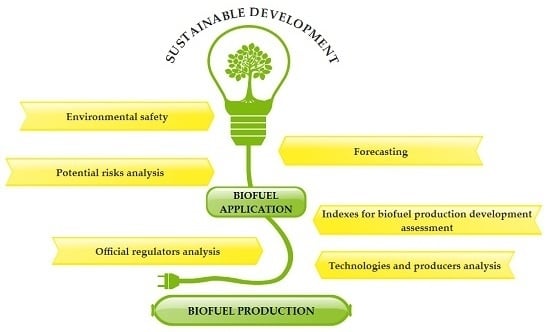

Biofuel Application as a Factor of Sustainable Development Ensuring: The Case of Russia

Abstract

:1. Introduction

2. Materials and Methods

3. General Trends of Biofuel Production Development and Some Prospectives for Russia (Research Background)

4. The Results of Analysis of Organisational and Economic Mechanisms Applied for Production of Biofuel in Russia: Status-Quo and Some Prospectives

4.1. Official Regulators and Participants of the Biofuel Market in Russia

4.2. Liquid Biofuel Producers

4.3. Producers and Consumers of Solid Biofuel

4.4. Producers and Consumers of Biogas

4.5. Prospects of Utilization of Algae and Wastewaters as Raw Material for Biofuel Production in Russia

4.6. Six Indexes for Assessment of the Biofuel Production Development

4.7. Application of the Proposed Indexes for Analysis of Potential Risks of Biofuel Production and Utilisation in Russia

5. Discussion

6. Conclusions

Acknowledgments

Conflicts of Interest

Abbreviation

| BF | Biofuel |

| REn | Renewable energy |

| TCE | Tons of coal equivalent |

| MW | Megawatt |

| HES | Heating electrical station |

| LFG | Landfill gas |

| JSC | Joint Stock Company |

| GW | Gigawatt |

| PJ | Petajoule |

| LLC | Limited Liability Company |

| BPP | Biogas power plant |

| GJ | Gigajoule |

| COD | Chemical oxygen demand |

References

- United Nations. Available online: https://www.un.org/sustainabledevelopment/ru/sustainable-development-goals/ (accessed on 20 June 2019).

- Ars Technica. Available online: https://arstechnica.com/science/2019/01/renewables-led-by-wind-provided-more-power-than-coal-in-germany-in-2018/ (accessed on 20 June 2019).

- GIS Renewable Energy Sources of Russia (GIS RESR). Available online: http://gisre.ru/tables#bio (accessed on 9 August 2019).

- Proskuryakova, L.N.; Ermolenko, G.V. The future of Russia’s renewable energy sector: Trends, scenarios and policies. Renew. Energy 2019, 143, 1670–1686. [Google Scholar] [CrossRef]

- Nuno, A.; John, F.A.S. How to ask sensitive questions in conservation: A review of specialized questioning techniques. Biol. Conserv. 2015, 189, 5–15. [Google Scholar] [CrossRef] [Green Version]

- Balagué, C.; de Valck, K. Using Blogs to Solicit Consumer Feedback: The Role of Directive Questioning Versus No Questioning. J. Interact. Mark. 2013, 27, 62–73. [Google Scholar] [CrossRef]

- Scoboria, A.; Memon, A.; Trang, H.; Frey, M. Improving responding to questioning using a brief retrieval training. J. Appl. Res. Mem. Cogn. 2013, 2, 210–215. [Google Scholar] [CrossRef]

- Bondarchuk, M.M. Questioning as a method of identifying requirements for qualifications of workers in the textile industry. Educ. Sci. Russ. Abroad 2019, 51, 98–101. [Google Scholar]

- Dolzhenko, Y.; Pozdnyakova, A. Online questionnaire survey as a modern and effective way of research. Transp. Bus. Russ. 2015, 1, 109–110. [Google Scholar]

- International Renewable Energy Agency (IRENA). Available online: http://resourceirena.irena.org/gateway/dashboard/?topic=4&subTopic=18 (accessed on 19 July 2019).

- International Renewable Energy Agency (IRENA). Available online: http://resourceirena.irena.org/gateway/dashboard/?topic=4&subTopic=16 (accessed on 19 July 2019).

- International Renewable Energy Agency (IRENA). REMAP 2030. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2017/Apr/IRENA_REmap_Russia_paper_2017.pdf (accessed on 19 July 2019).

- Renewable Energy Policy Network for the 21st Century (REN21). Renewables 2018. Global Status Report. Available online: http://www.ren21.net/gsr-2018/chapters/chapter_01/chapter_01/#sub_4 (accessed on 17 June 2019).

- Il`enkova, S.D.; Gohberg, L.M.; Kuznecov, V.I.; Yagudin, S.Y. Innovation Management; Moscow International Institute of Econometrics, Informatics, Finance and Law: Moscow, Russia, 2003. [Google Scholar]

- Dutta, S.; Reynoso, R.E.; Bernard, A.L. The Global Innovation Index 2015: Effective Innovation Policies for Development. Available online: https://www.wipo.int/edocs/pubdocs/en/wipo_pub_gii_2015-chapter1.pdf (accessed on 23 July 2019).

- Global Innovation Index 2018. Annex 2—Adjustments to the Global Innovation Index Framework and Year-on-Year Comparability of Results. Available online: https://www.wipo.int/edocs/pubdocs/en/wipo_pub_gii_2018-annex2.pdf (accessed on 23 July 2019).

- Crespo, N.F.; Crespo, C.F. Global innovation index: Moving beyond the absolute value of ranking with a fuzzy-set analysis. J. Bus. Res. 2016, 69, 5265–5271. [Google Scholar] [CrossRef]

- National Innovation Report in Russia. Available online: https://www.rvc.ru/upload/iblock/c64/RVK_innovation_2017.pdf (accessed on 23 July 2019).

- Aleskerov, F.; Egorova, L.; Gokhberg, L.; Myachin, A.; Sagieva, G. Pattern Analysis in the Study of Science, Education and Innovative Activity in Russian Regions. Procedia Comput. Sci. 2013, 17, 687–694. [Google Scholar] [Green Version]

- Miremadi, I.; Saboohi, Y.; Jacobsson, S. Assessing the performance of energy innovation systems: Towards an established set of indicators. Energy Res. Soc. Sci. 2018, 40, 159–176. [Google Scholar] [CrossRef]

- Binz, C.; Truffer, B. Global Innovation Systems—A conceptual framework for innovation dynamics in transnational contexts. Res. Policy 2017, 46, 1284–1298. [Google Scholar] [CrossRef]

- Janger, J.; Schubert, T.; Andries, P.; Rammer, C.; Hoskens, M. The EU 2020 innovation indicator: A step forward in measuring innovation outputs and outcomes? Res. Policy 2017, 46, 30–42. [Google Scholar] [CrossRef] [Green Version]

- Dziallas, M.; Blind, K. Innovation indicators throughout the innovation process: An extensive literature analysis. Technovation 2019, 80–81, 3–29. [Google Scholar] [CrossRef]

- Dong, J.; Xue, G.; Feng, T.; Liu, D. System Dynamics Modelling of Renewable Power Generation Investment Decisions under Risk. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 1–10. [Google Scholar]

- Pries, F.; Talebi, A.; Schillo, R.S.; Lemay, M.A. Risks affecting the biofuels industry: A US and Canadian company perspective. Energy Policy 2016, 97, 93–101. [Google Scholar] [CrossRef]

- Abdullah, B.; Muhammad, S.A.F.S.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Kulikova, E.E. Risk Management. Innovation Aspect; Berator-Publishing: Moscow, Russia, 2008. [Google Scholar]

- Gokhberg, L.; Sokolov, A. Technology foresight in Russia in historical evolutionary perspective. Technol. Forecast. Soc. 2017, 119, 256–267. [Google Scholar] [CrossRef]

- Hu, R.; Skea, J.; Hannon, M.J. Measuring the energy innovation process: An indicator framework and a case study of wind energy in China. Technol. Forecast. Soc. 2018, 127, 227–244. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Lopes, M.L.; Paulillo, S.C.; Godoy, A.; Cherubin, R.A.; Lorenzi, M.S.; Giometti, F.H.; Bernardino, C.D.; Amorim Neto, H.B.; Amorim, H.V. Ethanol production in Brazil: A bridge between science and industry. Braz. J. Microbiol. 2016, 47, 64–76. [Google Scholar] [CrossRef]

- Saracevic, E.; Frühauf, S.; Miltner, A.; Karnpakdee, K.; Munk, B.; Lebuhn, M.; Wlcek, B.; Leber, J.; Lizasoain, J.; Friedl, A.; et al. Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities. Energies 2019, 12, 2678. [Google Scholar] [CrossRef]

- Robak, K.; Balcerek, M. Review of Second Generation Bioethanol Production from Residual Biomass. Food Technol. Biotechnol. 2018, 56, 174–187. [Google Scholar] [CrossRef] [PubMed]

- Castro, R.C.A.; Ferreira, I.S.; Roberto, I.C.; Mussatto, S.I. Isolation and physicochemical characterization of different lignin streams generated during the second-generation ethanol production process. Int. J. Biol. Macromol. 2019, 129, 497–510. [Google Scholar] [CrossRef] [PubMed]

- Ruiz Olivares, A.; Carrillo-González, R.; del Carmen A. González-Chávez, M.; Soto Hernandez, R.M. Potential of castor bean (Ricinus communis L.) for phytoremediation of mine tailings and oil production. J. Environ. Manag. 2013, 114, 316–323. [Google Scholar] [CrossRef] [PubMed]

- Moncada, J.; Cardona, C.A.; Rincon, L.E. Design and analysis of a second and third generation biorefinery: The case of castorbean and microalgae. Bioresour. Technol. 2015, 198, 836–843. [Google Scholar] [CrossRef]

- Titova, E.; Bondarchuk, N.; Romanova, E. Economic aspects of plants cultivation used as raw materials for biofuel production. Int. Agric. J. 2017, 1, 54–61. [Google Scholar]

- Miskolczi, N.; Buyong, F.; Angyal, A.; Williams, P.T.; Bartha, L. Two stages catalytic pyrolysis of refuse derived fuel: Production of biofuel via syncrude. Bioresour. Technol. 2010, 101, 8881–8890. [Google Scholar] [CrossRef]

- Islam, Z.U.; Yu, Z.; Hassan, E.B.; Chang, D.; Zhang, H. Microbial conversion of pyrolytic products to biofuels: A novel and sustainable approach toward second-generation biofuels. J. Ind. Microbiol. Biotechnol. 2015, 42, 1557–1579. [Google Scholar] [CrossRef]

- Sarsekeyeva, F.; Zayadan, B.K.; Usserbaeva, A.; Bedbenov, V.S.; Sinetova, M.A.; Los, D.A. Cyanofuels: Biofuels from Cyanobacteria. Reality and perspectives. Photosynth. Res. 2015, 125, 329–340. [Google Scholar] [CrossRef]

- Chen, W.H.; Lin, B.J.; Huang, M.Y.; Chang, J.S. Thermochemical conversion of microalgal biomass into biofuels: A review. Bioresour. Technol. 2015, 184, 314–327. [Google Scholar] [CrossRef]

- Wang, Y.; Ho, S.H.; Yen, H.W.; Nagarajan, D.; Ren, N.Q.; Li, S.; Hu, Z.; Lee, D.J.; Kondo, A.; Chang, J.S. Current advances on fermentative biobutanol production using third generation feedstock. Biotechnol. Adv. 2017, 35, 1049–1059. [Google Scholar] [CrossRef]

- Lakatos, G.E.; Ranglova, K.; Manoel, J.C.; Grivalsky, T.; Kopecky, J.; Masojidek, J. Bioethanol production from microalgae polysaccharides. Folia Microbiol. (Praha) 2019, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Abo, B.O.; Odey, E.A.; Bakayoko, M.; Kalakodio, L. Microalgae to biofuels production: A review on cultivation, application and renewable energy. Rev. Environ. Health 2019, 34, 91–99. [Google Scholar] [CrossRef] [PubMed]

- Farrokh, P.; Sheikhpour, M.; Kasaeian, A.; Asadi, H.; Bavandi, R. Cyanobacteria as an eco-friendly resource for biofuel production: A critical review. Biotechnol. Prog. 2019, 35, e2835. [Google Scholar] [CrossRef] [PubMed]

- Vo Hoang Nhat, P.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Nguyen, P.D.; Bui, X.T.; Zhang, X.B.; Guo, J.B. Can algae-based technologies be an affordable green process for biofuel production and wastewater remediation? Bioresour. Technol. 2018, 256, 491–501. [Google Scholar] [CrossRef]

- McLeod, C.; Nerlich, B.; Mohr, A. Working with bacteria and putting bacteria to work: The biopolitics of synthetic biology for energy in the United Kingdom. Energy Res. Soc. Sci. 2017, 30, 35–42. [Google Scholar] [CrossRef]

- Schlör, H.; Venghaus, S.; Märker, C.; Hake, J.F. Managing the resilience space of the German energy system—A vector analysis. J. Environ. Manag. 2018, 218, 527–539. [Google Scholar] [CrossRef]

- Golberg, A.; Sack, M.; Teissie, J.; Pataro, G.; Pliquett, U.; Saulis, G.; Stefan, T.; Miklavcic, D.; Vorobiev, E.; Frey, W. Energy-efficient biomass processing with pulsed electric fields for bioeconomy and sustainable development. Biotechnol. Biofuels 2016, 9, 94. [Google Scholar] [CrossRef]

- Leksin, V.N.; Porfiryev, B.N. Socio-Economic Priorities of Sustainable Development of Russian Arctic Macro-Region. Econ. Reg. 2017, 13, 985–1004. [Google Scholar] [CrossRef]

- Kuzmenkova, V.D. Sustainable development of Russian regions. Proc. Vor. State Univ. Eng. Technol. 2016, 2, 257–261. [Google Scholar] [CrossRef]

- Bondarchuk, N.V.; Titova, E.S. Renewable energy prospects as one of sustainable development direction in some South Russian regions. South Russ. Ecol. Dev. 2017, 4, 12–31. [Google Scholar] [CrossRef]

- Mulko, L.; Rivarola, C.R.; Barbero, C.A.; Acevedo, D.F. Bioethanol production by reusable Saccharomyces cerevisiae immobilized in a macroporous monolithic hydrogel matrices. J. Biotechnol. 2016, 233, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Alalwan, H.A.; Alminshid, A.H.; Aljaafari, H.A.S. Promising evolution of biofuel generations. Subject review. Renew. Energy Focus 2019, 28, 127–139. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Laker, F.; Agaba, A.; Akatukunda, A.; Gazet, R.; Barasa, J.; Nanyonga, S.; Wendiro, D.; Wacoo, A.P. Utilization of Solid Waste as a Substrate for Production of Oil from Oleaginous Microorganisms. J. Lipids 2018, 2018, 1578720. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Withers, M.R.; Seifkar, N.; Field, R.P.; Barrett, S.R.; Herzog, H.J. Biomass logistics analysis for large scale biofuel production: Case study of loblolly pine and switchgrass. Bioresour. Technol. 2015, 183, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Purohit, P.; Chaturvedi, V. Biomass pellets for power generation in India: A techno-economic evaluation. Environ. Sci. Pollut. Res. Int. 2018, 25, 29614–29632. [Google Scholar] [CrossRef]

- Rafaj, P.; Kiesewetter, G.; Gul, T.; Schopp, W.; Cofala, J.; Klimont, Z.; Purohit, P.; Heyesa, C.; Amann, M.; Borken-Kleefeld, J.; et al. Outlook for clean air in the context of sustainable development goals. Glob. Environ. Chang. 2018, 53, 1–11. [Google Scholar] [CrossRef]

- Lyng, K.-A.; Brekke, A. Environmental Life Cycle Assessment of Biogas as a Fuel for Transport Compared with Alternative Fuels. Energies 2019, 12, 532. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of high-value food waste and food residues biorefineries with focus on unavoidable wastes from processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A. Italian Biogas Plants: Trend, Subsidies, Cost, Biogas Composition and Engine Emissions. Energies 2019, 12, 979. [Google Scholar] [CrossRef]

- He, K.; Zhang, J.; Zeng, Y. Knowledge domain and emerging trends of agricultural waste management in the field of social science: A scientometric review. Sci. Total Environ. 2019, 670, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Sun, Q.; Wang, W.; Lu, L.; Liu, M.; Li, J.; Yang, S.; Sun, Y.; Zhang, K.; Xu, J.; et al. Utilizations of agricultural waste as adsorbent for the removal of contaminants: A review. Chemosphere 2018, 211, 235–253. [Google Scholar] [CrossRef] [PubMed]

- Enes, T.; Aranha, J.; Fonseca, T.; Lopes, D.; Alves, A.; Lousada, J. Thermal Properties of Residual Agroforestry Biomass of Northern Portugal. Energies 2019, 12, 1418. [Google Scholar] [CrossRef]

- Yang, X.J.; Hu, H.; Tan, T.; Li, J. China’s renewable energy goals by 2050. Environ. Dev. 2016, 20, 83–90. [Google Scholar] [CrossRef]

- Liu, J. China’s renewable energy law and policy: A critical review. Renew. Sustain. Energy Rev. 2019, 99, 212–219. [Google Scholar] [CrossRef]

- Rueda-Bayona, J.G.; Guzmán, A.; Cabello Eras, J.J.; Silva-Casarín, R.; Bastidas-Arteaga, E.; Horrillo-Caraballo, J. Renewables energies in Colombia and the opportunity for the offshore wind technology. J. Clean. Prod. 2019, 220, 529–543. [Google Scholar] [CrossRef]

- Bórawski, P.; Bełdycka-Bórawska, A.; Szymańska, E.J.; Jankowski, K.J.; Dubis, B.; Dunn, J.W. Development of renewable energy sources market and biofuels in The European Union. J. Clean. Prod. 2019, 228, 467–484. [Google Scholar] [CrossRef]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment: Updated Bioeconomy Strategy. Available online: https://ec.europa.eu/research/bioeconomy/pdf/ec_bioeconomy_strategy_2018.pdf (accessed on 23 February 2019).

- Baral, N. What socio-demographic characteristics predict knowledge of biofuels. Energy Policy 2018, 122, 369–376. [Google Scholar] [CrossRef]

- Liu, B.; Shumway, C.R.; Yoder, J.K. Lifecycle economic analysis of biofuels: Accounting for economic substitution in policy assessment. Energy Econ. 2017, 67, 146–158. [Google Scholar] [CrossRef]

- Nugroho, Y.K.; Zhu, L. Platforms planning and process optimization for biofuels supply chain. Renew. Energy 2019, 140, 563–579. [Google Scholar] [CrossRef]

- Ratner, S.V.; Ratner, M.D. Developing Regional Environmental Management Models in Compliance with the Innovative Format of ISO 14001:2015. Dig. Financ. 2017, 22, 163–174. [Google Scholar] [CrossRef]

- Chen, R.; Qin, Z.; Han, J.; Wang, M.; Taheripour, F.; Tyner, W.; O’Connor, D.; Duffield, J. Life cycle energy and greenhouse gas emission effects of biodiesel in the United States with induced land, use change impacts. Bioresour. Technol. 2018, 251, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012. [Google Scholar] [CrossRef] [Green Version]

- Esteves, E.M.M.; Herrera, A.M.N.; Peçanha Esteves, V.P.; Rosário Vaz Morgado, C. Life cycle assessment of manure biogas production: A review. J. Clean. Prod. 2019, 219, 411–423. [Google Scholar] [CrossRef]

- Russia Renewable Energy Development Association. Available online: https://rreda.ru/bulletin (accessed on 8 August 2019).

- Budzianowski, W.M.; Budzianowska, D.A. Economic analysis of biomethane and bioelectricity generation from biogas using different support schemes and plant configurations. Energy 2015, 88, 658–666. [Google Scholar] [CrossRef]

- Budzianowski, W.M. A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energy Rev. 2016, 54, 1148–1171. [Google Scholar] [CrossRef]

- Ruiz, D.; San Miguel, G.; Corona, B.; Gaitero, A.; Domínguez, A. Environmental and economic analysis of power generation in a thermophilic biogas plant. Sci. Total Environ. 2018, 633, 1418–1428. [Google Scholar] [CrossRef]

- Mustapha, W.F.; Trømborg, E.; Bolkesjø, T.F. Forest-based biofuel production in the Nordic countries: Modelling of optimal allocation. For. Policy Econ. 2019, 103, 45–54. [Google Scholar] [CrossRef]

- Nutongkaew, P.; Waewsak, J.; Riansut, W.; Kongruang, C.; Gagnon, Y. The potential of palm oil production as a pathway to energy security in Thailand. Sustain. Energy Technol. 2019, 35, 189–203. [Google Scholar] [CrossRef]

- de Jong, S.; Hoefnagels, R.; Wetterlund, E.; Pettersson, K.; Faaij, A.; Junginger, M. Cost optimization of biofuel production—The impact of scale, integration, transport and supply chain configurations. Appl. Energy 2017, 195, 1055–1070. [Google Scholar] [CrossRef]

- Brosowski, A.; Krause, T.; Mantau, U.; Mahro, B.; Noke, A.; Richter, F.; Raussen, T.; Bischof, R.; Hering, T.; Blanke, C.; et al. How to measure the impact of biogenic residues, wastes and by-products: Development of a national resource monitoring based on the example of Germany. Biomass Bioenergy 2019, 127, 105275. [Google Scholar] [CrossRef]

- Tanzer, S.E.; Posada, J.; Geraedts, S.; Ramírez, A. Lignocellulosic marine biofuel: Technoeconomic and environmental assessment for production in Brazil and Sweden. J. Clean. Prod. 2019, 239, 117845. [Google Scholar] [CrossRef]

- Matraeva, L.; Solodukha, P.; Erokhin, S.; Babenko, M. Improvement of Russian energy efficiency strategy within the framework of “green economy” concept (based on the analysis of experience of foreign countries). Energy Policy 2019, 125, 478–486. [Google Scholar] [CrossRef]

- Popel, O.S. Renewable energy sources: The role and place in modern and promising energy. Russ. Chem. J. 2008, 6, 95–106. [Google Scholar]

- Ministry of Energy of Russian Federation. Available online: https://minenergo.gov.ru/node/987 (accessed on 8 August 2019).

- Ministry of Economic Development of the Russian Federation. Available online: http://economy.gov.ru/minec/activity/sections (accessed on 8 August 2019).

- Ministry of Natural Resources and Environment of the Russian Federation. Available online: http://www.mnr.gov.ru/docs/ (accessed on 8 August 2019).

- Ministry of Industry and Trade of the Russian Federation. Available online: http://minpromtorg.gov.ru/projects/general/ (accessed on 8 August 2019).

- Vyborg Forestry Development Corporation. Available online: http://vfdc.ru/ru (accessed on 17 August 2019).

- LLC “AltEnergo”. Biogas Station. Available online: http://altenergo.su/biogas/ (accessed on 21 June 2019).

- Sun, L.; Niquidet, K. Elasticity of import demand for wood pellets by the European Union. For. Policy Econ. 2017, 81, 83–87. [Google Scholar] [CrossRef]

- Pristupa, A.O.; Mol, A.P.J. Renewable energy in Russia: The take off in solid bioenergy? Renew. Sustain. Energy Rev. 2015, 50, 315–324. [Google Scholar] [CrossRef] [Green Version]

- Technological Platform “Bioenergy”. Available online: http://www.tp-bioenergy.ru/about/management/ (accessed on 25 July 2019).

- Technological Platform “Bioindustry and Bioresources” (BioTech2030). Available online: http://biotech2030.ru/deyatelnost/ (accessed on 25 July 2019).

- Agency for Strategic Initiatives. Available online: https://asi.ru/about_agency/ (accessed on 31 July 2019).

- Russian Biofuel Association (RBA). Available online: http://www.biotoplivo.ru/o-nas/ (accessed on 25 July 2019).

- ENBIO. Association of Biofuel Market Participants. Available online: http://enbio.ru/rubric/novosti (accessed on 25 July 2019).

- Federal Law of Russian Federation No. 35-FZ of March 26, 2003 “On Electric Energy”. Available online: http://www.consultant.ru/document/cons_doc_LAW_41502/ (accessed on 16 August 2019).

- Decree of the Russian Federation Government of November 13, 2009 No. 1715-r “On the Energy Strategy of Development of Russia before 2030”. Available online: https://www.garant.ru/products/ipo/prime/doc/96681/ (accessed on 11 June 2019).

- Federal Law of Russian Federation No. 171-FZ of November 22, 1995 “On Amendments in the State Regulation of Production and Turnover of Ethyl Alcohol, Alcoholic and Alcohol-Containing Products and Restriction of Alcoholic Products Consumption”. Available online: http://www.consultant.ru/document/cons_doc_LAW_8368/ (accessed on 16 August 2019).

- Federal Law of Russian Federation No. 448-FZ of November 28, 2018 “On State Regulation of Production and Turnover of Ethyl Alcohol, Alcoholic and Alcohol-containing Products and Restriction of Alcoholic Products Consumption”. Available online: http://www.consultant.ru/document/cons_doc_LAW_312102/ (accessed on 16 August 2019).

- Decree of the Russian Federation Government No. 1145 of September 27, 2018 “On Amending of Certain Acts of the Government of the Russian Federation Regarding the Promotion of the Use of Renewable Energy Sources”. Available online: http://www.consultant.ru/document/cons_doc_LAW_307870/ (accessed on 1 June 2019).

- Ministry of Energy of Russian Federation. News Report “Alexander Novak Report on the Development of Energy Efficiency and Energy Saving”. Available online: https://minenergo.gov.ru/node/9591 (accessed on 8 August 2019).

- Draft of the Decree of the Russian Federation Government “On Approval of the List of Key (Basic) Indicators of Public Non-Financial Accounting”. Available online: http://www.consultant.ru/cons/cgi/online.cgi?req=doc;base=PNPA;n=46279#08990458648385347 (accessed on 11 June 2019).

- Decree of the Russian Federation Government of April 2, 2014 No. 504-r “On Approval of an Action Plan to Ensure by 2020 the Reduction of Greenhouse Gas Emissions to No More Than 75 Percent of the Volume of These Emissions in 1990”. Available online: http://www.consultant.ru/document/cons_doc_LAW_161475/ (accessed on 11 June 2019).

- Order of the Russian Federation Government of November 3, 2018 No. 2381-r “On Amendments to the Federal Law “On Electric Power” Regarding the Development of Micro-Generation”. Available online: http://government.ru/activities/selection/301/34594/ (accessed on 11 June 2019).

- Acheampong, M.; Ertem, F.C.; Kappler, B.; Neubauer, P. In pursuit of Sustainable Development Goal (SDG) number 7: Will biofuels be reliable? Renew. Sustain. Energy Rev. 2017, 75, 927–937. [Google Scholar] [CrossRef]

- Tsita, K.G.; Kiartzis, S.J.; Ntavos, N.K.; Pilavachi, P.A. Next generation biofuels derived from thermal and chemical conversion of the Greek transport sector. Therm. Sci. Eng. Prog. 2019, 100387. [Google Scholar] [CrossRef]

- Boboescu, I.Z.; Chemarin, F.; Beigbeder, J.-B.; de Vasconcelos, B.R.; Munirathinam, R.; Ghislain, T.; Lavoie, J.-M. Making next-generation biofuels and biocommodities a feasible reality. Curr. Opin. Green Sustain. Chem. 2019, 20, 25–32. [Google Scholar] [CrossRef]

- Sun, C.H.; Fu, Q.; Liao, Q.; Xia, A.; Huang, Y.; Zhu, X.; Reungsang, A.; Chang, H.-X. Life-cycle assessment of biofuel production from microalgae via various bioenergy conversion systems. Energy 2019, 171, 1033–1045. [Google Scholar] [CrossRef]

- Resolution of the Government of Russian Federation No. 326 of April 15, 2014 “On Approval of the State Environmental Protection Program for 2012–2020”. Available online: http://www.consultant.ru/document/cons_doc_LAW_162183/ (accessed on 21 May 2019).

- Order of the Ministry of Natural Resources and Ecology of the Russian Federation of August 14, 2013 No. 298 “On Approval of a Comprehensive Strategy for the Treatment of Solid Municipal (Household) Waste in the Russian Federation”. Available online: https://www.garant.ru/products/ipo/prime/doc/70345114/ (accessed on 11 June 2019).

- Namsaraev, Z.B.; Gotovtsev, P.M.; Komova, A.V.; Vasilov, R.G. Current status and potential of bioenergy in the Russian Federation. Renew. Sustain. Energy Rev. 2018, 81, 625–634. [Google Scholar] [CrossRef]

- Decree of the Russian Federation Government No. 337-r of February 28, 2018 “On Approval of the Action Plan (“Road Map”) “Development of Biotechnologies and Gene Engineering” for 2018–2020”. Available online: http://www.garant.ru/products/ipo/prime/doc/71792682/ (accessed on 11 June 2019).

- Federal Law Draft “On Amending Article 217 of the Tax Code of the Russian Federation”. Available online: http://government.ru/activities/selection/302/37660/ (accessed on 21 July 2019).

- Moscow State University. Available online: https://www.msu.ru/science/sci-dir-1.html (accessed on 8 August 2019).

- Joint Institute for High Temperatures of the Russian Academy of Sciences. Available online: https://jiht.ru/science/ (accessed on 8 August 2019).

- The Federal Research Centre “Fundamentals of Biotechnology” of the Russian Academy of Sciences (Research Center of Biotechnology RAS). Available online: https://www.fbras.ru/napravleniya-nauchnyx-issledovanij/nauchnaya-deyatelnost (accessed on 25 July 2019).

- National Research Center “Kurchatov Institute”. Available online: http://www.nrcki.ru/catalog/index.shtml?g_show=7732&path=3977,7732 (accessed on 8 August 2019).

- National University of Oil and Gas “Gubkin University”. Available online: https://gubkin.ru/faculty/chemical_and_environmental/chairs_and_departments/general_and_inorganic_chemistry/ (accessed on 8 August 2019).

- University MEPhI (Moscow Engineering Physics Institute). Available online: https://mephi.ru/science/osnovnye_nauchnye_napravleniya.php (accessed on 8 August 2019).

- Moscow Polytechnic University. Available online: https://mospolytech.ru/index.php?id=7 (accessed on 8 August 2019).

- Decree of Ministry of Labor and Social Protection of Russian Federation No. 1047n of December 21, 2015 “On Approval of the Professional Standard “Specialist in the Organization of Bioenergy and Biofuel Production”. Available online: http://base.garant.ru/71312996/ (accessed on 14 June 2019).

- Order of the Russian Federation Government of August 11, 2011 No. 1393-r “On the Establishment of an Autonomous Non-Profit Organization “Agency of Strategic Initiatives for Promoting New Projects”. Available online: https://asi.ru/upload/medialibrary/3e7/1393-upd2.pdf (accessed on 15 June 2019).

- EnergyNet. Available online: http://www.nti2035.ru/markets/energynet (accessed on 31 July 2019).

- Decree of the Russian Federation Government No. 830-r of April 28, 2018 “On Approval of the Plan “Roadmap” to Legislation Improving and Administrative Barriers Removing to Ensure the Implementation of the National Technology Initiative “EnergyNet”. Available online: http://government.ru/docs/32548/ (accessed on 31 May 2019).

- Association “Nonprofit Partnership Council for Organizing Efficient System of Trading at Wholesale and Retail Electricity and Capacity Market” (Association “NP Market Council”). Available online: https://www.np-sr.ru/ru/market/vie/index.htm (accessed on 14 June 2019).

- Trading System Administrator of Wholesale Electricity Market Transactions (TSA). Available online: http://www.atsenergo.ru/vie (accessed on 14 June 2019).

- Global Energy. Association for the Development of International Research and Projects in the Field of Energy. Available online: https://globalenergyprize.org/ru/about-us/about-us (accessed on 25 July 2019).

- Ministry of Economic Development of the Republic of North Ossetia-Alania. Available online: http://economy.alania.gov.ru/news/278 (accessed on 14 June 2019).

- Interstate Standard (GOST 33872-2016). Fuel Denatured Bioethanol; Standartinform: Moscow, Russia, 2017; Available online: http://docs.cntd.ru/document/1200145331 (accessed on 11 June 2019).

- Interstate Standard (GOST 33131-2014). Mixtures of Biodiesel (B6–B20); Standartinform: Moscow, Russia, 2016; Available online: http://docs.cntd.ru/document/1200121053 (accessed on 11 June 2019).

- Interstate Standard (GOST 33113-2014). B100 Basic Biodiesel Fuel and Biodiesel Mixtures; Standartinform: Moscow, Russia, 2016; Available online: http://docs.cntd.ru/document/1200121050 (accessed on 11 June 2019).

- Ershov, M.A.; Grigoreva, E.V.; Habibullin, I.F.; Emelyanov, V.E.; Strekalina, D.M. Prospects of bioethanol fuels E30 and E85 application in Russia and technical requirements for their quality. Renew. Sustain. Energy Rev. 2016, 66, 228–232. [Google Scholar] [CrossRef]

- Joseph, O.O.; Loto, C.A.; Joseph, O.O.; Dirisu, J.O. Comparative Assessment of the Degradation Behaviour of API 5l X65 And Micro-Alloyed Steels in E20 Simulated Fuel Ethanol Environment. Energy Procedia 2019, 157, 1320–1327. [Google Scholar] [CrossRef]

- Johansen, L.C.R.; Hemdal, S.; Denbratt, I. Comparison of E10 and E85 spark ignited stratified combustion and soot formation. Fuel 2017, 205, 11–23. [Google Scholar] [CrossRef]

- Tao, J.; Yu, S.; Wu, T. Review of China’s bioethanol development and a case study of fuel supply, demand and distribution of bioethanol expansion by national application of E10. Biomass Bioenergy 2011, 35, 3810–3829. [Google Scholar] [CrossRef]

- Yusri, I.M.; Mamat, R.; Najafi, G.; Razman, A.; Awad, I.O.; Azmi, W.H.; Ishak, W.F.W.; Shaiful, A.I.M. Alcohol based automotive fuels from first four alcohol family in compression and spark ignition engine: A review on engine performance and exhaust emissions. Renew. Sustain. Energy Rev. 2017, 77, 169–181. [Google Scholar] [CrossRef] [Green Version]

- Group of Companies “Titan”. Available online: http://www.titan-group.ru/about/ (accessed on 21 August 2019).

- Osmakova, A.; Kirpichnikov, M.; Popov, V. Recent biotechnology developments and trends in the Russian Federation. New Biotechnol. 2018, 40, 76–81. [Google Scholar] [CrossRef]

- ETB “Catalytic Technologies”. Available online: http://www.etbcat.com/technology/ (accessed on 17 August 2019).

- Proskurina, S.; Heinimö, J.; Mikkilä, M.; Vakkilainen, E. The wood pellet business in Russia with the role of North-West Russian regions: Present trends and future challenges. Renew. Sustain. Energy Rev. 2015, 51, 730–740. [Google Scholar] [CrossRef]

- Resolution of the Government of Russia No. 1989-p of September 20, 2018 “On Approval of the Timber Complex of Russia Development Strategy until 2030”. Available online: http://government.ru/docs/34064/ (accessed on 15 March 2019).

- Rakitova, O.; Kholodkov, V. Final Report of the Pellet Market and Wood Resources in the North-West of Russian; Baltic 21 Lighthouse Project, the Baltic Sea Bioenergy Promotion Project; Biocenter: Saint-Petersburg, Russia, 2009. [Google Scholar]

- Pirus, M. Working on the future: Congress and exhibition “Biomass: Fuel and energy”. Lesprominform 2018, 4, 134–137. [Google Scholar]

- Committee on the Fuel and Energy Complex of the Leningrad Region. Available online: http://power.lenobl.ru/o-komitete/informatsionnye-sistemy/modul-gis-energoeffektivnost/ (accessed on 21 July 2019).

- The Renewable Materials Company “STORAENSO”. Available online: https://www.storaenso.com/ (accessed on 20 July 2019).

- INFOBIO. News Reports “Annually in the Arkhangelsk Region Introduced by Several Biofuel Boiler Houses”. Available online: http://www.infobio.ru/news/4577.html (accessed on 19 July 2019).

- Resolution of the Arkhangelsk Region Government of October 15, 2013 No. 487-pp “On Approval of the State Program of the Arkhangelsk Region “Development of Energy and Housing and Communal Services of the Arkhangelsk Region (2014–2024)”. Available online: http://docs.cntd.ru/document/462608457 (accessed on 14 June 2019).

- INFOBIO. News Reports “One More Pellet Production to Appear in Irkutsk Region”. Available online: http://www.infobio.ru/news/4586.html (accessed on 4 August 2019).

- INFOBIO. News Reports “In the Territory of the Krasnoyarsk Region Biofuels Apply to 41 Boiler”. Available online: http://www.infobio.ru/news/4589.html (accessed on 4 August 2019).

- Perederyi, S. And again about torrefaction. Borreal BioEnergy sawmill acquires for the production of black pellets. Lesprominform 2019, 4, 148–149. [Google Scholar]

- ROSTEPLO. Biogas Station “Luchki” Showed Historic Maximum Power Generation. Available online: http://www.rosteplo.ru/news/2018/02/20/1519067728-biogazovaya-stanciya-luchki-pokazala-istoricheskij (accessed on 15 June 2019).

- Resolution of the Belgorod Region Governor No. 52 of April 25, 2018 “On Approval of the Scheme and Program for the Development of the Electric Power Industry of the Belgorod Region for 2019–2023”. Available online: http://publication.pravo.gov.ru/Document/View/3100201804280001 (accessed on 14 June 2019).

- Akimova, V.V. Institutional factor of renewable energy development in the Belgorod Region. Bull. Mosc. Univ. (Ser. 5 Geogr.) 2017, 6, 18–24. [Google Scholar]

- Decree of the Belgorod Region Government No. 427-pp of October 29, 2012 “On Approving of the Long-Term Target Program “Development of Renewable Energy Sources for 2013–2015 and for the Period until 2020”. Available online: http://base.garant.ru/26350607/ (accessed on 14 June 2019).

- Decree of the Belgorod Region Government No. 475-pp of November 25, 2013 “On Amendments to the Belgorod Region Government No. 427-pp of October 29, 2012”. Available online: http://docs.cntd.ru/document/428669040#loginform (accessed on 14 June 2019).

- Order of the Belgorod Region Government No. 574-rp of December 8, 2014 “On Approving the Concept for the Development of Small Distributed Energy in the Belgorod Region until 2025”. Available online: http://altenergo-nii.ru/docs/574-rp.pdf (accessed on 14 June 2019).

- Decree of the Head of the Administration of the Tambov Region of April 25, 2018 No. 107 “On Approval of the Concept and Program of Electric Energy development in Tambov Region in 2019–2023”. Available online: http://gkh.tmbreg.ru/DOC/Pravo/2018/PGAO_107.pdf (accessed on 14 June 2019).

- Joint Stock Company “Biokhim” (JSC “Biokhim”). Available online: http://biohim68rsk.ucoz.ru (accessed on 14 May 2019).

- Decree of the Lipetsk Region Administration No. 319 of April 23, 2018 “On the Approval of Schemes and Programs for the Development of the Electric Power Industry of the Lipetsk region for 2019–2023”. Available online: http://publication.pravo.gov.ru/Document/View/4800201804250001 (accessed on 14 June 2019).

- Lang-Yona, N.; Kunert, A.T.; Vogel, L.; Kampf, C.J.; Bellinghausen, I.; Saloga, J.; Schink, A.; Ziegler, K.; Lucas, K.; Schuppan, D.; et al. Fresh water, marine and terrestrial Cyanobacteria display distinct allergen characteristics. Sci. Total Environ. 2018, 612, 767–774. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Parihar, P.; Singh, M.; Bajguz, A.; Kumar, J.; Singh, S.; Singh, V.P.; Prasad, S.M. Uncovering Potential Applications of Cyanobacteria and Algal Metabolites in Biology, Agriculture and Medicine: Current Status and Future Prospects. Front. Microbiol. 2017, 8, 515. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luan, G.; Lu, X. Tailoring cyanobacterial cell factory for improved industrial properties. Biotechnol. Adv. 2018, 36, 430–442. [Google Scholar] [CrossRef]

- Taparia, T.; Mvss, M.; Mehrotra, R.; Shukla, P.; Mehrotra, S. Developments and challenges in biodiesel production from microalgae: A review. Biotechnol. Appl. Biochem. 2016, 63, 715–726. [Google Scholar] [CrossRef]

- Chena, J.; Li, J.; Dong, W.; Zhang, X.; Tyagi, R.D.; Drogui, P.; Surampalli, R.Y. The potential of microalgae in biodiesel production. Renew. Sustain. Energy Rev. 2018, 90, 336–346. [Google Scholar] [CrossRef]

- Mathimani, T.; Baldinelli, A.; Rajendran, K.; Prabakar, D.; Matheswaran, M.; Van Leeuwen, R.P.; Pugazhendhi, A. Review on cultivation and thermochemical conversion of microalgae to fuels and chemicals: Process evaluation and knowledge gaps. J. Clean. Prod. 2019, 208, 1053–1064. [Google Scholar] [CrossRef]

- Collotta, M.; Champagne, P.; Mabee, W.; Tomasoni, G. Wastewater and waste CO2 for sustainable biofuels from microalgae. Algal Res. 2018, 29, 12–21. [Google Scholar] [CrossRef]

- Antonov, I.A.; Kotelev, M.S.; Afonin, D.S.; Gushin, P.A.; Ivanov, E.V. Isoprenoids oil of microalgae hydrocracking with production of winter and arctic diesel fuels. Bashkir Chem. J. 2012, 19, 170–172. [Google Scholar]

- Knoot, C.J.; Ungerer, J.; Wangikar, P.P.; Pakrasi, H.B. Cyanobacteria: Promising biocatalysts for sustainable chemical production. J. Biol. Chem. 2018, 293, 5044–5052. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Patidar, S.K. Microalgae harvesting techniques: A review. J. Environ. Manag. 2018, 217, 499–508. [Google Scholar] [CrossRef] [PubMed]

- Kopylov, A.; Romanenko, A.V.; Zabotkina, E.A.; Mineeva, N.M.; Krylova, I.N.; Maslennikova, T.S. Picocyanobacteria in eutrophic reservoirs of the Middle Volga: Abundance, production, viral infection. Zhurnal Obs. Biol. 2014, 75, 234–244. [Google Scholar]

- Sidelev, S.I.; Fomichev, A.A.; Babanazarova, O.V.; Zubishina, A.A. The detection of microcystin-producing Cyanobacteria in the Upper Volga watersheds. Mikrobiologiia 2013, 82, 370–371. [Google Scholar] [PubMed]

- Korneva, L.G. Invasions of alien species of planktonic algae into Holarctic freshwaters (review). Russ. J. Biol. Invasions 2014, 1, 5–33. [Google Scholar]

- Yoshida, M.; Yoshida, T.; Kashima, A.; Takashima, Y.; Hosoda, N.; Nagasaki, K.; Hiroishi, S. Ecological dynamics of the toxic bloom-forming cyanobacterium Microcystis aeruginosa and its cyanophages in freshwater. Appl. Environ. Microbiol. 2008, 74, 3269–3273. [Google Scholar] [CrossRef] [PubMed]

- IZVESTIYA. Dirty Story. How the Volga became the Dirtiest River in Russia? Available online: https://iz.ru/660518/izdaleka-dolgo (accessed on 10 June 2019).

- Zaytseva, N.V. The Problem of Development of Blue-Green Algae in the Votkinsky and Izhevsk Reservoirs. Mod. Sci. Res. Innov. 2014, 6. Available online: http://web.snauka.ru/issues/2014/06/36048 (accessed on 16 May 2019).

- Passport of Federal Project “Improving the Volga”. 2018. Available online: http://www.minstroyrf.ru/docs/17662/ (accessed on 17 July 2019).

- Ho, S.-H.; Chen, Y.-D.; Qu, W.-Y.; Liu, F.-Y.; Wang, Y. Chapter 8—Algal culture and biofuel production using wastewater. In Biomass, Biofuels, Biochemicals, Biofuels from Algae, 2nd ed.; Pandey, A., Chang, J.-S., Soccol, C.R., Lee, D.-J., Chisti, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 167–198. [Google Scholar]

- Guieysse, B.; Borde, X.; Munoz, R.; Hatti-Kaul, R.; Nugier-Chauvin, C.; Patin, H.; Mattiasson, B. Influence of the initial composition of algal-bacterial microcosms on the degradation of salicylate in a fed-batch culture. Biotechnol. Lett. 2002, 24, 531–538. [Google Scholar] [CrossRef]

- Milyutkin, V.A.; Borodulin, I.V.; Agarkov, E.A.; Rozenberg, G.S.; Kudinova, G.E. Technical Solution for Processing Blue-Green Algae in Biofuel. In Proceedings of the 35th Anniversary of the Volga Basin Institute of Ecology of the Russian Academy of Sciences and the 65th Anniversary of the Kuibyshev Biological Station “Ecological Problems of Large River Basins”, Togliatti, Russia, 15–19 October 2018; Rozenberg, G.S., Saksonov, S.V., Eds.; Anna: Togliatti, Russia, 2018. [Google Scholar]

- Milyutkin, V.A.; Topelkin, S.A.; Borodulin, I.V.; Agarkov, E.A. Renewable Energy Sources (REn)—Biofuels from the Blue-Green Algae Biomass—Cyanobacteria. In Proceedings of the II All-Russian (National) Scientific and Practical Conference “Priority Areas of Energy Development in the Agro-Industrial Complex”, Kurgan, Russia, 22 February 2018; Sukhanova, S.F., Maltsev, T.S., Eds.; Kurgan State Agricultural Academy: Kurgan, Russia, 2018. [Google Scholar]

- ECOVOLGA. Development of Unified Cyanobacteria Database in Saratov Storage Reservoir. Available online: http://ecovolga.com/ (accessed on 10 June 2019).

- Olabi, A.G. Circular economy and renewable energy. Energy 2019, 181, 450–454. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; De Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Svensson, N.; Funck, E.K. Management control in circular economy. Exploring and theorizing the adaptation of management control to circular business models. J. Clean. Prod. 2019, 233, 390–398. [Google Scholar] [CrossRef]

- Laso, J.; García-Herrero, I.; Margallo, M.; Bala, A.; Fullana-i-Palmer, P.; Irabien, A.; Aldaco, R. LCA-Based Comparison of Two Organic Fraction Municipal Solid Waste Collection Systems in Historical Centres in Spain. Energies 2019, 12, 1407. [Google Scholar] [CrossRef]

- Ratner, S.V. Circular economy: Theoretical bases and practical applications in the regional economy and management. Innovations 2018, 9, 29–37. [Google Scholar]

- Trabelsi, A.; Elouedi, Z.; Lefevre, E. Decision tree classifiers for evidential attribute values and class labels. Fuzzy Set Syst. 2019, 366, 46–62. [Google Scholar] [CrossRef]

- Dunjic, S.; Pezzutto, S.; Zubaryeva, A. Renewable energy development trends in the Western Balkans. Renew. Sustain. Energy Rev. 2016, 65, 1026–1032. [Google Scholar] [CrossRef]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Rechberger, H. Measuring the circular economy—A Multiple Correspondence Analysis of 63 metrics. J. Clean. Prod. 2019, 210, 200–216. [Google Scholar] [CrossRef]

- Avdiushchenko, A.; Zając, P. Circular Economy Indicators as a Supporting Tool for European Regional Development Policies. Sustainability 2019, 11, 3025. [Google Scholar] [CrossRef]

| № | Risks | Pq 1 | I 2 | Ir 3 | Addiction | |

|---|---|---|---|---|---|---|

| Influence Degree | Influence Level | |||||

| operational, resource | ||||||

| 1 | Variable raw material supplies | 2 | 4 | 8 | Minor | Reasonable |

| 2 | Narrow range of raw material application using existing equipment | 4 | 3 | 12 | Significant | Intolerable |

| distributive | ||||||

| 3 | Market stagnation | 3 | 3 | 9 | Moderate | Reasonable |

| 4 | Lack of relevant target market, insufficient supply, low volumes of sales and distribution | 2 | 5 | 10 | Moderate | Reasonable |

| financial | ||||||

| 5 | High expenditures for popularization events | 2 | 1 | 2 | Ignorable | Acceptable |

| 6 | Growth of the energy unit cost | 4 | 3 | 12 | Significant | Intolerable |

| 7 | Low efficiency of state subsidies | 2 | 5 | 10 | Moderate | Reasonable |

| 8 | Low efficiency of investments | 2 | 5 | 10 | Moderate | Reasonable |

| human resource | ||||||

| 9 | Insufficient human resources and low level of trained human resources | 5 | 3 | 15 | Significant | Intolerable |

| 10 | Low quality of educational programs of main and additional education | 3 | 3 | 9 | Moderate | Reasonable |

| № | Methods of Risk Management of Biofuel Production in Russia |

|---|---|

| 1 | Allocation of production in accordance with the accessibility of the raw material base |

| Obtainment of authentic information on suppliers | |

| Entering into supply agreements with several suppliers | |

| Planning of the required amount of raw materials for the provision of the supply system (when raw materials are supplied using own production) | |

| Insurance (of contractual obligations or own production of raw materials) | |

| Selection of reserve suppliers and opportunities for supplies of alternative raw materials | |

| 2 | Creation of production associations |

| Enhancement of production capabilities for the utilized types of raw materials | |

| 3 | Stimulation of work performance by state mechanisms |

| Support of innovative, science, technical potential | |

| 4 | Monitoring of cost characteristics of products |

| 5 | State control of market barriers lifting |

| Establishment of a uniform informational source with free access for end consumers | |

| 6 | Reduction of costs of energy production |

| State regulation of price-formation | |

| 7 | Reduction of expenditures per unit of product |

| 8 | Increase of production output |

| 9 | Formation of human resource reserve by creating training programs for specialists with higher and secondary education for the provision of all production systems |

| Optimization of personnel work depending on the level of employee efficiency | |

| Supervision of the structure and amount of salaries | |

| Compliance of the salary level of BF production enterprises active in a region with at least average regional salary | |

| Determination of incentive payments in the payroll fund for timely staff motivation | |

| 10 | Involvement of representatives of technological platforms acting in the area of energy, scientific organizations conducting fundamental and applied studies, producers of BF and BF-production equipment, educational institutions and other concerned parties in formation and implementation of educational programs |

| State approval of the educational programs and their constant improvement depending on the necessity of practical implementation of technological solutions | |

| Increase of qualification of enterprises’ personnel using their own capital and the federal budget |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Titova, E.S. Biofuel Application as a Factor of Sustainable Development Ensuring: The Case of Russia. Energies 2019, 12, 3948. https://doi.org/10.3390/en12203948

Titova ES. Biofuel Application as a Factor of Sustainable Development Ensuring: The Case of Russia. Energies. 2019; 12(20):3948. https://doi.org/10.3390/en12203948

Chicago/Turabian StyleTitova, Ekaterina S. 2019. "Biofuel Application as a Factor of Sustainable Development Ensuring: The Case of Russia" Energies 12, no. 20: 3948. https://doi.org/10.3390/en12203948

APA StyleTitova, E. S. (2019). Biofuel Application as a Factor of Sustainable Development Ensuring: The Case of Russia. Energies, 12(20), 3948. https://doi.org/10.3390/en12203948