1. Introduction

The transition from fossil-based economy into bio-based economy is high on the agenda both at the national and international levels. As a low-carbon energy resource and a carbon management mechanism, biomass is expected to play essential role in the transformation of energy sector under stringent climate change mitigation accords. Sweden is endowed with forestry that can potentially provide sustainable source of biomass for bioenergy production. Lignocellulosic biomass has a great potential to be utilized as bioenergy feedstock due to the high volume of residues generated from the production of pulp and timber, which derives during harvesting and thinning of trees onsite as well as during debarking and sawing at the production facilities. In the case of Sweden, efficient utilization of lignocellulosic wood is crucial to channel the vast feedstock potential for enabling impactful transition. A resource-efficient way of converting lignocellulosic biomass to fuels and chemicals is through fractionation into biomass basic components, namely cellulose, hemicellulose, and lignin. These components can separately be converted to fuels, chemicals, and materials through different thermo-chemical and biochemical processes. The thermo-chemical path essentially involves high-temperature conversion step, such as gasification, e.g., References [

1,

2], pyrolysis, e.g., References [

3,

4,

5], and hydrothermal liquefaction, e.g., References [

6,

7], which often are followed by chemical synthesis step to reach the desired final products. The biochemical route is rather based on fractionation of the feedstock under mild conditions to produce cellulosic materials, biofuels and chemicals, e.g., References [

8,

9,

10,

11,

12,

13]. Such a process falls well within the biorefinery concept, which effectively simulates a traditional refinery, in which all the major components of biomass are converted to different products and energy. Use of plant biomass in a biorefinery concept has already shown great potentials from energy potentials point of view and is an environmentally friendly approach, significantly reducing greenhouse gas emissions when replacing fossil diesel with biofuels [

14].

Regardless of the vast research focus on harnessing renewable energy for transport, such as electricity and hydrogen, the market penetration of these technologies has been somewhat slow, nor are these options directly applicable to the present road transportation fleet and distribution system. Even under the best-case scenario for deployment of electricity road fleet, achieving fossil free road transportation in Sweden by 2045 is expected to derive largely from biomass. Besides, many countries are enacting mandates for sustainable aviation fuel. Mandated switch from fossil aviation fuel to a sustainable equivalent adds to the competition for feedstock. Therefore, effective fractionation and utilization of all wood components are very important steps to ensure economic viability of new technologies and to minimize competition for feedstock.

Lignin, about 20–33% wt. of the dry content of lignocellulosic wood, is a typical example of underutilized resource. For instance, kraft pulping produces lignin as byproduct which often is combusted to generate the steam and power required to drive the process. In the context of biorefinery, a switch from lignin as a low-value material to a source to produce value-added chemicals and biomaterials is imperative. The recovery of high-purity lignin opens wide range of application areas from thermoplastic to biooils, e.g., References [

15,

16,

17]. One approach to obtain high-purity lignin is to recover it early in the process, prior to further processing of the carbohydrate fractions. This emphasizes the need to develop fractionation processes that are capable to produce distinct streams of cellulose, hemicellulose, and lignin, allowing to develop a wide portfolio of fuels, chemicals, and biomaterials that can be produced from biomass.

In this context, organosolv pretreatment/fractionation is regarded as one of the most promising methods for biomass fractionation, capable of producing relatively clean streams of cellulose, hemicellulose, and lignin. It involves the treatment of lignocellulosic biomass with organic solvents for fractionation of biomass into distinct streams at temperatures from 160 to 210 °C. During the process, solvents effectively solubilizes lignin and hemicellulose from the lignocellulosic biomass, which are separated in a form of liquor. Organosolv pretreatment process covers a broad range of organic solvents such as alcohols, organic acids and ketones. The organosolv fractionation generates a cellulose pulp that is highly susceptible to enzymatic hydrolysis and almost free of lignin, an aqueous liquid stream that contains the solubilized hemicellulosic sugars and other derivatives (i.e., furfural), and finally a solid stream of lignin. The lignin produced in this way is of high purity with very low sugar contaminants and most importantly has low ash content, is sulphur-free, and by maintaining a chemical structure close to the natural one [

8,

18].

Due to the high fractionation efficiency of organosolv pretreatment, the authors previously investigated its application on forest biomass [

8,

11,

18]. More specifically, a hybrid pretreatment and fractionation method was developed. The hybrid process combines the fractionation efficiency of conventional organosolv pretreatment and physical size reduction of the feedstock by steam explosion as a result of the sudden pressure drop. To achieve this, an explosive discharge step like in the steam explosion pretreatment process at the end of traditional organosolv cooking, effectively merging organosolv and steam explosion processes into a single-step process. This novel hybrid method was successfully applied for the pretreatment and fractionation of birch and spruce woodchips [

8,

18].

To emphasize the performance of novel process step for converting biomass, systemic mapping of a value chain utilizing the service of the technology in a biorefinery setup is relevant. Such assessment also enables comparison to other pathways of achieving the same service, for example many variants of pretreating lignocellulosic biomass are available such as organosolv, diluted acid, hot water, ammonia fiber explosion [

10,

19]. This study is motivated by the experimental outcomes of a hybrid organic solvent–steam explosion fractionation of lignocellulosic biomass to a cellulose-rich, a hemicellulose-rich and lignin streams, and aims to investigate the performance of this novel technique in a biorefinery setup.

2. Framework for Assessment

Design of biorefinery is stepwise process that combines, among other things, selecting high product throughput, exploring product market potential, valorizing side-streams to increase revenue, minimizing environmental impact and optimizing production cost. Given the nature of the study, i.e., investigation of the performance a novel pretreatment technique, ethanol was chosen as target product. Bioethanol is widely accepted bulk chemical used as feedstock for production specialty chemicals such as ethylene, with a global annual market of 130 Mt [

20], as drop-in fuel for road transport and most recently as feedstock for aviation fuel production. Besides, lignocellulosic ethanol has been the subject to many researchers establishing very good literature basis to benchmark the outcomes of this study.

Another major product of the biorefinery concepts is high-purity lignin. Although the market for lignin as bio-material is under development, organosolv lignin has purity advantage (compared to, e.g., kraft lignin and lignosulfonate) in areas such as bio-based binding agent and thermoplastic compounds [

20]. The following subsections present description of the major process units of the biorefinery concept investigated.

2.1. Feedstock Composition

The hybrid fractionation/pretreatment process was applied to both hardwood and softwood and the results were used as basis for the modelling activities in this study [

8,

18]. Birch woodchips with dry % wt. composition of 34.7 cellulose, 31.2 hemicellulose, 18.7 lignin, 15.4 extractives and ash and spruce woodchips 37.6 cellulose, 17.6 hemicellulose, 32.6 lignin and 12.2 others were used in the experimental campaigns.

2.1.1. Hybrid Organosolv–Steam Explosion Pretreatment

Birchwood with moisture content of 6% wt., ground to about 1 mm in size, was wetted using ethanol and fed to the pretreatment reactor. Most of the ethanol, more than 90%, is pumped directly into the reactor where saturated steam at 3 MPa was added both to raise the temperature and to maintain a 60% v/v ethanol-to-water solution inside the reactor. The reactor was operated at 200 °C with a holding time of 15 min once the operational temperature was reached. Inside the reactor the process was catalyzed using sulphuric acid with a concentration of 1% w/w of dry biomass. The target liquid-to-solid ratio (LSR) is to achieve a value below 10, which is important for steam economy. Following the pretreatment process the pretreated stream was discharged to an atmospheric cyclone separator and, in a subsequent stage, a cellulose-rich stream containing about 83% wt. of the cellulose in the initial feedstock was filtered-out. The stream left behind was an aqueous stream rich in hemicellulose and lignin. The cellulose-rich stream also contains about 11% and 14% wt. of the hemicellulose and the lignin in the initial feedstock, respectively. After separation of the cellulose-rich solids, the solvent was recovered using a mechanical vapor recompression evaporator. The hemicellulose and lignin-rich stream is passed through a centrifuge to separate solid-rich lignin stream, containing approx. 98% wt. lignin dry basis, from the aqueous solution. The aqueous stream can be concentrated to high sugar content molasses, which are present in the form monomers (such as xylose) and soluble oligomers (such as xylobiose).

Spruce with moisture content of 6.23% wt., ground to about 1 mm particle size, undergo same pretreatment procedure as described in the case of hardwood with a holding time and ethanol-to-water ratio inside the reactor of 30 min and 52% v/v, respectively. The cellulose-rich stream in the case of spruce contained about 84% wt. of the cellulose, 10% wt. of the hemicellulose and 21% wt. of the lignin in the initial feedstock. The extracted organosolv lignin for spruce was composed of 95% wt. lignin on dry basis. The concentration of hemicellulosic sugars in the aqueous solution for hardwood is about two times higher compare to that of softwood.

2.1.2. Liquefaction and Simultaneous Saccharification and Fermentation

The cellulose-rich pretreated solids were subjected to saccharification under high-gravity conditions. More specifically, pretreated birch solids were adjusted to a solid content of 20%

w/

w in 50 mM citrate buffer (ph 5). The enzyme used was Cellic

® CTec2 (Novozymes A/S, Bagsværd, Denmark) with total enzyme solution loading rate of 125 g/kg solids, i.e., 25 g per kg of the slurry. Saccharification took place at 50 °C for 8h. Then the temperature was reduced to 35 °C for the fermentation with the yeast. In the fermentation broth 1 g/L yeast extract, 0.5 g/L (NH

4)

2HPO

4, 0.025 g/L MgSO

4. 7H

2O was added and the initial yeast was 1 g/L. The final ethanol concentration in the broth, after 168 h, was 80 g/L [

18].

For spruce, the pretreated solids were adjusted to a solid content of 22%

w/

w for saccharification in the same buffer as in the case of birch. Enzyme load was the same, resulting in 27.5 g per kg slurry. The same saccharification conditions and nutrients were applied. The final ethanol concentration was 61.7 g/L [

8].

2.1.3. Product Recovery

Ethanol recovery is carried out in a multiple-column setup. The fermentation broth, at this stage most of the solids removed, containing mostly water and traces of volatiles such as CO2 needs to be purified to 99.5% w/w ethanol. The recovery process is composed of a beer column, a rectifier, a stripper, a distillation column, and a recovery unit for the entrainer. The fermentation broth is fed to the beer column with 30 trays and a reboiler pressure of 0.14 MPa, with pressure drop of 0.001 MPa/stage. Ethanol-rich stream, 90% w/w, is recovered at the top and sent to the rectification column, containing 40 trays and has same reboiler pressure and pressure-drop per stage as the beer column. Volatiles, mostly CO2, containing vapor phase ethanol and water are vented at the top and sent to stripping column to recover the ethanol using water as stripping medium. The liquid product from the stripper is distilled separately to increase its ethanol concentration to about 70% w/w before being sent to the rectification column. Glycerol entrainer is supplied to the 1-stage to facilitate the purification to 99.5% w/w ethanol in the rectification column. Glycerol is recovered at 100% w/w in a separate column, containing 10 trays with a reboiler pressure 0.15 MPa and pressure-drop 0.05 MPa/stage, and recycled back to the rectification column after being cooled to about 40 °C.

2.1.4. Combined Heat and Power (CHP) System

A dedicated CHP system was considered for supplying the utility requirements of the conceptual process envisioned in this work. There are several reasons for doing so. First, the hybrid organosolv–steam explosion pretreatment process utilizes steam, which was directly supplied to the reactor, thermally (to maintain the reactor temperature at the desired level) and chemically (to facilitate disintegration of the biomass into its components). Hence, all the water added to the reactor to reach the targeted liquid-to-solid ratio (assumed LSR of 10), must be in the form of steam. This results in a significant amount of steam demand. Supplying steam to a standalone operation of such steam-intensive process externally can be logistically challenging.

Second, the biorefinery concept’s convert part of the organic substance in the feedstock to final products such as ethanol, lignin and pentose monomers. Thus, considerable part of the organic content of the original feedstock end-up in the fermentation and purification stillage. The stillage, after screening and drying, presents opportunity that can be utilized to fuel a steam boiler that generates part of the steam required in the process at high pressure. Falling bark and forest residues are used to balance fuel deficit to the steam boiler.

Third, increase the products portfolio. By introducing a back-pressure turbine and an electric generator, the high-pressure steam (HPS) is used to generate electricity as it expands to the pressure levels required in the process, i.e., intermediate pressure steam (IPS) 3–3.5 MPa for the pretreatment reactor and low-pressure steam (LPS) 0.4–0.7 MPa for the product upgrading section. The electricity produced was partly used to drive unit processes and equipment, and the surplus was sold to the grid generating additional revenue.

The CHP system was sized such that the HPS generated in the boiler of the CHP system was matched to the total steam demand of the biorefinery. The HPS was generated at a maximum steam pressure and temperature of 120 bar and 520 °C. High-level assessment approach was assumed when evaluating the steam demand of the biorefinery concepts, i.e., only the major steam consumers such as the pretreatment reactor (IPS) and product upgrading (LPS) were considered. LPS may also be used to augment solvent recovery and concentration of the hemicellulose sugars processes in case the feed stream to the evaporators require preheating. Heating loads for streams below the temperature of 85 °C were assumed to be satisfied via heat exchangers network with other process streams that require cooling.

2.1.5. Process Simulation

The biorefinery concepts simulated are based on woody-biomass feedstock derived from the processing of soft- and hardwood. To derive mass and energy balance a flowsheet of the biorefinery concept was simulated in UniSim Design R460.1 developed by Honeywell. The plant was assumed to be in Sweden, with annual operational time of 7881 h, corresponding to 355 days with an availability of 92.5%. The thermodynamic model non-random two liquids (NRTL) was applied. The target production capacity was set to 50 ktons of dry lignin per year.

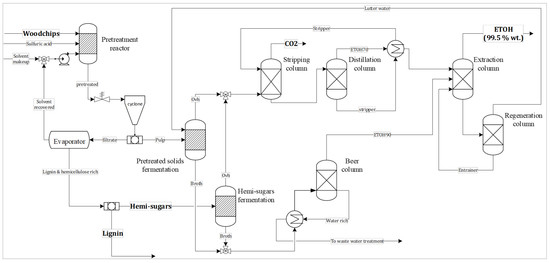

Figure 1 presents systemic overview of the simulated process.

The hybrid organosolv–steam explosion process fractionates woody biomass into cellulose-rich, hemicellulose-rich and lignin. Sawdust or chipped wood was mixed with ethanol in a solvent to dry biomass ratio of 6:1 for hardwood and 5:1 for softwood. The reactor was heated to 200 °C by addition of saturated steam at 3 MPa to achieve ethanol concentration of 60% v/v and 52% v/v for hardwood and softwood, respectively.

The solvent recovery and the evaporator for concentrating hemicellulose sugars are simulated as mechanical vapor recompression (MVR) evaporators. The incoming streams were flashed to 0.06 MPa and the vapor generated was recompressed to 0.1 MPa and used as heat source to the evaporation units.

As shown in

Figure 1, the hybrid pretreatment produces a stream containing hemicellulosic sugars and, to a much lesser extent, C6- sugars resulted from the dissolution of hemicellulose and cellulose, respectively. Depending on how this stream was treated, two process configurations for each type of wood were evaluated. The two alternatives were either to concentrate the hemicellulose-rich stream into a hemicellulose syrup final product or co-ferment it to increase ethanol yield. The process configurations and their acronyms (used hereafter) are as follows:

HWBF (hardwood biomass fractionation): pretreated hardwood solids and hemicellulose sugars converted to ethanol.

HWBFX (hardwood biomass fractionation with hemicellulose extraction): pretreated hardwood solids converted to ethanol and hemicellulose sugars marketed.

SWBF (softwood biomass fractionation): pretreated softwood solids and hemicellulose sugars converted to ethanol.

SWBFX (softwood biomass fractionation with hemicellulose extraction): pretreated softwood solids converted to ethanol and hemicellulose sugars marketed.

2.2. Economic Analysis

The economic assessment was performed using the equipment inventory of the process flowsheet developed in UniSim Design. Accordingly, the major process units were sized based on the mass and energy balance derived from the developed flowsheet,

Figure A1.

The total fixed capital investment (TFCI) was calculated according to the factorial method proposed by Sinnott and Towler [

21]. The purchased equipment cost (PEC) was evaluated using equipment cost correlations outlined by Woods [

22]. To this end, correction factors to adjust for fluid-solid processes were applied. In addition, factors that account for installation and erecting (60% of PEC), piping (50%), instrumentation and control (60%), electrical (20%), civil works (30%), structure and buildings (20%), lagging and paint (10%) were applied when estimating the inside battery limit (ISBL) cost. To calculate the TFCI, outside battery limit (OSBL) cost was added to the estimated ISBL cost by applying factors that account for design and engineering (30% of ISBL) and contingency (10%). PEC values were updated to 2014 using chemical engineering plant cost index (CEPCI) of 576. All monetary values reported refer to Euro value of the year 2014.

To compute the production cost of ethanol, fixed and variable operating costs were calculated using the data presented in

Table 1. The plant was assumed to be operational 355 days with an availability of 92.5%, corresponds to 7881 operational hours per year.

To determine the profitability of the biorefinery concepts minimum ethanol selling price (MESP) was evaluated as an economic indicator. The production of ethanol reaches full-scale after three years by assuming 30% and 70% of the full capacity for Year 1 and Year 2, respectively. The MESP was calculated using a discounted cash flow model. A discount rate of 10% was used for the basecase (

Table 2). For the investment, loan to equity ratio of 4 and loan interest rate of 4% was applied. A working capital equivalent to 5% TFCI was added. The economic lifetime of the plant was set to 30 years.

4. Discussion

Organosolv pulping, often discussed as an alternative process to conventional chemical pulping process, has not been the favored pulping process due to high production cost. The cost of recovering the organic solvent and low pulp yield—for example relative to kraft pulping—being the main drivers. Compared to conventional chemical pulping processes, for the capacity of the biorefinery plants investigated, the steam consumption to recover the solvent adds equivalent to about 15–20% of the amount steam required for the hybrid pretreatment reactor or alternatively consumes 7–9 MWel in case MVR evaporator was used to recover the solvent. In contrast, the chemicals recovery process of kraft pulping produce steam when the pulping byproduct black liquor is combusted to recover the cooking chemicals. This holds true even for kraft mills with the option of lignin extraction, e.g., via lignoboost process, in which case part of the lignin enough to allow black liquor combustion in recovery boiler is left in the stream [

27,

28]. On the positive side, the organosolv lignin has quality advantage over kraft lignin which contains impurities derived from the pulping chemicals, such as sulphur. With growing interest in high-quality lignin, the hybrid pretreatment process is likely to become an attractive option. When markets that appreciate sulphur- and odor-free lignin are in place, chemical pulp mills may reconsider their position towards organosolv processes.

Degradation of hemicellulose was identified as one of the major sources of inefficiencies that limited the yield of the hybrid pretreatment process. The harsh conditions of the pretreatment reactor, rather tuned to favor pulp yield, stimulated excessive degradation to the hemicellulose fraction of the feedstock hampering the yield hemicellulose sugars. The economic evaluations have shown the cases with hemicellulose sugars marketing option performed better than those with hemicellulose sugars fermentation to ethanol option, highlighting the importance of minimizing degradation of hemicellulosic derivates in the pretreatment reactor. Therefore, devising methods that enable the recovery of hemicellulosic fractions early during the pretreatment process would contribute a great measure to the realization of profitable biorefinery concepts employing the service of the hybrid pretreatment technique. Alternatively, the performance of the process towards hemicellulose fraction can be improved by integrating value chains that valorize the degraded hemicellulosic derivatives to marketable products such as furfural and acetic acid. However, these value chains were not investigated here.

Ethanol was targeted as final product given the investigative nature of the study. Nonetheless,

Figure 3 shows that the combined earnings from lignin and hemicellulose syrup contributed more than ethanol sales. This indicates targeting high value products would improve process economics. Lignin, being the second major product of the biorefinery, generated significant part of the income. The lignin market, currently under development phase, is expected to grow fast depending on the intended application area. For example, applications as binding agent or thermoplastics would favor lignin prices towards the high-end of the range used in the sensitivity analysis. Moreover, hydrogenolytic depolymerization of lignin is an active research area pursued by many researchers and institutions in the context of value-added biochemicals and biofuels, e.g., References [

16,

29,

30,

31].

Under the experimental campaigns, the hybrid pretreatment process was characterized by high LSR which rendered the full-scale process energy intensive as all the water added to the pretreatment reactor was in the form saturated steam at pressure of 3 MPa. Future developments must target to reduce the LSR well below the experimental value to achieve improved process performance in terms of energy and water usage. To further minimize process water consumption, the water required for saccharification step can be sourced from the lutter water after ethanol purification process or elsewhere in the process. For a commercial scale installation, all or part of the thermal energy required to maintain the hybrid pretreatment process at the desired reactor temperature may be satisfied using external heat source instead of directly supplying steam to the reactor as was the case for the experimental campaigns. This can be achieved via heat exchangers designed to preheat the organosolv solvent to a desired temperature level and by maintaining the external walls of the reactor insulated to minimize heat losses.

To illustrate on the performance of integrated process configurations, Pinch Analysis [

32] was applied to the biorefinery concepts and a split grand composite curve for the HW case is shown in

Figure 5 as a representative. The so-called integrated grand composite curve takes into account the major process streams that require heating or cooling including that of the CHP system, see, e.g., References [

33,

34,

35]. Minimum temperature difference was applied to each stream according to its heat transfer nature, i.e., 20 °C for combustion products and 4 °C for steam and aqueous streams. The red composite curve derives from the biorefinery process streams and the combustion streams of the CHP system. The lower profile of the red composite curve below 290 °C originates from the streams of the bioethanol process; whereas the upper profile represents the thermal energy of the combustion products which is split between radiative (at 850 °C) and convective (850–150 °C) heat transfer segments. The blue composite curve shows the steam Rankine cycle streams, in which the upper part represents generation of the HPS (superheating, evaporation and part of feedwater preheating segments) and the low part for condensation of process HPS (regeneration column reboiler), IPS (pretreatment and rectification column reboiler) and LPS (pretreatment, beer and distillation columns reboilers). As depicted in

Figure 5, the thermal loads for ethanol recovery and upgrading take place at constant temperatures which are conveniently satisfied using condensing steam extracted from the back-pressure turbine. The heat demand of the pretreatment reactor also spans between 85 °C and slightly over 200 °C, requiring saturated steam both at 0.4 MPa (for the low temperature segment) and 3 MPa (for the high-temperature part). In addition,

Figure 5 illustrates graphically how well the steam system exploits the heat pocket created by the hot combustion and biorefinery streams while providing information on amount and pressure levels of the steam used by the bioethanol process. It is worth mentioning that the gap between the ordinate axis and left-end of the blue curve at 0.4 MPa represents the net power production of the CHP system.

5. Concluding Remarks

Hardwood and softwood chips based biorefinery concepts producing ethanol (0.12–0.15 t), lignin (0.12 t) and sugars (0.06–0.07 t; mainly from hemicellulose) per ton of dry woodchips with an overall energy efficiency of 70–78% were investigated. The biorefinery concepts were derived from a full-scale simulation model that was developed based on lab scale experimental data. Under the assumed economic condition, the biorefinery concepts resulted in net present value ranging from −198 to 15 M€ and the corresponding IRR in the range −1.75–10.7%. However, the sensitivity analysis with projected values of key technical and economic parameters showed potential for profitability, resulting in IRR as high as 17% for HWBFX case.

The hybrid organosolv–steam explosion pretreatment is an energy intensive process requiring significant amounts of IPS that adversely affected the process economy. Integration of the biorefinery with an existing CHP system or a sawmill with a boiler could improve its economic performance. Besides, degradation of hemicellulosic sugar derivatives during the pretreatment stage reduced the hemicellulose sugars yield, which negatively affected the economic performance. Therefore, a great deal more effort should be made to improve steam consumption and minimize hemicellulose degradation during the pretreatment process.