1. Introduction

The “pretreatment” of lignocellulosic biomass is a process that enhances enzymatic digestibility by improving access to the enzymes. It is a key step in determining the efficiency of biofuel production from a lignocellulosic biomass, which is recalcitrant to enzymatic hydrolysis [

1]. Because the crystal structure of cellulose hinders its hydrolysis by enzymes, efficient pretreatment of the biomass should be done to make access to the enzyme easier [

2]. There are three types of pretreatment techniques: Physical, chemical, and biological [

3]. Biological pretreatment is not an attractive option on an industrial scale because of the very slow reaction rate [

1]. Currently, chemical pretreatment is the most popular technique used in the industry. Chemical pretreatment mainly uses solvents, such as sulfuric acid, hydrochloric acid, and alkalis, to remove or detach the lignin and hemicellulose from cellulose [

4]. However, chemical pretreatments usually result in the production of huge amounts of toxic chemicals and inhibitors of fermentation and are responsible for the loss of biomass [

5]. On the other hand, physical pretreatment, specifically mechanical pretreatment, is an environmentally friendly pretreatment method. It increases the surface area of biomass, reduces its crystallinity, and limits the production of inhibitors [

6]. It includes disk milling [

7], electron beam irradiation [

8], high-pressure homogenization [

9], photocatalysis [

10], and hot compression [

11]. Sometimes, mechanical and chemical pretreatments are used in conjunction to overcome the disadvantages associated with the use of a single pretreatment method. Various combinations of pretreatments, such as hydrothermal and ball milling [

12], hot water and disk milling [

13], alkaline and dry milling [

14], and acidic solutions and ball milling, have been reported to improve sugar production [

15,

16].

Despite their low efficiency and higher energy consumption, mechanical pretreatment methods can retain intact byproducts, which can be further used for the production of value-added products. A facile biofuel production is possible because mechanical methods do not require any extraneous steps, such as rinsing the biomass or changing the buffer [

17]. However, it should be amenable to large-scale processes for industrial applications. In recent times, the focus of pretreatment research has been moving toward eco-friendly, economical, and time-effective solutions, which would also allow for simplified large-scale operations [

18]. Recently, new industrial technologies, such as high hydrostatic pressure [

19], high-pressure homogenizer [

20], microwave [

21], and ultrasound technologies [

22], have been applied as green pretreatment methods for large-scale treatment of lignocellulosic biomasses. However, these technologies are not yet ready for industrial application because of high capital costs and insufficient proofs of concept [

18].

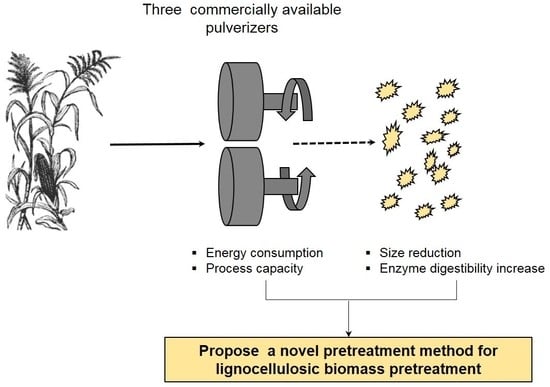

In this study, we determined the potential of three commercially available mechanical pulverizers for use in the pretreatment of lignocellulosic biomasses.

To enhance enzymatic digestibility and to address the issue of energy consumption associated with pretreatment, mechanical pretreatments of corn stover were performed using three commercially available continuous pulverizers. If commercially available pulverizers can be employed for lignocellulosic biomass pretreatments, they can be used in the industry immediately, and would therefore promote the industrialization of lignocellulosic biofuel production.

2. Materials and Methods

Corn stover was used as a model biomass because it is an abundant biomass resource in the USA and Asian countries. The corn stover provided by CJ Cheil Jedang, Republic of Korea, was grown and harvested in China in September 2015. The corn stover used in this study contained 34.8 wt % glucan. The corn stover was ground, and <5 mm particles were collected. It contained 12% moisture and was air-dried at 60 °C before use.

All of the pulverizers used in this study were manufactured by Daega Powder Systems Co., Ltd. (Bucheon, Korea), and are commercially available. They were a continuous ball mill (CBM), an air classifier mill (ACM), and a high-speed mill (HSM). The ball mill employs grinding balls, such as steel or ceramic balls, to pulverize target materials. A cylindrical drum containing the material to be pulverized and the grinding balls rotate about a horizontal axis. During rotation, the balls move and are impacted by each other, resulting in the fracturing of the material, which yields fine biomass particles. The air classifier mill consists of a mechanical impact zone and a classifying zone. The mechanical impact zone has a round vertical housing that encloses an internal classifying wheel and an impact rotor. Impact hammers are mounted around the edge of a rotor disc located below the classifier wheel. The biomass that leaves the grinding zone reaches the classifier, and if it is small enough, it is removed from the system. If it is big, it is recirculated to the hold-up. The high-speed mill is similar to the air classifier mill. It employs a hammer and a liner. By rotating the hammer at high speed, the combined forces of impulsion, friction, compression, and shearing are applied to the materials between the hammer and the liner. It has a screen to separate the material less than a specific size to the bottom. Continuous pretreatment is feasible because all of the devices mentioned here use air flow to convey the feeding biomass to the grinding zone and the fine biomass out of the mill. A schematic illustration of all of the pulverizers used in this study is given in

Figure 1. The continuous ball mill pulverizer had a diameter of 380 mm and a length of 965 mm in the mill chamber. Grinding balls having diameters of 30 mm and 50 mm were used at a ratio of 80:82 (w/w), respectively. The air classifier mill had a mill chamber having an inner diameter of 190 mm and an interior length of 80 mm. The high-speed mill had an inner diameter of 220 mm and an interior length of 100 mm. These were equipped with an air separator to continuously separate the fine particles. Corn stover was continuously supplied to the hopper manually.

After milling, the size of the corn stover was analyzed using a particle size distribution analyzer (LA-950V2; Horiba, Kyoto, Japan). Enzymatic digestibility was evaluated by measuring the glucose yield. To measure the glucose yield, pretreated corn stover was added to commercial cellulase (Cellic CTec3; Novozymes, Bagsvaerd, Denmark) dissolved in 0.1 M sodium citrate (pH 4.8) at a ratio of 2% solids (

w/

v). To prevent microbial contamination, sodium azide was added to a concentration of 0.04%. An enzyme reaction was performed at 50 °C for 72 h with 200 rpm agitation. The concentration of glucose produced was measured using test strips (Glucose Test Method, Merck, Darmstadt, Germany). The color change was analyzed using a Reflectometer (Rqflex plus 10, Merck, Darmstadt, Germany). Finally, the yield of glucose was calculated using Equation (1):

The energy requirement for corn stover pulverization was measured using a wattmeter (KEM2500; KORINS, China) that measured actual electricity used and was divided by the quantity of corn stover produced.

The process capacity was calculated by measuring the weight of the output of pulverized corn stover over a specific time period. The weight was finally converted to the weight of collecting particles for 24 h.

3. Results and Discussion

Mechanical pretreatments are effective in reducing the size of corn stovers. The reduction in size results in an increase in the surface area of biomass available for the action of cellulase. Previous studies have shown that mechanical pulverization also reduces the crystallinity of cellulose [

6,

12]. The reduction in size and crystallinity upon milling are the main factors responsible for enhancing the production of sugar. After milling, the size of corn stover is reduced to a micron scale. Size distributions of milled corn stovers are shown in

Figure 2. The peak sizes of corn stover after milling in the CBM, ACM, and HSM were found to be 100, 260, and 230 µm, respectively (

Figure 2). Although the peak size of corn stover milled in the CBM was the smallest, the size distribution in this case was broader when compared to that obtained with the ACM or HSM (

Figure 2a). Some corn stover particles were larger than 1000 µm when milled in the CBM, but most of the particles were smaller when milled in the ACM or HSM. Large-sized corn stover particles were difficult for cellulase to digest, and this could have been the reason for the low glucose yield. In contrast, the size distribution after milling in the ACM was relatively narrower, and most of the corn stover particles were smaller than 1000 µm (

Figure 2b). The mean diameters of the corn stover particles after pulverization are presented in

Table 1. The corn stover pulverized by the HSM showed the smallest mean diameter, 167.6 µm: Similar mean diameters were obtained when using the other two mills. Noticeably, the corn stover milled in the CBM showed a higher standard deviation, which resulted in variable glucose conversion yields and reduced the reproducibility of the process. The corn stovers pulverized in the ACM or HSM showed relatively smaller standard deviations than those pulverized in the CBM. The sizes of the pulverized corn stover were larger than those reported in a previous study [

16], in which corn stover was chopped and the pulverized corn stover was collected through a 40-mesh. The collected sample was again milled with a high-energy nanoball mill. The final superfine corn stover particles had a median particle size of 15.10 µm. The median sizes of the corn stover after milling in the CBM, ACM, and HSM in this study were found to be 99.77, 180.26, and 131.32 µm, respectively. However, commercial pulverizing machines having large processing capacities were used in this study. The shape of corn stover before and after the pretreatment did not change significantly (data not shown).

The enhancement in enzyme digestibility with the use of pulverizers was investigated by determining the improvement in glucose yield. The yield was only 14.0% in the case of non-pretreated corn stover. Milling in the ACM and HSM led to drastic improvements in the glucose yields (

Figure 3), with the yields increasing by 3.5- and 3.1-fold, respectively, when compared to that obtained with non-pretreated corn stover. Typically, the glucose yield was 49% when only the ACM was used without the assistance of chemical catalysts. After pulverizing in the CBM, the glucose yield increased only by 2.1-fold, which was relatively lower than the increase in the case of the ACM and HSM (

Figure 3). This would result from the existence of large-sized corn stover particles and a higher standard deviation in the size distribution of the samples pulverized in the CBM (

Figure 2a and

Table 1). The velocity of the enzyme reaction was very fast in the pulverized samples. In all of the pretreated samples, it was observed that more than 93% of enzymatic hydrolysis was complete in 12 h.

Energy consumption is an important factor in evaluating the performance of mechanical pretreatments, which usually require high levels of energy [

23]. The energy requirement for pulverization was quite different depending on the pulverizer (

Table 2). The HSM consumed only 0.26 MWh of energy in pulverizing 1 ton of corn stover, whereas the ACM required 1.85 times more energy compared to the HSM. However, the CBM consumed much more energy (about 28.5 times more) when compared to the HSM. The consumption of higher energy leads to an increase in the cost of the process, making the competitiveness of the product low in the market.

With regard to the process capacity, the ACM and HSM showed similar capacities of 0.61 and 0.58 ton/day, respectively (

Table 2). However, the CBM could pulverize only 50 kg of corn stover in a day. In contrast, the ACM and HSM had 10 times more process capacity than the CBM did. The pulverizers used in this study were commercially available general powder pulverizers and were not designed for biomass pretreatment. The process capacity could be improved if they are customized for this purpose. Both the ACM and HSM showed higher (26.05- and 43.18-fold, respectively) energy efficiencies for producing glucose than the CBM did.

The three types of pulverizers were tested for their applicability in continuous biomass pretreatment. Use of the ACM and HSM resulted in similar (~44%–50%) glucose yields and consumed less energy. The process capacity for these two was also good. However, in the case of the CBM, the glucose yield was low, energy consumption was high, and the process capacity was small. Although, the glucose yield was higher in the case of the ACM and HSM compared to that obtained with the CBM, about 50% of the cellulose remained unhydrolyzed after the enzymatic catalysis. The remaining cellulose can be used in the production of value-added products rather than biofuel. Currently, the major hindrance in the commercialization of lignocellulosic biofuel is its low market competitiveness [

24]. The utilization of coproducts for making value-added products can possibly raise its competitiveness. For example, the residual cellulose after enzymatic hydrolysis can be used to produce nanocellulose or cellulose fibers for medical or cosmetic applications. As mentioned earlier, the use of mechanical pretreatment does not produce toxic byproducts and does not need washing or detoxification steps. Therefore, the process would remain very simple with the use of the ACM or HSM for pretreatment, which would promote the industrialization of biofuel production from lignocellulosic biomasses. Several previous studies in which mechanical methods have been used showed higher glucose yields than those obtained in the present study [

6,

16,

17]. However, process capacity and energy consumption should be considered when comparing pretreatment methods. For example, the glucose conversion efficiency was 82% when a planetary ball mill was used to treat rice straw [

6]. However, the energy requirement was 2080 MJ/kg, and the process capacity was only 18 g/day. Although a high glucose yield was obtained using this method, it is not suitable for industrial applications where processing at a mass scale is needed. Kim et al. subsequently used hot water and disk milling [

13]. They obtained an 89% glucose yield, and the energy consumption was about 10 MWh/kg, which was 10 times more than in this study. If the pulverizers used in this study are employed in conjunction with other chemical methods, glucose yield would increase, as in the study of Kim et al. Another combinational pretreatment method, dry alkaline and centrifugal milling, had an energy efficiency of 0.888 ton-glucose/MWh [

14], which was lower than that obtained with the ACM and HSM. Based upon these viewpoints, the pulverizing methods used in this study could be candidates for lignocellulosic biomass pretreatment in industrial applications when considering both energy efficiency and process capacity.

4. Conclusions

Three commercially available pulverizers were tested for their applicability to the continuous pretreatment of lignocellulosic biomasses in terms of size reduction, enzyme hydrolysis, process capacity, and energy requirements. The three tested pulverizers did not show any significant differences in particle size reduction. However, the corn stovers pulverized by the air classifier mill or high-speed mill showed similar glucose yields, whereas the samples prepared with the continuous ball mill resulted in lower glucose yields. The highest glucose yields were 49% and 44% for the air classifier mill and high-speed mill, respectively. Both of these mills also showed good performance with regard to energy consumption and process capacity. In our results, about 0.6 tons of corn stover could be processed in a day, with glucose yields in the ~45%–49% range when the ACM and HSM were used. Moreover, the use of the air classifier mill and high-speed mill showed high pretreatment energy efficiencies (1.02 and 1.69 ton-glucose/MWh for the ACM and HSM, respectively). Therefore, both the air classifier mill and high-speed mill can be used in the continuous pretreatment of lignocellulosic biomasses, which is needed in the biofuel production industry.