Tactile Perception of Roughness and Hardness to Discriminate Materials by Friction-Induced Vibration

Abstract

:1. Introduction

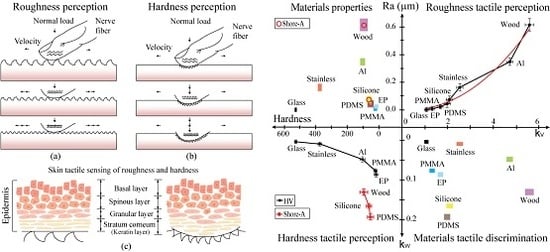

1.1. Material Tactile Discrimination

1.2. Objective of the Paper

2. Experimental

2.1. Material Preparation and Method

2.2. Experimental Apparatus and Procedure

3. Result and Discussion

3.1. Tactile Perception of Glass, Aluminum, Silicone, and Pig Skin

3.2. Tactile Discrimination of Aluminum with Different Roughness

3.3. Tactile Discrimination of PDMS with Different Hardness

3.4. Common Materials’ Roughness and Hardness Tactile Discrimination

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gueorguiev, D.; Bochereau, S.; Mouraux, A.; Hayward, V.; Thonnard, J.L. Touch uses frictional cues to discriminate flat materials. Sci. Rep. 2016, 6, 25553. [Google Scholar] [CrossRef] [PubMed]

- Morley, J.W.; Goodwin, A.W.; Darian-Smith, I. Tactile discrimination of gratings. Exp. Brain Res. 1983, 49, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, M.A.; Whitehouse, J.M.; Lamotte, R.H. Tactile detection of slip: Surface microgeometry and peripheral neural codes. J. Neurophysiol. 1990, 63, 1323–1332. [Google Scholar] [PubMed]

- Hollins, M.; Risner, S.R. Evidence for the duplex theory of tactile texture perception. Percept. Psychophys. 2000, 62, 695–705. [Google Scholar] [CrossRef] [PubMed]

- Hertenstein, M.J.; Weiss, S.J. The Handbook of Touch: Neuroscience, Behavioral, and Health Perspectives, 1st ed.; Springer: Berlin, Germany, 2011; pp. 226–230. [Google Scholar]

- Scheibert, J.; Debrégeas, G. The role of fingerprints in the coding of tactile information probed with a biomimetic sensor. Science 2009, 323, 1503–1506. [Google Scholar]

- Fagiani, R.; Massi, F.; Chatelet, E.; Berthier, Y.; Akay, A. Tactile perception by friction induced vibrations. Tribol. Int. 2011, 44, 1100–1110. [Google Scholar] [CrossRef] [Green Version]

- Wandersman, E.; Candelier, R.; Debrégeas, G.; Prevost, A. Texture-induced modulations of friction force: The fingerprint effect. Phys. Rev. Lett. 2011, 107, 164301. [Google Scholar] [CrossRef] [PubMed]

- Cauna, N. Nature and functions of the papillary ridges of the digital skin. Anat. Rec. 1954, 119, 449–468. [Google Scholar] [CrossRef] [PubMed]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing: From humans to humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Delmas, P.; Hao, J.; Rodatdespoix, L. Molecular mechanisms of mechanotransduction in mammalian sensory neurons. Nat. Rev. Neurosci. 2011, 12, 139–153. [Google Scholar] [CrossRef] [PubMed]

- Dargahi, J.; Najarian, S. Human tactile perception as a standard for artificial tactile sensing—A review. Int. J. Med. Robot. Comput. Assist. Surg. 2004, 1, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Graz, I.; Krause, M.; Bauer-Gogonea, S.; Bauer, S.; Lacour, S.P.; Ploss, B.; Zirkl, M.; Stadlober, B.; Wagner, S. Flexible active-matrix cells with selectively poled bifunctional polymer-ceramic nanocomposite for pressure and temperature sensing skin. J. Appl. Phys. 2009, 106, 034503. [Google Scholar] [CrossRef]

- Ding, S.; Bhushan, B. Tactile perception of skin and skin cream by friction induced vibrations. J. Colloid Int. Sci. 2016, 481, 131–143. [Google Scholar] [CrossRef] [PubMed]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Lu, N.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [PubMed]

- Yeo, W.H.; Kim, Y.S.; Lee, J.; Ameen, A.; Shi, L.; Li, M.; Wang, S.; Ma, R.; Jin, S.H.; Kang, Z.; et al. Multi-functional electronics: Multifunctional epidermal electronics printed directly onto the skin. Adv. Mater. 2013, 25, 2772. [Google Scholar] [CrossRef]

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Gutbrod, S.R.; Bonifas, A.P.; Su, Y.; Sulkin, M.S.; Lu, N.; Chung, H.J.; Jang, K.I.; Liu, Z.; Ying, M.; et al. 3D multifunctional integumentary membranes for spatiotemporal cardiac measurements and stimulation across the entire epicardium. Nat. Commun. 2014, 5, 3329. [Google Scholar] [CrossRef] [PubMed]

- Cabboi, A.; Putelat, T.; Woodhouse, J. The frequency response of dynamic friction: Enhanced rate-and-state models. J. Mech. Phys. Sol. 2016, 92, 210–236. [Google Scholar] [CrossRef]

- Yang, T.; Xie, D.; Li, Z.; Zhu, H. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R Rep. 2017, 115, 1–37. [Google Scholar] [CrossRef]

- Bensmaia, S.J.; Hollins, M. The vibrations of texture. Somatosens. Mot. Res. 2003, 20, 33–43. [Google Scholar] [CrossRef] [PubMed]

- Manfredi, L.R.; Saal, H.P.; Brown, K.J.; Zielinski, M.C.; Polashock, V.S.; Bensmaia, S.J. Natural scenes in tactile texture. J. Neurophys. 2014, 111, 1792–1802. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, C. The slip hypothesis: Tactile perception and its neuronal bases. Trends Neurosci. 2016, 39, 449–462. [Google Scholar] [CrossRef] [PubMed]

- Zahouani, H.; Vargiolu, R.; Boyer, G.; Pailler-Mattei, C.; Laquièze, L.; Mavon, A. Friction noise of human skin in vivo. Wear 2009, 267, 1274–1280. [Google Scholar] [CrossRef]

- Ho, H.N.; Jones, L.A. Contribution of thermal cues to material discrimination and localization. Percept. Psychophys. 2006, 68, 118–128. [Google Scholar] [CrossRef] [PubMed]

- Tiest, W.M.; Kappers, A.M. Tactile perception of thermal diffusivity. Atten. Percept. Psychophys. 2009, 71, 481–489. [Google Scholar] [CrossRef] [PubMed]

- Thieulin, C.; Pailler-Mattei, C.; Vargiolu, R.; Lancelot, S.; Zahouani, H. Study of the tactile perception of bathroom tissues: Comparison between the sensory evaluation by a handfeel panel and a tribo-acoustic artificial finger. Colloids Surf. B Biointerfaces 2016, 150, 417–425. [Google Scholar] [CrossRef] [PubMed]

- Skedung, L.; Arvidsson, M.; Chung, J.Y.; Stafford, C.M.; Berglund, B.; Rutland, M.W. Feeling small: Exploring the tactile perception limits. Sci. Rep. 2013, 3, 2617. [Google Scholar] [CrossRef] [PubMed]

- Connor, C.E.; Johnson, K.O. Neural coding of tactile texture: Comparison of spatial and temporal mechanisms for roughness perception. J. Neurosci. Off. J. Soc. Neurosci. 1992, 12, 3414–3426. [Google Scholar]

- Klatzky, R.L.; Lederman, S.J. Tactile roughness perception with a rigid link interposed between skin and surface. Percept. Psychophys. 1999, 61, 591–607. [Google Scholar] [CrossRef] [PubMed]

- Hollins, M.; Bensmaïa, S.J.; Washburn, S. Vibrotactile adaptation impairs discrimination of fine, but not coarse, textures. Somatosens. Mot. Res. 2001, 18, 253–262. [Google Scholar] [CrossRef] [PubMed]

- Avilés, J.M.; Muñoz, F.M.; Kleinböhl, D.; Sebastián, M.; Jiménez, S.B. A new device to present textured stimuli to touch with simultaneous EEG recording. Behav. Res. Methods 2010, 42, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Delhaye, B.; Hayward, V.; Lefèvre, P.; Thonnard, J.L. Texture-induced vibrations in the forearm during tactile exploration. Front. Behav. Neurosci. 2012, 6, 37. [Google Scholar] [CrossRef] [PubMed]

- Breitwieser, C.; Kaiser, V.; Neuper, C.; Müller-Putz, G.R. Stability and distribution of steady-state somatosensory evoked potentials elicited by vibro-tactile stimulation. Med. Biol. Eng. Comput. 2012, 50, 347–357. [Google Scholar] [CrossRef] [PubMed]

- Libouton, X.; Barbier, O.; Berger, Y.; Plaghki, L.; Thonnard, J.L. Tactile roughness discrimination of the finger pad relies primarily on vibration sensitive afferents not necessarily located in the hand. Behav. Brain Res. 2012, 229, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Weber, A.I.; Saal, H.P.; Lieber, J.D.; Cheng, J.W.; Manfredi, L.R.; Dammann, J.F.; Bensmaia, S.J. Spatial and temporal codes mediate the tactile perception of natural textures. Proc. Natl. Acad. Sci. USA 2013, 110, 17107–17112. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Zhang, J.; Chen, S.; Chen, N.; Zhu, H.; Ge, S.; Zhang, S. Tactile perception of skin and skin cream. Tribol. Lett. 2015, 59, 24. [Google Scholar] [CrossRef]

- Moungou, A.; Thonnard, J.L.; Mouraux, A. EEG frequency tagging to explore the cortical activity related to the tactile exploration of natural textures. Sci. Rep. 2016, 6, 20738. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Bhushan, B. Adhesion, friction and wear characterization of skin and skin cream using atomic force microscope. Colloids Surf. B Biointerfaces 2010, 76, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Kandel, E.; Schwartz, J.; Jessell, T. Principles of Neural Science, 5th ed.; McGraw-Hill: New York, NY, USA, 2000; pp. 430–450. [Google Scholar]

- Kappers, A.M. Human perception of shape from touch. Phil. Trans. R. Soc. Lond. 2011, 366, 3106–3114. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kim, M.; Lee, Y.; Lee, H.S.; Ko, H. Fingertip skin-inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli. Sci. Adv. 2015, 1, e1500661. [Google Scholar] [CrossRef] [PubMed]

- Jofre-Reche, J.A.; Pulpytel, J.; Fakhouri, H.; Arefi-Khonsari, F.; Martín-Martínez, J.M. Surface treatment of polydimethylsiloxane (pdms) with atmospheric pressure rotating plasma jet modeling and optimization of the surface treatment conditions. Plasma Processes Polym. 2016, 13, 459–469. [Google Scholar] [CrossRef]

- Thomson, W.T. Theory of Vibration with Applications, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2005; pp. 786–791. [Google Scholar]

- Bendat, J.S.; Piersol, A.G. Random Data, 4th ed.; Wiley: New York, NY, USA, 2010; pp. 465–476. [Google Scholar]

| Mesh Number | 60 | 120 | 220 | 400 | 800 | 1000 |

|---|---|---|---|---|---|---|

| Ra (µm) | 1.618 | 0.842 | 0.624 | 0.368 | 0.241 | 0.165 |

| Hardness | 103.6 | 103.2 | 102.6 | 102.1 | 102.1 | 102 |

| kv | 4.73 | 3.51 | 2.42 | 1.84 | 1.41 | 0.96 |

| kw | 0.061 | 0.041 | 0.053 | 0.062 | 0.048 | 0.063 |

| Name | Wood | Al | Stainless | Silicone | PDMS | EP | PMMA | Glass |

|---|---|---|---|---|---|---|---|---|

| Ra (µm) | 0.615 | 0.368 | 0.163 | 0.075 | 0.045 | 0.023 | 0.008 | 0.002 |

| Hardness | 95.2 | 102.6 | 372.1 | 56.4 | 53.1 | 16.5 | 21.6 | 530.6 |

| kv | 5.57 | 4.71 | 2.52 | 2.08 | 1.97 | 1.68 | 1.32 | 1.07 |

| kw | 0.133 | 0.053 | 0.008 | 0.162 | 0.191 | 0.084 | 0.0751 | 0.0007 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, S.; Pan, Y.; Tong, M.; Zhao, X. Tactile Perception of Roughness and Hardness to Discriminate Materials by Friction-Induced Vibration. Sensors 2017, 17, 2748. https://doi.org/10.3390/s17122748

Ding S, Pan Y, Tong M, Zhao X. Tactile Perception of Roughness and Hardness to Discriminate Materials by Friction-Induced Vibration. Sensors. 2017; 17(12):2748. https://doi.org/10.3390/s17122748

Chicago/Turabian StyleDing, Shuyang, Yunlu Pan, Mingsi Tong, and Xuezeng Zhao. 2017. "Tactile Perception of Roughness and Hardness to Discriminate Materials by Friction-Induced Vibration" Sensors 17, no. 12: 2748. https://doi.org/10.3390/s17122748

APA StyleDing, S., Pan, Y., Tong, M., & Zhao, X. (2017). Tactile Perception of Roughness and Hardness to Discriminate Materials by Friction-Induced Vibration. Sensors, 17(12), 2748. https://doi.org/10.3390/s17122748