Improved Analysis on the Fin Reliability of a Plate Fin Heat Exchanger for Usage in LNG Applications

Abstract

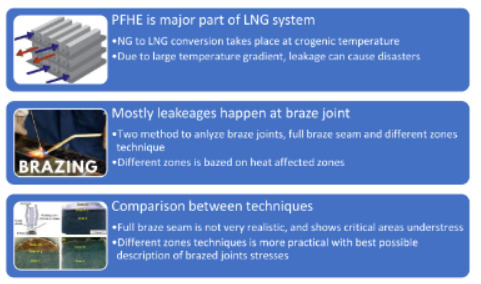

:1. Introduction

2. Materials and Methods

ANSYS Software for Analysis

3. Results and Discussions

3.1. Stress for Brazed Joint in Upper/Lower Brazed Seam of PFHE Using Earlier Yield Criteria and Modified Different Zones Strength Criteria for a Plain Fin

3.2. Vertical Strength of Brazed Joint Using Normal Yield Criteria and Different Zones Criteria

3.3. Modified Margin of Safety by Using Different Zones Criteria

4. Conclusions

- (a)

- Along the upper face of the brazed seam, using both the full brazed seam and different zones techniques, stress has decreased using latter method by 18 %. Hence, if there is variable strength along the upper face of the braze seam, stresses decrease significantly, but that is not critical for failure. Along the lower face y-axis, stress using the different zones technique is increased by 13% and becomes critical as becomes close to the yield strength of the filler material. So, the variable strength in the brazed seam is critical and more reliable for failure along the lower face of the braze seam, which happens due to the variable heat input in the brazed joints.

- (b)

- For vertical strength plain fins, stresses are again increased when the different zones technique is used by 5% as compared to full brazed seam method. So, by using the different zones technique, the reliability of the PFHE can be further improved.

- (c)

- Hence, the applying different zones technique to the braze seam has a significant effect on stresses magnitude in the PFHE. Stresses magnitudes have changed especially along the y-axis and the equivalent stress for both the horizontal and vertical directions of the fin brazed joints.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Equivalent Stress | |

| First Principle Stress | |

| Second Principle Stress | |

| Third Principle Stress | |

| Yield Strength | |

| Normal Stress Ratio | |

| Shear Stress Ratio | |

| Maximum Normal Stress Acting on the Braze Joint | |

| Maximum Shear Stress Acting on Braze Joint | |

| Tensile Strength of Brazed Joint | |

| Shear Strength of Brazed Joint | |

| Strength of Material | |

| Load Applied | |

| Co-efficient of Thermal Expansion for Required Material | |

| Thermal Stress in the Material | |

| Modulus of Elasticity | |

| Yield Stress |

References

- Popov, D.; Fikiin, K.; Stankov, B.; Alvarez, G.; Youbi-Idrissi, M.; Damas, A.; Evans, J.; Brown, T. Cryogenic heat exchangers for process cooling and renewable energy storage: A review. Appl. Therm. Eng. 2019, 153, 275–290. [Google Scholar] [CrossRef]

- Lim, W.; Choi, K.; Moon, I. Current status and perspectives of liquefied natural gas (LNG) plant design. Ind. Eng. Chem. Res. 2013, 52, 3065–3088. [Google Scholar] [CrossRef]

- Raja, B.D.; Jhala, R.; Patel, V. Many-objective optimization of cross-flow plate-fin heat exchanger. Int. J. Therm. Sci. 2017, 118, 320–339. [Google Scholar] [CrossRef]

- Guo, K.; Zhang, N.; Smith, R. Design optimisation of multi-stream plate fin heat exchangers with multiple fin types. Appl. Therm. Eng. 2018, 131, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Juan, D.; Hai-Tao, Z. Numerical simulation of a plate-fin heat exchanger with offset fins using porous media approach. Heat Mass Transf. 2018, 54, 745–755. [Google Scholar] [CrossRef]

- Ligterink, N.; Hageraats-Ponomareva, S.; Velthuis, J. Mechanical integrity of PFHE in LNG liquefaction process. Energy Procedia 2012, 26, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Khoshvaght-Aliabadi, M.; Jafari, A.; Sartipzadeh, O.; Salami, M. Thermal–hydraulic performance of wavy plate-fin heat exchanger using passive techniques: Perforations, winglets, and nanofluids. Int. Commun. Heat Mass Transf. 2016, 78, 231–240. [Google Scholar] [CrossRef]

- Li, K.; Wen, J.; Yang, H.; Wang, S.; Li, Y. Sensitivity and stress analysis of serrated fin structure in plate-fin heat exchanger on cryogenic condition. Int. J. Therm. Sci. 2019, 145, 106013. [Google Scholar] [CrossRef]

- Ma, H.; Hou, C.; Yang, R.; Li, C.; Ma, B.; Ren, J.; Liu, Y. The influence of structure parameters on stress of plate-fin structures in LNG heat exchanger. J. Nat. Gas Sci. Eng. 2016, 34, 85–99. [Google Scholar] [CrossRef]

- Ma, H.; Chen, J.; Cai, W.; Shen, C.; Yao, Y.; Jiang, Y. The influence of operation parameters on stress of plate-fin structures in LNG heat exchanger. J. Nat. Gas Sci. Eng. 2015, 26, 216–228. [Google Scholar] [CrossRef]

- Mota, F.A.; Ravagnani, M.A.; Carvalho, E. Comparative Analysis of Two Modeling Approaches for Optimizing Plate Heat Exchangers. Int. J. Phys. Math. Sci. 2015, 8, 629–632. [Google Scholar]

- Khoshvaght-Aliabadi, M.; Khoshvaght, M.; Rahnama, P. Thermal-hydraulic characteristics of plate-fin heat exchangers with corrugated/vortex-generator plate-fin (CVGPF). Appl. Therm. Eng. 2016, 98, 690–701. [Google Scholar] [CrossRef]

- Shahdad, I.; Fazelpour, F. Numerical analysis of the surface and geometry of plate fin heat exchangers for increasing heat transfer rate. Int. J. Energy Environ. Eng. 2018, 9, 155–167. [Google Scholar] [CrossRef] [Green Version]

- Peng, X.; Li, D.; Li, J.; Jiang, S.; Gao, Q. Improvement of Flow Distribution by New Inlet Header Configuration with Splitter Plates for Plate-Fin Heat Exchanger. Energies 2020, 13, 1323. [Google Scholar] [CrossRef] [Green Version]

- Ameur, H.; Sahel, D.; Menni, Y. Numerical investigation of the performance of perforated baffles in a plate-fin heat exchanger. Therm. Sci. 2020, 90. [Google Scholar] [CrossRef] [Green Version]

- Ramachandra, K.S.; Manjunatha, S.S.; Seetharamu, K.N. Performance analysis of plate-fin heat exchanger used for case drain oil cooling application in variable displacement pumps. J. Phys. Conf. Ser. 2020, 1473, 012022. [Google Scholar] [CrossRef]

- Onah, T.; Nwankwo, A.; Enugu, E.N. Design and Development of a Trapezoidal Plate Fin Heat Exchanger for the Prediction of Heat Exchanger Effectiveness. J. Energy Technol. Policy 2019, 9, 2224–3232. [Google Scholar]

- Nagarajan, V.; Chen, Y.; Wang, Q.; Ma, T. Hydraulic and thermal performances of a novel configuration of high temperature ceramic plate-fin heat exchanger. Appl. Energy 2014, 113, 589–602. [Google Scholar] [CrossRef]

- Ma, H.; Cai, W.; Zheng, W.; Chen, J.; Yao, Y.; Jiang, Y. Stress characteristics of plate-fin structures in the cool-down process of LNG heat exchanger. J. Nat. Gas Sci. Eng. 2014, 21, 1113–1126. [Google Scholar] [CrossRef]

- Ma, H.; Cai, W.; Yao, Y.; Jiang, Y. Investigation on stress characteristics of plate-fin structures in the heat-up process of LNG heat exchanger. J. Nat. Gas Sci. Eng. 2016, 30, 256–267. [Google Scholar] [CrossRef]

- Ma, H.; Qin, G.; Bai, X.; Wang, L.; Liang, Z. Effect of initial temperature on joint of aluminum alloy to galvanized steel welded by MIG arc brazing-fusion welding process. Int. J. Adv. Manuf. Technol. 2016, 86, 3135–3143. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, G.; Zhang, Y.; Wu, K. Research on microstructure and mechanical properties of laser keyhole welding–brazing of automotive galvanized steel to aluminum alloy. Mater. Des. 2013, 45, 24–30. [Google Scholar] [CrossRef]

- Sillapasa, K.; Surapunt, S.; Miyashita, Y.; Mutoh, Y.; Seo, N. Tensile and fatigue behavior of SZ, HAZ and BM in friction stir welded joint of rolled 6N01 aluminum alloy plate. Int. J. Fatigue 2014, 63, 162–170. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, J.; Yang, S.; Tao, W.; Wu, F.; Xia, W. Experiment-based regional characterization of HAZ mechanical properties for laser welding. Int. J. Adv. Manuf. Technol. 2015, 78, 1629–1640. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, J.; He, P.; Hackl, H. Interfacial microstructure and mechanical properties of aluminium–zinc-coated steel joints made by a modified metal inert gas welding–brazing process. Mater. Charact. 2007, 58, 588–592. [Google Scholar] [CrossRef]

- Dørum, C.; Lademo, O.-G.; Myhr, O.R.; Berstad, T.; Hopperstad, O.S. Finite element analysis of plastic failure in heat-affected zone of welded aluminium connections. Comput. Struct. 2010, 88, 519–528. [Google Scholar] [CrossRef]

- Zhang, L.; Xuan, J.; Shi, T. Obtaining More Accurate Thermal Boundary Conditions of Machine Tool Spindle Using Response Surface Model Hybrid Artificial Bee Colony Algorithm. Symmetry 2020, 12, 361. [Google Scholar] [CrossRef] [Green Version]

- Saeed, T.; Abbas, I.; Marin, M. A GL Model on Thermo-Elastic Interaction in a Poroelastic Material Using Finite Element Method. Symmetry 2020, 12, 488. [Google Scholar] [CrossRef] [Green Version]

- Ke, H.; Lin, Y.; Ke, Z.; Xiao, Q.; Wei, Z.; Chen, K.; Xu, H. Analysis Exploring the Uniformity of Flow Distribution in Multi-Channels for the Application of Printed Circuit Heat Exchangers. Symmetry 2020, 12, 314. [Google Scholar] [CrossRef] [Green Version]

- Saggu, M.H.; Sheikh, N.A.; Niazi, U.M.; Irfan, M.; Glowacz, A. Predicting the Structural Reliability of LNG Processing Plate-Fin Heat Exchanger for Energy Conservation. Energies 2020, 13, 2175. [Google Scholar] [CrossRef]

- Nayeb-Hashemi, H.; Lockwood, M. The effect of processing variables on the microstructures and properties of aluminum brazed joints. J. Mater. Sci. 2002, 37, 3705–3713. [Google Scholar] [CrossRef]

- Meuwissen, M.; Oomens, C.; Baaijens, F.; Petterson, R.; Janssen, J. Determination of the elasto-plastic properties of aluminium using a mixed numerical–experimental method. J. Mater. Process. Technol. 1998, 75, 204–211. [Google Scholar] [CrossRef]

- Gere, J.M.; Goodno, B.J. Mechanics of Materials, 8th ed.; Cengage Learning: Stamford, CT, USA, 2009. [Google Scholar]

- Ma, H.; He, B.; Lan, S.; Liu, Y.; Gao, X.; Xue, X.; Hou, C.; Li, C. The stress characteristics of plate-fin structures at the different operation parameters of LNG heat exchanger. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2018, 73, 13. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-H.; Lee, S.-B. Effect of a brazing process on mechanical and fatigue behavior of alclad aluminum 3005. J. Mech. Sci. Technol. 2012, 26, 2111–2115. [Google Scholar] [CrossRef]

- Biswas, R.; Strawn, R.C. Tetrahedral and Hexahedral mesh adaptation for CFD problems. Appl. Numer. Math. 1998, 26, 135–151. [Google Scholar] [CrossRef]

- Shah, R.; Focke, W. Plate heat exchangers and their design theory. Heat Transf. Equip. Des. 1988, 227, 254. [Google Scholar]

- Lin, M.-T.; El-Deiry, P.; Chromik, R.R.; Barbosa, N.; Brown, W.L.; Delph, T.J.; Vinci, R.P. Temperature-dependent microtensile testing of thin film materials for application to microelectromechanical system. Microsyst. Technol. 2006, 12, 1045–1051. [Google Scholar] [CrossRef]

- Yamamoto, N.; Makino, H.; Yamamoto, T. Young’s modulus and coefficient of linear thermal expansion of ZnO conductive and transparent ultra-thin films. Adv. Mater. Sci. Eng. 2011, 2011, 136127. [Google Scholar] [CrossRef] [Green Version]

- Bray, J. Properties and selection: Nonferrous alloys and special purpose materials. Asm Met. Handb. 1990, 92. [Google Scholar]

- Shigley, J.E. Shigley’s Mechanical Engineering Design; Tata McGraw-Hill Education: New York, NY, USA, 2011. [Google Scholar]

- Flom, Y. Evaluation of brazed joints using failure assessment diagram. In Proceedings of the 5th International Brazing and Soldering Conference (IBSC), Las Vegas, NV, USA, 22–25 April 2012. [Google Scholar]

| Fin Profile | Height of Fin (mm) | Thickness of Fin (mm) | Thickness of Plate (mm) | Depth of PFHE (mm) | Total Flow Area per Fin (mm2) | Brazing Seam Thickness (mm) First Method | Brazing Seam Thickness (mm) Second Method | ||

|---|---|---|---|---|---|---|---|---|---|

| Zone 1 | Zone 2 | Zone 3 | |||||||

| Plain fin [19] | 6 | 0.4 | 1.6 | 2.5 | 3.12 | 0.1 | 0.033 | 0.034 | 0.033 |

| Material Name [9] | Range of Temperature (K) [9] | Variation in Modulus of Elasticity with Temperature (E) GPa [9,38] | Variation in Co-efficient of Thermal Expansion (10−6) (1/K) [9,39] | Pre-Brazed Yield Strength from Literature (MPa) [34] | Post Brazed Yield Strength from Experiment (MPa) [31,35,40,41] |

|---|---|---|---|---|---|

| Al 3003 | 305 | 68.9 | 22.4 | 145 | 124.2 |

| 205 | 70.6 | 19.7 | 145 | 124.2 | |

| 195 | 72.4 | 16.9 | 145 | 124.2 | |

| 175 | 73.2 | 15.9 | 145 | 124.2 | |

| 145 | 74.5 | 14.4 | 145 | 124.2 | |

| Al 4004 | 305 | 94.6 | 15.1 | 142 | 112 |

| 205 | 96.4 | 14.9 | 142 | 112 | |

| 195 | 98.2 | 14.7 | 142 | 112 | |

| 175 | 98.8 | 14.6 | 142 | 112 | |

| 145 | 99.6 | 14.5 | 142 | 112 | |

| Interface brazed | 305 | 77 | 15.1 | 142 | 109 |

| 205 | 82.5 | 14.8 | 142 | 109 | |

| 195 | 83.1 | 14.6 | 142 | 109 | |

| 175 | 84.3 | 14.5 | 142 | 109 | |

| 145 | 86 | 14.5 | 142 | 109 |

| Stress Type | Type | Previous Factor of Safety | Modified Factor of Safety |

|---|---|---|---|

| Equivalent Stress | Plain | 2.1 | 2.6 |

| Normal x-axis Stress | Plain | 2.8 | 2.8 |

| Normal y-axis Stress | Plain | 9.3 | 9.3 |

| Stress Type | Type | Previous Factor of Safety | Modified Factor of Safety |

|---|---|---|---|

| Equivalent Stress | Plain | 1.3 | 1.1 |

| Normal x-axis Stress | Plain | 5.6 | 5.6 |

| Normal y-axis Stress | Plain | 1.3 | 1.1 |

| Shear yz-axis Stress | Plain | 4.1 | 4.1 |

| Stress Type | Type | Previous Factor of Safety | Modified Factor of Safety |

|---|---|---|---|

| Equivalent Stress | Plain | 1.6 | 1.5 |

| Normal x-axis Stress | Plain | 3.2 | 3.2 |

| Normal y-axis Stress | Plain | 3.7 | 3.7 |

| Shear yz-axis Stress | Plain | 2.2 | 2.2 |

| Margin of Safety For | Upper Face of Braze Seam (Full Braze Seam) | Modification in Upper Face of Braze Seam (Different Zones Technique) | Lower Face of Braze Seam (Full Braze Seam) | Modification in Lower Face of Braze Seam (Different Zones Technique) | Vertical Direction of Braze Seam (Full Braze Seam) | Modification in Vertical Direction of Braze Seam (Different Zones Technique) |

|---|---|---|---|---|---|---|

| Along X-axis | ||||||

| Plain | 1.7 | 1.7 | 4.5 | 4.5 | 2 | 2 |

| Along Y-Axis | ||||||

| Plain | 5.9 | 5.9 | 0.3 | 0.2 | 0.9 | 0.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saggu, M.H.; Sheikh, N.A.; Muhamad Niazi, U.; Irfan, M.; Glowacz, A.; Legutko, S. Improved Analysis on the Fin Reliability of a Plate Fin Heat Exchanger for Usage in LNG Applications. Energies 2020, 13, 3624. https://doi.org/10.3390/en13143624

Saggu MH, Sheikh NA, Muhamad Niazi U, Irfan M, Glowacz A, Legutko S. Improved Analysis on the Fin Reliability of a Plate Fin Heat Exchanger for Usage in LNG Applications. Energies. 2020; 13(14):3624. https://doi.org/10.3390/en13143624

Chicago/Turabian StyleSaggu, Mustansar Hayat, Nadeem Ahmed Sheikh, Usama Muhamad Niazi, Muhammad Irfan, Adam Glowacz, and Stanislaw Legutko. 2020. "Improved Analysis on the Fin Reliability of a Plate Fin Heat Exchanger for Usage in LNG Applications" Energies 13, no. 14: 3624. https://doi.org/10.3390/en13143624

APA StyleSaggu, M. H., Sheikh, N. A., Muhamad Niazi, U., Irfan, M., Glowacz, A., & Legutko, S. (2020). Improved Analysis on the Fin Reliability of a Plate Fin Heat Exchanger for Usage in LNG Applications. Energies, 13(14), 3624. https://doi.org/10.3390/en13143624