Liquid Water Transport Behavior at GDL-Channel Interface of a Wave-Like Channel

Abstract

:Highlights

- -

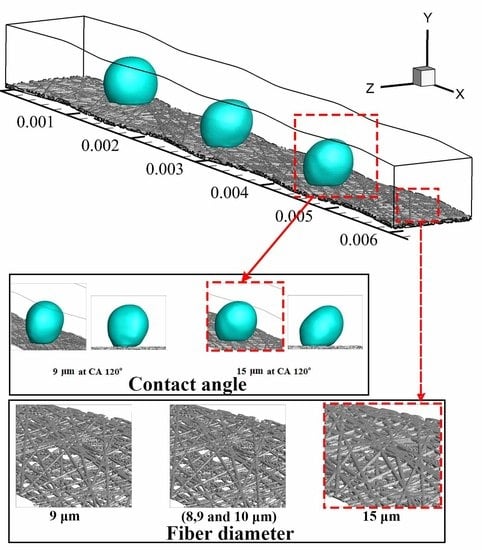

- VOF model is designed to analyze the two-phase flow on reconstructed GDL microstructures.

- -

- Fiber diameter of the GDL influences the contact angle of liquid water on its surface.

- -

- Non-uniform fibrous structures promote the transport of liquid water.

- -

- Choice of smaller fiber diameter favours in-plane average speed of liquid water.

- -

- The droplet speed decreases under low inlet velocity, whereas it increases under high velocity.

1. Introduction

2. Numerical Methods

2.1. Algorithmic Reconstruction of GDL Microstructure

- Fiber radius

- Fiber height

- Number of layers

- Target porosity

- i.

- Initiate the state of the pseudo-random number generator.

- ii.

- Estimate the number of fibers required per layer from porosity.

- iii.

- Randomly generate the points for the fiber layers on specified planes.

- iv.

- Randomly generate the fiber orientations for fibers.

- v.

- Calculate porosity.

- vi.

- When necessary: Change the number of fibers per layer and iterate steps i and iii–v until porosity converges.

- vii.

- Create all the layers.

2.2. Governing Equations

2.3. Model Assumptions

- The GDL is treated as carbon paper.

- The carbon fibers in the GDL microstructure are straight cylinders randomly arranged in a plane with uniform and non-uniform diameters.

- The carbon fiber orientation is perpendicular to the direction of the GDL thickness and can be overlapped.

- The procedure with polytetrafluoroethylene treatment is ignored.

- The two-phase flow inside the channel is incompressible, transient and laminar.

- Transport properties of the fluids keep constant, and no phase change occurs in the process.

2.4. Computational Domain

2.5. Boundary and Initial Conditions

2.6. Numerical Procedures

2.7. Model Validation and Grid Independence

3. Results and Discussion

3.1. Comparative Check: Rough versus Smooth Surface

3.2. Analysis of Permeability

3.3. Effect of Surface Structure

3.4. Effect of GDL Contact Angle

3.5. Effect of Droplet Size

3.6. Effect of Superficial Velocity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

List of Symbols

| Volume fraction of the gas phase | |

| Volume fraction of the liquid phase | |

| C | Kozeny–Carman constant/m2 |

| ɛ | Porosity |

| Momentum source term linked to the surface tension effect/N | |

| Gravitational acceleration vector/m s−2 | |

| k | Permeability m2 |

| Mean surface curvature at the two-phase interface/m−1 | |

| Dynamic viscosity of the interacting mixture/Pa s | |

| Unit normal vector to the wall | |

| Modified pressure/kPa | |

| R | Radius of fiber/µm |

| Averaged liquid phase density/kg m−3 | |

| Surface tension coefficient/J s−1 | |

| Unit normal tangential vector to the wall | |

| Static contact angle/˚ | |

| Velocity vector/m s−1 | |

| Gas phase velocity vector/m s−1 | |

| Liquid phase velocity vector/m s−1 | |

| Relative velocity of both phases at interface/m s−1 | |

| Position vector/m |

References

- Jin, D.; Ocone, R.; Jiao, K.; Xuan, J. Energy and AI. Energy AI 2020, 1, 100002. [Google Scholar] [CrossRef]

- Bejan, A. AI and freedom for evolution in energy science. Energy AI 2020, 1, 100001. [Google Scholar] [CrossRef]

- Zhang, X.; Higier, A.; Zhang, X.; Liu, H. Experimental studies of effect of land width in PEM fuel cells with serpentine flow field and carbon cloth. Energies 2019, 12, 471. [Google Scholar] [CrossRef] [Green Version]

- Hyun Kim, J.; Tae Kim, W. Numerical investigation of gas-liquid two-phase flow inside PEMFC gas channels with rectangular and trapezoidal cross sections. Energies 2018, 11, 1403. [Google Scholar]

- Ijaodola, O.; Ogungbemi, E.; Khatib, F.N.; Wilberforce, T.; Ramadan, M.; El Hassan, Z.; Thompson, J.; Olabi, A.G. Evaluating the effect of metal bipolar plate coating on the performance of proton exchange membrane fuel cells. Energies 2018, 11, 3203. [Google Scholar] [CrossRef] [Green Version]

- Mortazavi, M.; Tajiri, K. In-Plane Microstructure of Gas Diffusion Layers with Different Properties for PEFC. J. Fuel Cell Sci. Technol. 2014, 11, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Benziger, J.N.; David, B.; Tom, B.; Johannah, I. Water flow in the gas diffusion layer of PEM fuel cells. J. Membr. Sci. 2005, 261, 98–106. [Google Scholar] [CrossRef]

- Fadzillah, D.M.; Rosli, M.I.; Talib, M.Z.M.; Kamarudin, S.K.; Daud, W.R.W. Review on microstructure modelling of a gas diffusion layer for proton exchange membrane fuel cells. Renew. Sustain. Energy Rev. 2016, 11, 235. [Google Scholar] [CrossRef]

- Park, J.W.; Jiao, K.; Li, X. Numerical investigations on liquid water removal from the porous gas diffusion layer by reactant flow. Appl. Energy 2010, 87, 2180–2186. [Google Scholar] [CrossRef]

- Froning, D.; Brinkmann, J.; Reimer, U.; Schmidt, V.; Lehnert, W.; Stolten, D. 3D analysis, modeling and simulation of transport processes in compressed fibrous microstructures, using the Lattice Boltzmann method. Electrochem. Acta 2013, 110, 325–334. [Google Scholar] [CrossRef] [Green Version]

- Vinh, N.D.; Kim, H.M. Comparison of numerical and experimental studies for flow-field optimization based on under-rib convection in polymer electrolyte membrane fuel cells. Energies 2016, 9, 844. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Liu, Z.; Liu, F.; Liu, W. Numerical simulation of water transport in a proton exchange membrane fuel cell flow channel. Energies 2018, 11, 1770. [Google Scholar] [CrossRef] [Green Version]

- Kakaee, A.H.; Molaeimanesh, G.R.; Elyasi Garmaroudi, M.H. Impact of PTFE distribution across the GDL on the water droplet removal from a PEM fuel cell electrode containing binder. Int. J. Hydrog. Energy 2018, 43, 15481–15491. [Google Scholar] [CrossRef]

- Balzarotti, R.; Latorrata, S.; Mariani, M.; Gallo, S.P.; Dotelli, G. Optimization of Perfluoropolyether-Based Gas Diffusion Media Preparation for PEM Fuel Cells. Energies 2020, 13, 1831. [Google Scholar] [CrossRef] [Green Version]

- Niu, Z.; Bao, Z.; Wu, J.; Wang, Y.; Jiao, K. Two-phase flow in the mixed-wettability gas diffusion layer of proton exchange membrane fuel cells. Appl. Energy 2018, 232, 443–450. [Google Scholar] [CrossRef]

- Jeong, H.C.; Ki Tae, P.; Dong, H.J.; Sang, G.K.; Sung, H.K. Numerical modeling and experimental study of the influence of GDL properties on performance in a PEMFC. Int. J. Hydrog. Energy 2011, 36, 1837–1845. [Google Scholar]

- Niu, Z.; Wu, J.; Bao, Z.; Wang, Y.; Yin, Y.; Jiao, K. Two-phase flow and oxygen transport in the perforated gas diffusion layer of proton exchange membrane fuel cell. Int. J. Heat Mass Transf. 2019, 139, 58–68. [Google Scholar] [CrossRef] [Green Version]

- Yiotis, A.G.; Kainourgiakis, M.E.; Charalambopoulou, G.C.; Stubos, A.K. Microscale characterisation of stochastically reconstructed carbon fiber-based Gas Diffusion Layers; effects of anisotropy and resin content. J. Power Sources 2016, 320, 153–167. [Google Scholar] [CrossRef]

- Hwang, C.; Masayoshi, I.; Hiroshi, I.; Tetsuhiko, M.; Akihiro, N.; Yasuo, H.; Naoto, Y.; Atsushi, K.; Tetsuya, Y. Influence of properties of gas diffusion layers on the performance of polymer electrolyte-based unitized reversible fuel cells. Int. J. Hydrog. Energy 2011, 36, 1740–1753. [Google Scholar] [CrossRef] [Green Version]

- Hung, C.J.; Liu, C.H.; Ko, T.H.; Chen, W.H.; Cheng, S.H.; Chen, W.S.; Yu, A.; Kannan, A.M. Effect of diffusion layers fabricated with different fiber diameters on the performance of low temperature proton exchange membrane fuel cells. J. Power Sources 2013, 221, 134–140. [Google Scholar] [CrossRef]

- Shahraeeni, M.; Hoorfar, M. Pore-network modeling of liquid water flow in gas diffusion layers of proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2014, 39, 10697–10709. [Google Scholar] [CrossRef]

- Agaesse, T.; Lamibrac, A.; Büchi, F.N.; Pauchet, J.; Prat, M. Validation of pore network simulations of ex-situ water distributions in a gas diffusion layer of proton exchange membrane fuel cells with X-ray tomographic images. J. Power Sources 2016, 331, 462–474. [Google Scholar] [CrossRef] [Green Version]

- Straubhaar, B.; Pauchet, J.; Prat, M. Pore network modeling of condensation in gas diffusion layers of proton exchange membrane fuel cells. Int. J. Heat Mass Transf. 2016, 102, 891–901. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Montana, A.; Chen, F. Evaluation of porosity and thickness on effective diffusivity in gas diffusion layer. J. Power Sources 2017, 342, 252–265. [Google Scholar] [CrossRef]

- Yin, Y.; Wu, T.; He, P.; Du, Q.; Jiao, K. Numerical simulation of two-phase cross flow in microstructure of gas diffusion layer with variable contact angle. Int. J. Hydrog. Energy 2014, 39, 15772–15785. [Google Scholar] [CrossRef]

- Ferreira, R.; Falcao, D.; Oliveria, V.; Pinto, A. Numerical simulations of two-phase flow in proton exchange membrane fuel cells using the volume of fluid method—A review. J. Power Sources 2015, 277, 329–342. [Google Scholar] [CrossRef]

- Niu, Z.; Wang, Y.; Jiao, K.; Wu, J. Two-Phase Flow Dynamics in the Gas Diffusion Layer of Proton Exchange Membrane Fuel Cells: Volume of Fluid Modeling and Comparison with Experiment. J. Electrochem. Soc. 2018, 165, F613–F620. [Google Scholar] [CrossRef]

- Niu, Z.; Jiao, K.; Wang, Y.; Du, Q.; Yin, Y. Numerical simulation of two-phase cross flow in the gas diffusion layer microstructure of proton exchange membrane fuel cells. Int. J. Energy Res. 2018, 42, 802–816. [Google Scholar] [CrossRef] [Green Version]

- He, G.; Yamazaki, Y.; Abudula, A. The effect of wall roughness on the liquid removal in micro-channels related to a proton exchange membrane fuel cell (PEMFC). J. Power Sources 2010, 195, 1561–1568. [Google Scholar] [CrossRef]

- Chen, L.; Luan, H.B.; He, Y.L.; Tao, W.Q. Effects of Roughness of Gas Diffusion Layer Surface on Liquid Water Transport in Micro Gas Channels of a Proton Exchange Membrane Fuel Cell. Numer. Heat Transf. Part A Appl. 2012, 62, 295–318. [Google Scholar] [CrossRef]

- Chen, L.; He, Y.L.; Tao, W.Q. Effects of surface microstructures of gas diffusion layer on water droplet dynamic behaviors in a micro gas channel of proton exchange membrane fuel cells. Int. J. Heat Mass Transf. 2013, 60, 252–262. [Google Scholar] [CrossRef]

- Ashrafi, M.; Shams, M. Effects of heterogeneous surface of gas diffusion layers on droplet transport in microchannels of PEM fuel cells. Int. J. Hydrog. Energy 2015, 41, 1–16. [Google Scholar] [CrossRef]

- Chen, S.; Doolen, G.D. Lattice Boltzmann method for fluid flows. Annu. Rev. Fluid Mech 1998, 30, 329–364. [Google Scholar] [CrossRef] [Green Version]

- Palakurthi, N.; Konangi, S.; Ghia, U.; Comer, K. Micro-scale simulation of unidirectional capillary transport of wetting liquid through 3D fibrous porous media: Estimation of effective pore radii. Int. J. Multiph. Flow 2015, 77, 48–57. [Google Scholar] [CrossRef]

- Vallabh, R.; Banks-Lee, P.; Seyam, A.F. New approach for determining tortuosity in fibrous Porous Media. J. Eng. Fibers Fabr. 2010, 5, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Thiedmann, R.; Fleischer, F.; Hartnig, C.; Lehnert, W.; Schmidt, V. Stochastic 3d modeling of the gdl structure in pemfcs based on thin section detection. J. Electrochem. Soc. 2008, 155, B391–B399. [Google Scholar] [CrossRef]

- Flückiger, R.; Marone, F.; Stampanoni, M.; Wokaun, A.; Büchi, F.N. Investigation of liquid water in gas diffusion layers of polymer electrolyte fuel cells using X-ray tomographic microscopy. Electrochim. Acta 2011, 56, 2254–2262. [Google Scholar] [CrossRef]

- Zhou, X.; Niu, Z.; Li, Y.; Sun, X.; Du, Q.; Xuan, J.; Jiao, K. Investigation of two-phase flow in the compressed gas diffusion layer microstructures. Int. J. Hydrog. Energy 2019, 44, 26498–26516. [Google Scholar] [CrossRef]

- Anyanwu, I.S.; Hou, Y.; Xi, F.; Wang, X.; Yin, Y.; Du, Q.; Jiao, K. Comparative analysis of two-phase flow in sinusoidal channel of different geometric configurations with application to PEMFC. Int. J. Hydrog. Energy 2019, 44, 13807–13819. [Google Scholar] [CrossRef]

- Miwa, M.; Nakajima, A.; Fujishima, A.; Hashimoto, K.; Watanabe, T. Effects of the Surface Roughness on Sliding Angles of Water Droplets on Superhydrophobic Surfaces. Langmuir 2000, 16, 5754–5760. [Google Scholar] [CrossRef]

- Habibi, M.; Ruiz, E.; Lebrun, G.; Laperrie‘re, L. Effect of surface density and fiber length on the porosity and permeability of nonwoven flax reinforcement. Text. Res. J. 2018, 88, 1776–1787. [Google Scholar] [CrossRef]

- Davies, C.N. The Separation of Airborne Dust and Particles. Proc. Instit. Mech. Eng. Pt. B Manag. Eng. Manuf. 1953, 1, 185–231. [Google Scholar]

- Feser, J.P.; Prasad, A.K.; Advani, S.G. Experimental characterization of in-plane permeability of gas diffusion layers. J. Power Sources 2006, 162, 1226–1231. [Google Scholar] [CrossRef]

- Anyanwu, I.S.; Hou, Y.; Chen, W.; Pan, F.; Du, Q.; Xuan, J.; Jiao, K. Numerical investigation of liquid water transport dynamics in novel hybrid sinusoidal flow channel designs for PEMFC. Energies 2019, 12, 4031. [Google Scholar] [CrossRef] [Green Version]

- Bao, N.; Zhou, Y.; Jiao, K.; Yin, Y.; Du, Q.; Chen, J. Effect of Gas Diffusion Layer Deformation on Liquid Water Transport in Proton Exchange Membrane Fuel Cell. Eng. Appl. Comp. Fluid Mech. 2014, 8, 26–43. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anyanwu, I.S.; Niu, Z.; Jiao, D.; Najmi, A.-U.-H.; Liu, Z.; Jiao, K. Liquid Water Transport Behavior at GDL-Channel Interface of a Wave-Like Channel. Energies 2020, 13, 2726. https://doi.org/10.3390/en13112726

Anyanwu IS, Niu Z, Jiao D, Najmi A-U-H, Liu Z, Jiao K. Liquid Water Transport Behavior at GDL-Channel Interface of a Wave-Like Channel. Energies. 2020; 13(11):2726. https://doi.org/10.3390/en13112726

Chicago/Turabian StyleAnyanwu, Ikechukwu S., Zhiqiang Niu, Daokuan Jiao, Aezid-Ul-Hassan Najmi, Zhi Liu, and Kui Jiao. 2020. "Liquid Water Transport Behavior at GDL-Channel Interface of a Wave-Like Channel" Energies 13, no. 11: 2726. https://doi.org/10.3390/en13112726

APA StyleAnyanwu, I. S., Niu, Z., Jiao, D., Najmi, A. -U. -H., Liu, Z., & Jiao, K. (2020). Liquid Water Transport Behavior at GDL-Channel Interface of a Wave-Like Channel. Energies, 13(11), 2726. https://doi.org/10.3390/en13112726