Development of an MFL Coil Sensor for Testing Pipes in Extreme Temperature Conditions

Abstract

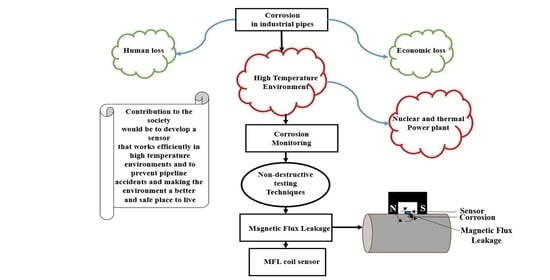

:1. Introduction

2. Principle of MFL Testing

3. Permanent Magnets and Magnetic Sensors at High Temperature

4. Design of Coil Sensor

5. Methodology and Measurement Setup for High Temperature Testing

5.1. Finite Element Analysis

5.2. Experimental Set Up

5.3. Coil Impedance

5.4. Magnitude of Magnetic Flux Density

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Poullikkas, A. Economic analysis of power generation from parabolic trough solar thermal plants for the Mediterranean region—A case study for the island of Cyprus. Renew. Sustain. Energy Rev. 2009, 13, 2474–2484. [Google Scholar] [CrossRef]

- Papaelias, M.; Cheng, L.; Kogia, M.; Mohimi, A.; Kappatos, V.; Selcuk, C.; Constantinou, L.; Gómez Muñoz, C.Q.; Garcia Marquez, F.P.; Gan, T.H. Inspection and structural health monitoring techniques for concentrated solar power plants. Renew. Energy 2015, 85, 1178–1191. [Google Scholar] [CrossRef]

- Scrubbs, T. The role of NDE in the life management of steam turbine rotors. Insight 2004, 46, 529–532. [Google Scholar]

- Guillot, S.; Faika, A.; Rakhmatullina, A.; Lambert, J.; Verona, E.; Echegut, P.; Bessadaa, C.; Calvet, N.; Py, X. Corrosion effects between molten salts and thermal storage material for concentrated solar power plants. Appl. Energy. 2012, 94, 174–181. [Google Scholar] [CrossRef]

- Kogia, M. High Temperature Electro-Magnetic Acoustic Transducer for Guided Wave Testing. Ph.D. Thesis, Brunel University of London, London, UK, 2017. [Google Scholar]

- Posteraro, K. Thwart Corrosion under Industrial Insulation. Chem. Eng. Prog. 1999, 95, 43–47. [Google Scholar]

- De Vogelaere, F. Corrosion under insulation. Process. Saf. Prog. 2009, 28, 30–35. [Google Scholar] [CrossRef]

- Kumar, M.S.; Sujata, M.; Venkataswamy, M.A.; Bhaumik, S.K. Failure analysis of a stainless steel pipeline. Eng. Fail. Anal. 2008, 15, 497–504. [Google Scholar] [CrossRef]

- Jen, K.C.; Legoux, J.G.; Parent, L. Experimental evaluation of clad metallic buffer rods for high temperature ultrasonic measurements. NDT E Int. 2000, 33, 145–153. [Google Scholar] [CrossRef]

- Cegla, B.F.; Davies, O.J. Ultrasonic crack monitoring at high temperatures using SH waves, Review of Progress in Quantitative Non-destructive Evaluation. In AIP Conference Proceedings; American Institute of Physics: University Park, MD, USA, 2010; pp. 980–987. [Google Scholar]

- Tittman, B.; Parks, D.; Zhang, O. High temperature piezo electrics—A comparison. In Proceedings of the 13th International Symposium on Non-Destructive Characterization of Materials (NDCM-XIII), Le Mans, France, 20–24 May 2013. [Google Scholar]

- Beattie, G. Acoustic emission principles and instrumentation. J. Acoust. Emiss. 1983, 2, 95–128. [Google Scholar]

- Nair, A.; Cai, S.C. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Runow, P. The use of acoustic emission methods as aids to the structural integrity assessment of nuclear power plants. Int. J. Press. Vessel. Pip. 1985, 21, 59–69. [Google Scholar] [CrossRef]

- Bently, P.G. A review of acoustic emission for pressurized water reactor applications. NDT Int. 1981, 14, 329–335. [Google Scholar] [CrossRef]

- Scruby, C.; Wadley, H. An assessment of acoustic emission for nuclear pressure vessel monitoring. Prog. Nucl. Energy 1982, 11, 275–297. [Google Scholar] [CrossRef]

- Steel, A.J.; Reuben, L.R. Recent developments in monitoring of engines using acoustic emission. J. Strain Anal. Eng. Des. 2005, 40, 45–57. [Google Scholar] [CrossRef]

- Hensman, J.; Mills, R.; Pierce, S.G.; Worden, K.; Eaton, M. Locating acoustic emission sources in complex structures using Gaussian processes. Mech. Syst. Signal Process. 2010, 24, 211–223. [Google Scholar] [CrossRef]

- Johnson, J.; Kim, K.; Zhang, S.; Wu, D.; Jiang, X. High temperature acoustic emission sensing tests using an Yttrium calcium oxyborate sensor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 805–814. [Google Scholar] [CrossRef] [PubMed]

- Hou, R.; Hutson, D.; Kirk, J.K.; Fu, Q.Y. AIN thin film transducers for high temperature non-destructive testing applications. J. Appl. Phys. 2012, 111, 074510. [Google Scholar] [CrossRef]

- Vetterlein, J.; Klümper-Westkamp, H.; Hirsch, T.; Mayr, P. Eddy current testing at high temperatures for controlling heat treatment processes. In Proceedings of the International Symposium of Non Destructive Testing in Civil Engineering (NDT-CE 2003), Berlin, Germany, 16–19 September 2003. [Google Scholar]

- Klümper-Westkamp, H.; Zoch, H.W.; Reimche, W.; Bach, W.F. High temperature resistant eddy current sensor for “in situ” monitoring the material microstructure development of steel alloys during heat treatment—Bainite sensor. Procedia Eng. 2011, 25, 1605–1608. [Google Scholar] [CrossRef] [Green Version]

- Emerson Process Management Reliability Solutions, Knoxville, TN, USA. Available online: www.emersonprocess.com/csi (accessed on 4 September 2016).

- Omni Instruments Ltd.; Dundee, UK. Available online: www.omniistruments.co.uk/ (accessed on 4 September 2016).

- Urayama, R.; Uchimoto, T.; Takagi, T. Application of EMAT/EC dual probe to monitoring of wall thinning in high temperature environment. Int. J. Appl. Electromagn. Mech. 2010, 33, 1317–1327. [Google Scholar] [CrossRef]

- Coramik, M.; Ege, Y. Discontinuity inspection in pipelines: A comparison review. Measurement 2017, 111, 359–373. [Google Scholar] [CrossRef]

- Cheng, J.C.; Wang, T.H.; Zhang, S.Y. Normal mode expansion method for laser-generated ultrasonic Lamb waves in orthotropic thin plates. Appl. Phys. B 2000, 70, 57–63. [Google Scholar] [CrossRef]

- Cheng, L.; Choi, R.W.; Lee, J.G.; Kim, G.Y.; Moon, S.H.; Bae, Y.C. Oil-Tank Weld Detection Using EMAT. Int. J. Hum. Robot. 2017, 14, 1750008. [Google Scholar] [CrossRef]

- Dixon, S.; Burrows, S.E.; Dutton, B.; Fan, Y. Detection of cracks in metal sheets using pulsed laser generated ultrasound and EMAT detection. Ultrasonics 2011, 51, 7–16. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Zhou, L.; Jacobs, W.; Hunt, P.; Davis, C. Real-time in-line steel microstructure control through magnetic properties using an EM sensor. J. Magn. Magn. 2019, 490, 165504. [Google Scholar] [CrossRef]

- Rao, B. Magnetic Flux Leakage Technique: Basics. J. Non-Destr. Test. Eval. 2012, 11, 7–17. [Google Scholar]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef]

- COMSOL. Multiphysics AC/DC Module User’s Guide; COMSOL Inc.: Stockholm, Sweden, 2017. [Google Scholar]

- Rao, A.S. Alnico permanent magnets an overview. In Proceedings of the Electrical/Electronics Insulation Conference, Chicago, IL, USA, 4–7 October 1993. [Google Scholar]

- Temperature Effects on Permanent Magnets. Available online: https://www.magnetexpert.com/technical-advice-i685/temperature-effects-on-magnets-i683 (accessed on 8 April 2019).

- Kogia, M.; Cheng, L.; Mohimi, A.; Kappatos, V.; Gan, H.T.; Balachandran, W.; Selcuk, C. Electromagnetic Acoustic Transducers Applied to High Temperature Plates for Potential Use in the Solar Thermal Industry. Appl. Sci. 2015, 5, 1715–1734. [Google Scholar] [CrossRef] [Green Version]

- Kogia, M.; Gan, T.H.; Balachandran, W.; Livadas, M.; Kappatos, V.; Szabo, I.; Mohimi, A.; Round, A. High-Temperature Shear Horizontal Electromagnetic Acoustic Transducer for Guided Wave Inspection. Sensors 2016, 16, 582. [Google Scholar] [CrossRef] [Green Version]

- Audruschak, N.; Saletes, I.; Filleter, T.; Sinclair, A. An NDT guided wave technique for the identification of corrosion defects at support locations. NDT E Int. 2015, 75, 72–79. [Google Scholar] [CrossRef]

- Rochaz, L.V.; Cuchet, R.; Vaudaine, M.H. A new GMR sensor based on NiFe/Ag multilayers. Sens. Actuators Phys. 2000, 81, 53–56. [Google Scholar] [CrossRef]

- B64290L0618X027 EPCOS. Available online: https://www.tme.eu/gb/details/b64290l0618x027/ring-ferrites (accessed on 9 May 2020).

- Wu, J.; Fang, H.; Li, L.; Huang, X.; Kang, Y.; Sun, Y.; Tang, C. A Lift-Off-Tolerant Magnetic Flux Leakage Testing Method for Drill Pipes at Wellhead. Sensors 2017, 17, 201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Red Alnico Horseshoe Magnet 47 kg Pull 54 × 83 × 70 mm by Horseshoe. Available online: https://www.first4magnets.com/horseshoe-c42/red-alnico-horseshoe-magnet-47kg-pull-54-x-83-x-70mm (accessed on 7 August 2020).

- Azad, A.; Kim, N. Design and Optimization of an MFL Coil Sensor Apparatus Based on Numerical Survey. Sensors 2019, 19, 4869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Characteristics | Values |

|---|---|

| Ferrite core | T175-2 |

| Reference permeability(µ0) | 10 |

| Material Density | 5.0 g/cm3 |

| Temperature coefficient of permeability(+ ppm/°C) | 95 |

| Co-efficient of linear expansion (+ ppm/°C) | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sathappan, N.; Tokhi, M.O.; Penaluna, L.; Zhao, Z.; Duan, F.; Shirkoohi, G.; Kaur, A. Development of an MFL Coil Sensor for Testing Pipes in Extreme Temperature Conditions. Sensors 2021, 21, 3033. https://doi.org/10.3390/s21093033

Sathappan N, Tokhi MO, Penaluna L, Zhao Z, Duan F, Shirkoohi G, Kaur A. Development of an MFL Coil Sensor for Testing Pipes in Extreme Temperature Conditions. Sensors. 2021; 21(9):3033. https://doi.org/10.3390/s21093033

Chicago/Turabian StyleSathappan, Nagu, Mohammad Osman Tokhi, Liam Penaluna, Zhangfang Zhao, Fang Duan, Gholamhossein Shirkoohi, and Aman Kaur. 2021. "Development of an MFL Coil Sensor for Testing Pipes in Extreme Temperature Conditions" Sensors 21, no. 9: 3033. https://doi.org/10.3390/s21093033

APA StyleSathappan, N., Tokhi, M. O., Penaluna, L., Zhao, Z., Duan, F., Shirkoohi, G., & Kaur, A. (2021). Development of an MFL Coil Sensor for Testing Pipes in Extreme Temperature Conditions. Sensors, 21(9), 3033. https://doi.org/10.3390/s21093033