Fixing Efficiency Values by Unfixing Compressor Speed: Dynamic Test Method for Heat Pumps

Abstract

:1. Introduction

2. Materials and Methods

3. Results

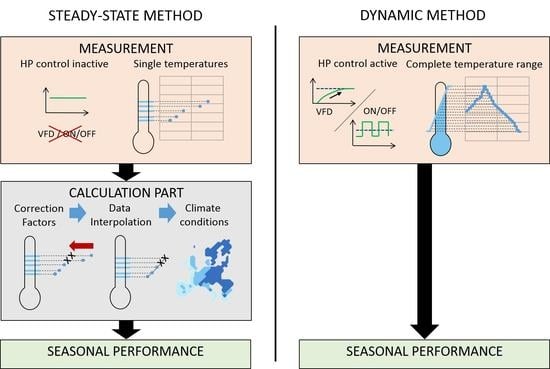

3.1. Concept of the Dynamic Method

- The outdoor temperature profile shall represent the average European climate according to the mean occurrence of each temperature from the EN 14825. Therefore, the temperature range of the profile is between −10 °C and 15 °C and the duration of each individual outdoor temperature corresponds to the weighting from the BIN distribution.

- The test duration per temperature sequence shall be chosen to maintain high reproducibility, in particular, for certain operating conditions such as defrost cycles.

- The total test period and the expenses of the dynamic test should be equal or less than the current standard tests.

- The profile should take into account both an increase and a decrease of outdoor temperature and thus reflect the behavior of the HP during changes of the day temperature.

3.2. Experimental Data

3.2.1. Tests with GSHP

3.2.2. Tests with ASHP

3.2.3. Precision of the Dynamic Test Method

4. Discussion

5. Conclusions

- It considers the real control behavior of HPs.

- It can be conducted independently from manufacturer support and makes special test modes obsolete.

- It considers the whole temperature range of a heating season (from −10 °C to 15 °C for average European climate) directly by measurement, specifically those sequences that are commonly linearly interpolated in current standards.

- It makes linear interpolation and the prescription of invariables obsolete and hence gives a closer approximation of the field performance of HPs and could reduce the need for field tests.

- It has the potential to achieve a high degree of automation and could be easily modified to new technologies.

- The optimum values for the permitted deviations and tolerances are to be defined.

- The temperature sequences can be further shortened. Therefore, the influence of the stabilization phase on the average results should be investigated for all temperature sequences.

- The feasibility for testing fixed-speed HPs should be investigated.

- The use of climate box and electrical resistance should be examined.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ASHP | air source heat pump |

| GSHP | ground source heat pump |

| COP | coefficient of performance |

| HiL | Hardware-in-the-Loop |

| HP | heat pump |

| PLR | part load ratio |

| SCOP | seasonal coefficient of performance |

| VFD | variable frequency drive |

Appendix A

References

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving better energy-efficient air conditioning—A review of technologies and strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Heat Roadmap Europe 2050. Heating and Cooling Facts and Figures—The Transformation towards a Low-Carbon Heating & Cooling Sector. Heat Roadmap Europe, 2017. Available online: https://www.isi.fraunhofer.de/content/dam/isi/dokumente/cce/2017/29882_Brochure_Heating-and-Cooling_web.pdf (accessed on 18 March 2019).

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recyl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- Connolly, D.; Lund, H.; Mathiesen, B.V. Smart energy Europe: The technical and economic impact of one potential 100% renewable energy scenario for the European Union. Renew. Sustain. Energy Rev. 2016, 60, 1634–1653. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H.; Karlsson, K. 100% renewable energy systems, climate mitigation and economic growth. Appl. Energy 2011, 88, 488–501. [Google Scholar] [CrossRef]

- Li, G. Investigations of life cycle climate performance and material life cycle assessment of packaged air conditioners for residential application. Sustain. Energy Tech. Assess 2015, 11, 114–125. [Google Scholar] [CrossRef]

- Shao, S.; Shi, W.; Li, X.; Chen, H. Performance representation of variable-speed compressor for inverter air conditioners based on experimental data. Int. J. Refrig. 2004, 27, 805–815. [Google Scholar] [CrossRef]

- Tu, Q.; Zhang, L.; Cai, W.; Guo, X.; Yuan, X.; Deng, C.; Zhang, J. Control strategy of compressor and sub-cooler in variable refrigerant flow air conditioning system for high EER and comfortable indoor environment. Appl. Therm. Eng. 2018, 141, 215–225. [Google Scholar] [CrossRef]

- Choi, J.M.; Kim, Y.C. Capacity modulation of an inverter-driven multi-air conditioner using electronic expansion valves. Energy 2003, 28, 141–155. [Google Scholar] [CrossRef]

- Jeong, K.; Choi, J.M. Capacity modulation of a cascade heat pump with the variation of compressor speed and electronic expansion valve opening. Renew. Sustain. Energy 2014, 6, 053107. [Google Scholar] [CrossRef]

- Park, Y.C.; ChulKim, Y.; Min, M.-K. Performance analysis on a multi-type inverter air conditioner. Energy Convers. Manag. 2000, 42, 1607–1621. [Google Scholar] [CrossRef]

- Chen, W.; Zhou, X.; Deng, S. Development of control method and dynamic model for multi evaporator air conditioners (MEAC). Energy Convers. Manag. 2005, 46, 451–465. [Google Scholar]

- DIN Normenausschuss Kältetechnik (FNKä). DIN EN 14825:2016 Air Conditioners, Liquid Chilling Packages and Heat Pumps, with Electrically Driven Compressors, for Space Heating and Cooling—Testing and Rating at Part Load Conditions and Calculation of Seasonal Performance; DIN Normenausschuss Kältetechnik (FNKä): Berlin, Germany, 2016. [Google Scholar]

- Standards Australia and New Zealand Standards. AS/NZS 3823:2014 Performance of Electrical Appliances—Air Conditioners and Heat Pumps; Standards Australia and New Zealand Standards: Sydney, Australia; Wellington, New Zealand, 2014. [Google Scholar]

- Air Conditioning, Heating and Refrigeration Institute. ANSI/AHRI 210/240:2008. Standard for Performance Rating of Unitary Air-Conditioning & Air-Source Heat Pump Equipment; Air Conditioning, Heating and Refrigeration Institute: Arlington, VA, USA, 2008. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc. ASHRAE, ANSI/ASHRAE Standard 116-2010 Methods of Testing for Rating Seasonal Efficiency of Unitary Air Conditioners and Heat Pumps; American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc.: Atlanta, GA, USA, 2010. [Google Scholar]

- Japanese Industrial Standards Committee. JIS C9612: 2013 Room Air Conditioners; Japanese Industrial Standards Committee: Tokyo, Japan, 2013. [Google Scholar]

- Gomes, A.; Antunes, C.H.; Martinho, J. A physically-based model for simulating inverter type air conditioners/heat pumps. Energy 2013, 50, 110–119. [Google Scholar] [CrossRef]

- Cuevas, C.; Lebrun, J. Testing and modelling of a variable speed scroll compressor. Appl. Therm. Eng. 2009, 29, 469–478. [Google Scholar] [CrossRef]

- Lee, S.H.; Jeon, Y.; Chung, H.J.; Cho, W.; Kim, Y. Simulation-based optimization of heating and cooling seasonal performances of an air-to-air heat pump considering operating and design parameters using genetic algorithm. Appl. Therm. Eng. 2018, 144, 362–370. [Google Scholar] [CrossRef]

- Menegon, D.; Soppelsa, A.; Fedrizzi, R. Development of a new dynamic test procedure for the laboratory characterization of a whole heating and cooling system. Appl. Energy 2017, 205, 976–990. [Google Scholar] [CrossRef]

- Haller, M.Y. Dynamic whole system testing of combined renewable heating systems - The current state of the art. Energy Build. 2013, 66, 667–677. [Google Scholar] [CrossRef]

- Riederer, P.; Partenay, V.; Raguideau, O. Dynamic test method for the determination of the global seasonal performance factor of heat pumps used for heating cooling and domestic hot water preparation. In Proceedings of the 11th International IBPSA Conference, Glasgow, UK, 27–30 July 2009. [Google Scholar]

- Huchtemann, K.; Engel, H.; Mehrfeld, P.; Nürenberg, M.; Mueller, D. Testing method for evaluation of a realistic seasonal performance of heat pump heating systems: Determination of typical days. In Proceedings of the 12th REHVA World Congress, Aalborg, Denmark, 22–25 May 2016. [Google Scholar]

- Mavuri, S. Field behaviour of inverter air conditioners effect on seasonal performance. IJAIEM 2015, 4, 18–25. [Google Scholar]

- Grote, K.H.; Feldhusen, J. Thermodynamik. In Dubbel-Taschenbuch fuer den Maschinenbau; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2005; p. D45. [Google Scholar]

- European Commission. Commission Delegated Regulation (EU) No 811/2013. Off. J. Eur. Union 2013, L289, 136–161. [Google Scholar]

- Meier, A.K.; Hill, J.E. Energy test procedures for appliances. Energy Build. 1997, 26, 23–33. [Google Scholar] [CrossRef]

| HP# | HP Type | Rated Heating Capacity (kW) | Declared (%) | Temperature Level (°C) |

|---|---|---|---|---|

| 1 | GSHP | 8.2 | 144 | 55 |

| 2 | ASHP | 9.2 | 156 | 35 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palkowski, C.; Zottl, A.; Malenkovic, I.; Simo, A. Fixing Efficiency Values by Unfixing Compressor Speed: Dynamic Test Method for Heat Pumps. Energies 2019, 12, 1045. https://doi.org/10.3390/en12061045

Palkowski C, Zottl A, Malenkovic I, Simo A. Fixing Efficiency Values by Unfixing Compressor Speed: Dynamic Test Method for Heat Pumps. Energies. 2019; 12(6):1045. https://doi.org/10.3390/en12061045

Chicago/Turabian StylePalkowski, Carsten, Andreas Zottl, Ivan Malenkovic, and Anne Simo. 2019. "Fixing Efficiency Values by Unfixing Compressor Speed: Dynamic Test Method for Heat Pumps" Energies 12, no. 6: 1045. https://doi.org/10.3390/en12061045

APA StylePalkowski, C., Zottl, A., Malenkovic, I., & Simo, A. (2019). Fixing Efficiency Values by Unfixing Compressor Speed: Dynamic Test Method for Heat Pumps. Energies, 12(6), 1045. https://doi.org/10.3390/en12061045