The Role of Innovation in Industry Product Deployment: Developing Thermal Energy Storage for Concentrated Solar Power

Abstract

:1. Introduction

2. Innovation in Concentrating Solar Power (CSP)

- A case based on the acquisition of new competences in the field of solar energy but that integrated and enhanced the existing competences in conventional power plant engineering.

- A product innovation to offer renewable solar plants with energy dispatchability. A process innovation for excellence in manufacturing and operation processes.

- A system innovation (solar plant parabolic through collector and tower plants) but also a component innovation. In a solar plant there are many critical components designed, “ad-hoc” that constitute in themselves new products/equipment for the value chain. Solar receivers, thermal energy storage systems, solar trackers, specific measurement equipment, etc.

- A disruptive innovation (PS-10 the first commercial solar thermal plant in the world) but also an incremental innovation for cost reduction and efficiency improvement: parabolic trough solar thermal plants with large opening manifolds, tower plants with superheated steam and molten salts.

- Technological risks: materials in extreme conditions of temperature and pressure, corrosion associated with heat transfer fluids, desert environments and subject to wind loads, physical limits on optical properties, thermodynamic limits.

- Non-technological component: geographies and first to market.

3. Case Study: Thermal Energy Storage (TES) for CSP at Abengoa

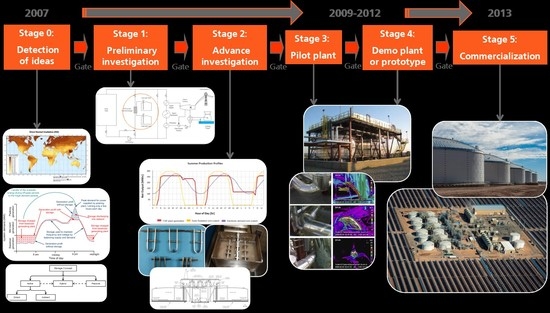

- The first stage was the creation of the R&D network in 2007, funded with the Spanish CENIT project ConSOLida 2008–1005, where the biggest challenges were the confidentiality needed between the company and the R&D institutions, the training activity needed, the need to achieve results following a schedule fixed by market demands, and last but not least, the need to develop deep relationships of trust.

- The second stage was the testing at pilot plant at the University of Lleida, where a 0.3 MWht pilot plant was built to carry out a deep characterisation of the molten salt properties [38]. At the same time research was carried out at the University of Barcelona, where thermomechanical testing under operating conditions of container materials such as A516Gr70 were developed [39], and at Inasmet, where corrosion tests were performed [40].

- The TES pilot plant was integrated in a parabolic trough plant that uses thermal oil as HTF. The heat transfer fluid cedes heat to the salt through a heat exchanger. The design capacity of the plant was 2.1 MWth with four hours of thermal storage, representing a total thermal capacity of 8.4 MWth. The salts used in this system are the so-called solar salts, comprising a mix of NaNO3 (sodium nitrate) and KNO3 (potassium nitrate).

- The next step was the development of high-level collaboration with a framework of collaboration agreement of the newly developed TES system (Interconecta Thesto ITC-20111050) to develop a new TES concept for direct steam generation, based on solid particle and phase change materials (PCM) solutions. The idea was to explore alternatives to the molten salt sensible heat TES with more technologically complex solutions, leveraging the baseline developments.

- Then, advanced development of the technology was achieved with several frameworks of collaboration in thermochemical storage with European funding under the H2020 funding scheme.

- To finally achieve leadership in the sector with 6000 MWht installed in a thermal storage system, strong collaboration agreements with several R&D partners worldwide, and the development of hybridization new concepts.

4. The Dichotomy: Private versus Public Funding

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Veugelers, R.; Cassiman, B. R&D cooperation between firms and universities. Some empirical evidence from Belgian manufacturing. Int. J. Ind. Organ. 2005, 23, 355–379. [Google Scholar]

- Cockburn, I.M.; Henderson, R.M. Publicly funded science and the productivity of the pharmaceutical industry. Innov. Policy Econ. 2000, 1, 1–34. [Google Scholar] [CrossRef] [Green Version]

- Coad, A.; Rao, R. Innovation and firm growth in high-tech sectors: A quantile regression approach. Res. Policy 2008, 37, 633–648. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Miozzo, M. Which types of knowledge-intensive business services firms collaborate with universities for innovation? Res. Policy 2019, 48, 1633–1646. [Google Scholar] [CrossRef]

- Shubbak, M.H. The technological system of production and innovation: The case of photovoltaic technology in China. Res. Policy 2019, 48, 993–1015. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Jeppesen, J.; Bandsholm, J.; Asmussen, J.; Balachandran, R.; Vestergaard, S.; Andersen, T.H.; Sørensen, T.K.; Bjørn-Thygesen, F. Navigating the “paradox of openness” in energy and transport innovation: Insights from eight corporate clean technology research and development case studies. Energy Policy 2017, 105, 236–245. [Google Scholar] [CrossRef] [Green Version]

- Im, H.J.; Shon, J. The effect of technological imitation on corporate innovation: Evidence from US patent data. Res. Policy 2019, 48, 103802. [Google Scholar] [CrossRef]

- Schoonhoven, C.B.; Eisenhardt, K.M.; Lyman, K. Speeding products to market: Waiting time to first product introduction in new firms. Adm. Sci. Q. 1990, 35, 177–207. [Google Scholar] [CrossRef]

- Ortiz-Villajos, J.M.; Sotoca, S. Innovation and business survival: A long-term approach. Res. Policy 2018, 47, 1418–1436. [Google Scholar] [CrossRef]

- Iqbal, A.M.; Khan, A.S.; Bashir, F.; Senin, A.A. Evaluating national innovation system of Malaysia based on university-industry research collaboration: A system thinking approach. Asian Soc. Sci. 2015, 11, 45–60. [Google Scholar]

- Ivascu, L.; Cirjaliu, B.; Draghici, A. Business model for the university-industry collaboration in open innovation. Procedia Econ. Financ. 2016, 39, 674–678. [Google Scholar] [CrossRef] [Green Version]

- Chesbrough, H. Open Innovation Results: Going Beyond the Hype and Getting Down to Business. 2019. Available online: https://www.oxfordscholarship.com/view/10.1093/oso/9780198841906.001.0001/oso-9780198841906 (accessed on 7 June 2020). [CrossRef]

- Xu, K.; Huang, K.F.; Gao, S. Technology sourcing, appropriability regimes, and new product development. J. Eng. Technol. Manag. 2012, 29, 265–280. [Google Scholar] [CrossRef]

- De Silva, M.; Howells, J.; Meyer, M. Innovation intermediaries and collaboration: Knowledge–based practices and internal value creation. Res. Policy 2018, 47, 70–87. [Google Scholar] [CrossRef]

- Bowonder, B.; Miyake, T. Technology management: A knowledge ecology perspective. Int. J. Technol. Manag. 2000, 19, 7–8. [Google Scholar] [CrossRef]

- Grillitsch, M.; Schubert, T.; Srholec, M. Knowledge base combinations and firm growth. Res. Policy 2019, 48, 234–247. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2017. 2018. Available online: https://www.irena.org/publications/2018/Jan/Renewable-power-generation-costs-in-2017 (accessed on 7 June 2020).

- Siegel, N. Where do we go from here? ASME J. Sol. Energy Eng. 2019, 141, 020301. [Google Scholar] [CrossRef] [Green Version]

- Cooper, R.G. Stage-gate systems: A new tool for managing new products. Bus. Horiz. 1990, 33, 44–54. [Google Scholar] [CrossRef]

- Cooper, R.G. The drivers of success in new-product development. Ind. Mark. Manag. 2019, 76, 36–47. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Prieto, C.; Miró, L.; Gasia, J.; Peiró, G. Design and start-up of two pilot plants for molten salts storage testing. In Energy Sustainability; 2016; 9p, ES2016-59268, V001T04A009; Available online: https://asmedigitalcollection.asme.org/ES/proceedings-abstract/ES2016/50220/V001T04A009/231285 (accessed on 7 June 2020).

- Prieto, C.; Ruiz-Cabañas, F.J.; Rodríguez-Sanchez, A.; Rubio Abujas, C.; Fernández, A.I.; Martínez, M.; Oró, E.; Cabeza, L.F. Effect of the impurity magnesium nitrate in the thermal decomposition of the solar salt. Sol. Energy 2019, 192, 186–192. [Google Scholar] [CrossRef]

- Prieto, C.; Osuna, R.; Fernández, A.I.; Cabeza, L.F. Molten salt facilities, lessons learnt at pilot plant scale to guarantee commercial plants; heat losses evaluation and correction. Renew. Energy 2016, 94, 175–185. [Google Scholar] [CrossRef] [Green Version]

- Prieto, C.; Osuna, R.; Fernández, A.I.; Cabeza, L.F. Thermal storage in a MW scale. Molten salt solar thermal pilot facility: Plant description and commissioning experiences. Renew. Energy 2016, 99, 852–866. [Google Scholar] [CrossRef]

- Prieto, C.; Rodríguez-Sánchez, A.; Ruiz-Cabañas, F.J.; Cabeza, L.F. Feasibility study of freeze recovery options in parabolic trough collector plants working with molten salt as heat transfer fluid. Energies 2019, 12, 2340. [Google Scholar] [CrossRef] [Green Version]

- Abengoa. 2017. Available online: http://www.abengoa.es/web/es/noticias_y_publicaciones/noticias/historico/2017/08_agosto/20170816-NP-Xina.html (accessed on 20 May 2020).

- Mohammed bin Rashid Al Maktoum Solar Park. 2020. Available online: https://www.dewa.gov.ae/en/about-us/strategic-initiatives/mbr-solar-park (accessed on 20 May 2020).

- CSP Focus. Waad al Shamal. 2017. Available online: http://www.cspfocus.cn/en/market/detail_262.html (accessed on 20 May 2020).

- Abengoa. 2016. Available online: http://www.abengoa.com/web/en/noticias_y_publicaciones/noticias/historico/2016/02_febrero/abg_20160205.html (accessed on 11 March 2020).

- Alguacil, M.; Prieto, C.; Rodriguez, A.; Lohr, J. Direct steam generation in parabolic trough collectors. Energy Procedia 2014, 49, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Montero, C.; Navío, R.; Llorente, P.; Romero, M.C.; Martínez, J. CRS sales: Abengoa’s molten salt pilot power tower plant celebrates one year of uninterrupted operation. Energy Procedia 2014, 49, 488–497. [Google Scholar] [CrossRef] [Green Version]

- Prieto, C.; Fereres, S.; Ruiz-Cabañas, F.J.; Rodriguez-Sanchez, A.; Montero, C. Carbonate molten salt solar thermal pilot facility: Plant design, commissioning and operation up to 700 °C. Renew. Energy 2020, 151, 528–541. [Google Scholar] [CrossRef]

- Quero, M.; Korzynietz, R.; Ebert, M.; Jiménez, A.A.; del Río, A.; Brioso, J.A. Solugas—Operation experience of the first solar hybrid gas turbine system at MW scale. Energy Procedia 2014, 49, 1820–1830. [Google Scholar] [CrossRef] [Green Version]

- Del Rio, A.; Korzynietz, R.; Brioso, J.A.; Gallas, M.; Ordóñez, I.; Quero, M.; Díaz, C. Soltrec—Pressurized volumetric solar air receiver technology. Energy Procedia 2015, 69, 360–368. [Google Scholar] [CrossRef] [Green Version]

- González-Roubaud, E.; Pérez-Osorio, D.; Prieto, C. Review of commercial thermal energy storage in concentrated solar power plants: Steam vs. molten salts. Renew. Sustain. Energy Rev. 2017, 80, 133–148. [Google Scholar] [CrossRef]

- Cassiman, B.; Veugelers, R.; Arts, S. Mind the gap: Capturing value from basic research through combining mobile investors and partnerships. Res. Policy 2018, 47, 1811–1824. [Google Scholar] [CrossRef]

- Bodas Freitas, I.M.; Geuna, A.; Rossi, F. Finding the right partners: Institutional and personal modes of governance of university–industry interactions. Res. Policy 2013, 42, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Peiró, G.; Prieto, C.; Gasia, J.; Jové, J.; Miró, L.; Cabeza, L.F. Two-tank molten salts thermal energy storage system for solar power plants at pilot plant scale: Lessons learnt and recommendations for its design, start-up and operation. Renew. Energy 2018, 121, 236–248. [Google Scholar] [CrossRef]

- Prieto, C.; Gallardo-González, J.; Ruiz-Cabañas, F.J.; Barreneche, C.; Martínez, M.; Segarra, M.; Fernández, A.I. Study of corrosion by Dynamic Gravimetric Analysis (DGA) methodology. Influence of chloride content in solar salt. Sol. Energy Mater. Sol. Cells 2016, 157, 526–532. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Cabañas, F.J.; Prieto, C.; Osuna, R.; Madina, V.; Fernández, A.I.; Cabeza, L.F. Corrosion testing device for in-situ corrosion characterization in operational molten salts storage tanks: A516 Gr70 carbon steel performance under molten salts exposure. Sol. Energy Mater. Sol. Cells 2016, 157, 383–392. [Google Scholar] [CrossRef]

- Rajalo, S.; Vadi, M. University-industry innovation collaboration: Reconceptualization. Technovation 2017, 62–63, 42–54. [Google Scholar] [CrossRef]

- Liew, M.S.; Tengku Shahdan, T.N.; Lim, E.S. Enablers in enhancing the relevancy of university-industry collaboration. Procedia Soc. Behav. Sci. 2013, 93, 1889–1896. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Cabañas, F.J.; Prieto, C.; Madina, V.; Fernández, A.I.; Cabeza, L.F. TES-PS10 postmortem tests: Carbon steel corrosion performance exposed to molten salts under relevant operation conditions and lessons learnt for commercial scale-up. J. Energy Storage 2019, 26, 100922. [Google Scholar] [CrossRef]

- Hasan, S.; Koning, R. Conversations and idea generation: Evidence from a field experiment. Res. Policy 2019, 48, 103811. [Google Scholar] [CrossRef]

- Shaikh, M.; Levina, N. Selecting an open innovation community as an alliance partner: Looking for healthy communities and ecosystems. Res. Policy 2019, 48, 103766. [Google Scholar] [CrossRef]

- Maskus, K.E.; Milani, S.; Neumann, R. The impact of patent protection and financial development on industrial R&D. Res. Policy 2019, 48, 355–370. [Google Scholar]

- Lilliestam, J.; Labordena, M.; Patt, A.; Pfenninger, S. Empirically observed learning rates for concentrating solar power and their responses to regime change. Nat. Energy 2017, 2, 17094. [Google Scholar] [CrossRef]

- Arrilucea, E.; Kuittinen, H. Case Study Report: US SunShot Initiative and Reflections of the Chinese Solar Energy Policies. 2018. Available online: http://www.jiip.eu/mop/wp/wp-content/uploads/2018/09/US_SunShot_ArriluceaKuittinen.pdf (accessed on 7 June 2020).

| Strategy | Horizon 1 (2007) | Horizon 2 (2012) | Horizon 3 (2020) |

|---|---|---|---|

| Business and products | Saturated and superheated towers: PS10, PS20, and PS50 | - Parabolic trough collector - Molten salt tower and superheater tower | Dispatchability: effective response to the “electricity peak demand” |

| Objectives: master technologies | - Parabolic trough technology - Superheated steam towers - Saturated steam towers - Heliostats - Molten salts thermal energy storage - Solar field calculation codes | - Molten salt tower - Advanced cycles - Heliostat of the future - Collector of the future | - Design receivers at higher temperature - Seek breakthrough innovations - Hybrid solutions |

| Main actions | - Support PS10 and PS20 - New funding for research and development (R&D) facilities - Manage IP portfolio - Manage costs and grants follow up | - Operation of molten salt pilot plant - Engineering of a commercial molten salt tower plant - Operation of air receiver solar plant Solugas - Potent maps and IP gap identification | - Assess feasibility of new concepts (high temperature, light management) - New fluids and materials - Technical surveillance - File patents in key technologies |

| Type of CSP | Name | Power | Solar Collectors | Heat Transfer Fluid | Maximum Working Temperature | Operation | Hours of Operation | Used in Commercial Plant | Reference |

|---|---|---|---|---|---|---|---|---|---|

| Trough technology | Repow | 2.1 MWt | 1 loop of 600 m (4 collector) | Oil | 400 °C | 2007–2012 | 30,000 h in 2014 | PTC components used in Solnova 1 (Spain) Xina Solar One | [26] |

| 2 larger aperture collectors of 300 m | Oil | 400 °C | 2014–2016 | 500 h | DEWA Hybrid solar-gas plant WAS (Waad Al-Shamal) | [27] [28] | |||

| Indirect molten salt storage | Molten salts dual tank TES | 9 MWht | --- | Oil/MS | 400 °C | 2009–2012 | >32,000 | Solana Power Plant | [21,22,23,24] |

| Superheater steam receiver | Eureka | 5 MWt | 60 heliostats of 120 m2 | Solar salt | 550 °C | 2009–2011 | >2000 | Khi Solar One | [29] |

| Direct steam generation | Eureka-DSG | 8 MWt | 3 loops saturated; 2 loops superheated | Water | 550 °C | 2009–2011 | 2000 | Process heat | [30] |

| Molten salt receiver | CRS Sales | 5 MWt | 85 heliostats of 120 m2 | Solar salt | 565 °C | 2012–2015 | 3600 | Cerro Dominador | [31] |

| New HTF | Avanza2 | --- | --- | Ternary carbonate | 700 °C | 2014–2015 | 1000 | --- | [32] |

| Gas receiver (tubular receiver and volumetric pressurized air receiver) | Solugas | 3 MWt | 69 heliostats of 120 m2 | Air | 800 | 2012–2014 | 1200 | --- | [33] |

| Cersol | 105 kWht | 1000 | 2014 | 100 | --- | --- | |||

| Soltrec | 3 MWt | 1000 | 2015 | 200 | --- | [34] |

| Receiver Panel Conditions | Flow Conditions | ||

|---|---|---|---|

| Paths | 2 | HTF | Superheated steam |

| Panels | 6 | Inlet temperature | 300 °C |

| Passes per panel | 4 | Outlet temperature | 530 °C |

| Tubes per pass | 7 | Inlet pressure | 85 bar |

| – | – | Mass flow | 3.4 kg/s |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prieto, C.; Fereres, S.; Cabeza, L.F. The Role of Innovation in Industry Product Deployment: Developing Thermal Energy Storage for Concentrated Solar Power. Energies 2020, 13, 2943. https://doi.org/10.3390/en13112943

Prieto C, Fereres S, Cabeza LF. The Role of Innovation in Industry Product Deployment: Developing Thermal Energy Storage for Concentrated Solar Power. Energies. 2020; 13(11):2943. https://doi.org/10.3390/en13112943

Chicago/Turabian StylePrieto, Cristina, Sonia Fereres, and Luisa F. Cabeza. 2020. "The Role of Innovation in Industry Product Deployment: Developing Thermal Energy Storage for Concentrated Solar Power" Energies 13, no. 11: 2943. https://doi.org/10.3390/en13112943

APA StylePrieto, C., Fereres, S., & Cabeza, L. F. (2020). The Role of Innovation in Industry Product Deployment: Developing Thermal Energy Storage for Concentrated Solar Power. Energies, 13(11), 2943. https://doi.org/10.3390/en13112943