Fuzzy Nonlinear Dynamic Evaporator Model in Supercritical Organic Rankine Cycle Waste Heat Recovery Systems

Abstract

:1. Introduction

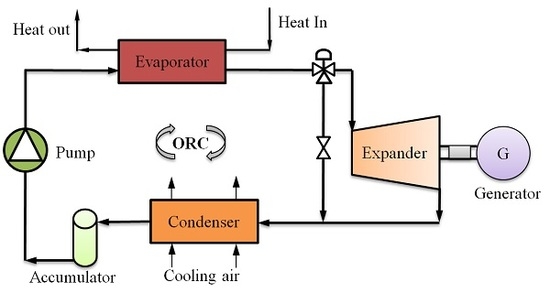

2. ORC-WHR System

3. Model Development

3.1. Evaporator Model

3.1.1. Finite Volume Model

- The heat exchanger model is assumed to be one-dimensional, and the heat transfer to surrounding environment is neglected.

- The momentum conservation is not considered in the model and the pressure variation within the model is assumed to be negligible.

- The heat transfer between the heat source and the refrigerant takes place not by conduction but by convection.

- Heat exchanger wall is uniformly built, and thermo-physical properties are assumed to be constant.

- Thermo-physical properties of refrigerant and heat source fluid for each discrete segment are constant.

Solution Methodology

Time-Step Determination

Simulation Procedure

Numerical Issues

Transient Response Simulation

Simulation Time Constraint in Dynamic Scenario

3.1.2. Fuzzy Based Dynamic Evaporator Model

3.1.3. Evaporator Model Validation

3.2. Other Component Models

3.2.1. Pump Model

3.2.2. Expander Model

3.2.3. Condenser Model

3.2.4. Accumulator Model

3.3. Model Integration

- The pump delivers the refrigerant mass flow rate at a proportion to the speed of the pump. Given the inlet and outlet pressure, the electrical power requirement to drive the pump and the temperature of the fluid at the outlet can be calculated.

- There is no enthalpy loss in between the pump and the evaporator. The heat recovery in the evaporator is a function of the inlet flow conditions and working pressure of the fluids.

- The expander can rotate freely without imposing any speed constraint. The amount of work output is a function of the enthalpy at the inlet and outlet of the expander.

- Provided the condenser outlet temperature is constant, the model calculates the required cooling power to achieve the desired temperature at the outlet.

- Given the inlet conditions and mass of the fluid, the accumulator maintains the outlet enthalpy and fluid level.

4. Results and Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Heat transfer area, m2 | |

| Specific heat capacity, kJ/kgK | |

| Hydraulic diameter, m | |

| Friction factor | |

| Specific enthalpy, kJ/kg | |

| Heat transfer coefficient, kW/m2K | |

| Thermal conductivity, W/mK | |

| Length, m | |

| Mass flow rate, kg/s | |

| Rotational speed of pump, RPM | |

| Number of segments | |

| Node | |

| Nusselt number | |

| Pressure, kPa | |

| Q | Heat input, kW |

| Reynolds number | |

| s | Second |

| Temperature, K | |

| Volume, m3 | |

| v | Velocity, m/s |

| Power output, kW or plate width, m | |

| Pressure loss, kPa | |

| Time step | |

| Efficiency, % | |

| Dynamic viscosity, Pa.s or Membership functions | |

| Density, kg/m3 | |

| Specific volume, m3/kg | |

| Absolute roughness, m | |

| Response time, s | |

| Convergence coefficient | |

| Relative level | |

| Subscripts | |

| ac | accumulator |

| c | cold |

| cy | cycle |

| con | condenser |

| ev | evaporator |

| exp | expander |

| h | heat source |

| i | inlet |

| j | segments notation |

| l | liquid |

| max | maximum |

| min | minimum |

| o | outlet |

| p | pump, pipe |

| pl | plate |

| r | refrigerant |

| t | time |

References

- IPCC Climate Change 2014: Mitigation of Climate Change. Available online: https://www.ipcc.ch/report/ar5/wg3/ (accessed on 1 June 2016).

- Boretti, A. Recovery of exhaust and coolant heat with R245fa organic Rankine cycles in a hybrid passenger car with a naturally aspirated gasoline engine. Appl. Therm. Eng. 2012, 36, 73–77. [Google Scholar] [CrossRef]

- Johansson, M.T.; Söderström, M. Electricity generation from low-temperature industrial excess heat—An opportunity for the steel industry. Energy Effic. 2014, 7, 203–215. [Google Scholar] [CrossRef]

- Gheith, R.; Aloui, F.; Ben Nasrallah, S. Determination of adequate regenerator for a Gamma-type Stirling engine. Appl. Energy 2015, 139, 272–280. [Google Scholar] [CrossRef]

- Ziviani, D.; Beyene, A.; Venturini, M. Advances and challenges in ORC systems modeling for low grade thermal energy recovery. Appl. Energy 2014, 121, 79–95. [Google Scholar] [CrossRef]

- Gao, H.; Liu, C.; He, C.; Xu, X.; Wu, S.; Li, Y. Performance analysis and working fluid selection of a supercritical organic rankine cycle for low grade waste heat recovery. Energies 2012, 5, 3233–3247. [Google Scholar] [CrossRef]

- Shu, G.; Yu, G.; Tian, H.; Wei, H.; Liang, X. A Multi-Approach Evaluation System (MA-ES) of Organic Rankine Cycles (ORC) used in waste heat utilization. Appl. Energy 2014, 132, 325–338. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Y.; Li, Y.; Hou, G.; Fang, F. Generalized predictive control applied in waste heat recovery power plants. Appl. Energy 2013, 102, 320–326. [Google Scholar] [CrossRef]

- Tian, H.; Shu, G.; Wei, H.; Liang, X.; Liu, L. Fluids and parameters optimization for the organic Rankine cycles (ORCs) used in exhaust heat recovery of Internal Combustion Engine (ICE). Energy 2012, 47, 125–136. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhou, N.J.; Guo, J.; Wang, X.Y. Fluid selection and parametric optimization of organic Rankine cycle using low temperature waste heat. Energy 2012, 40, 107–115. [Google Scholar] [CrossRef]

- Sun, J.; Li, W. Operation optimization of an organic rankine cycle (ORC) heat recovery power plant. Appl. Therm. Eng. 2011, 31, 2032–2041. [Google Scholar] [CrossRef]

- Quoilin, S.; Aumann, R.; Grill, A.; Schuster, A.; Lemort, V.; Spliethoff, H. Dynamic modeling and optimal control strategy of waste heat recovery Organic Rankine Cycles. Appl. Energy 2011, 88, 2183–2190. [Google Scholar] [CrossRef]

- Hou, G.; Sun, R.; Hu, G.; Zhang, J. Supervisory predictive control of evaporator in Organic Rankine Cycle (ORC) system for waste heat recovery. In Proceedings of the 2011 International Conference on Advanced Mechatronic Systems, Zhengzhou, China, 11–13 August 2011. [Google Scholar]

- Zhang, J.; Zhang, W.; Hou, G.; Fang, F. Dynamic modeling and multivariable control of organic Rankine cycles in waste heat utilizing processes. Comput. Math. Appl. 2012, 64, 908–921. [Google Scholar] [CrossRef]

- Schuster, A.; Karellas, S.; Aumann, R. Efficiency optimization potential in supercritical Organic Rankine Cycles. Energy 2010, 35, 1033–1039. [Google Scholar] [CrossRef]

- Glover, S.; Douglas, R.; Glover, L.; McCullough, G. Preliminary analysis of organic Rankine cycles to improve vehicle efficiency. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 1142–1153. [Google Scholar] [CrossRef]

- Lecompte, S.; Huisseune, H.; van den Broek, M.; De Paepe, M. Methodical thermodynamic analysis and regression models of organic Rankine cycle architectures for waste heat recovery. Energy 2015, 87, 60–76. [Google Scholar] [CrossRef]

- Chen, H.; Goswami, D.Y.; Rahman, M.M.; Stefanakos, E.K. A supercritical Rankine cycle using zeotropic mixture working fluids for the conversion of low-grade heat into power. Energy 2011, 36, 549–555. [Google Scholar] [CrossRef]

- Dai, X.; Shi, L.; An, Q.; Qian, W. Screening of hydrocarbons as supercritical ORCs working fluids by thermal stability. Energy Convers. Manag. 2016, 126, 632–637. [Google Scholar] [CrossRef]

- Glover, S.; Douglas, R.; Glover, L.; Mccullough, G.; Mckenna, S. Automotive waste heat recovery: working fluid selection and related boundary conditions. Int. J. Automot. Technol. 2015, 16, 399–409. [Google Scholar] [CrossRef]

- Glover, S.; Douglas, R.; De Rosa, M.; Zhang, X.; Glover, L. Simulation of a multiple heat source supercritical ORC (Organic Rankine Cycle) for vehicle waste heat recovery. Energy 2015, 93, 1568–1580. [Google Scholar] [CrossRef]

- Karellas, S.; Schuster, A.; Leontaritis, A.D. Influence of supercritical ORC parameters on plate heat exchanger design. Appl. Therm. Eng. 2012, 33–34, 70–76. [Google Scholar] [CrossRef]

- Yağli, H.; Koç, Y.; Koç, A.; Görgülü, A.; Tandiroğlu, A. Parametric optimization and exergetic analysis comparison of subcritical and supercritical organic Rankine cycle (ORC) for biogas fuelled combined heat and power (CHP) engine exhaust gas waste heat. Energy 2016, 111, 923–932. [Google Scholar] [CrossRef]

- Le, V.L.; Feidt, M.; Kheiri, A.; Pelloux-Prayer, S. Performance optimization of low-temperature power generation by supercritical ORCs (organic Rankine cycles) using low GWP (global warming potential) working fluids. Energy 2014, 67, 513–526. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Nguyen, B.K.; Thornhill, D. Investigation of waste heat recovery system at supercritical conditions with vehicle drive cycles. J. Mech. Sci. Technol. 2017, 31, 923–936. [Google Scholar] [CrossRef] [Green Version]

- Braimakis, K.; Preißinger, M.; Brüggemann, D.; Karellas, S.; Panopoulos, K. Low grade waste heat recovery with subcritical and supercritical Organic Rankine Cycle based on natural refrigerants and their binary mixtures. Energy 2015, 88, 80–92. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Soulatiantork, P.; Nguyen, B.K. Simulation of Waste Heat Recovery System with Fuzzy Based Evaporator Model. In 11th Asian Control Conference (ASCC); IEEE: Gold Coast, Australia, 2017; pp. 2143–2147. [Google Scholar]

- Chowdhury, J.I.; Nguyen, B.K.; Thornhill, D. Dynamic model of supercritical Organic Rankine Cycle waste heat recovery system for internal combustion engine. Int. J. Automot. Technol. 2017, 18, 589–601. [Google Scholar] [CrossRef] [Green Version]

- Bamgbopa, M.O.; Uzgoren, E. Numerical analysis of an organic Rankine cycle under steady and variable heat input. Appl. Energy 2013, 107, 219–228. [Google Scholar] [CrossRef]

- Feru, E.; Willems, F.; de Jager, B.; Steinbuch, M. Modeling and control of a parallel waste heat recovery system for Euro-VI heavy-duty diesel engines. Energies 2014, 7, 6571–6592. [Google Scholar] [CrossRef]

- Chowdhury, J.; Nguyen, B.; Thornhill, D. Modelling of Evaporator in Waste Heat Recovery System using Finite Volume Method and Fuzzy Technique. Energies 2015, 8, 14078–14097. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.Y.; Li, C.; Xiao, L.; Li, Y.R.; Liu, C. The role of outlet temperature of flue gas in organic Rankine cycle considering low temperature corrosion. J. Mech. Sci. Technol. 2014, 28, 5213–5219. [Google Scholar] [CrossRef]

- Han, S.; Seo, J.B.; Choi, B.S. Development of a 200 kW ORC radial turbine for waste heat recovery. J. Mech. Sci. Technol. 2014, 28, 5231–5241. [Google Scholar] [CrossRef]

- Kakaç, S.; Liu, H.; Pramuanjaroenkij, A. Heat Exchangers: Selection, Rating and Thermal Design, 3rd ed.; CRC Press: Boca Raton, 2012. [Google Scholar]

- Patiño, J.; Llopis, R.; Sánchez, D.; Sanz-Kock, C.; Cabello, R.; Torrella, E. A comparative analysis of a CO2 evaporator model using experimental heat transfer correlations and a flow pattern map. Int. J. Heat Mass Transf. 2014, 71, 361–375. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP; Version 9.0; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2010.

- Hawn, D. Development of a Dynamic Model of a Counterflow Compact Heat Exchanger for Simulation of the GT-MHR Recuperator using MATLAB and Simulink. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Zhang, J.; Zhou, Y.; Wang, R.; Xu, J.; Fang, F. Modeling and constrained multivariable predictive control for ORC (Organic Rankine Cycle) based waste heat energy conversion systems. Energy 2014, 66, 128–138. [Google Scholar] [CrossRef]

- Michel, A.; Kugi, A. Accurate low-order dynamic model of a compact plate heat exchanger. Int. J. Heat Mass Transf. 2013, 61, 323–331. [Google Scholar] [CrossRef]

- Fuzzy Logic Systems. Available online: http://www.control-systems-principles.co.uk (accessed on 15 April 2015).

- Nguyen, B.K.N.B.K.; Ahn, K.A.K. Feedforward Control of Shape Memory Alloy Actuators Using Fuzzy-Based Inverse Preisach Model. IEEE Trans. Control Syst. Technol. 2009, 17, 434–441. [Google Scholar] [CrossRef]

- Ross, T. Fuzzy Logic with Engineering Applications, 3rd ed.; John Wiley: Chichester, UK, 2011. [Google Scholar]

- Ahn, K.K.; Kha, N.B. Modeling and control of shape memory alloy actuators using Preisach model, genetic algorithm and fuzzy logic. Mechatronics 2008, 18, 141–152. [Google Scholar] [CrossRef]

- Installation and Service Manual: Hydra-Cell Industrial Pumps. Available online: http://www.hydra-cell.com/product/D03-hydracell-pump.html (accessed on 1 May 2015).

- Wei, D.; Lu, X.; Lu, Z.; Gu, J. Dynamic modeling and simulation of an Organic Rankine Cycle (ORC) system for waste heat recovery. Appl. Therm. Eng. 2008, 28, 1216–1224. [Google Scholar] [CrossRef]

- Declaye, S.; Quoilin, S.; Guillaume, L.; Lemort, V. Experimental study on an open-drive scroll expander integrated into an ORC (Organic Rankine Cycle) system with R245fa as working fluid. Energy 2013, 55, 173–183. [Google Scholar] [CrossRef]

- Quoilin, S. Sustainable energy conversion through the use of Organic Rankine Cycles for waste heat recovery and solar applications. Ph.D. Thesis, University of Liège, Liège, Wallonia, Belgium, October 2011. [Google Scholar]

- Haaland, S.E. Simple and Explicit Formulas for the Friction Factor in Turbulent Pipe Flow. J. Fluids Eng. 1983, 105, 89–90. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Chemical formula | CH2FCF3 |

| Molar mass | 102.03 kg/kmol |

| Critical point density | 511.9 kg/m3 |

| Critical Pressure | 4.06 MPa |

| Maximum pressure | 70 MPa |

| Boiling point temperature | 247.08 K |

| Critical temperature | 374 K |

| Autoignition temperature | 1016 K |

| Constant Input Conditions | Transient Condition (Step Change) | Ideal 63% Response Time | Enthalpy and Temperature at 63% Response Time |

|---|---|---|---|

| kg/s | K Step down | kJ/kg | |

| K | |||

| kg/s | K | ||

| kg/s | kg/s Step down | kJ/kg | |

| K | |||

| K | K | ||

| kg/s | kg/s Step down | kJ/kg | |

| K | |||

| K | K |

| No. of Segments | Total Simulated Run-Time of the System (Steady + Dynamic) | Actual Computing Time of the Simulation |

|---|---|---|

| 10 | 1300 s | 2040 s |

| 20 | 1300 s | 3820.6 s |

| 50 | 1300 s | 9131.8 s |

| 100 | 1300 s | 17,782 s |

| Rule Number | IF is | AND is | AND is | THEN is | AND is |

|---|---|---|---|---|---|

| 1 | L | L | L | L | VL |

| 2 | L | L | M | M | L |

| 3 | L | L | H | M | L |

| 4 | L | M | L | L | L |

| 5 | L | M | M | L | LM |

| 6 | L | M | H | VH | M |

| 7 | L | H | L | M | LM |

| 8 | L | H | M | H | M |

| 9 | L | H | H | VH | MH |

| 10 | M | L | L | VL | VL |

| 11 | M | L | M | L | L |

| 12 | M | L | H | L | L |

| 13 | M | M | L | VL | LM |

| 14 | M | M | M | L | M |

| 15 | M | M | H | M | MH |

| 16 | M | H | L | VL | M |

| 17 | M | H | M | L | MH |

| 18 | M | H | H | M | VH |

| 19 | H | L | L | VL | VL |

| 20 | H | L | M | VL | L |

| 21 | H | L | H | VL | L |

| 22 | H | M | L | VL | LM |

| 23 | H | M | M | L | M |

| 24 | H | M | H | L | MH |

| 25 | H | H | L | VL | M |

| 26 | H | H | M | L | H |

| 27 | H | H | H | L | VH |

| Model Output | Fitness (%) | RMSE | MAPE (%) | Simulation Time (s) | |

|---|---|---|---|---|---|

| Fuzzy Model | FV Model | ||||

| 90.32 | 1.10 (K) | 0.19 | 5.19 s | 3820.6 s | |

| 91.24 | 3.09 (K) | 0.58 | |||

| Parameter | Symbol | Value | References |

|---|---|---|---|

| Pump efficiency | 0.75 | [2,21] | |

| Expander efficiency | 0.8 | [2,38] | |

| Evaporator heat transfer area | A | 5.78 m2 | [28] |

| Evaporator plate length | L | 0.478 m | |

| Evaporator plate width | W | 0.124 m | |

| Number of plates | Npl | 100 | |

| Thermal conductivity | K | 15 W/m K |

| Parameters | FV Based Overall Model | Fuzzy Based Overall Model | MAPE (%) |

|---|---|---|---|

| 5996.64 kPa | 5996.7 kPa | 0.001% | |

| 2.53 kW | 2.61 kW | 3.11% | |

| 9.78 | 9.42 | 3.82% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, J.I.; Nguyen, B.K.; Thornhill, D.; Hu, Y.; Soulatiantork, P.; Balta-Ozkan, N.; Varga, L. Fuzzy Nonlinear Dynamic Evaporator Model in Supercritical Organic Rankine Cycle Waste Heat Recovery Systems. Energies 2018, 11, 901. https://doi.org/10.3390/en11040901

Chowdhury JI, Nguyen BK, Thornhill D, Hu Y, Soulatiantork P, Balta-Ozkan N, Varga L. Fuzzy Nonlinear Dynamic Evaporator Model in Supercritical Organic Rankine Cycle Waste Heat Recovery Systems. Energies. 2018; 11(4):901. https://doi.org/10.3390/en11040901

Chicago/Turabian StyleChowdhury, Jahedul Islam, Bao Kha Nguyen, David Thornhill, Yukun Hu, Payam Soulatiantork, Nazmiye Balta-Ozkan, and Liz Varga. 2018. "Fuzzy Nonlinear Dynamic Evaporator Model in Supercritical Organic Rankine Cycle Waste Heat Recovery Systems" Energies 11, no. 4: 901. https://doi.org/10.3390/en11040901

APA StyleChowdhury, J. I., Nguyen, B. K., Thornhill, D., Hu, Y., Soulatiantork, P., Balta-Ozkan, N., & Varga, L. (2018). Fuzzy Nonlinear Dynamic Evaporator Model in Supercritical Organic Rankine Cycle Waste Heat Recovery Systems. Energies, 11(4), 901. https://doi.org/10.3390/en11040901