because this parametric variable is not affected by thermal issues because it does not alter the volume of the windings or the volume of the PMs.