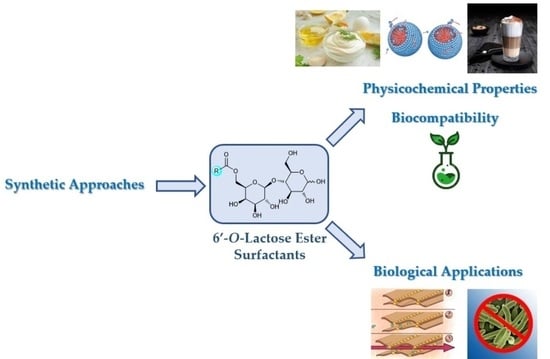

6′-O-Lactose Ester Surfactants as an Innovative Opportunity in the Pharmaceutical Field: From Synthetic Methods to Biological Applications

Abstract

:1. Introduction

2. Synthetic Procedures

3. Physicochemical and Biocompatibility Properties

3.1. Surface Active Properties (Surface Tension (σ) and Critical Micelle Concentration (CMC))

3.2. Emulsion Properties

3.3. Foaming Properties

3.4. Particle Size Distributions

3.5. Thermal Analysis

3.6. Biocompatibility and Safety

4. Biological Applications

4.1. Permeability Enhancing

4.2. Antimicrobial Activity

4.3. Antibiofilm Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De, S.; Malik, S.; Ghosh, A.; Saha, R.; Saha, B. A review on natural surfactants. RSC Adv. 2015, 5, 65757–65767. [Google Scholar] [CrossRef]

- Mnif, I.; Ellouz-Chaambouni, S.; Ghribi, D. Glycolipid biosurfactants, main classes, functional properties and related potential applications in environmental biotechnology. J. Polym. Environ. 2018, 26, 2192–2206. [Google Scholar] [CrossRef]

- Plou, F.J.; Cruces, M.A.; Ferrer, M.; Fuentes, G.; Pastor, E.; Bernabé, M.; Christensen, M.; Comelles, F.; Parra, J.L.; Ballesteros, A. Enzymatic acylation of di- and trisaccharides with fatty acids: Choosing the appropriate enzyme, support and solvent. J. Biotechnol. 2002, 96, 55–66. [Google Scholar] [CrossRef] [Green Version]

- AlFindee, M.N.; Zhang, Q.; Subedi, Y.P.; Shreshta, J.P.; Kawasaki, Y.; Grilley, M.; Takemoto, J.Y.; Chang, C.-W.T. One-step synthesis of carbohydrate esters as antibacterial and antifungal agents. Bioorg. Med. Chem. 2018, 26, 765–774. [Google Scholar] [CrossRef]

- Staroń, J.; Dąbrowski, J.M.; Cichoń, E.; Guzik, M. Lactose esters: Synthesis and biotechnological applications. Crit. Rev. Biotechnol. 2018, 38, 245–258. [Google Scholar] [CrossRef]

- Ferrer, M.; Cruces, M.A.; Plou, F.J.; Pastor, E.; Fuentes, G.; Bernabé, M.; Ballesteros, A. Chemical versus enzymatic catalysis for the regioselective synthesis of sucrose esters of fatty acids. Stud. Surf. Sci. Catal. 2000, 130, 509–514. [Google Scholar] [CrossRef]

- Coelho, A.L.S.; Orlandelli, R.C. Immobilized microbial lipases in the food industry: A systematic literature review. Crit. Rev. Food Sci. Nutr. 2021, 61, 1689–1703. [Google Scholar] [CrossRef]

- Walsh, M.K.; Bombyk, R.A.; Wagh, A.; Bingham, A.; Berreau, L.M. Synthesis of lactose monolaurate as influenced by various lipases and solvents. J. Mol. Catal. B Enzym. 2009, 60, 171–177. [Google Scholar] [CrossRef]

- Zaidan, U.H.; Rahman, M.B.A.; Othman, S.S.; Basri, M.; Abdulmalek, E.; Rahman, R.N.Z.A.; Salleh, A.B. Biocatalytic production of lactose ester catalysed by mica-based immobilised lipase. Food Chem. 2012, 131, 199–205. [Google Scholar] [CrossRef]

- Enayati, M.; Gong, Y.; Goddard, J.M.; Abbaspourrad, A. Synthesis and characterization of lactose fatty acid ester biosurfactants using free and immobilized lipases in organic solvents. Food Chem. 2018, 266, 508–513. [Google Scholar] [CrossRef]

- Zhang, X.; Song, F.; Taxipalati, M.; Wei, W.; Feng, F. Comparative study of surface-active properties and antimicrobial activities of disaccharide monoesters. PLoS ONE 2014, 9, e114845. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.M.; Sandhu, G.; Walsh, M.K. Growth inhibitory properties of lactose fatty acid esters. Saudi J. Biol. Sci. 2017, 24, 1483–1488. [Google Scholar] [CrossRef] [Green Version]

- Liang, M.Y.; Banwell, M.G.; Wang, Y.; Lan, P. Effect of variations in the fatty acid residue of lactose monoesters on their emulsifying properties and biological activities. J. Agric. Food Chem. 2018, 66, 12594–12603. [Google Scholar] [CrossRef]

- Cho, Y.B.; Seo, G. High activity of acid-treated quail eggshell catalysts in the transesterification of palm oil with methanol. Bioresour. Technol. 2010, 101, 8515–8519. [Google Scholar] [CrossRef]

- Viriya-empikul, N.; Krasae, P.; Puttasawat, B.; Yoosuk, B.; Chollacoop, N.; Faungnawakij, K. Waste cells of mollusk and egg as biodiesel production catalysts. Bioresour. Technol. 2010, 101, 3765–3767. [Google Scholar] [CrossRef]

- Enayati, M.; Gong, Y.; Abbaspourrad, A. Synthesis of lactose lauryl ester in organic solving using aluminosilicate zeolite as catalyst. Food Chem. 2019, 279, 401–407. [Google Scholar] [CrossRef]

- Lucarini, S.; Fagioli, L.; Campana, R.; Cole, H.; Duranti, A.; Baffone, W.; Vllasaliu, D.; Casettari, L. Unsaturated fatty acids lactose esters: Cytotoxicity, permeability enhancement and antimicrobial activity. Eur. J. Pharm. Biopharm. 2016, 107, 88–96. [Google Scholar] [CrossRef]

- Perinelli, D.R.; Lucarini, S.; Fagioli, L.; Campana, R.; Vllasaliu, D.; Duranti, A.; Casettari, L. Lactose oleate as new biocompatible surfactant for pharmaceutical applications. Eur. J. Pharm. Biopharm. 2018, 124, 55–62. [Google Scholar] [CrossRef]

- Lucarini, S.; Fagioli, L.; Cavanagh, R.; Liang, W.; Perinelli, D.; Campana, M.; Stolnik, S.; Lam, J.; Casettari, L.; Duranti, A. Synthesis, structure–activity relationships and in vitro toxicity profile of lactose-based fatty acid monoesters as possible drug permeability enhancers. Pharmaceutics 2018, 10, 81. [Google Scholar] [CrossRef] [Green Version]

- Campana, R.; Merli, A.; Verboni, M.; Biondo, F.; Favi, G.; Duranti, A.; Lucarini, S. Synthesis and evaluation of saccharide-based aliphatic and aromatic esters as antimicrobial and antibiofilm agents. Pharmaceuticals 2019, 12, 186. [Google Scholar] [CrossRef] [Green Version]

- Griffin, W.C. Calculation of HLB values of non-ionic surfactants. J. Soc. Cosmet. Chem. 1954, 5, 249–256. [Google Scholar]

- Organic Chemistry Portal. Available online: https://www.organic-chemistry.org/prog/ (accessed on 6 October 2021).

- McCartney, F.; Perinelli, D.R.; Tiboni, M.; Cavanagh, R.; Lucarini, S.; Palmieri, G.P.; Casettari, L.; Brayden, D.J. Permeability-enhancing effects of three laurate-disaccharide monoesters across isolated rat intestinal mucosae. Int. J. Pharm. 2021, 601, 120593. [Google Scholar] [CrossRef]

- Wagh, A.; Shen, S.; Shen, F.A.; Miller, C.D.; Walsh, M.K. Effect of lactose monolaurate on pathogenic and nonpathogenic bacteria. Appl. Environ. Microbiol. 2012, 78, 3465–3468. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Nummer, B.; Walsh, M.K. Antilisterial activity of lactose monolaurate in milk, drinkable yogurt and cottage cheese. Lett. Appl. Microbiol. 2013, 58, 156–162. [Google Scholar] [CrossRef]

- Marçon, F.; Moreau, V.; Helle, F.; Thiebault, N.; Djedaïni-Pilard, F.; Mullié, C. Alkylated oligomaltosides as new alternative preservatives: Antimicrobial activity, cytotoxicity and preliminary investigation of their mechanism of action. J. Appl. Microbiol. 2013, 115, 977–986. [Google Scholar] [CrossRef]

| Immobilized Lipase | Type | Acyl Donor | Solvent | Molar Ratio Lactose/Acyl Donor | Drying Agent | T (°C) | Time (h) | Yield (%) | Refs. | # |

|---|---|---|---|---|---|---|---|---|---|---|

| Novozyme 435 | Candida antharctica | Vinyl laurate | 2M2B | 1:3 | MS 3 Å | 55 | 24–72 | 22 | [8] | 1d |

| Novozyme 435 | Candida antharctica | Caprylic acid | n-Hexanes | 1:1 | MS 4 Å | 55 | 12 | 80 | [10] | 1b |

| Lauric acid | 50 | 10 | 93 | 1d | ||||||

| Palmitic acid | 55 | 12 | 97 | 1f | ||||||

| NER-CRL | Candida rugosa | Capric acid | Acetone | 2:1 | MS | 50 | 48 | 70 | [9] | 1c |

| Novozyme | Thermomyces lanuginous | Vinyl laurate | Acetone | 1:3 | MS 3 Å | 55 | 24–72 | 43 | [8] | 1d |

| Lipozyme® TL IM | Thermomyces lanuginous | Vinyl caprylate | 2M2B/ DMSO (4:1) | 1:10 | MS 4 Å | 50 | 4 | nr | [11] | 1b |

| Vinyl caprate | 1c | |||||||||

| Vinyl laurate | 1d | |||||||||

| TM2 | Thermomyces lanuginous | Vinyl caprylate | 2M2B | 1:2.1 | MS | 60 | 48 | nr | [12] | 1b |

| Vinyl caprate | 1c | |||||||||

| Vinyl laurate | 1d | |||||||||

| Vinyl myristate | 1e | |||||||||

| Lipozyme® TL IM | Thermomyces lanuginous | Vinyl caproate | dry THF/Py (1:1) | 1:3 | – | 55 | 48 | 76 | [13] | 1a |

| Vinyl caprylate | 71 | 1b | ||||||||

| Vinyl caprate | 65 | 1c | ||||||||

| Vinyl laurate | 63 | 1d | ||||||||

| Vinyl myristate | 78 | 1e | ||||||||

| Vinyl palmitate | 71 | 1f | ||||||||

| Vinyl stearate | 58 | 1g | ||||||||

| Amano Lipase PS-C I | Pseudomonas cepacia | Vinyl laurate | 2M2B | 1:3 | MS 3 Å | 55 | 24–72 | 57 | [8] | 1d |

| Lipozyme® | Mucor miehei | Vinyl laurate | 2M2B | 1:3 | MS 3 Å | 55 | 24–72 | 52 | [8] | 1d |

| Compound | Lactose Ester | MW | HLB a | LogP b |

|---|---|---|---|---|

| 1a | Caproate C6 | 440.4 | 13.5 | −2.16 |

| 1b | Caprylate C8 | 468.5 | 12.7 | −1.25 |

| 1c | Caprate C10 | 496.6 | 12.0 | −0.34 |

| 1d | Laurate C12 | 524.6 | 11.4 | 0.57 |

| 1e | Myristate C14 | 552.7 | 10.8 | 1.48 |

| 1f | Palmitate C16 | 580.7 | 10.3 | 2.39 |

| 1g | Stearate C18 | 608.8 | 9.8 | 3.30 |

| 2a | Palmitoleate C16:1 Δ9 | 578.7 | 10.3 | 2.14 |

| 2b | Oleate C18:1 Δ9 | 606.7 | 9.8 | 3.04 |

| 2c | Nervonate C24:1 Δ15 | 690.9 | 8.6 | 5.77 |

| 3a | Phenylacetate (Pa) | 460.4 | 12.9 | −2.53 |

| 3b | Biphenylacetate (Bpa) | 536.5 | 11.1 | −0.87 |

| 3c | p-Phenylbenzoate (p-Pb) | 522.5 | 11.4 | −0.87 |

| 3d | Triphenylacetate (Tpa) | 612.6 | 9.7 | 0.79 |

| Microorganism | C6 1a | C8 1b | C10 1c | C12 1d | C14 1e | C16 1f | C18 1g | C16(Δ9) 2a | C18(Δ9) 2b | C24(Δ15) 2c | Pa 3a | Bpa 3b | p-Pb 3c | Tpa 3d |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B. cereus 13061 | <5000 | <3000 | <1000 | <1000 | ||||||||||

| E. faecalis ATCC 29212 | Na b | 256 | 128 | 256 | 64 | >256 | na | 64 | 128 | 64 | 256 | 256 | 256 | 256 |

| E. faecalis V538 | na | <5000 | <1000 | na | ||||||||||

| L. monocytogenes ATCC7644 | 256 | 256 | >256 | >256 | >256 | 64 | 256 | 64 | 256 | 256 | 256 | 256 | ||

| L. monocytogenes EGDe | <3000 | <3000 | <100 | na | ||||||||||

| M. KMS NA | na | <1000 | <50 | <5000 | ||||||||||

| S. aureus ATCC 25923 | na | na | >512 | >512 | na | na | na | |||||||

| S. aureus (MRSA) ATCC 43300 | na | na | na | >512 | >512 | na | na | |||||||

| S. aureus ATCC 43387 | 256 | 256 | >256 | >256 | >256 | 128 | 128 | 128 | >256 | 256 | 256 | 256 | ||

| S. aureus CICC 21600 | >4000 | 4000 | 500 | |||||||||||

| S. mutans FSL R2- | na | na | <1000 | na | ||||||||||

| S. suis 89/1591 | <3000 | <3000 | <1000 | <3000 | ||||||||||

| E. coli ATCC 25922 | na | na | na | >512 | na | na | na | |||||||

| E. coli O157:H7 ATCC 35150 | 256 | 256 | >256 | >256 | >256 | 64 | 128 | 64 | 256 | 256 | 256 | 256 | ||

| K. pneumoniae ATCC 13883 | 256 | 256 | >256 | >256 | >256 | 256 | 256 | 256 | 256 | |||||

| P. aeruginosa ATCC 27853 | na | na | >512 | >512 | >512 | na | na | |||||||

| P. aeruginosa ATCC 9027 | 256 | 256 | >256 | >256 | >256 | 128 | 128 | 128 | >256 | 256 | 256 | 256 | ||

| S. enterica CMCC 50094 | na | >512 | na | >512 | >512 | na | na | |||||||

| S. enteritidis ATCC 13076 | 256 | 256 | >256 | >256 | >256 | 128 | 128 | 64 | 256 | 256 | 256 | 256 | ||

| Y. enterocolitica ATCC 27729 | 64 | 128 | 64 | |||||||||||

| C. albicans ATCC 10231 | 256 | 128 | 256 | 256 | 256 | 64 | 128 | 64 | 256 | 256 | 256 | 256 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verboni, M.; Lucarini, S.; Duranti, A. 6′-O-Lactose Ester Surfactants as an Innovative Opportunity in the Pharmaceutical Field: From Synthetic Methods to Biological Applications. Pharmaceuticals 2021, 14, 1306. https://doi.org/10.3390/ph14121306

Verboni M, Lucarini S, Duranti A. 6′-O-Lactose Ester Surfactants as an Innovative Opportunity in the Pharmaceutical Field: From Synthetic Methods to Biological Applications. Pharmaceuticals. 2021; 14(12):1306. https://doi.org/10.3390/ph14121306

Chicago/Turabian StyleVerboni, Michele, Simone Lucarini, and Andrea Duranti. 2021. "6′-O-Lactose Ester Surfactants as an Innovative Opportunity in the Pharmaceutical Field: From Synthetic Methods to Biological Applications" Pharmaceuticals 14, no. 12: 1306. https://doi.org/10.3390/ph14121306

APA StyleVerboni, M., Lucarini, S., & Duranti, A. (2021). 6′-O-Lactose Ester Surfactants as an Innovative Opportunity in the Pharmaceutical Field: From Synthetic Methods to Biological Applications. Pharmaceuticals, 14(12), 1306. https://doi.org/10.3390/ph14121306