Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles

Abstract

:1. Introduction

2. Materials and Methods

- -

- five three-year-old whole trees,

- -

- five six-year-old whole trees,

- -

- five nine-year-old whole trees,

- -

- five three-year-old stems without branches,

- -

- five six-year-old stems without branches,

- -

- five nine-year-old stems without branches.

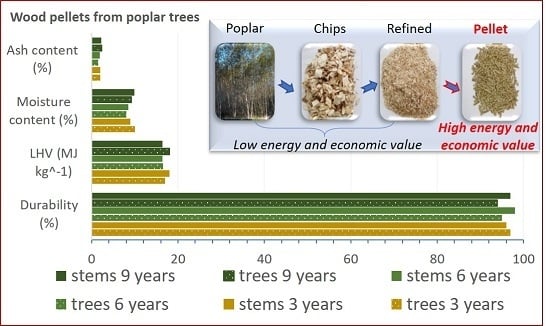

3. Results

3.1. Size Characteristics of the Crops

3.2. Dehydration Process and Moisture Content of Different Types of Biomass

3.3. Length, Diameter and Bulk Density of the Pellets

3.4. Heating Value, Ash Content, Ash Melting Point and Heavy Metals of the Pellets

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, Y.; Finell, M.; Larsson, S.; Wang, X.; Zhang, J.; Wei, R.; Liu, L. Biofuel pellets made at low moisture content e Influence of water in the binding mechanism of densified biomass. Biomass Bioenergy 2017, 98, 8–14. [Google Scholar] [CrossRef]

- Picchio, R.; Spina, R.; Sirna, A.; Monaco, A.L.; Civitarese, V.; Del Giudice, A.; Suardi, A.; Pari, L. Characterization of Woodchips for Energy from Forestry and Agroforestry Production. Energies 2012, 5, 3803–3816. [Google Scholar] [CrossRef]

- IPCC Climate Change. Synthesis Report Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK. Available online: https://www.researchgate.net/publication/262260453_IPCC_2007_Climate_Change_2007_Synthesis_Report_Contribution_of_Working_Groups_I_II_III_to_the_Fourth_Assessment_Report_of_the_Intergovernmental_Panel_on_Climate_Change_Geneva (accessed on 6 February 2019).

- European Commission. 2020 Climate & Energy Package. Combating Climate Change the EU Leads the Way, European Move Service 24. Available online: https://ec.europa.eu/clima/policies/strategies/2020_en (accessed on 8 January 2019).

- Tumuluru, J.S. Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef] [Green Version]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Sánchez, J.; Curt, M.D.; Sanz, M.; Fernández, J. A proposal for pellet production from residual woody biomass in the island of Majorca (Spain). AIMS Energy 2015, 3, 480–504. [Google Scholar] [CrossRef] [Green Version]

- Associazione Italiana Energie Agroforestali (AIEL). Available online: http://www.aielenergia.it/public/rassegna_stampa/378_1%20febbraio%202019%20biomassapp.it.pdf (accessed on 10 July 2019).

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production—A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Alberici, S.; Boeve, S.; van Breevoort, P. Subsidies and Costs of EU Energy. European Commission. Available online: https://ec.europa.eu/energy/en/content/inal-report-ecofys (accessed on 12 January 2019).

- Peksa-Blanchard, M.; Dolzan, P.; Grassi, A.; Heinimoe, J.; Junginger, M.; Ranta, T.; Walter, A. Global Wood Pellets Market and Industry: Policy, Drivers, Market Status and Raw Material Potential; IEA bioenergy Task 40; International Energy Agency: Paris, France, 2007; Available online: https://www.researchgate.net/publication/27709106_Global_Wood_Pellets_Markets_and_Industry_Policy_Drivers_Market_Status_and_Raw_Material_Potential (accessed on 15 February 2019).

- Gravelsins, A.; Muižniece, I.; Blumberga, A.; Blumberga, D. Economic sustainability of pellet production in Latvia. Energy Procedia 2017, 142, 531–537. [Google Scholar] [CrossRef]

- GSE (Energy Services Manager). Rapporto Delle Attività. Energia in Movimento. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20delle%20attivit%C3%A0/GSE_RA2017.pdf (accessed on 5 March 2019).

- Haruna, N.Y.; Afzalb, M.T. Effect of Particle Size on Mechanical Properties of Pellets Made from Biomass Blends. Procedia Eng. 2016, 148, 93–99. [Google Scholar] [CrossRef] [Green Version]

- Supin, M. Wood Processing and Furniture Manufacturing Challenges on the World Market: Wood Pellet Global Market Development 2015. pp. 255–260. Available online: https://www.researchgate.net/publication/286443751_Wood_Pellet_Global_Market_Development (accessed on 7 February 2019).

- Acda, M.N.; Jara, A.A.; Daracan, V.C.; Devera, E.E. Opportunities and Barriers to Wood Pellet Trade in the Philippines. Ecosyst. Dev. J. 2016, 6, 27–31. Available online: https://www.researchgate.net/publication/303680604_Opportunities_and_barriers_to_wood_pellet_trade_in_the_Philippines (accessed on 7 February 2019).

- European Biomass Association (AEBIOM) Bioenergy. A Local and Renewable Solution for Energy Security. Available online: https://www.slideshare.net/AEBIOM2/biomass (accessed on 8 January 2019).

- Verhoest, C.; Ryckmans, Y. Industrial Wood Pellets Report. Available online: http://www.bpa-intl.com/images/stories/present-1/PELLCERT%20-%20Industrial%20Wood%20Pellets%20Report%20(2012).pdf (accessed on 5 March 2019).

- GSE (Energy Services Manager). Rapporto Statistico. Energia Da Fonti Rinnovabili. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Rapporto%20statistico%20GSE%20-%202016.pdf (accessed on 5 March 2019).

- Energia Dall’agricoltura: Innovazioni Sostenibili Per la Bioeconomia. Available online: http://agroener.crea.gov.it (accessed on 1 June 2019).

- Di Candilo, M.; Facciotto, G. Colture da biomassa ad uso energetico Potenzialità e prospettive. In Progetti Di Ricerca Suscace e Faesi. Recenti Acquisizioni Scientifiche per Le Colture Energetiche; Supplemento n. 2 a Sherwood-Foreste ed Alberi Oggi n. 183; Compagnia delle Foreste Srl: Roma, Italy, 2012; pp. 10–19. [Google Scholar]

- Paris, P.; Mareschi, L.; Sabatti, M.; Pisanelli, A.; Ecosse, A.; Nardin, F.; Scarascia-Mugnozza, G. Comparing hybrid Populus clones for SRF across northern Italy after two biennial rotations: Survival, growth and yield. Biomass Bioenergy 2011, 35, 1524–1532. [Google Scholar] [CrossRef]

- Facciotto, G. Storia della SRF e suo sviluppo in Italia. In Progetti Di Ricerca Suscace e Faesi. Recenti Acquisizioni Scientifiche per Le Colture Energetiche; Supplemento n. 2 a Sherwood-Foreste ed Alberi Oggi n. 183; Compagnia delle Foreste Srl: Roma, Italy, 2012; pp. 26–30. [Google Scholar]

- Verani, S.; Sperandio, G.; Picchio, R.; Marchi, E.; Costa, C. Sustainability Assessment of a Self-Consumption Wood-Energy Chain on Small Scale for Heat Generation in Central Italy. Energies 2015, 8, 5182–5197. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, C.P.; Kofman, P.D.; Angus-Hankin, C.M. Guidelines for Conducting Harvesting Trials in Short Rotation Forestry; Forestry Research Paper; Aberdeen University: Aberdeen, UK, 1997; pp. 1–50. [Google Scholar]

- Bergström, D.; Israelsson, S.; Öhman, M.; Dahlqvist, S.-A.; Gref, R.; Boman, C.; Wästerlund, I. Effects of raw material particle size distribution on the characteristics of Scots pine sawdust fuel pellets. Fuel Process. Technol. 2008, 89, 1324–1329. [Google Scholar] [CrossRef]

- Monaco, A.L.; Todaro, L.; Sarlatto, M.; Spina, R.; Calienno, L.; Picchio, R. Effect of moisture on physical parameters of timber from Turkey oak (Quercus cerris L.) coppice in Central Italy. For. Stud. China 2011, 13, 276–284. [Google Scholar] [CrossRef]

- EN ISO 18122. Solid Biofuels—Determination of Ash Content; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- CEN/TS 15370-1. Solid Biofuels—Method for the Determination of Ash Melting Behaviour. Part 1: Characteristic Temperatures Method; CEN/TS: Geneva, Switzerland, 2006. [Google Scholar]

- EN ISO 18125. Solid Biofuels—Determination of Heating Value; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Ghafghazi, S.; Sowlati, T.; Sokhansanj, S.; Bi, X.; Melin, S. Particulate matter emissions from combustion of wood in district heating applications. Renew. Sustain. Energy Rev. 2011, 15, 3019–3028. [Google Scholar] [CrossRef]

- EN ISO 16968. Solid Biofuels—Determination of Minor Elements; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 16948. Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 16994. Solid Biofuels—Determination of Total Content of Sulfur and Chlorine; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- EN ISO 17828. Solid Biofuels—Determination of Bulk Density; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 17829. Solid Biofuels—Determination of Length and Diameter of Pellets; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 17831–1. Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. Part 1: Pellets; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- EN ISO 18134-1. Solid Biofuels—Determination of Moisture Content—Oven Dry Method; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Pelosi, C.; Agresti, G.; Calienno, L.; Lo Monaco, A.; Picchio, R.; Santamaria, U.; Vinciguerra, V. Application of spectroscopic techniques for the study of the surface changes in poplar wood and possible implications in conservation of wooden artefacts. In Proceedings of the SPIE—The International Society for Optical Engineering, Munich, Germany, 30 May 2013; Volume 8790, p. 879014. [Google Scholar]

- Picchio, R.; Verani, S.; Sperandio, G.; Spina, R.; Marchi, E. Stump grinding on a poplar plantation: Working time, productivity, and economic and energetic inputs. Ecol. Eng. 2012, 40, 117–120. [Google Scholar] [CrossRef]

- Civitarese, V.; Faugno, S.; Picchio, R.; Assirelli, A.; Sperandio, G.; Saulino, L.; Crimaldi, M.; Sannino, M. Production of selected short-rotation wood crop species and quality of obtained biomass. Eur. J. For. Res. 2018, 137, 541–552. [Google Scholar] [CrossRef]

- Bergante, S.; Facciotto, G.; Minotta, G. Identification of the main site factors and management intensity affecting the establishment of Short-Rotation-Coppices (SRC) in Northern Italy through stepwise regression analysis. Open Life Sci. 2010, 5, 522–530. [Google Scholar] [CrossRef]

- Di Matteo, G.; Sperandio, G.; Verani, S. Field performance of poplar for bioenergy in southern Europe after two coppicing rotations: Effects of clone and planting density. iForest—Biogeosci. For. 2012, 5, 224–229. [Google Scholar] [CrossRef]

- Bungart, R.; Hüttl, R.F. Growth dynamics and biomass accumulation of 8-year-old hybrid poplar clones in a short-rotation plantation on a clayey-sandy mining substrate with respect to plant nutrition and water budget. Eur. J. For. Res. 2004, 123, 105–115. [Google Scholar] [CrossRef]

- Hauk, S.; Knoke, T.; Wittkopf, S. Economic evaluation of short rotation coppice systems for energy from biomass—A review. Renew. Sustain. Energy Rev. 2014, 29, 435–448. [Google Scholar] [CrossRef]

- Huber, J.A.; May, K.; Hülsbergen, K.J. Allometric tree biomass models of various species grown in short-rotation agroforestry systems. Eur. J. For. Res. 2017, 136, 75–89. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Kovacs, H.; Szemmelveisz, K. Heavy metal contaminated biomass combustion as treatment after phytoremediation—A review. Mater. Sci. Eng. 2016, 41, 69–78. [Google Scholar]

- Ružinská, E.; Štollmann, V.; Hagara, V.; Jabłoński, M. Analysis of selected heavy metals in biomass for preparation of biofuels—Part I. Toxicological effects of heavy metals. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2015, 92, 383–389. [Google Scholar]

- Obernbergera, I.; Theka, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their Combustion behavior. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Samuelsson, R.; Thyrel, M.; Sjöström, M.; Lestander, T.A. Effect of biomaterial characteristics on pelletizing properties and biofuel pellet quality. Fuel Process. Technol. 2009, 90, 1129–1134. [Google Scholar] [CrossRef]

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Filbakk, T.; Skjevrak, G.; Høibø, O.; Dibdiakova, J.; Jirjis, R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011, 92, 871–878. [Google Scholar] [CrossRef]

- EN ISO 17225. Solid Biofuels—Fuel specifications and classes—Part 2: Graded wood pellets; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Toscano, G.; Riva, G.; Pedretti, E.F.; Corinaldesi, F.; Mengarelli, C.; Duca, D. Investigation on wood pellet quality and relationship between ash content and the most important chemical elements. Biomass Bioenergy 2013, 56, 317–322. [Google Scholar] [CrossRef]

- Monedero, E.; Portero, H.; Lapuerta, M. Pellet blends of poplar and pine sawdust: Effects of material composition, additive, moisture content and compression die on pellet quality. Fuel Process. Technol. 2015, 132, 15–23. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Porsö, C.; Hansson, P.-A. Time-dependent climate impact of heat production from Swedish willow and poplar pellets—In a life cycle perspective. Biomass Bioenergy 2014, 70, 287–301. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.-S.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.-S.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust Renew. Energy 2014, 62, 18–23. [Google Scholar]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuelpellets. Wood Fibre Sci. 2009, 41, 414–425. [Google Scholar]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.M.; Ahn, B.J.; Choi, D.H.; Han, G.-S.; Jeong, H.-S.; Ahn, S.H.; Yang, I. Effects of densification variables on the durability of wood pellets fabricated with Larix kaempferi C. and Liriodendron tulipifera L. sawdust. Biomass Bioenergy 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass Pelletisation: A review. Bioresources 2012, 7, 4451–4490. [Google Scholar]

- Adapa, P.; Tabil, L.; Shoenau, G.; Opoku, A. Pelleting characteristics of selected biomass with and without steam explosion pretreatment. Int. J. Agric. Biol. Eng. 2010, 3, 62–79. [Google Scholar]

- Brand, M.A.; Barnasky, R.R.D.S.; Carvalho, C.A.; Buss, R.; Waltrick, D.B.; Jacinto, R.C. Thermogravimetric analysis for characterization of the pellets produced with different forest and agricultural residues. Ciênc. Rural 2018, 48, 1–10. [Google Scholar] [CrossRef]

- Toscano, G.; Alfano, V.; Scarfone, A.; Pari, L. Pelleting Vineyard Pruning at Low Cost with a Mobile Technology. Energies 2018, 11, 2477. [Google Scholar] [CrossRef]

| Harvesting Cycle | 3 Years | 6 Years | 9 Years |

|---|---|---|---|

| Branches and tops | 17.65% (bc) | 19.41% (ac) | 20.36% (a) |

| Stems | 82.35% | 80.59% | 79.64% |

| Type of Biomass Source | Trees T0 20 February | Chips T1 20 April | Refined T2 31 May | Pellet T3 1 June | Δ T3/T2 |

|---|---|---|---|---|---|

| 3 years old whole tree | 52.28% (±0.96) | 46.05% (±4.07) | 9.53% (±0.38) | 8.32% (±0.37) | −12.72% (±2.42) *** |

| 3 years old stem | 52.72% (±0.73) | 46.69% (±3.07) | 10.21% (±0.43) | 8.46% (±0.35) | −17.04% (±4.77) *** |

| 6 years old whole tree | 53.98% (±0.87) | 45.77% (±4.39) | 10.05% (±0.55) | 8.30% (±0.23) | −17.25% (±4.72) *** |

| 6 years old stem | 53.88% (±1.36) | 48.03% (±3.43) | 9.43% (±0.33) | 8.71% (±0.31) | −7.61% (±4.96) ** |

| 9 years old whole tree | 56.27% (±1.81) | 47.95% (±3.93) | 9.32% (±0.63) | 8.35% (±0.31) | −10.24% (±4.54) * |

| 9 years old stem | 56.85% (±2.09) | 50.78% (±4.53) | 10.40% (±0.39) | 8.47% (±0.37) | −18.53% (±4.94) *** |

| Average | 54.74% | 46.05% | 9.76% | 8.50% | −12.62% |

| Biomass Source after Pelletization | LHV (MJ·kg−1) | Ash (%) | Ash Melting Point (°C) |

|---|---|---|---|

| 3 years old whole tree | 17.67 a ±0.27 | 2.78 a ±0.09 | 1433.4 c ±4.4 |

| 3 years old stem | 17.85 a ±0.38 | 2.71 a ±0.31 | 1455.8 d ±5.8 |

| 6 years old whole tree | 17.85 a ±0.11 | 1.82 c ±0.23 | 1404.6 c ±17.2 |

| 6 years old stem | 17.68 a ±0.26 | 1.89 c ±0.08 | 1433.2 c ±4.3 |

| 9 years old whole tree | 17.72 a ±0.28 | 2.27 b ±0.06 | 1479.8 a ±1.1 |

| 9 years old stem | 17.55 a ±0.62 | 1.87 c ±0.04 | 1457.6 b ±4.6 |

| Biomass Source after Pelletization | As (mg·kg−1) | Cd (mg·kg−1) | Cr (mg·kg−1) | Cu (mg·kg−1) | Pb (mg·kg−1) | Ni (mg·kg−1) | Zn (mg·kg−1) |

|---|---|---|---|---|---|---|---|

| 3 years old whole tree | 0.0050 b,c ±0.0007 | 0.2282 a ±0.0011 | 0.1562 b ±0.0015 | 0.9330 c ±0.0071 | 0.0352 e ±0.0004 | 0.2406 c ±0.0009 | 12.1950 c ±0.1897 |

| 3 years old stem | 0.0056 a,c ±0.0009 | 0.2318 a ±0.0056 | 0.1440 c ±0.0007 | 0.8874 e ±0.0017 | 0.0464 c ±0.0009 | 0.2222 d ±0.0019 | 11.4421 d ±0.2845 |

| 6 years old whole tree | 0.0046 b,c ±0.0009 | 0.1946 c,d ±0.0082 | 0.1558 b ±0.0024 | 0.8306 f ±0.0138 | 0.0320 f ±0.0012 | 0.2022 e ±0.0013 | 12.5868 c ±0.2566 |

| 6 years old stem | 0.0028 d ±0.0011 | 0.1966 c ±0.0018 | 0.1058 e ±0.0043 | 0.9950 a ±0.0007 | 0.0418 d ±0.0013 | 0.1742 f ±0.0011 | 12.3915 c ±0.2021 |

| 9 years old whole tree | 0.0068 a ±0.0011 | 0.2028 b ±0.0011 | 0.2462 a ±0.0055 | 0.9470 b ±0.0102 | 0.0756 a ±0.0005 | 1.6852 a ±0.0018 | 14.4502 a ±0.1057 |

| 9 years old stem | 0.0044 b,c,d ±0.0005 | 0.1878 d ±0.0018 | 0.1308 d ±0.0029 | 0.9078 d ±0.0100 | 0.0678 b ±0.0011 | 0.3354 b ±0.0009 | 14.3222 b ±0.1020 |

| Biomass Source before Pelletization | LHV (MJ·kg−1) | Ash (%) | Ash Melting Point (°C) |

|---|---|---|---|

| 3 years old whole tree | 16.93 ±0.07 | 2.14 ±0.21 | 1438.2 ±3.11 |

| 3 years old stem | 17.07 ±0.15 | 2.97 ±0.22 | 1378.6 ±23.6 |

| 6 years old whole tree | 17.47 ±0.09 | 1.95 ±0.34 | 1377.0 ±6.8 |

| 6 years old stem | 16.72 ±0.34 | 2.39 ±0.21 | 1433.0 ±4.39 |

| 9 years old whole tree | 17.74 ±0.31 | 2.57 ±0.20 | 1406.0 ±4.42 |

| 9 years old stem | 16.35 ±0.32 | 2.42 ±0.13 | 1431.8 ±1.1 |

| Biomass Source before Pelletization | As (mg·kg−1) | Cd (mg·kg−1) | Cr (mg·kg−1) | Cu (mg·kg−1) | Pb (mg·kg−1) | Ni (mg·kg−1) | Zn (mg·kg−1) |

|---|---|---|---|---|---|---|---|

| 3 years old whole tree | 0.0018 ±0.0004 | 0.2222 ±0.0013 | 0.1522 ±0.0051 | 0.9126 ±0.0017 | 0.0256 ±0.0005 | 0.2226 ±0.0005 | 10.7319 ±0.1648 |

| 3 years old stem | 0.0056 ±0.0009 | 0.2328 ±0.0062 | 0.2292 ±0.0059 | 0.9193 ±0.0091 | 0.1008 ±0.0008 | 0.3434 ±0.0013 | 11.9100 ±0.0624 |

| 6 years old whole tree | 0.0058 ±0.0008 | 0.1912 ±0.0006 | 0.2072 ±0.0062 | 0.8707 ±0.0018 | 0.1338 ±0.1935 | 0.4136 ±0.0009 | 13.4410 ±0.1845 |

| 6 years old stem | 0.0120 ±0.0010 | 0.2050 ±0.0009 | 0.1448 ±0.0033 | 1.0230 ±0.0024 | 0.0654 ±0.0005 | 0.3366 ±0.0011 | 12.6780 ±0.1146 |

| 9 years old whole tree | 0.0070 ±0.0012 | 0.2064 ±0.0038 | 0.1242 ±0.0016 | 0.9782 ±0.0045 | 0.0750 ±0.0029 | 1.3270 ±0.0060 | 15.3179 ±0.3089 |

| 9 years old stem | 0.0046 ±0.0009 | 0.1866 ±0.0009 | 0.2026 ±0.0032 | 0.9099 ±0.0056 | 0.0688 ±0.0004 | 1.4142 ±0.0008 | 14.8296 ±0.2872 |

| Parameter | Refined | Pellet | Δ (%) | t-Value | DF | p-Value |

|---|---|---|---|---|---|---|

| LHV (MJ·kg−1) | 17.05 ± 0.52 | 17.72 ± 0.38 | +3.95 * | −5.959 | 58 | 0.001 |

| Ash content (%) | 2.41 ± 0.38 | 2.22 ± 0.43 | −7.88 | 1.819 | 58 | >0.05 |

| As (mg·kg−1) | 0.006 ± 0.003 | 0.005 ± 0.002 | −20.62 | 1.950 | 58 | >0.05 |

| Cd (mg·kg−1) | 0.207 ± 0.020 | 0.207 ± 0.018 | 0 | 0.088 | 58 | >0.05 |

| Cr (mg·kg−1) | 0.177 ± 0.039 | 0.156 ± 0.044 | −11.45 | 1.872 | 58 | >0.05 |

| Cu (mg·kg−1) | 0.936 ± 0.085 | 0.917 ± 0.053 | −2.03 | 1.404 | 58 | >0.05 |

| Pb (mg·kg−1) | 0.078 ± 0.079 | 0.049 ± 0.017 | −36.34 | 1.919 | 58 | >0.05 |

| Ni (mg·kg−1) | 0.676 ± 0.503 | 0.476 ± 0.552 | −29.52 | 1.463 | 58 | >0.05 |

| Zn (mg·kg−1) | 13.15 ± 2.023 | 12.90 ± 1.145 | −1.90 | 0.656 | 58 | >0.05 |

| Ash melting point (°C) | 1404.2 ± 38.2 | 1444.1 ± 25.2 | +2.84 * | −4.773 | 58 | 0.001 |

| Years | 3 | 6 | 9 | |||

|---|---|---|---|---|---|---|

| Type | Tree | Stem | Tree | Stem | Tree | Stem |

| Diameter | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Length | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Moisture content | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Ash content | □ | □ | ✓ | ✓ | □ | ✓ |

| LHV | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Bulk density | □ | □ | □ | □ | □ | □ |

| N | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| S | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| As | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Cd | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Cr | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Cu | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Pb | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Ni | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Zn | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Ash melting point | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

| Durability | ✓✓✓ | ✓✓ | ✓✓✓ | ✓✓ | □ | □ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles. Energies 2019, 12, 2973. https://doi.org/10.3390/en12152973

Civitarese V, Acampora A, Sperandio G, Assirelli A, Picchio R. Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles. Energies. 2019; 12(15):2973. https://doi.org/10.3390/en12152973

Chicago/Turabian StyleCivitarese, Vincenzo, Andrea Acampora, Giulio Sperandio, Alberto Assirelli, and Rodolfo Picchio. 2019. "Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles" Energies 12, no. 15: 2973. https://doi.org/10.3390/en12152973

APA StyleCivitarese, V., Acampora, A., Sperandio, G., Assirelli, A., & Picchio, R. (2019). Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles. Energies, 12(15), 2973. https://doi.org/10.3390/en12152973