A Standard-Based Method to Simulate the Behavior of Thermal Solar Systems with a Stratified Storage Tank

Abstract

:1. Introduction

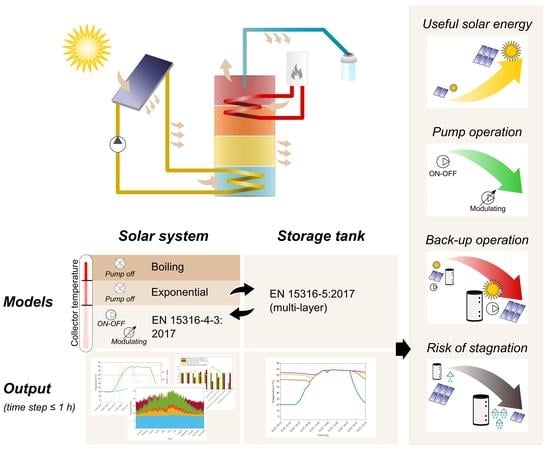

2. Standard-Based Modeling

2.1. Standardized Methods for Thermal Solar Systems

2.2. Standardized Method for Stratified Storage

2.3. Modified Dynamic Hourly Method

- The solar fluid is usually a mixture of glycol and water, not water alone.

- In a real installation, the thermal solar system is driven by a controller that controls and switches on and off the pump according to the specific conditions

- When the pump is off, the solar collectors and the storage tank are independent of each other and the average temperature of the collectors depends on the balance between collected solar heat and thermal losses of the collector alone

- The temperature of the collector may even reach the boiling point. Then the temperature remains constant during the evaporation process and it rises again during superheating, after complete evaporation of the fluid within the collector.

- Steady state condition. When the pump is on and the solar fluid flow rate is , the standard framework of a steady problem is maintained and the balance on the water-side of the solar collector reads:which is exactly the equation proposed by the standard (in 2017 version of EN 15316-4-3, in the formula for the calculation of the solar energy should be divided by the time step to obtain an energy flow).

- Exponential behavior. When the pump is off due to the solar collector temperature exceeding a safety threshold , the problem can no longer be considered as stationary. Approximating the expression of the captured energy as a first-degree polynomial (that is to say, neglecting , which leads to underestimate the thermal losses, especially at high temperature), Equation (4) becomeswhere is the reference collector area for and . In case cannot be neglected, a coefficient could be used in Equation (8) instead of , with temperature difference between collector and external air at the previous time step. The differential Equation (8) can be written in the formonce the coefficients and have been defined:The solution to the differential equation is

- Boiling. When the boiling temperature is reached, the solar input contributes to the evaporation process at constant temperature. This amount of energy must be released completely before the fluid can condense and the temperature can decrease again. A basic model can be introduced in which pressure remains constant during the process, the phase change is uniform in the solar field, and the solar field is at a uniform temperature. When the boiling temperature is achieved the energy balance reads that, in the considered time step of length , the energy available for liquid evaporation is the difference between solar input and thermal losses :The total energy contained in the evaporated solar fluid at time step h iswith energy stored as latent heat during the previous time step, that is to say, in the portion of liquid that has already evaporated. When equals the latent heat of evaporation of the remaining liquid, all the collectors content has evaporated. When becomes zero, the fluid has completely condensed back to liquid. It was chosen to neglect the superheating of the evaporated solar fluid, since the modified method is conceived as a tool to size the plant so to limit the overheating periods as much as possible. In this respect, the sole achievement of boiling periods is a warning that a correction is needed. Moreover, the main time constant of the whole evaporation/recondensation process if often far below the hour.

- Input:

- hourly weather and consumption data

- system information, including collector, storage and fluid characteristics, and control settings

- Calculation scripts:

- main code based on EN 15316-4-3

- function to check the pertinent case as per Table 1 at each time step

- code to calculate the fluid flow rate at the beginning of each time step based on the chosen pump control type (standard, on/off with overtemperature lock-out or modulating)

- storage module, invoked by the main script to provide the stratified storage tank thermal profile and the solar loop inlet and outlet temperatures

- Output:

- temperature and status time series for the desired period

- yearly number of pump operating hours, back-up operating hours and overheating occurrences

3. A Case Study

3.1. Preliminary Sizing and Standard Simulations

3.2. Modified Method: On-Off Control

3.3. Influence of Control Strategy

4. Discussion

- the pump works almost all the time except in the case of modulating control: moreover, with this control the pump works above 95% only 4% of the time; this highlights the benefit of efficient variable speed control for these applications using modern electronic pumps;

- the reduction of the back-up operating time is linked to the increase in the captured solar energy, either due to the addition of collectors or to the sunnier geographical location (such as Lampedusa, one of the three Southern Italy’s localities in Italian climatic zone A): the higher the delivered solar energy, the lower the back-up operating time;

- on the other hand, back-up operating time increases as the storage tank volume or the flow rate are decreased.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols | ||

| Calculation interval | h | |

| Q | Thermal energy | kWh |

| Thermal energy flow | W | |

| I | Solar irradiance | W/m |

| Temperature | C | |

| T | Absolute temperature | K |

| Reduced temperature of the collector | (m K)/W | |

| Collector reference area | m | |

| Collector zero-loss efficiency | - | |

| Collector efficiency | - | |

| First-order heat loss coefficient | W/(m K) | |

| Second-order heat loss coefficient | W/(m K) | |

| Incidence angle modifier at 50 | - | |

| Effective heat capacity of the collector | J/K | |

| Solar fluid mass flow rate | kg/s | |

| Solar fluid specific heat | J/(kg K) | |

| V | Volume | L |

| H | Heat loss | W/K |

| P | Electric power | W |

| Subscripts | ||

| h | Hourly | |

| m | Monthly | |

| avg | Average | |

| boil | Boiling | |

| bu | Back-up | |

| col | Collector | |

| dis | Distribution | |

| e | External | |

| eff | Effective | |

| evap | Evaporated | |

| ls | Losses | |

| min | Minimum | |

| nd | Need | |

| off | Off | |

| on | On | |

| out | Output | |

| pmp | Pump | |

| set | Thermostat setting | |

| sol | Solar | |

| sto | Storage | |

| vol | Volume | |

| W | Domestic water heating |

References

- Ivancic, A.; Mugnier, D.; Stryi-Hipp, G.; Weiss, W. Solar Heating and Cooling Technology Roadmap; Technical Report; European Technology Platform on Renewable Heating and Cooling (RHC): Brussels, Belgium, 2014. [Google Scholar]

- Fabbri, K.; Tronchin, L.; Tarabusi, V. Energy retrofit and economic evaluation priorities applied at an Italian case study. Energy Procedia 2014, 45, 379–384. [Google Scholar] [CrossRef] [Green Version]

- Pezzutto, S.; Croce, S.; Zambotti, S.; Kranzl, L.; Novelli, A.; Zambelli, P. Assessment of the Space Heating and Domestic Hot Water Market in Europe—Open Data and Results. Energies 2019, 12, 1760. [Google Scholar] [CrossRef] [Green Version]

- Gautam, A.; Chamoli, S.; Kumar, A.; Singh, S. A review on technical improvements, economic feasibility and world scenario of solar water heating system. Renew. Sustain. Energy Rev. 2017, 68, 541–562. [Google Scholar] [CrossRef]

- Hernandez, P.; Kenny, P. Net energy analysis of domestic solar water heating installations in operation. Renew. Sustain. Energy Rev. 2012, 16, 170–177. [Google Scholar] [CrossRef]

- Harrison, S.; Cruickshank, C. A review of strategies for the control of high temperature stagnation in solar collectors and systems. Energy Procedia 2012, 30, 793–804. [Google Scholar] [CrossRef] [Green Version]

- Frank, E.; Mauthner, F.; Fischer, S. Overheating Prevention and Stagnation Handling in Solar Process Heating Applications; Technical Report A.1.2, International Energy Agency, Solar Heating and Cooling Programme (IEA SHC); International Energy Agency: Paris, France, 2012. [Google Scholar]

- Quiles, P.; Aguilar, F.; Aledo, S. Analysis of the overheating and stagnation problems of solar thermal installations. Energy Procedia 2013, 48, 172–180. [Google Scholar] [CrossRef] [Green Version]

- Botpaev, R.; Louvet, Y.; Perers, B.; Furbo, S.; Vajen, K. Drainback solar thermal systems: A review. Sol. Energy 2016, 128, 41–60. [Google Scholar] [CrossRef] [Green Version]

- Kessentini, H.; Castro, J.; Capdevila, R.; Oliva, A. Development of flat plate collector with plastic transparent insulation and low-cost overheating protection system. Appl. Energy 2014, 133, 206–223. [Google Scholar] [CrossRef]

- Eismann, R. Accurate analytical modeling of flat plate solar collectors: Extended correlation for convective heat loss across the air gap between absorber and cover plate. Sol. Energy 2015, 122, 1214–1224. [Google Scholar] [CrossRef] [Green Version]

- Hussain, S.; Harrison, S. Experimental and numerical investigations of passive air cooling of a residential flat-plate solar collector under stagnation conditions. Sol. Energy 2015, 122, 1023–1036. [Google Scholar] [CrossRef]

- Streicher, W. Minimising the risk of water hammer and other problems at the beginning of stagnation of solar thermal plants-A theoritical approach. Sol. Energy 2001, 69, 187–196. [Google Scholar] [CrossRef]

- Rossiter, W., Jr.; Godette, M.; Brown, P.; Galuk, K. An investigation of the degradation of aqueous ethylene glycol and propylene glycol solutions using ion chromatography. Sol. Energy Mater. 1985, 11, 455–467. [Google Scholar] [CrossRef]

- Clifton, J.; Rossiter, W., Jr.; Brown, P. Degraded aqueous glycol solutions: pH values and the effects of common ions on suppressing pH decreases. Sol. Energy Mater. 1985, 12, 77–86. [Google Scholar] [CrossRef]

- Monticelli, C.; Brunoro, G.; Trabanelli, F.; Frignani, A. Corrosion in solar heating systems. I. Copper behaviour in water/glycol solutions. Mater. Corros. 1986, 37, 479–484. [Google Scholar] [CrossRef]

- Monticelli, C.; Brunoro, G.; Trabanelli, G.; Frignani, A. Corrosion in solar heating systems. II. Corrosion behaviour of AA 6351 in water/glycol solutions. Mater. Corros. 1987, 38, 83–88. [Google Scholar] [CrossRef]

- Monticelli, C.; Brunoro, G.; Frignani, A.; Zucchi, F. Corrosion behaviour of the aluminium alloy AA 6351 in glycol/water solutions degraded at elevated temperature. Mater. Corros. 1988, 39, 379–384. [Google Scholar] [CrossRef]

- Dow Chemical Company. Engineering and Operating Guides for Ethylene and Propylene Glycol-based Heat Transfer Fluids; Technical Report; Dow Chemical Company: Midland, MI, USA, 2008. [Google Scholar]

- Hubbard-Hall. Cracked Glycols: An Underestimated Problem; Technical Report; Hubbard-Hall Inc.: Waterbury, CT, USA, 2010. [Google Scholar]

- Cholewa, T. Improving energy efficiency of hot water storage tank by use of obstacles. Rocz. Ochr. Sr. 2013, 15, 392–404. [Google Scholar]

- Fertahi, S.D.; Jamil, A.; Benbassou, A. Review on Solar Thermal Stratified Storage Tanks (STSST): Insight on stratification studies and efficiency indicators. Sol. Energy 2018, 176, 126–145. [Google Scholar] [CrossRef]

- Han, Y.; Wang, R.; Dai, Y. Thermal stratification within the water tank. Renew. Sustain. Energy Rev. 2009, 13, 1014–1026. [Google Scholar] [CrossRef]

- Chandra, Y.; Matuska, T. Stratification analysis of domestic hot water storage tanks: A comprehensive review. Energy Build. 2019, 187, 110–131. [Google Scholar] [CrossRef]

- Steinert, P.; Göppert, S.; Platzer, B. Transient calculation of charge and discharge cycles in thermally stratified energy storages. Sol. Energy 2013, 97, 505–516. [Google Scholar] [CrossRef]

- Kicsiny, R.; Farkas, I. Improved differential control for solar heating systems. Sol. Energy 2012, 86, 3489–3498. [Google Scholar] [CrossRef]

- Ntsaluba, S.; Zhu, B.; Xia, X. Optimal flow control of a forced circulation solar water heating system with energy storage units and connecting pipes. Renew. Energy 2016, 89, 108–124. [Google Scholar] [CrossRef] [Green Version]

- Valdiserri, P. Evaluation and control of thermal losses and solar fraction in a hot water solar system. Int. J. Low-Carbon Technol. 2018, 13, 260–265. [Google Scholar] [CrossRef]

- Klein, S.; Beckman, W.; Duffie, J. A Design Procedure for Solar Heating Systems. Sol. Energy 1976, 18, 113–127. [Google Scholar] [CrossRef]

- Klein, S.; Beckman, W.; Duffie, J. A Design Procedure for Solar Air Heating Systems. Sol. Energy 1977, 19, 509–512. [Google Scholar] [CrossRef] [Green Version]

- Shrivastava, R.; Kumar, V.; Untawale, S. Modeling and simulation of solar water heater: A TRNSYS perspective. Renew. Sustain. Energy Rev. 2017, 67, 126–143. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; John Wiley & Sons Inc: Hoboken, NJ, USA, 2012. [Google Scholar]

- Camargo Nogueira, C.; Vidotto, M.; Toniazzo, F.; Debastiani, G. Software for designing solar water heating systems. Renew. Sustain. Energy Rev. 2016, 58, 361–375. [Google Scholar] [CrossRef]

- Gojak, M.; Ljubinac, F.; Banjac, M. Simulation of solar water heating system. FME Trans. 2019, 47, 1–6. [Google Scholar] [CrossRef]

- European Committee for Standardization (CEN). EN 15316-4-3–Energy Performance of Buildings-Method for Calculation of System Energy Requirements and System Efficiencies-Part 4-3: Heat GeneratIon SystemS, ThermaL Solar anD Photovoltaic Systems, Module M3-8-3, M8-8-3, M11-8-3; European Committee for Standardization: Bruxelles, Belgium, 2017. [Google Scholar]

- Socal, L. The new dynamic hourly method for the calculation of the envelope needs (Il nuovo metodo orario dinamico per il calcolo dei fabbisogni dell’involucro). Progetto 2000 2018, 54, 24. (In Italian) [Google Scholar]

- REHVA. EPB Standards-Energy Performance of Buildings Standards. Available online: https://www.rehva.eu/activities/epb-center-on-standardization/epb-standards-energy-performance-of-buildings-standards (accessed on 9 August 2019).

- European Committee for Standardization (CEN). EN 15316-5—Energy Performance of Buildings—Method for Calculation of System Energy Requirements and System Efficiencies—Part 5: Space Heating and DHW sTorage Systems (Not Cooling), Module M3-7, M8-7; European Committee for Standardization: Bruxelles, Belgium, 2017. [Google Scholar]

- Photovoltaic Geographical Information System (PVGIS). Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 26 November 2019).

- Siuta-Olcha, A.; Cholewa, T. Research of thermal stratification processes in water accumulation tank in exploitive conditions of solar hot water installation. In Proceedings of the 41st International Congress and Exhibition on Heating, Refrigerating and Air Conditioning, Belgrade, Serbia, 1–3 December 2010. [Google Scholar]

- Pernigotto, G.; Prada, A.; Gasparella, A. Extreme reference years for building energy performance simulation. J. Build. Perform. Simul. 2019. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EU) No 814/2013 of 2 August 2013 implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to EcodesigN Requirements for Water Heaters and Hot Water Storage Tanks Text with EEA Relevance; European Commission: Brussels, Belgium, 2013. [Google Scholar]

| Conditions at Time Step | ||||

|---|---|---|---|---|

| Case | Pump State | Calculation Type | ||

| 1 | On | Yes | Yes | Steady (to standard) |

| 2 | Off | No | Yes | Exponential |

| 3 | Off | No | No | Boiling |

| Characteristic | Symbol | Value | Unit |

|---|---|---|---|

| Collector area | A | 1.9 | m |

| Peak collector efficiency | 0.8 | - | |

| First order collector heat loss coefficient | 4.35 | W/(m K) | |

| Second order collector heat loss coefficient | 0.01 | W/(m K) | |

| Incidence angle modifier | 0.91 | - | |

| Collector volume content | 1.5 | L | |

| Storage volume | 500 | L | |

| Storage heat loss | 2.44 | W/K |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piana, E.A.; Grassi, B.; Socal, L. A Standard-Based Method to Simulate the Behavior of Thermal Solar Systems with a Stratified Storage Tank. Energies 2020, 13, 266. https://doi.org/10.3390/en13010266

Piana EA, Grassi B, Socal L. A Standard-Based Method to Simulate the Behavior of Thermal Solar Systems with a Stratified Storage Tank. Energies. 2020; 13(1):266. https://doi.org/10.3390/en13010266

Chicago/Turabian StylePiana, Edoardo Alessio, Benedetta Grassi, and Laurent Socal. 2020. "A Standard-Based Method to Simulate the Behavior of Thermal Solar Systems with a Stratified Storage Tank" Energies 13, no. 1: 266. https://doi.org/10.3390/en13010266

APA StylePiana, E. A., Grassi, B., & Socal, L. (2020). A Standard-Based Method to Simulate the Behavior of Thermal Solar Systems with a Stratified Storage Tank. Energies, 13(1), 266. https://doi.org/10.3390/en13010266