A Magnetoresistive Tactile Sensor for Harsh Environment Applications

Abstract

:1. Introduction

2. Materials and Methods

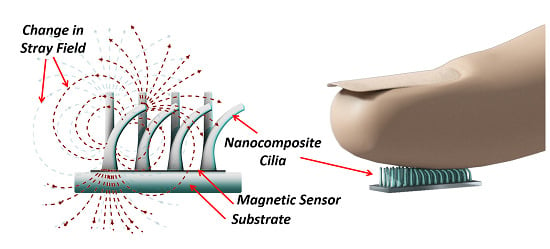

2.1. Tactile Sensing Concept

2.2. Fabrication

2.3. Characterization

3. Results and Discussion

3.1. Nanocomposite Characterization

3.2. GMR Sensor Response and Thermal Stability

3.3. Tactile Sensor Response

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| NWs | Nanowires |

| GMI | Giant magnetoimpedance |

| GMR | Giant magnetoresistive |

| PDMS | Polydimethylsiloxane |

| SDS | Sodium dodecyl sulfate |

| PMMA | Poly (methylmethcrylate) |

References

- Kawasaki, H.; Komatsu, T.; Uchiyama, K. Dexterous anthropomorphic robot hand with distributed tactile sensor: Gifu hand II. IEEE ASME Trans. Mechatron. 2002, 7, 296–303. [Google Scholar] [CrossRef]

- Sadao, O.; Terunuma, Y. New tactile sensor like the human hand and its applications. Sens. Actuators A Phys. 1992, 35, 9–15. [Google Scholar]

- Mukai, T.; Onishi, M.; Odashima, T.; Hirano, S.; Luo, Z. Development of the Tactile Sensor System of a Human-Interactive Robot “RI-MAN”. IEEE Trans. Robot. 2008, 24, 505–512. [Google Scholar] [CrossRef]

- Kerpa, O.; Weiss, K.; Worn, H. Development of a flexible tactile sensor system for a humanoid robot. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 27–31 October 2003; Volume 1, pp. 1–6.

- Dargahi, J.; Parameswaran, M.; Payandeh, S. A micromachined piezoelectric tactile sensor for an endoscopic grasper-theory, fabrication and experiments. J. Microelectromech. Syst. 2000, 9, 329–335. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Kashani, S.M.T.; Najarian, S.; Panahi, F.; Naeini, S.M.M.; Mojra, A. A medical tactile sensing instrument for detecting embedded objects, with specific application for breast examination. Int. J. Med. Robot. Comput. Assist. Surg. 2010, 6, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, H.; Lin, Z.H.; Zhou, Y.S.; Jing, Q.; Su, Y.; Yang, J.; Chen, J.; Hu, C.; Wang, Z.L. Human skin based triboelectric nanogenerators for harvesting biomechanical energy and as self-powered active tactile sensor system. ACS Nano 2013, 7, 9213–9222. [Google Scholar] [CrossRef] [PubMed]

- Eason, E.V.; Hawkes, E.W.; Windheim, M.; Christensen, D.L.; Libby, T.; Cutkosky, M.R. Stress distribution and contact area measurements of a gecko toe using a high-resolution tactile sensor. Bioinspir. Biomim. 2015, 10. [Google Scholar] [CrossRef] [PubMed]

- Park, M.; Park, Y.J.; Chen, X.; Park, Y.K.; Kim, M.S.; Ahn, J.H. MoS2-Based Tactile Sensor for Electronic Skin Applications. Adv. Mater. 2016, 28, 2556–2562. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, P.; Schotter, J.; Shoshi, A.; Eggeling, M.; Bethge, O.; Hütten, A.; Brückl, H. Artificial cilia of magnetically tagged polymer nanowires for biomimetic mechanosensing. Bioinspir. Biomim. 2011, 6. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, M.A.; English, J.M.; Von Arx, M.; Allen, M.G. Wireless micromachined ceramic pressure sensor for high-temperature applications. J. Microelectromech. Syst. 2002, 11, 337–343. [Google Scholar] [CrossRef]

- Young, D.J.; Du, J.; Zorman, C.A.; Ko, W.H. High-temperature single-crystal 3C-SiC capacitive pressure sensor. IEEE Sens. J. 2004, 4, 464–470. [Google Scholar] [CrossRef]

- Liu, G.D.; Cui, W.P.; Hu, H.; Zhang, F.S.; Zhang, Y.X.; Gao, C.C.; Hao, Y.L. April High temperature pressure sensor using a thermostable electrode. In Proceedings of the IEEE 10th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xi’an, China, 7–11 April 2015; pp. 201–204.

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.N.; Chun, J.; Chae, S.A.; Ahn, C.W.; Kim, I.W.; Kim, S.W.; Wang, Z.L.; Baik, J.M. Silk fibroin-based biodegradable piezoelectric composite nanogenerators using lead-free ferroelectric nanoparticles. Nano Energy 2015, 14, 87–94. [Google Scholar] [CrossRef]

- Taghavi, M.; Mattoli, V.; Sadeghi, A.; Mazzolai, B.; Beccai, L. A Novel Soft Metal-Polymer Composite for Multidirectional Pressure Energy Harvesting. Adv. Energy Mater. 2014, 4. [Google Scholar] [CrossRef]

- Alfadhel, A.; Kosel, J. Magnetic Nanocomposite Cilia Tactile Sensor. Adv. Mater. 2015, 27, 7888–7892. [Google Scholar] [CrossRef] [PubMed]

- Alfadhel, A.; Kosel, J. Magnetic micropillar sensors for force sensing. In Proceedings of the 2015 IEEE Sensors Applications Symposium (SAS), Zadar, Croatia, 13–15 April 2015; pp. 1–4.

- Khan, M.A.; Alfadhel, A.; Kosel, J. Magnetic Nanocomposite Cilia Energy Harvester. IEEE Trans. Magn. 2016, PP. [Google Scholar] [CrossRef]

- Alfadhel, A.; Li, B.; Zaher, A.; Yassine, O.; Kosel, J. A magnetic nanocomposite for biomimetic flow sensing. Lab Chip 2014, 14, 4362–4369. [Google Scholar] [CrossRef] [PubMed]

- Alnassar, M.; Ivanov, I.P.; Kosel, J. Flexible Magnetoelectric Nanocomposites with Tunable Properties. Adv. Electron. Mater. 2016, 2. [Google Scholar] [CrossRef]

- Yi, Y.; Zaher, A.; Yassine, O.; Kosel, J.; Foulds, I.G. A remotely operated drug delivery system with an electrolytic pump and a thermoresponsive valve. Biomicrofluidics 2015, 9. [Google Scholar] [CrossRef] [PubMed]

- Zaher, A.; Li, S.; Yassine, O.; Khashab, N.; Pirmoradi, N.; Lin, L.; Kosel, J. Osmotically driven drug delivery through remote-controlled magnetic nanocomposite membranes. Biomicrofluidics 2015, 9. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, Y.P.; Alfadhel, A.; Alnassar, M.; Perez, J.; Vázquez, M.; Chuvilin, A.; Kosel, J. Tunable magnetic nanowires for biomedical and harsh environment applications. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Parkin, S.P. Giant magnetoresistance in magnetic nanostructures. Annu. Rev. Mater. Sci. 1995, 25, 357–388. [Google Scholar] [CrossRef]

- Melzer, M.; Kaltenbrunner, M.; Makarov, D.; Karnaushenko, D.; Karnaushenko, D.; Sekitani, T.; Someya, T.; Schmidt, O.G. Imperceptible magnetoelectronics. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Pannetier, M.; Fermon, C.; Goff, G.; Simola, J.; Kerr, J.E. Femtotesla magnetic field measurement with magnetoresistive sensors. Science 2004, 304, 1648–1650. [Google Scholar] [CrossRef] [PubMed]

- Timoshenko, S. History of Strength of Materials; McGraw-Hill: New York, NY, USA, 1953. [Google Scholar]

- Nielsch, K.; Müller, F.; Li, A.P.; Gösele, U. Uniform Nickel Deposition into Ordered Alumina Pores by Pulsed Electrodeposition. Adv. Mater. 2000, 12, 582–586. [Google Scholar] [CrossRef]

- Freitas, P.P.; Ferreira, R.; Cardoso, S.; Cardoso, F. Magnetoresistive sensors. J. Phys. Condens. Matter 2007, 19. [Google Scholar] [CrossRef]

- Freitas, P.P.; Cardoso, S.; Ferreira, R.; Martins, V.R.; Guedes, A.; Cardoso, F.; Loureiro, J.; Macedo, R.; Chaves, R.; Amaral, J.P. Optimization and integration of magnetoresistive sensors. SPIN 2011, 1, 71–91. [Google Scholar] [CrossRef]

- Silva, A.; Leitao, D.; Amaral, J.; Valadeiro, J.; Cardoso, S.; Freitas, P.P. Linearization strategies for high sensitivity magnetoresistive sensors. Eur. Phys. J. Appl. Phys. 2015, 72. [Google Scholar] [CrossRef]

- Tang, K.C.; Liao, E.; Ong, W.L.; Wong, J.D.S.; Agarwal, A.; Nagarajan, R.; Yobas, L. Evaluation of bonding between oxygen plasma treated polydimethyl siloxane and passivated silicon. J. Phys. Conf. Ser. 2006, 34, 155–161. [Google Scholar] [CrossRef]

- Coey, J.M.D. Magnetism and Magnetic Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Gehanno, V.; Freitas, P.P.; Veloso, A.; Ferreira, J.; Almeida, B.; Sousa, J.B.; Soares, J.C.; daSilva, M.F. Ion beam deposition of Mn-Ir spin valves. IEEE Trans. Magn. 1999, 35, 4361–4367. [Google Scholar] [CrossRef]

- Lederman, T. Performance of metallic antiferromagnets for use in spin-valve read sensors. IEEE Trans. Magn. 1999, 35, 794–799. [Google Scholar] [CrossRef]

- Liu, M.; Sun, J.; Chen, Q. Influences of heating temperature on mechanical properties of polydimethylsiloxane. Sens. Actuators A Phys. 2009, 151, 42–45. [Google Scholar] [CrossRef]

| Temperature (°C) | Operating Range (mN) or (kPa) | Sensitivity (Ω/mN) or (Ω/kPa) | Maximum ΔR @ 15 mN (Ω) | Resolution (mN) or (kPa) | Noise Level ± (Ω) |

|---|---|---|---|---|---|

| 20 | 0–15.0 | 46 | 700 | 1.31 | 30 |

| 50 | 0–16.2 | 39 | 581 | 1.69 | 33 |

| 80 | 0–16.5 | 35 | 531 | 2.17 | 38 |

| 110 | 0–17.1 | 29.4 | 462 | 2.85 | 42 |

| 140 | 0–17.4 | 25 | 385 | 3.91 | 49 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfadhel, A.; Khan, M.A.; Cardoso, S.; Leitao, D.; Kosel, J. A Magnetoresistive Tactile Sensor for Harsh Environment Applications. Sensors 2016, 16, 650. https://doi.org/10.3390/s16050650

Alfadhel A, Khan MA, Cardoso S, Leitao D, Kosel J. A Magnetoresistive Tactile Sensor for Harsh Environment Applications. Sensors. 2016; 16(5):650. https://doi.org/10.3390/s16050650

Chicago/Turabian StyleAlfadhel, Ahmed, Mohammed Asadullah Khan, Susana Cardoso, Diana Leitao, and Jürgen Kosel. 2016. "A Magnetoresistive Tactile Sensor for Harsh Environment Applications" Sensors 16, no. 5: 650. https://doi.org/10.3390/s16050650

APA StyleAlfadhel, A., Khan, M. A., Cardoso, S., Leitao, D., & Kosel, J. (2016). A Magnetoresistive Tactile Sensor for Harsh Environment Applications. Sensors, 16(5), 650. https://doi.org/10.3390/s16050650