1. Introduction

NO

is a trace gas poisonous for humans, animals and plants. It is not only poisonous in itself but also the cause of summer smog (ozone). Due to the impact of sunlight, NO

splits into likewise poisonous NO and a free oxygen radical. The latter forms ozone (O

) together with the atmospheric O

. The primary origins of NO

are combustion processes of fossil fuels in motor vehicles and power plants [

1]. The background concentration in the atmosphere is between 5 and 30 ppb [

2]. However, close to its source it can be several magnitudes higher, thus being injurious to health [

3]. Therefore, accurate measurements in the ppb range represent a wide application field, e.g., monitoring at inner-city traffic junctions, in tunnels and underground car parks [

4]. To serve these claims, the sensor must not only be sensitive and selective, but also economical. So far, NO

is measured by electrochemical sensors or large absorption photometers. Electrochemical sensors show a high sensitivity to NO

, are small and cost effective, but require a frequent replacement due to their limited lifespan. IR absorption photometers on the other hand need an absorption path of several meters to gain a sufficient sensitivity, which makes them very large and costly.

One of the most effective methods for trace gas measurement regarding sensitivity and selectivity is photoacoustic spectroscopy (PAS). The photoacoustic (PA) effect was discovered in 1880 by Alexander Graham Bell. The principle is based on the absorption of electromagnetic radiation by a medium of interest. The radiation energy is converted into heat. When using a pulsed radiation source, a thermal pressure wave is formed within the absorbing medium, which can then be sensed as sound by a microphone. The amplitude of the acoustic signal is directly proportional to the number of molecules in an absorbing gas which enables the determination of gas concentrations following proper calibration. However, due to the lack of appropriate instrumentation such as microphones, electronics and light sources, the PA effect was almost completely forgotten for more than half a century [

5]. Gradually, with progress on the field of light sources, came new applications and possibilities on gas sensing via PAS. The technical developments of recent years have revealed powerful LEDs for a wide range of wavelengths. These are highly compact, robust, efficient and inexpensive compared to lasers. Especially UV-LEDs fit the absorption spectrum of NO

well (see

Figure 1), making them the light source of choice for our approach. UV-LEDs have already been used for PAS of NO

by Santiago et al. in 2006, achieving a limit of detection (LOD) of 5 ppm (3

) [

6]. Five years later, Saarela et al. presented their LED setup with a LOD of 10 ppb with a signal to noise ratio (SNR) of one, though with limitations regarding long-term measurement due to heat-up of the cell by the used LED array [

7].

PA measurement is usually performed within a closed cell. The cavity can be used for resonant amplification. Various cell designs for usage with lasers have been proposed and investigated by Miklós and Hess [

5]. Due to the limited focusing and collimating capability of LEDs, however, in conventional cell designs the light hits the inner walls with high probability (outlined in

Figure 2a). There, it absorbs as well and generates unwanted noise (interfering signal offset), which results in a worse LOD. Lassen et al. [

10] followed the approach of using an integrating sphere with a high reflectance for signal enhancement and the attenuation of the background absorption. Their achieved LOD is 1.9 ppm with a SNR of one.

The main focus of this work is the reduction of the background signal by minimizing the light incidence on the inside walls of the PA cell. This is achieved by using a concept named T-cell. It is derived from a geometry that consists of an absorption chamber and a perpendicular resonance cylinder, where the standing wave pattern is formed (see

Figure 2b). The resonator has a pressure node at the joint to the absorption chamber and a pressure maximum, where the microphone is mounted. Up till now, T-cells have been used with lasers, e.g., by Baumann et al. 2005 [

11] and Liu et al. 2006 [

12], yet these cell designs are not suited for LEDs. We present a cell where the dimensions are defined in a way that a non-contact feedthrough of the LED beam is possible. Furthermore, they were iteratively optimized by finite elements method (FEM) simulations using ANSYS Workbench. A constructed prototype was fabricated from aluminum by rapid prototyping methods. The sensor was characterized by gas measurements. The present paper is an extended version of work published in Ref. [

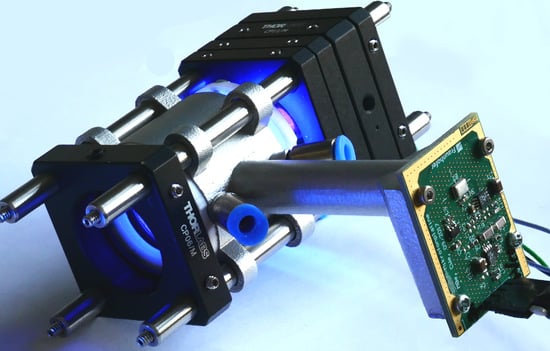

13].

3. Results and Discussion

Figure 5 shows the results of the frequency response measurement. The third harmonic is with 3.7 kHz close to the design target of 4 kHz. Compared to the modes found in simulation, the measured ones are lower due to the extended resonator length caused by the microphone mounting. Besides this shift, the other modes are also close to the predicted frequencies. The fifth mode, however, amplifies the signal less than expected.

The third harmonic gives the best signal amplification with a Q-factor of 12.4. Due to the high quality factor, the third harmonic was chosen as frequency range for the following gas measurements. Despite the fact that the PA effect scales inversely proportional with the modulation frequency we found that the first harmonic could hardly be excited, independent of the electrical high pass cutoff frequency.

Figure 6a shows the photoacoustic signal during the frequency sweeps for different concentrations of NO

. As expected, the resonance amplitude rises with increasing NO

concentration. Once a concentration step is established, the sweeps are almost congruent to each other. Because NO

was diluted in synthetic air, the contained oxygen (20% per 4.3 ppm NO

) caused a resonance frequency shift of up to 60 Hz. This value is consistent with the theoretical shift due to change in speed of sound of the gas matrix. Without NO

, the oxygen concentration had no influence on the signal amplitude (also shown in

Figure 6a). The maximum value of every sweep was evaluated within the data processing of the custom board.

Figure 6b shows these values plotted against the NO

setpoint. It can be observed that the relation is linear as expected. The sensitivity can be determined by the slope of the graph which is around 125 counts per ppm. From the standard deviation shown in

Figure 6b and the sensitivity, a noise equivalent concentration of 32 ppb (1

) is calculated. This results in a LOD at around 200 ppb (6

).

Figure 7 shows the processed data plotted against the time, together with the NO

concentration setpoint. Due to residual stray light, there is a zero gas offset of 370 counts which is normalized to 100%. The signal offset is equivalent to 2.88 ppm. This is significantly lower than the offset equivalent to 65.4 ppm, that was observed in an H-cell with the same setup as shown in

Figure A1. Due to the small offset, there is no observable drift in the zero signal during the measurement time of five hours. The data rate of the measurement was low (0.25 min

) due to the simple algorithm choosing only one data point per sweep. With an intelligent tracking algorithm, the data rate could be increased to 1–10 s

without any loss of resolution. Although there is photodissociation of NO

below 415 nm, the presented measurement does not seem to be affected by this dissociation, due to continuous gas flow [

7].

The data from the zero point stability measurement is evaluated in an Allan plot that is shown in

Figure 8. For one second of averaging time, the Allan deviation is around 10 counts which translates into 80 ppb of NO

. For longer averaging times of up to 1000 s, this value drops to 3 ppb. For longer intervals the Allan deviation rises again but stays below 10 ppb. The reason for this could be fluctuations in ambient temperature, atmospheric NO

or the resonance frequency.

4. Conclusions

We have shown a novel approach for highly sensitive NO detection using a photoacoustic sensor operating in the UV. This sensor combines for the first time the advantages of low-cost components (UV-LED, commercial MEMS microphone) with a T-shaped cell fabricated in rapid prototyping. The T-shaped cell enables a “non-contact” feedthrough of the divergent LED beam in the absorption cylinder, leading to a significant reduction of background signal and thus higher sensitivity. The PA cell was first simulated in ANSYS to find optimal geometries for absorption and resonance cell, and the spatial pressure amplitude and its gradient. After fabrication of the cell in aluminum and setup of the complete sensor system, this was characterized with NO concentrations ranging from 850 ppb to 4.3 ppm. From this measurement, a LOD of around 200 ppb (6 ) could be deduced. Furthermore, the results show no observable drift in the zero signal for at least five hours.

Our study shows the possibility of reliably measuring NO in concentrations well below 1 ppm using a compact photoacoustic setup (100 mm × 40 mm × 750 mm) with commercially available, low-cost components. This makes the sensor an alternative to the commonly used electrochemical cells for NO monitoring. Future work will comprise an advanced resonator design that might allow even higher resolution while enabling a further miniaturization of the sensor. Furthermore, we plan a more detailed study on the reproducibility and repeatability of the sensor system.