1. Introduction

One of the most important global environmental problems nowadays is processing and recovery of various waste [

1,

2]. Vast areas are excluded from agricultural use due to the arrangement of landfill sites for industrial and municipal waste [

1,

3,

4]. Apart from the above factors, each particular type of waste is characterized by a certain group of factors hazardous for the environment. For instance, typical coal mining and coal processing waste is fire-hazardous and contains heavy metals and acid-forming substances that become sources of integrated environmental pollution under severe exposure to natural factors [

2]: solar energy, water, and air. Oil and petroleum waste are toxic. Storing such liquids under the conditions that do not comply with regulatory requirements leads to water pollution and acid rains as well as enhances the greenhouse effect [

5]. Landfill storage of untreated municipal solid waste (MSW) can be the cause of pollution ground waters and air by bacterial flora as well as a source of dioxins and furans (PCDD/Fs) in case uncontrollable local combustion occurs at a landfill [

4,

6].

There is an urgent need for an effective solution to the problem of waste treatment in the short term if the global environmental situation is to be preserved at the same level at least [

4]. Experts estimate [

7,

8] that, despite the advances in waste management, the technologies now widely used for the treatment of waste (primarily and municipal) will not completely solve the issue of environmental pollution.

Table 1 illustrates waste generation in 2018 and projections for the near future by country [

4]. It is shown (

Table 1) that waste generation all over the world grows rapidly. Therefore, the problem of waste recovery calls for the development of drastic solutions.

Nowadays, countries that stockpile their waste mainly at landfill sites (75–95%) take considerable efforts to develop waste management (regarding MSW). However, a low dynamics of waste management system transformation does not lead to a substantial improvement of the environmental situation. These countries are [

4] the Russian Federation (MSW dumping at landfill sites is 95.0% of the total amount of annual waste generation), Turkey (98.0%), Ukraine (94.1%), Chile (93.7%), Mongolia (93.5%), Belarus (84.0%), Thailand (80.5%), Greece (80.0%), and India (77.0%).

The Russian Federation can be used as an example to provide the following typical statistical data that characterize quite a low level of waste management and common waste treatment technology development. As reported by the Russian Federal State Statistics Service, 6220.6 Mt of municipal and industrial waste were accumulated in Russia during 2017, which is 14.32% more than the statistical data for 2016 [

9]. About 50% of such waste is recovered, while the rest is buried in the soil (about 13%) and stored at open-air disposal sites (about 37%). So far, more than 94 billion t of industrial waste have been collected in Russia; more than a half of it comes from the extraction and processing of solid and liquid hydrocarbons. Due to a low level of recycling and decontamination of industrial waste, a great amount of it (28.4 billion t) is stockpiled at open sites of industrial enterprises, which take up about 1 Mha of land.

The situation is much more critical with MSW. The level of its processing in Russia does not exceed 5%. The main method of treatment is sorting and separation of recyclables. The rest of the waste is usually stored at open-air disposal sites [

10,

11]. Although the share of MSW in the total volume of Russia’s waste is about 1% (or 57 Mt in 2017), it is this type of waste that poses the greatest threat to the population, as large disposal sites of MSW are located close to where most of the population resides (in the suburbs of large cities and megalopolises). The low level of MSW recovery is explained by the undeveloped waste management infrastructure. In Russia, it is represented by about 240 MSW treatment facilities; about 50 sorting complexes; and 3 incineration plants with annual capacities of 75, 200, and 750 t of MSW recovery by burning.

Thus, the share of recoverable waste is less than 50% on average, which is only provided by the industrial use of bulk waste to fill up mined-out spaces in the natural raw material extraction and to rehabilitate disturbed lands. In Russia, the level of manufacturing waste recovery does not exceed 30–60%, whereas that of MSW recovery is just about 5%. The experience of countries with a high level of MSW management development [

12] (Germany’s MSW recovery is 67.6% of the total amount of annual waste generation, that of South Korea is 59.0%, that of Slovenia is 57.8%, that of Austria is 57.7%, that of the Netherlands is 54.2%, that of Belgium is 53.7%, and that of Switzerland is 52.5%) shows that the rational organization of waste recycling can boost these indicators to 50–70% [

13,

14].

Modernizing waste management and giving up the accumulation and burial of waste in favor of its processing and reuse requires an intermediate stage of waste treatment in the next 20–30 years. Within this period, the technologies of industrial recovery of waste by burning it for the production of electricity and heat will be in high demand [

15,

16,

17,

18]. Implementing such technologies will reduce the growing amount of waste at landfills. This will preserve the boundaries of landfill sites or, in some cases, even shrink them due to the combustion of waste that is unsuitable for recycling.

Therefore, it is a relevant task to develop industrial technologies to recover large amounts of MSW. The most efficient solution to this task is combustion of waste to produce power [

16,

17,

19,

20], e.g., at trash incineration plants. However, the construction and operation of technically sophisticated industrial facilities using MSW direct combustion are commercially unviable [

21]. Moreover, electricity generation also requires extra investments in the development of new modifications of steam turbines, designed for relatively low parameters of water vapor [

22,

23]. Another technical problem, involving large investments, is strict flue gas cleaning requirements. Nowadays, there are rather tough legal restrictions [

10,

24,

25] on the content of harmful substances in the flue gases of MSW incineration plants (EU 94/67/EEC), which will entail additional installation and maintenance expenses for costly gas filtration systems.

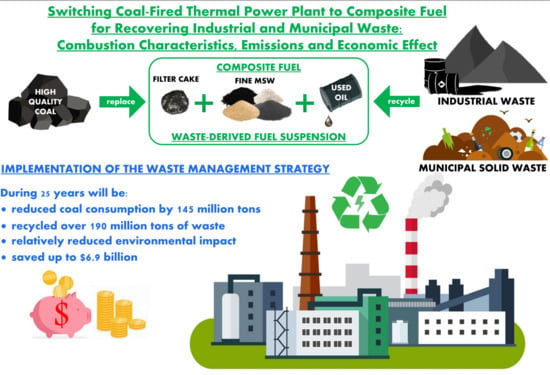

One of the alternative approaches to solving this problem is adding fine particles of MSW to composite liquid fuel based on a mixture of wet coal with a combustible liquid. Typical components are coal processing waste and used oils (engine, turbine, transformer, and other). According to a theoretical analysis [

26], burning composite fuels containing 10–20% of MSW make it possible to decrease the area of territories for MSW disposal by 20–30%. The above approach is economically efficient because free combustible waste will replace costly fossil fuels to produce electrical and thermal energy.

The design, development, and implementation of promising technologies require an in-depth study of technical, environmental, and economic aspects of a new approach to waste disposal. Therefore, the purpose of this study is to experimentally investigate the mechanism, conditions, and characteristics of composite liquid fuel combustion; to investigate the concentration of anthropogenic emissions in flue gases; as well as to analyze the economic effect of switching coal-fired thermal power plants (TPPs) to composite fuel based on industrial and municipal waste, when three neighboring industrialized regions of the Russian Federation employ the strategy to recover various combustible waste.

5. Conclusions

This paper suggests switching three typical coal-fired TPPs to composite liquid fuel, as illustrated by three neighboring regions of the Russian Federation to implement the developed strategy of industrial and municipal waste recovery. Thermal and electrical energy will be produced by these TPPs on a full scale from the composite liquid fuel combustion. Fuel slurries will be produced and transported to consumers through pipelines from the central fuel preparation plant.

Over 25 years of putting the suggested strategy into practice, 145 Mt of high-quality coal is to be saved. About 10.1 TW·h of electricity and 9.7 Pcal of heat will be generated by the recovery of 190–260 Mt of industrial and municipal waste: 130–260 Mt of FC, 25–38 Mt of MSW, and up to 19 Mt of used oils. The measures proposed for the three municipal regions will solve the problems of recovering used oils and coal processing waste. Burning MSW as a composite fuel component will solve the problem of its landfill disposal until the waste management system has been transferred to MSW recovery and reuse.

The positive economic effect with due consideration of modernizing the fuel feeding systems of the three TPPs and of constructing a central fuel preparation plant will make up 5.7 to 6.9 billion dollars, or 65–78%, respectively, of the main costs of TPPs operating on coal for 25 years. This is attributed to a decisive impact (85–95%) of the fuel constituent (energy resource acquisition) in a typical structure of total costs and to the cost of energy resources, which differs 2.5–3.5 times for coals and waste-based composite fuel (in terms of a unit of energy released during fuel combustion).

The maximum concentrations of the main anthropogenic emissions (CO2 at 16–18%; CO at 180–370 ppm; NOx at 190–400 ppm; and SOx at 75–135 ppm) in the flue gases of composite fuel do not exceed those from dry coal combustion (CO2 at 16–18%; CO at 258–344 ppm; NOx at 340–513 ppm; and SOx at 450–526 ppm).