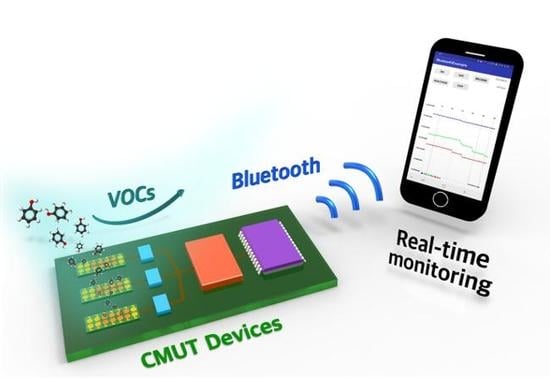

A Capacitive Micromachined Ultrasonic Transducer-Based Resonant Sensor Array for Portable Volatile Organic Compound Detection with Wireless Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design and Fabrication of CMUT Sensors

2.2. Chemically Sensitive Layers

2.3. Design and Implementation of Wireless, Portable Sensor Platform

2.4. Experimental Setup for Detection of VOCs

3. Results and Discussion

3.1. Characterization of CMUT Sensors

3.2. Chemical Response of CMUT Sensors to VOCs

3.3. Portable CMUT Chemical Sensor with Wireless Transmission

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cho, S.-Y.; Yoo, H.-W.; Kim, J.Y.; Jung, W.-B.; Jin, M.L.; Kim, J.-S.; Jeon, H.-J.; Jung, H.-T. High-resolution p-type metal oxide semiconductor nanowire array as an ultrasensitive sensor for volatile organic compounds. Nano Lett. 2016, 16, 4508–4515. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Jang, M.; Suslick, K.S. Preoxidation for colorimetric sensor array detection of VOCs. J. Am. Chem. Soc. 2011, 133, 16786–16789. [Google Scholar] [CrossRef] [PubMed]

- Mahapatra, N.; Ben-Cohen, A.; Vaknin, Y.; Henning, A.; Hayon, J.; Shimanovich, K.; Greenspan, H.; Rosenwaks, Y. Electrostatic selectivity of volatile organic compounds using electrostatically formed nanowire sensor. ACS Sens. 2018, 3, 709–715. [Google Scholar] [CrossRef] [PubMed]

- Stavila, V.; Schneider, C.; Mowry, C.; Zeitler, T.R.; Greathouse, J.A.; Robinson, A.L.; Denning, J.M.; Volponi, J.; Leong, K.; Quan, W.; et al. Thin film growth of nbo MOFs and their integration with electroacoustic devices. Adv. Funct. Mater. 2016, 26, 1699–1707. [Google Scholar] [CrossRef]

- Battiston, F.M.; Ramseyer, J.-P.; Lang, H.P.; Baller, M.K.; Gerber, Ch.; Gimzewski, J.K.; Meyer, E.; Guntherodt, H.-J. A chemical sensor based on a microfabricated cantilever array with simultaneous resonance-frequency and bending readout. Sens. Actuators B 2001, 77, 122–131. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, K.K.; Kupnik, M.; Oralkan, Ö.; Khuri-Yakub, B.T. Chemical vapor detection using a capacitive micromachined ultrasonic transducer. Anal. Chem. 2011, 83, 9314–9320. [Google Scholar]

- Grate, J.W. Acoustic wave microsensor arrays for vapor sensing. Chem. Rev. 2000, 100, 2627–2648. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Park, K.K.; Kupnik, M.; Khuri-Yakub, B.T. Functionalization layers for CO2 sensing using capacitive micromachined ultrasonic transducers. Sens. Actuators B Chem. 2012, 174, 87–93. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, K.K.; Kupnik, M.; Melosh, N.A.; Khuri-Yakub, B.T. Mesoporous thin-film on highly-sensitive resonant chemical sensor for relative humidity and CO2 detection. Anal. Chem. 2012, 84, 3063–3066. [Google Scholar]

- Wang, Z.; Hou, C.; De, Q.; Gu, F.; Han, D. One-step synthesis of co-doped In2O3 nanorods for high response of formaldehyde sensor at low temperature. ACS Sens. 2018, 3, 468–475. [Google Scholar] [CrossRef] [PubMed]

- Steinhauer, S.; Chapelle, A.; Menini, P.; Sowwan, M. Local CuO nanowire growth on microhotplates: In situ electrical measurements and gas sensing application. ACS Sens. 2016, 1, 503–507. [Google Scholar] [CrossRef]

- Kumar, R.; Geol, N.; Kumar, M. UV-activated MoS2 based fast and reversible NO2 sensor at room temperature. ACS Sens. 2017, 2, 1744–1752. [Google Scholar] [CrossRef] [PubMed]

- Jalal, A.H.; Alam, F.; Roychoudhury, S.; Umasankar, Y.; Pala, N.; Bhansali, S. Prospects and challenges of volatile organic compound sensors in human healthcare. ACS Sens. 2018, 3, 1246–1263. [Google Scholar] [CrossRef] [PubMed]

- Svechkarev, D.; Sadykov, M.R.; Bayles, K.W.; Mohs, A.M. Ratiometric fluorescent sensor array as a versatile tool for bacterial pathogen identification and analysis. ACS Sens. 2018, 3, 700–708. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Park, K.K.; Oralkan, Ö.; Kupnik, M.; Khuri-Yakub, B.T. A multichannel oscillator for a resonant chemical sensor system. IEEE Trans. Ind. Electron. 2014, 61, 5632–5640. [Google Scholar] [CrossRef]

- Penza, M.; Cassano, G.; Aversa, P.; Antolini, F.; Cusano, A.; Consales, M.; Giordano, M.; Nicolais, L. Carbon nanotubes-coated multi-transducing sensors for VOCs detection. Sens. Actuators B 2005, 111–112, 171–180. [Google Scholar] [CrossRef]

- Park, S.; Yoon, I.; Lee, S.; Kim, H.; Seo, J.-W.; Chung, Y.; Unger, A.; Kupnik, M.; Lee, H.J. CMUT-based resonant gas sensor array for VOC detection with low operating voltage. Sens. Actuators B 2018, 273, 1556–1563. [Google Scholar] [CrossRef]

- Ju, S.; Lee, K.-Y.; Min, S.-J.; Yoo, Y.K.; Hwang, K.S.; Kim, S.K.; Yi, H. Single-carbon discrimination by selected peptides for individual detection of volatile organic compounds. Sci. Rep. 2015, 5, 9196. [Google Scholar] [CrossRef] [PubMed]

- Seok, C.; Mahmud, M.M.; Kumar, M.; Adelegan, O.J.; Yamaner, F.Y.; Oralkan, O. A low-power wireless multichannel gas sensing system based on a capacitive micromachined ultrasonic transducer (CMUT) array. IEEE Internet Things J. 2019, 6, 831–843. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, I.; Eom, G.; Lee, S.; Kim, B.K.; Kim, S.K.; Lee, H.J. A Capacitive Micromachined Ultrasonic Transducer-Based Resonant Sensor Array for Portable Volatile Organic Compound Detection with Wireless Systems. Sensors 2019, 19, 1401. https://doi.org/10.3390/s19061401

Yoon I, Eom G, Lee S, Kim BK, Kim SK, Lee HJ. A Capacitive Micromachined Ultrasonic Transducer-Based Resonant Sensor Array for Portable Volatile Organic Compound Detection with Wireless Systems. Sensors. 2019; 19(6):1401. https://doi.org/10.3390/s19061401

Chicago/Turabian StyleYoon, Inug, Gayoung Eom, Sungwoo Lee, Bo Kyeong Kim, Sang Kyung Kim, and Hyunjoo J. Lee. 2019. "A Capacitive Micromachined Ultrasonic Transducer-Based Resonant Sensor Array for Portable Volatile Organic Compound Detection with Wireless Systems" Sensors 19, no. 6: 1401. https://doi.org/10.3390/s19061401

APA StyleYoon, I., Eom, G., Lee, S., Kim, B. K., Kim, S. K., & Lee, H. J. (2019). A Capacitive Micromachined Ultrasonic Transducer-Based Resonant Sensor Array for Portable Volatile Organic Compound Detection with Wireless Systems. Sensors, 19(6), 1401. https://doi.org/10.3390/s19061401