Stabilization/Solidification of Heavy Metals and PHe Contaminated Soil with β-Cyclodextrin Modified Biochar (β-CD-BC) and Portland Cement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation and Modification of Biochar

2.3. Experimental Method

2.3.1. Solidification/Stabilization Experiment

2.3.2. Unconfined Compressive Strength (UCS) Test

2.3.3. Analytical Method

3. Results and Discussion

3.1. Characterization of BC and β-CD-BC

3.2. Solidification/Stabilization Experiment

3.2.1. Single Factor Experiment

Leachability of PHe

Leachability of Heavy Metals

3.2.2. The Response Surface Experiments

The Results of Box–Behnken Design and the Variance Analysis of Model

Response Surface Analysis and Experimental Verification

3.3. Synchronous Adsorption Investigations of Pb, Cu, Cr, Cd, Zn, and PHe System

3.4. Unconfined Compressive Strength (UCS) Test

4. Conclusions

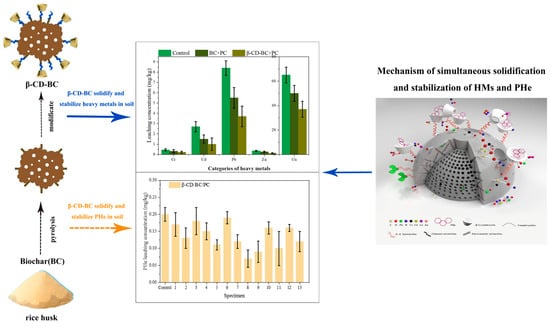

- (1)

- The number of oxygen-containing functional groups on the surface of BC modified by β-CD increased. β-CD-BC still has well-developed void structure and specific surface area.

- (2)

- The compressive strength test shows that the strength is positively correlated with the amount of PC and the curing time, and the compressive strength is stable after 14 days. After β-CD-BC/PC curing, the speciation of HMs changed significantly, the residual Cu content increased from 56% to 75%; the residual Cr content increased from 54% to 82%; the residual CD content increased from 37% to 77%; residual Zn content increased from 61% to 87%; residual Pb increased from 59% to 79%.

- (3)

- β-CD-BC achieves the adsorption of PHe through hydrophobic effect and π-π interaction, and enhances the adsorption of Pb, Cu, Cr, Cd, Zn through complexation and electrostatic attraction. This avoids the competition between the two pollutants for adsorption sites and improves the adsorption performance and adsorption capacity of BC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Zhu, C.; Liu, X.; Li, F.; Li, H.; Ye, J. Biochar amendment immobilizes arsenic in farmland and reduces its bioavailability. Environ. Sci. Pollut. Res. 2018, 25, 34091–34102. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Liu, Z.; Xu, Y.; Zhou, S.; Wu, Y.; Wang, J.; Huang, Z.; Shi, Y. Remediating Potentially Toxic Metal and Organic Co-Contamination of Soil by Combining InSitu Solidification/Stabilization and Chemical Oxidation: Efficacy, Mechanism, and Evaluation. Int. J. Environ. Res. Public Health 2018, 15, 2595. [Google Scholar] [CrossRef] [Green Version]

- Pu, H.; Mastoi, A.K.; Chen, X.; Song, D.; Qiu, J.; Yang, P. An integrated method for the rapid dewatering and solidification/stabilization of dredgedcontaminated sediment with a high water content. Front. Environ. Sci. Eng. 2021, 15, 67. [Google Scholar] [CrossRef]

- Eisa, H.M.; Vaezi, I.; Ardakani, A.M. Evaluation of solidification/stabilization in arsenic-contaminated soils using lime dust and cement kiln dust. Bull. Eng. Geol. Environ. 2020, 79, 1683–1692. [Google Scholar] [CrossRef]

- Gao, R.L.; Tang, M.; Fu, Q.L.; Guo, G.G.; Li, X.; Hu, H.Q. Fractions Transformation of Heavy Metals in Compound Contaminated Soil Treated with Biochar, Montmorillonite and Mixed Addition. Environ. Sci. 2017, 38, 361–367. [Google Scholar]

- Ouhadi, V.R.; Yong, R.N.; Deiranlou, M. Enhancement of cement-based solidification/stabilization of a lead-contaminated smectite clay. J. Hazard. Mater. 2021, 403, 123969. [Google Scholar] [CrossRef]

- Huang, G.; Jiang, X.; Wanyan, H.; Chen, C.; Jin, X.; Zhang, Y. Effects of Different Materials on the Stabilization of Heavy Metals in Sediments. Res. Environ. Sci. 2012, 25, 563–567. [Google Scholar]

- Raja, R.; Pal, S. Remediation of heavy metal contaminated soils by solidification/stabilization with fly ash, quick lime and blast furnace slag. J. Indian Chem. Soc. 2019, 96, 481–486. [Google Scholar]

- Ahmad, M.; Usman, A.R.; Al-Faraj, A.S.; Ahmad, M.; Sallam, A.; Al-Wabel, M.I. Phosphorus-loaded biochar changes soil heavy metals availability and uptakepotential of maize (Zea mays L.) plants. Chemosphere 2017, 194, 327–339. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi, S.; Gitipour, S.; Ghazban, F.; Hedayati, H. Treatment of Petroleum Drill Cuttings Using Stabilization/Solidification Method by Cement and Modified Clay Mixes. Iran. J. Health Saf. Environ. 2017, 4, 781–797. [Google Scholar]

- Sora, I.N.; Pelosato, R.; Botta, D.; Dotelli, G. Chemistry and microstructure of cement pastes admixed with organic liquids. J. Eur. Ceram. Soc. 2002, 22, 1463–1473. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Jin, F.; Al-Tabbaa, A. The performance of blended conventional and novel binders in the in-situ tabilization/solidification of a contaminated site soil. J. Hazard. Mater. 2015, 285, 46–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kogbara, R.B.; Al-Tabbaa, A.; Yi, Y.; Stegemann, J.A. Cement–fly ash stabilisation/solidification of contaminated soil: Performance properties and initiation of operating envelopes. Appl. Geochem. 2013, 33, 64–75. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Usman, A.R.A.; El-Naggar, A.H.; Aly, A.A.; Ibrahim, H.M.; Elmaghraby, S.; Al-Omran, A. Conocarpus biochar as a soil amendment for reducing heavymetal availability and uptake by maize plants. Saudi J. Biol. Sci. 2015, 22, 503–511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alsbaiee, A.; Smith, B.J.; Xiao, L.; Ling, Y.; Helbling, D.E.; Dichtel, W.R. Rapid removal of organic micropollutants from water by a porous β-cyclodextrin polymer. Nature 2016, 529, 190–194. [Google Scholar] [CrossRef]

- Liu, H.H.; Cai, X.Y.; Wang, Y.; Chen, J.W. Adsorption mechanism-based screening of cyclodextrin polymers for adsorption and separation of pesticides from water. Water Res. 2011, 45, 3499–3511. [Google Scholar] [CrossRef] [PubMed]

- Zhao, E.P.; Repo, E.; Yin, D.L.; Meng, Y.; Jafari, S.; Sillanpaa, M. EDTA-cross-linked beta-cyclodextrin: An environmentally friendly bifunctional adsorbent for simultaneous adsorption of metals and cationic dyes. Environ. Sci. Technol. 2015, 49, 10570–10580. [Google Scholar] [CrossRef] [PubMed]

- Li, B.Y.; Li, K.Q. Effect of nitric acid pre-oxidation concentration on pore structure and nitrogen/oxygen active decoration sites of ethylenediamine -modified biochar for mercury (II) adsorption and the possible mechanism. Chemosphere 2019, 220, 28–39. [Google Scholar] [CrossRef]

- Liang, J.; Yang, Z.; Tang, L.; Zeng, G.; Yu, M.; Li, X.; Wu, H.; Qian, Y.; Li, X.; Luo, Y. Changes in heavy metal mobility and availability from contaminatedwetland soil remediated with combined biochar-compost. Chemosphere 2017, 181, 281–288. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, B.L.; Chen, Z.M.; Zhu, L.Z.; Schnoor, J.L. Insight into multiple and multilevel structures of biochars and their potential environmental applications: A critical review. Environ. Sci. Technol. 2018, 52, 5027–5047. [Google Scholar] [CrossRef]

- Jiang, B.N.; Lin, Y.Q.; Mbog, J.C. Biochar derived from swine manure digestate and applied on the removals of heavy metals and antibiotics. Bioresour. Technol. 2018, 270, 603–611. [Google Scholar] [CrossRef] [PubMed]

- Borah, H.J.; Gogoi, M.; Das, D.B.; Hazarika, S. Cyclodextrins-glutaraldehyde cross-linked nanofiltration membrane for recovery of resveratrol from plant extract. J. Environ. Chem. Eng. 2020, 8, 103620. [Google Scholar] [CrossRef]

- He, J.; Li, Y.; Wang, C.; Zhang, K.; Lin, D.; Kong, L.; Liu, J. Rapid adsorption of Pb, Cu and Cd from aqueous solutions by β-cyclodextrin polymers. Appl. Surf. Sci. 2017, 426, 29–39. [Google Scholar] [CrossRef]

- Pei, Z.; Li, L.; Sun, L.; Zhang, S.; Shao, X.; Yang, S.; Wen, B. Adsorption characteristics of 1,2,4-trichlorobenzene, 2,4,6-trichlorophenol, 2-naphthol and naphthalene on graphene and graphene oxide. Carbon 2013, 51, 156–163. [Google Scholar] [CrossRef]

- Chen, Q.; Zheng, J.; Zheng, L.; Dang, Z.; Zhang, L. Classical theory and electron-scale view of exceptional Cd(II) adsorption onto mesoporous cellulose biochar via experimental analysis coupled with DFT calculations. Chem. Eng. J. 2018, 350, 1000–1009. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Z.; Chen, B. Adsorption of polycyclic aromatic hydrocarbons by graphene and graphene oxide nanosheets. Environ. Sci. Technol. 2014, 48, 4817–4825. [Google Scholar] [CrossRef]

- Choong, C.E.; Ibrahim, S.; Yoon, Y.; Jang, M. Removal of lead and bisphenol A using magnesium silicate impregnated palm-shell waste powdered activated carbon: Comparative studies on single and binary pollutant adsorption. Ecotoxicol. Environ. Saf. 2018, 148, 142–151. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Hu, Y.; Xu, G.; Li, M.; Zhu, Y.; Jiang, L.; Tu, Y.; Zhu, X.; Xie, X.; Li, A. Green synthesis of a magnetic β-cyclodextrin polymer for rapid removal of organic micro-pollutants and heavy metals from dyeing wastewater. Environ. Res. 2020, 180, 108796. [Google Scholar] [CrossRef]

- Dong, P.H.; Hayano, K.; Kikuchi, Y.; Takahashi, H.; Morikawa, Y. Deformation and crushing of particles of cement treat granulate soil. Soils Found. 2011, 51, 611–624. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Zentar, R.; Abriak, N.E.; Di, S. Long-term mechanical performance of marine sediments solidified with cement, lime, and fly ash. Mar. Geores. Geotechnol. 2018, 36, 123–130. [Google Scholar] [CrossRef]

| pH | Organic Matter/g·kg−1 | Particle Composition/% | TN/g·kg−1 | TP/g·kg−1 | CEC/cmol·kg−1 | ||

|---|---|---|---|---|---|---|---|

| Sand | Power | Clay | |||||

| 7.6 | 26.31 | 26.86 | 49.41 | 25.12 | 1.05 | 6.53 | 12.6 |

| Specimen | Curing Time (d) | Biochar Ratio (%) | Cement Ratio (%) |

|---|---|---|---|

| 1 | 10 | 5 | 6 |

| 2 | 20 | 7.5 | 12 |

| 3 | 30 | 10 | 18 |

| Sample | A Curing Time (d) | B Biochar Ratio (%) | C Cement Ratio (%) |

|---|---|---|---|

| 1 | 10 | 5.0 | 12 |

| 2 | 10 | 7.5 | 6 |

| 3 | 10 | 7.5 | 18 |

| 4 | 10 | 10.0 | 12 |

| 5 | 20 | 5.0 | 6 |

| 6 | 20 | 5.0 | 18 |

| 7 | 20 | 7.5 | 12 |

| 8 | 20 | 10.0 | 6 |

| 9 | 20 | 10.0 | 18 |

| 10 | 30 | 5.0 | 12 |

| 11 | 30 | 7.5 | 6 |

| 12 | 30 | 7.5 | 18 |

| 13 | 30 | 10.0 | 12 |

| Specimen | Specific Surface Area | Pore Volume (cm3/g) | Average Pore Size (nm) |

|---|---|---|---|

| β-CD-BC | 115.3880 | 0.141730 | 4.91317 |

| BC | 51.3219 | 0.077551 | 4.91317 |

| Source | df | Sum of Squares | Mean Squares | F Value | Prob > F |

|---|---|---|---|---|---|

| Model | 9 | 2.6 × 10−2 | 2.883 × 10−3 | 12.47 | 0.00016 |

| A | 1 | 6.328 × 10−3 | 6.328 × 10−3 | 27.36 | 0.0012 |

| B | 1 | 1.200 × 10−2 | 1.200 × 10−2 | 51.95 | 0.0002 |

| C | 1 | 3.403 × 10−3 | 3.403 × 10−3 | 14.72 | 0.0064 |

| AB | 1 | 2.500 × 10−5 | 2.500 × 10−5 | 0.11 | 0.7519 |

| AC | 1 | 1.056 × 10−3 | 1.056 × 10−3 | 4.57 | 0.0699 |

| BC | 1 | 0.000 | 0.000 | 0.000 | 1.0005 |

| A2 | 1 | 2.780 × 10−4 | 2.780 × 10−4 | 1.20 | 0.3092 |

| B2 | 1 | 2.502 × 10−3 | 2.502 × 10−3 | 10.82 | 0.0133 |

| C2 | 1 | 3.701 × 10−4 | 3.701 × 10−4 | 1.60 | 0.2463 |

| Residual | 7 | 1.619 × 10−3 | 5.396 × 10−4 |

| Source | df | Sum of Squares | Mean Squares | F Value | Prob > F |

|---|---|---|---|---|---|

| Model | 9 | 111.10 | 123.46 | 21.50 | 0.0003 |

| A | 1 | 46.80 | 46.80 | 8.15 | 0.0245 |

| B | 1 | 612.15 | 612.15 | 106.60 | <0.0001 |

| C | 1 | 284.53 | 284.53 | 49.55 | 0.0002 |

| AB | 1 | 48.02 | 48.02 | 8.36 | 0.0233 |

| AC | 1 | 1.55 | 1.55 | 0.27 | 0.6194 |

| BC | 1 | 23.81 | 23.81 | 4.15 | 0.0811 |

| A2 | 1 | 69.36 | 69.36 | 12.08 | 0.0103 |

| B2 | 1 | 4.46 | 4.46 | 0.78 | 0.4076 |

| C2 | 1 | 18.81 | 18.81 | 3.28 | 0.1132 |

| Residual | 7 | 40.20 | 5.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Li, H.; Li, Y.; Chen, X.; Li, X.; Wang, L.; Zhang, W.; Zhou, Y. Stabilization/Solidification of Heavy Metals and PHe Contaminated Soil with β-Cyclodextrin Modified Biochar (β-CD-BC) and Portland Cement. Int. J. Environ. Res. Public Health 2022, 19, 1060. https://doi.org/10.3390/ijerph19031060

Li G, Li H, Li Y, Chen X, Li X, Wang L, Zhang W, Zhou Y. Stabilization/Solidification of Heavy Metals and PHe Contaminated Soil with β-Cyclodextrin Modified Biochar (β-CD-BC) and Portland Cement. International Journal of Environmental Research and Public Health. 2022; 19(3):1060. https://doi.org/10.3390/ijerph19031060

Chicago/Turabian StyleLi, Geng, Haibo Li, Yinghua Li, Xi Chen, Xinjing Li, Lixin Wang, Wenxin Zhang, and Ying Zhou. 2022. "Stabilization/Solidification of Heavy Metals and PHe Contaminated Soil with β-Cyclodextrin Modified Biochar (β-CD-BC) and Portland Cement" International Journal of Environmental Research and Public Health 19, no. 3: 1060. https://doi.org/10.3390/ijerph19031060

APA StyleLi, G., Li, H., Li, Y., Chen, X., Li, X., Wang, L., Zhang, W., & Zhou, Y. (2022). Stabilization/Solidification of Heavy Metals and PHe Contaminated Soil with β-Cyclodextrin Modified Biochar (β-CD-BC) and Portland Cement. International Journal of Environmental Research and Public Health, 19(3), 1060. https://doi.org/10.3390/ijerph19031060