1. Introduction

Combining multi-material fused-filament fabrication (FFF) and functional composite materials enables the fabrication of an object with embedded functional elements (sensorics [

1], actuation [

2], heating [

3], and energy storage [

4], etc.) in a single-step printing process.

FFF 3D printing is based on the deposition of the melted filament feedstock onto the build surface. Sequentially deposited traces of melted material in horizontal layers form the fused printed structure. Filament FFF materials must exhibit a melting point in the working temperature range of the FFF 3D printer and a suitable viscosity so the material can be melted and extruded through the nozzle. Filaments can be manufactured with the addition of various filler particles with functional properties that enable the fabrication of functional structures.

Conductivity is achieved with various conductive fillers, based on conductive carbon nanomaterials and metals that are mixed with a thermoplastic matrix to ensure the printability of the composite material [

5]. The most conductive filaments found were based on metal fillers (e.g., two-dimensional silver powder [

6], nickel and tin alloy [

7], and silver-coated copper nanowires [

8]) with an approximately three-orders-of-magnitude worse conductivity than bulk copper. More common are filaments based on carbon fillers (e.g., carbon black (CB) [

9], graphene [

10], and carbon nanotubes [

11]) that exhibit an additional three orders-of-magnitude worse conductivity than composites with metal fillers.

Polymer nanocomposites are used for sensor fabrication in various applications [

12], including biomedical applications [

13] and interactive robotics, like electronic skin [

14,

15]. The piezo-resistive characteristic of conductive FFF materials is often exploited for strain sensing. Maurizi et al. [

1] printed a functional small-strain-rate sensor in a dual extrusion process. Kim et al. [

16] and Christ et al. [

17] researched highly flexible high-strain-rate sensors that can be used in wearable electronics. A fully printed functional accelerometer was presented by Liu et al. [

18]. Force-sensing potential was also demonstrated with a multi-axial force sensor, fabricated by Kim et al. [

19]. Kwok et al. [

9] researched a conductive composite material based on carbon black (CB) and performed electrical, thermal and UV stress tests, before fabricating a functional temperature sensor. Clower et al. [

20] printed a Sierpinski tetrahedron-based antenna, where the advantages of additive manufacturing (AM) were utilized for the fabrication of a geometrically complex structure capable of wide-band multi-frequency wireless-signal transmission. In comparison to 3D-printed structures with embedded metal wires [

21] and electronic chips [

22,

23], single-process 3D-printed sensors have the potential to fabricate multi-material functional structures with a structure/property relationship without the need for additional technology or intervention during the fabrication process.

Process parameters have been shown to have an influence on the conductivity of a printed structure. For the Electrifi material [

24] used in this work, the manufacturer specifies the right process parameters to attain a higher conductivity of the printed structure, or in other words, to minimize the degradation of the conductive network in the material during the extrusion process. Watschke et al. [

3] researched the effects of raster angle, print speed, flow rate, and extrusion temperature on the conductivity and heat-radiation capacity for four different filaments, including the Electrifi. Hampel et al. [

25] identified the optimal process parameters (layer height, printing speed, nozzle temperature, and cooling) and derived a conductive model for the electrical circuit’s fabrication. Zhang et al. [

26] characterized a CB/ABS composite by measuring the resistivity and its anisotropy for filament, fiber, and cubic samples.

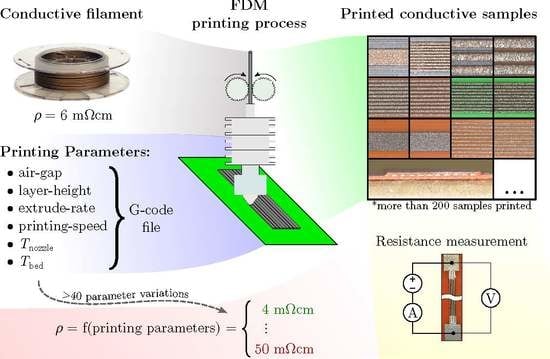

The main focus of this study are the optimal process parameters for highly conductive printed elements (conductors) for the transmission of sensor signals. Although the study is based on previous research [

3,

25,

26], the process parameters are studied for a complete printability value range with high discretization. Five samples were printed for every parameter variation, so the repeatability of the printing process was ensured and the effect of individual printing parameters confidently deduced. The experimental results for six parameters with a combined 41 value variations enabled an insight into the underlying mechanisms, essential for the optimization of the FFF process for a highly conductive structure’s fabrication. Additional experiments with embedded conducting traces were performed to study the effect of the printing of an insulating material on the resistivity. As a whole, this work provides the practical information about the effect the printing process has on the conductivity of the printed structure. It provides the explanation of underlying mechanisms and how the degrading effects can be minimized to attain improved repeatability of the electrical properties and higher electrical conductivity of the printed conductors.

The paper is organized as follows: the researched process parameters, conductive sample fabrication and resistivity measurements are presented in

Section 2, followed by the presentation and discussion of the results (

Section 3) and conclusions of the study (

Section 5).

3. Results

The results are presented as the resistivity (i.e., the inverse of the conductivity) plotted against the values of each defined parameter (see

Table 1). In the following figures (

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17 and

Figure 18) the point represents the average of five samples printed with identical parameters, while the error bars represent the range from the lowest to the highest measured value. The results in statistical form are also presented in

Table 3 with included mean resistivity and standard deviation of resistivity measurement for every parameter variation.

The results from the layer-height variation (

Figure 11) showed 0.15 to 0.2 mm to be the optimum layer height. A greater layer height than the default 0.2 mm increased the resistivity by less than 5%, and a lesser layer height increased the resistivity by 20%. The increased resistivity for a lower layer height could be due to the decreased printing quality and increased surface-to-volume ratio of the sample.

The increased deformation of the extruding material in conjunction with the low storage modulus and high viscosity of the Electrifi material [

24] contributed to a reduced surface quality of the printed traces. An uneven and cracked surface reduced the effective conducting section area of the sample and increased the resistivity.

Electrifi and other metal/polymer nanocomposites suffer from oxidation of the filler particles, which is accelerated at high temperatures of the FFF process [

3,

7,

8]. Oxidation of the exposed material increases the resistance of the filler particles and can break the conducting connections, so increasing the resistivity of the composite system. Reducing the layer height for a constant trace width increases the surface/volume ratio of the trace. That means more of the material is exposed to the atmosphere and the external nozzle surface, and the negative effect of thermo-oxidation is increased.

The trace spacing is one of the parameters that showed significant potential for resistivity reduction. Increasing the gap between the traces substantially reduced the resistivity (see

Figure 12), reaching the lowest resistivity when the air gap between the traces ensured no contact between the already-deposited traces and the moving nozzle occurred during the printing (see

Figure 2).

In conventional FFF printed structures, the distance between the individual traces is set so the porosity is minimal, since this negatively effects the mechanical properties of the printed structure. Tightly deposited traces enable increased diffusion of the polymer chains in the contact region, which increases the weld strength and consequently the strength of the whole structure.

In terms of the electrical properties of the Electifi material, contact between the individual traces reduced the electrical performance. The degrading effect of the thermal and mechanical contacts between the deposited and extruding material (and the nozzle) can be attributed to the increased cooling time of the material and the mechanical deformations of the deposited traces. An increased cooling time translated into a longer time in the temperature range of accelerated oxidation. In addition to the increased oxidation, the deposited traces experienced secondary deformation as the extruding material heated and deformed the solidified traces. This deformation could break the conducting connections in the material and increase the resistance of the printed structure. In addition, if the parameter was set too low, the tightly packed extruding material could cause material buildup on the nozzle surface, reducing the surface quality and the conducting section area and ultimately increasing the resistance of the printed conductor.

When the trace spacing was increased over 0.55 mm the contact between the nozzle or extruding material and the deposited material was prevented, as can be observed in

Figure 2b). This produced the lowest resistivity for this sample group, at

cm (see

Table 3).

The results showed that in terms of material consumption, the most effective conductor was printed with a trace spacing wide enough to eliminate any contact with the deposited material. In tightly packed, multi-material structures with embedded conductors, a wide trace spacing and an increased volume consumption might not be the best solution. With the experimentally determined effect of the trace spacing, the printing process can be optimized for the resistivity and conductor volume requirements.

Printing-speed variations in the investigated range only contributed 5% to the resistivity deviation from the nominal filament resistivity. The results in

Figure 13 and

Table 3 show a slight increase in the measurement scatter with a printing speed faster than 20 mm/s.

The Electrifi material, because of its high filler content, exhibited a higher viscosity than the typical FFF polymers like PLA and ABS. The high viscosity and low storage modulus were more evident at high printing speeds, when the material extrusion and adhesion to the print surface became unstable. Lower stability of the process increased the scattering of the material properties, including the resistivity, which can be observed in

Figure 13 and in

Table 3.

In

Figure 3 the effect of printing speed on the air gap between the traces can be observed. The effect of trace spacing (air gap) on the resistivity was determined to be significant (see

Figure 12), while the change in air gap with printing-speed variation was not evident. The effect of the trace spacing parameters was in the thermal contact between the already-deposited material and the extruding material and the nozzle. At various printing speeds the trace width and consequently the air gap between the traces changed, but no thermal contact occurred. For that reason, a change in the air gap (trace spacing) did not have an effect on the resistivity of the samples printed at various printing speeds.

The results of the extrusion-rate variation showed that a lower extrusion rate lowered the resistivity (see

Figure 14 and

Table 3).

The cause for this might be the viscous flow conditions in the nozzle. Increasing the extrusion rate required a higher filament-feeding force, which increased the pressure and shear rate in the nozzle narrowing. Higher shear rates are known to break apart the clusters of the filler particles in the nanowire and nanotube polymer composites [

34]. Breaking the conducting network increases the resistivity on the macro scale. In addition, a fast extrusion rate deforms the extruding trace with material overflow, which can break apart the conducting nanoparticle clusters and increase the resistivity.

The effect of nozzle temperature on the resistivity was expected. The manufacturer specified that the optimal range for the extrusion of an Electrifi filament was between 130 and 160

[

24]. This was confirmed by our experiment and the optimal temperature of 145

for our setup was determined (see

Figure 15 and

Table 3).

The results showed, that the thermo-oxidation of copper nanowires in the Electrifi material was most pronounced at nozzle temperatures over 160 . At nozzle temperatures of 180 and 200 the resistivity was 5- and 12-times higher, respectively. In contrast to the effect of oxidation, a lower nozzle temperature also increased the resistivity (∼80% increase at ). The lower temperature of the polymer composite melt in the extruder caused a higher viscosity. The higher viscosity of the flowing polymer at a constant volumetric flow rate increased the shear stress in the nozzle. The shear stress damaged the microstructure (breaking the conductive nanowire clusters and the individual nanowires) of the composite system. The optimal nozzle temperature was, therefore, a compromise between the desired viscosity of the polymer melt and a minimized time in the high-temperature range of increased oxidation.

The results of print-bed temperature variation showed a range from 50 to 90

to be avoided (see

Figure 16). At 60

, which is the melting point of the Electrifi composite [

24], the resistivity increased by 100%. At temperatures over 80

, the resistivity dropped back to the initial values, while the measurement scatter remained high (better observable in

Table 3).

The results present an insight into the interplay of multiple mechanisms of degradation and formation for the conductive network in the polymer matrix. The effect of these mechanisms was dependent on the temperature of the material.

At print-bed temperatures around 60 the degrading effect on the conductivity was evident. With an increased cooling time for the extruding material, thermo-oxidation was more pronounced and the samples exhibit an increased resistivity. With an increased print-bed temperature, the negative effect of the thermo-oxidation was increased. Contrary to this notion, the negative effect of oxidation was reversed at . Therefore, a previously unnoticed mechanism of conductive-network formation must have been at play in this temperature range.

A study of the conductive network’s formation in polymer nanocomposites has shown that the formation of the conductive network is possible when the matrix material is in a liquid phase and nanoparticles can diffuse between the polymer chains. Nanoparticles and interparticle attractive forces can form new conducting pathways, decreasing the resistivity on the macro-scale [

34].

In practical terms the results of print-bed temperature show that when the extruded material was kept completely melted for the time of printing, copper nanowires (and clusters of nanowires) in the polymer melt agglomerated and formed secondary clusters, which decreased the resistivity of the printed structure.

Samples for the print-bed temperature experiment were printed without an air gap (see

Table 2 and

Figure 6). The results of trace spacing (air gap) showed that the contact between the deposited traces increased the resistivity (see

Figure 12), which was confirmed with the samples for print-bed temperature at 30 and 40

. The results showed that the negative effect of a low trace spacing could be reversed at print-bed temperatures of 100 and 110

.

To confirm that the resistivity reduction is possible after the extrusion and that the conductive network can form new connections, an additional experiment was performed. Printed samples were kept on the print surface after the printing and the temperature of the heat bed was increased from 40

(during printing) to 110

(after printing). During the melting phase, the temperature of the samples was measured to be around 105

(∼5

drop because of convection with the ambient air). The time of exposure was set to 1, 5 and 15 minutes. As a control, two sample boards were printed: one with active cooling during extrusion and one without. The resistivity measurement results are shown in

Figure 17 and in

Table 3.

It was evident that an optimal time of exposure existed as the mechanisms of conductive network formation through nanoparticle motion and thermo-oxidation affected the conductive properties of the material.

No active cooling during the printing resulted in a higher resistivity, as was expected. Active cooling without the melting phase after printing resulted in samples with the expected nominal resistivity of cm. If the samples were subjected to the melting phase after the printing the resistivity decreased at 1 and 5 min and increased at 15 min of exposure. One of the samples exposed to 5 min melting phase exhibited the lowest resistivity achieved in this study, i.e., cm.

The results of the sample heating after printing showed that the network formation had a superior effect on the resistivity for 5 min. After 5 min the conductive network formation slowed and oxidation becomes the influencing factor in conductive-network degradation, resulting in a substantially increased resistivity at 15 min. To further determine the material’s optimal time period in the melted state, additional experiments with varying print-bed temperatures and a higher discretization of the heating time period should be performed.

Figure 18 shows the results of embedding the conductive filaments. It was found that the insulating traces, printed in between and over the conducting traces, increased the resistivity by approximately 70%. The resistivity of the embedded traces increased because of the thermal diffusion between the extruding PLA and the deposited Electifi traces. The extruding PLA (

= 200–215

) heated the Electrifi traces and accelerated the oxidation of the copper filler. In addition, the heated traces deformed under the increased temperatures and loads of the extruding material. The deformation of the matrix polymer broke apart some of the connected clusters of conducting filler, consequently increasing the resistivity of the trace.

4. Discussion

The results showed an interplay of the multiple influential mechanisms of degradation and formation of the conductive network in the material. Thermo-oxidation was shown to be the most degrading for the conductive properties of the Electrifi material. Although the oxidative degradation is most prominent at nozzle temperatures over 160 , its effect is also noticeable at lower nozzle temperatures, when the print-bed temperature is increased and the traces experience secondary thermal contact with the extruding material or the nozzle. Therefore, the oxidative degradation of the electrical performance can be minimized with optimal printing temperatures, but also with active cooling of the extruding material and reduced thermal contact between the deposited and extruding material (large trace spacing). The trace-spacing adjustments can lower the resistivity by an additional 20%.

Another degradation mechanism was most noticeable with the extrusion rate variation. The extent of the damage of the established conducting network in the filament is also dependent on the pressure and shear rate in the nozzle narrowing [

34]. Shear degradation of the conductive network can be minimized with low printing speeds and extrusion rates, which can conversely increase the time of the high temperature exposure and consequent oxidation. The material flow rate (as a function of trace dimensions, printing speed, and extrusion rate) must therefore be experimentally determined as a compromise between the oxidative and shear degradation of the conductive network. The results showed that when printing at the optimum nozzle temperature of 145

and at a low extrusion rate, the printing speed can contribute an additional 10% to the resistivity reduction. The shear stress and temperature of the material in the extruder is dependent on the internal shape, surface and material of the extruder and the nozzle [

27,

35]. Therefore, the optimum parameters can deviate for different FFF printers and nozzle configurations.

Another mechanism was discovered with the variation of the print-bed temperature. The diffusion of nanoparticles and nanoparticle clusters in the polymer melt can be utilized for a decrease of the resistivity after the printing process, without technological modification or manual intervention. An additional experiment showed that this mechanism can have a contribution of ∼20% resistivity reduction to already optimally printed samples, reaching a resistivity of

cm, which is 40% lower that the filament resistivity specified by the manufacturer [

24]. In the case of thin conductors in close proximity to the print surface, the heat bed can be utilized for the melt phase after the printing process. Additionally, the printed conductors have to be supported to prevent the deformation of the melted material. The necessary support and the problem of heating of the embedded conductors are the main limitations in a resistivity decrease for the melting phase after the printing.

Although layer height, trace spacing, extrusion rate, printing speed, nozzle temperature, and print- bed temperature have a coupled effect on the discovered conductivity degradation/formation mechanisms, an optimal printing strategy can be deduced. Primarily, the printability of the material in a specific parameter range has to be ensured. As multiple researchers have already found that oxidation is the main factor in a resistivity increase in metal/polymer nanocomposites (excluding noble metals) [

3,

7,

8], it has to be minimized to retain the conductive properties of the filament material. Since high temperatures accelerate the oxidation process [

36], low nozzle temperatures and increased cooling of the extruding material can reduce the filler oxidation. Further, a low printing speed and extrusion rate reduce the shear rate in the nozzle narrowing and reduce the damage of the established conductive network during the extrusion. Furthermore, resistivity can be reduced with the melting of the conductive material after the printing process (if this is technologically possible) enabling the formation of new conducting pathways. The optimum time in the melted state has to be determined with preliminary tests, as the effect of network formation and oxidation are dependent on the conductive material (filler and polymer matrix properties), the ambient conditions and the shape of the printed structure.

The process parameters have a coupled effect on the flow (shear), thermal, and phase state of the composite system. To advance our knowledge of influential mechanisms, the effects of the process parameters have to be decoupled. Shear degradation of the filler nanoparticles with a high aspect ratio (wires, tubes, rods) can be studied in conjunction with models for polymer melt flow in the extruder [

27,

35] to decouple the effect of nozzle temperature (influencing the viscosity) and material flow rate (dependent on trace dimensions, extrusion rate, and printing speed) on the shear stress in the extruding material.

The oxidation of copper nanowires and other metal nanoparticles was already thoroughly studied [

36,

37] and practical solutions exist, mostly in the form of coatings with ligand molecules [

38] and inert metals [

8].

The promise of conductive-network formation was already discussed in research literature [

34]. The mechanism is driven by the thermal and shear state of the polymer melt. Finding the optimal thermal state for increased nanoparticle diffusion and secondary agglomeration after the extrusion process can be determined for a specific material with a thermal model of the conducting structure in conjunction with resistivity measurements.