E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser †

Abstract

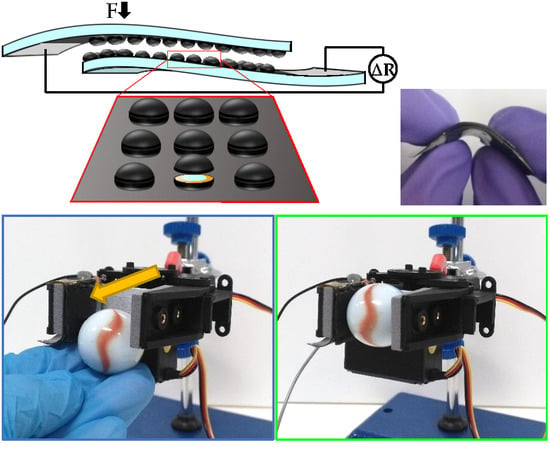

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Fabrication and Laser Engraving of h-PDMS Molds

2.3. Fabrication of E-Skin Sensors

2.4. Morphological Characterization of Micro-Structured s-PDMS Films

2.5. Electrical Characterization of Films and Sensors

3. Results and Discussion

3.1. Hard PDMS Molds Patterning

3.2. Characterization of Coated s-PDMS Micro-Structured Films

3.3. Electrical Characterization of E-Skin Piezoresistive Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hammock, M.L.; Chortos, A.; Tee, B.C.K.; Tok, J.B.H.; Bao, Z. 25th anniversary article: The evolution of electronic skin (E-Skin): A brief history, design considerations, and recent progress. Adv. Mater. 2013, 25, 5997–6038. [Google Scholar] [CrossRef] [PubMed]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–951. [Google Scholar] [CrossRef] [PubMed]

- Someya, T.; Sekitani, T.; Iba, S.; Kato, Y.; Kawaguchi, H.; Sakurai, T. A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl. Acad. Sci. USA 2004, 101, 9966–9970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, W.; Niu, X.; Zhao, R.; Pei, Q. Elastomeric transparent capacitive sensors based on an interpenetrating composite of silver nanowires and polyurethane. Appl. Phys. Lett. 2013, 102, 083303–083309. [Google Scholar] [CrossRef]

- Schwartz, G.; Tee, B.C.-K.; Mei, J.; Appleton, A.L.; Kim, D.H.; Wang, H.; Bao, Z. Flexible polymer transistors with high pressure sensitivity for application in electronic skin and health monitoring. Nat. Commun. 2013, 4, 1859–1867. [Google Scholar] [CrossRef]

- Yao, H.B.; Ge, J.; Wang, C.F.; Wang, X.; Hu, W.; Zheng, Z.J.; Ni, Y.; Yu, S.H. A flexible and highly pressure-sensitive graphene-polyurethane sponge based on fractured microstructure design. Adv. Mater. 2013, 25, 6692–6698. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Su, Y.; Joe, P.; Yona, R.; Liu, Y.; Kim, Y.-S.; Huang, Y.Y.; Damadoran, A.R.; Xia, J.; Martin, L.W.; et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat. Commun. 2014, 5, 4496–4506. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Ha, M.; Jung, Y.D.; Lim, H.; Kim, S.Y.; Ko, H. Giant Tunneling Piezoresistance of Composite Elastomers with Interlocked Microdome Arrays for Ultrasensitive and Multimodal Electronic Skins. ACS Nano 2014, 8, 4689–4697. [Google Scholar] [CrossRef]

- Pang, C.; Koo, J.H.; Nguyen, A.; Caves, J.M.; Kim, M.G.; Chortos, A.; Kim, K.; Wang, P.J.; Tok, J.B.H.; Bao, Z. Highly skin-conformal microhairy sensor for pulse signal amplification. Adv. Mater. 2015, 27, 634–640. [Google Scholar] [CrossRef]

- Park, H.; Jeong, Y.R.; Yun, J.; Hong, S.Y.; Jin, S.; Lee, S.-J.; Zi, G.; Ha, J.S. Stretchable Array of Highly Sensitive Pressure Sensors Consisting of Polyaniline Nanofibers and Au-Coated. ACS Nano 2015, 9, 9974–9985. [Google Scholar] [CrossRef]

- Kim, D.-I.; Trung, T.Q.; Hwang, B.-U.; Kim, J.-S.; Jeon, S.; Bae, J.; Park, J.-J.; Lee, N.-E. A Sensor Array Using Multi-functional Field-effect Transistors with Ultrahigh Sensitivity and Precision for Bio-monitoring. Sci. Rep. 2015, 5, 12705–12716. [Google Scholar] [CrossRef] [PubMed]

- Cai, F.; Yi, C.; Liu, S.; Wang, Y.; Liu, L.; Liu, X.; Xu, X.; Wang, L. Ultrasensitive, passive and wearable sensors for monitoring human muscle motion and physiological signals. Biosens. Bioelectron. 2016, 77, 907–913. [Google Scholar] [CrossRef]

- Shin, K.-Y.; Lee, J.S.; Jang, J. Highly sensitive, wearable and wireless pressure sensor using free-standing ZnO nanoneedle/PVDF hybrid thin film for heart rate monitoring. Nano Energy 2016, 22, 95–104. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Joe, P.; Tuzman, O.L.; Park, K.; Lee, K.J.; Shi, Y.; Huang, Y.; Rogers, J.A. Recent progress in flexible and stretchable piezoelectric devices for mechanical energy harvesting, sensing and actuation. Extrem. Mech. Lett. 2016, 9, 269–281. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S.; et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747–5758. [Google Scholar] [CrossRef] [PubMed]

- Gerratt, A.P.; Michaud, H.O.; Lacour, S.P. Elastomeric Electronic Skin for Prosthetic Tactile Sensation. Adv. Funct. Mater. 2015, 25, 2287–2295. [Google Scholar] [CrossRef]

- Rocha, R.P.; Lopes, P.A.; De Almeida, A.T.; Tavakoli, M.; Majudu, C. Fabrication and characterization of bending and pressure sensors for a soft prosthetic hand. J. Micromech. Microeng. 2018, 28, 034001–034011. [Google Scholar] [CrossRef]

- Pang, C.; Lee, G.-Y.; Kim, T.; Kim, S.M.; Kim, H.N.; Ahn, S.-H.; Suh, K.-Y. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795–801. [Google Scholar] [CrossRef]

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002–3010. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132–3140. [Google Scholar] [CrossRef]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef]

- Choong, C.-L.; Shim, M.-B.; Lee, B.-S.; Jeon, S.; Ko, D.-S.; Kang, T.-H.; Bae, J.; Lee, S.H.; Byun, K.-E.; Im, J.; et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef]

- Yin, X.; Vinod, T.P.; Jelinek, R. A flexible high-sensitivity piezoresistive sensor comprising a Au nanoribbon-coated polymer sponge. J. Mater. Chem. C 2015, 3, 9247–9252. [Google Scholar] [CrossRef] [Green Version]

- Chun, S.; Kim, Y.; Oh, H.-S.; Bae, G.; Park, W. A highly sensitive pressure sensor using a double-layered graphene structure for tactile sensing. Nanoscale 2015, 7, 11652–11659. [Google Scholar] [CrossRef]

- Bae, G.Y.; Pak, S.W.; Kim, D.; Lee, G.; Kim, D.H.; Chung, Y.; Cho, K. Linearly and Highly Pressure-Sensitive Electronic Skin Based on a Bioinspired Hierarchical Structural Array. Adv. Mater. 2016, 28, 5300–5306. [Google Scholar] [CrossRef]

- Huang, Z.; Gao, M.; Yan, Z.; Pan, T.; Khan, S.A.; Zhang, Y.; Zhang, H.; Lin, Y. Pyramid microstructure with single walled carbon nanotubes for flexible and transparent micro-pressure sensor with ultra-high sensitivity. Sens. Actuators A Phys. 2017, 266, 345–351. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.B.; Tee, B.C.-K.; Stoltenberg, R.M.; Chen, C.V.H.-H.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.-K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef]

- Zang, Y.; Zhang, F.; Huang, D.; Gao, X.; Di, C.; Zhu, D. Flexible suspended gate organic thin-film transistors for ultra-sensitive pressure detection. Nat. Commun. 2015, 6, 6269–6278. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633–1643. [Google Scholar] [CrossRef]

- Pi, Z.; Zhang, J.; Wen, C.; Zhang, Z.B.; Wu, D. Flexible piezoelectric nanogenerator made of poly(vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) thin film. Nano Energy 2014, 7, 33–41. [Google Scholar] [CrossRef]

- Fan, F.-R.; Lin, L.; Zhu, G.; Wu, W.; Zhang, R.; Wang, Z.L. Transparent Triboelectric Nanogenerators and Self-Powered Pressure Sensors based on Micropatterned Plastic Films. Nano Lett. 2012, 12, 3109–3114. [Google Scholar] [CrossRef]

- Lin, L.; Xie, Y.; Wang, S.; Wu, W.; Niu, S.; Wen, X.; Wang, Z.L. Triboelectric Active Sensor Array for Self-Powered Static and Dynamic Pressure Detection and Tactile Imaging. ACS Nano 2013, 7, 8266–8274. [Google Scholar] [CrossRef]

- Zhu, G.; Yang, W.Q.; Zhang, T.; Jing, Q.; Chen, J.; Zhou, Y.S.; Bai, P.; Wang, Z.L. Self-powered, ultrasensitive, flexible tactile sensors based on contact electrification. Nano Lett. 2014, 14, 3208–3213. [Google Scholar] [CrossRef]

- Seol, M.-L.; Woo, J.-H.; Lee, D.-I.; Im, H.; Hur, J.; Choi, Y.-K. Nature-Replicated Nano-in-Micro Structures for Triboelectric Energy Harvesting. Small 2014, 10, 3887–3894. [Google Scholar] [CrossRef]

- Kim, K.; Jung, M.; Kim, B.; Kim, J.; Shin, K.; Kwon, O.-S.; Jeon, S. Low-voltage, high-sensitivity and high-reliability bimodal sensor array with fully inkjet-printed flexible conducting electrode for low power consumption electronic skin. Nano Energy 2017, 41, 301–307. [Google Scholar] [CrossRef]

- Zhou, Y.; He, J.; Wang, H.; Qi, K.; Nan, N.; You, X.; Shao, W.; Wang, L.; Ding, B.; Cui, S. Highly sensitive, self-powered and wearable electronic skin based on pressure-sensitive nanofiber woven fabric sensor. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, J.; Cai, H.; Wu, Y.; Ding, H.; Pan, N.; Wang, X. Highly sensitive and skin-like pressure sensor based on asymmetric double-layered structures of reduced graphite oxide. Sens. Actuators B Chem. 2018, 255, 1262–1267. [Google Scholar] [CrossRef]

- Liu, W.; Liu, N.; Yue, Y.; Rao, J.; Luo, C.; Zhang, H.; Yang, C.; Su, J.; Liu, Z.; Gao, Y. A flexible and highly sensitive pressure sensor based on elastic carbon foam. J. Mater. Chem. C 2018, 6, 1451–1459. [Google Scholar] [CrossRef]

- Yu, G.; Hu, J.; Tan, J.; Gao, Y.; Lu, Y.; Xuan, F. A wearable pressure sensor based on ultra-violet/ozone microstructured carbon nanotube/polydimethylsiloxane arrays for electronic skins. Nanotechnology 2018, 29, 115502–115513. [Google Scholar] [CrossRef]

- Wang, L.; Jackman, J.A.; Tan, E.-L.; Park, J.H.; Potroz, M.G.; Hwang, E.T.; Cho, N.-J. High-performance, flexible electronic skin sensor incorporating natural microcapsule actuators. Nano Energy 2017, 36, 38–45. [Google Scholar] [CrossRef]

- Park, J.; Kim, M.; Lee, Y.; Lee, H.S.; Ko, H. Fingertip skin-inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli. Sci. Adv. 2015, 1, e1500661. [Google Scholar] [CrossRef]

- Kim, S.Y.; Park, S.; Park, H.W.; Park, D.H.; Jeong, Y.; Kim, D.H. Highly Sensitive and Multimodal All-Carbon Skin Sensors Capable of Simultaneously Detecting Tactile and Biological Stimuli. Adv. Mater. 2015, 27, 4178–4185. [Google Scholar] [CrossRef]

- Gui, Q.; He, Y.; Gao, N.; Tao, X.; Wang, Y. A Skin-Inspired Integrated Sensor for Synchronous Monitoring of Multiparameter Signals. Adv. Funct. Mater. 2017, 27, 1702050–1702058. [Google Scholar] [CrossRef]

- Dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. Piezoresistive E-Skin Sensors Produced with Laser Engraved Molds. Adv. Electron. Mater. 2018, 4, 1800182–1800192. [Google Scholar] [CrossRef]

- Dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. E-Skin Pressure Sensors Made by Laser Engraved PDMS Molds. Proceedings 2018, 2, 1039. [Google Scholar] [CrossRef]

- Huft, J.; Da Costa, D.J.; Walker, D.; Hansen, C.L. Three-dimensional large-scale microfluidic integration by laser ablation of interlayer connections. Lab Chip 2010, 10, 2358–2365. [Google Scholar] [CrossRef]

- Fogarty, B.A.; Heppert, K.E.; Cory, T.J.; Hulbutta, K.R.; Martin, R.S.; Lunte, S.M. Rapid fabrication of poly(dimethylsiloxane)-based microchip capillary electrophoresis devices using CO2 laser ablation. Analyst 2005, 130, 924–930. [Google Scholar] [CrossRef]

- Riahi, M. CO2 Laser and Micro-Fluidics. In CO2 Laser-Optimisation and Application; Dumitras, D.C., Ed.; InTech: London, UK, 2012; pp. 307–324. ISBN 978-953-51-0351-6. [Google Scholar]

- Ha, M.; Lim, S.; Park, J.; Um, D.-S.; Lee, Y.; Ko, H. Bioinspired Interlocked and Hierarchical Design of ZnO Nanowire Arrays for Static and Dynamic Pressure-Sensitive Electronic Skins. Adv. Funct. Mater. 2015, 25, 2841–2849. [Google Scholar] [CrossRef]

- Grzybowski, B.A.; Brittain, S.T.; Whitesides, G.M. Thermally actuated interferometric sensors based on the thermal expansion of transparent elastomeric media. Rev. Sci. Instrum. 1999, 70, 2031–2037. [Google Scholar] [CrossRef]

| Power = 7.5 W | ||||||||

|---|---|---|---|---|---|---|---|---|

| Laser Engraving Direction | Horizontal | Vertical | ||||||

| Theoretical Pitch (µm) | 150 | 150 | 200 | 200 | 150 | 150 | 200 | 200 |

| Theoretical Diameter (µm) | 100 | 200 | 100 | 200 | 100 | 200 | 100 | 200 |

| Theoretical Sum (µm) | 250 | 350 | 300 | 400 | 250 | 350 | 300 | 400 |

| Real Pitch (µm) | 0 | 23 | 43 | 37 | 63 | 63 | 103 | 95 |

| Real Diameter (µm) | 240 | 322 | 260 | 350 | 183 | 277 | 186 | 280 |

| Real Sum (µm) | 240 | 345 | 303 | 387 | 246 | 339 | 289 | 375 |

| Relative Difference | −4.0% | −1.3% | 0.9% | −3.3% | −1.4% | −3.0% | −3.7% | −6.3% |

| Without PMMA | With PMMA | ||||

|---|---|---|---|---|---|

| Theoretical Pitch (µm) | 150 | 200 | 150 | 200 | |

| Low Pressure (0 kPa–0.4 kPa) | Sensitivity (kPa−1) | −4.8 × 10−1 | −6.4 × 10−1 | −5.4 × 10−1 | −1.8 × 10−1 |

| High Pressure (1.2 kPa–100 kPa) | Sensitivity (kPa−1) | −5.8 × 10−3 | −5.8 × 10−3 | −2.3 × 10−3 | −6.4 × 10−3 |

| Reference | Transduction Mechanism | Micro-Structuration Process and Shape | Pressure Sensitivity and Range | Maximum Pressure Tested | Relaxation Time | Number of Pressure Cycles | TCR and Range |

|---|---|---|---|---|---|---|---|

| [5] | Capacity | - | 5 × 10−4 kPa−1 (<1 MPa) | 1 MPa | NA | NA | - |

| [6] | Capacity | Photolitography Pyramids | 8.4 kPa−1 (<8 kPa) 0.38 kPa−1 (>30 kPa) | ~60 kPa | 10 ms | 15,000 | - |

| [10] | Capacity | Photolitography Fibers | 0.58 kPa−1 (<0.5 kPa) | 10 kPa | 30 ms | 3000 | - |

| [29] | Capacity | - | 2.3 × 10−4 kPa-1 (<0.8 MPa) | 800 kPa | NA | NA | - |

| [44] | Capacity | - | (3.4–5) × 10−2 kPa−1 (<0.1 kPa) 5 × 10−4 kPa−1 (10 kPa–25 kPa) | 25 kPa | NA | 2000 | ~ 0.2%/°C (25–50 °C) |

| [34] | Triboelectricity | Photolitography Pyramids | 0.31 kPa−1 (<3 kPa) 1 × 10−2 kPa−1 (3 kPa–13 kPa) | 90 kPa | 5 ms | 30,000 | - |

| [9] | Piezoresistivity | Photolitography Domes | −15.1 kPa−1 (<0.5 kPa) | 59 kPa | 40 ms | 1000 | - |

| [26] | Piezoresistivity | Photolitography Domes | 14 kPa−1 (<5 kPa) 3.2 kPa-1 (5 kPa–10 kPa) | 12 kPa | 30 ms | 10,000 | - |

| [37] | Piezoresistivity | Photolitography Pyramids | 2.5 kPa−1 (<250 Pa) | 5 kPa | 20 ms | 100,000 | 0.32%/°C (40–43 °C) |

| [42] | Piezoresistivity | Using nylon as mold Cubic-like structures | 56.36 kPa−1 (<1 kPa) 2.51 kPa−1 (1 kPa–10 kPa) | 10 kPa | 300 ms | 25,000 | - |

| [43] | Piezoresistivity | Photolitography Domes | NA | 49.5 kPa | NA | 5000 | 2.93%/°C (20–40 °C) |

| [45] | Piezoresistivity | Stretching Wrinfles | NA | NA | NA | 300 | 2.38%/°C (30–65 °C) |

| This work | Piezoresistivity | Laser engraving Domes | −(1.8–6.4) × 10−1 kPa−1 (<400 Pa) −(2.3–6.4) × 10−3 kPa−1 (1.2 kPa–100 kPa) | 100 kPa | (28 ± 7) ms | 27,500 | 8.3%/°C (25–45 °C) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Farinha, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser. Sensors 2019, 19, 899. https://doi.org/10.3390/s19040899

dos Santos A, Pinela N, Alves P, Santos R, Farinha R, Fortunato E, Martins R, Águas H, Igreja R. E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser. Sensors. 2019; 19(4):899. https://doi.org/10.3390/s19040899

Chicago/Turabian Styledos Santos, Andreia, Nuno Pinela, Pedro Alves, Rodrigo Santos, Ricardo Farinha, Elvira Fortunato, Rodrigo Martins, Hugo Águas, and Rui Igreja. 2019. "E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser" Sensors 19, no. 4: 899. https://doi.org/10.3390/s19040899

APA Styledos Santos, A., Pinela, N., Alves, P., Santos, R., Farinha, R., Fortunato, E., Martins, R., Águas, H., & Igreja, R. (2019). E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser. Sensors, 19(4), 899. https://doi.org/10.3390/s19040899