Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock

Abstract

:1. Introduction

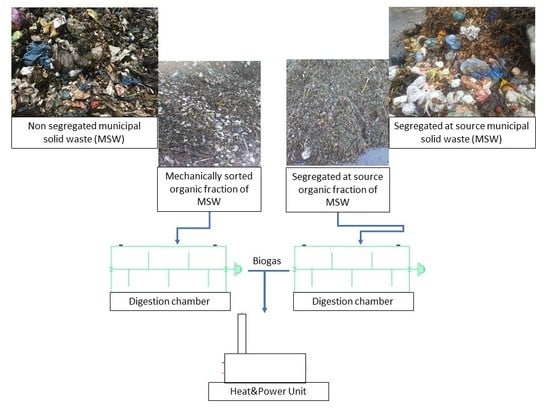

2. Materials and Methods

2.1. The ms-OFMWS Characterization

2.2. The ss-OFMWS Characterization

2.3. The AD Full-Scale Research

2.4. Analytical Methods

2.5. Calculation Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arumugam, A.; Ponnusami, V. Biodiesel Production from Calophyllum Inophyllum Oil a Potential Non-Edible Feedstock: An Overview. Renew. Energy 2019, 131, 459–471. [Google Scholar] [CrossRef]

- Heidari, R.; Yazdanparast, R.; Jabbarzadeh, A. Sustainable Design of a Municipal Solid Waste Management System Considering Waste Separators: A Real-World Application. Sustain. Cities Soc. 2019, 47, 101457. [Google Scholar] [CrossRef]

- Deus, R.M.M.; Mele, F.D.D.; Bezerra, B.S.S.; Battistelle, R.A.G.A.G. A Municipal Solid Waste Indicator for Environmental Impact: Assessment and Identification of Best Management Practices. J. Clean. Prod. 2020, 242, 118433. [Google Scholar] [CrossRef]

- Seadon, J.K. Sustainable Waste Management Systems. J. Clean. Prod. 2010, 18, 1639–1651. [Google Scholar] [CrossRef]

- Panigrahi, S.; Dubey, B.K. A Critical Review on Operating Parameters and Strategies to Improve the Biogas Yield From Anaerobic Digestion of Organic Fraction of Municipal Solid Waste. Renew. Energy 2019, 143, 779–797. [Google Scholar] [CrossRef]

- Dieckmann, E.; Sheldrick, L.; Tennant, M.; Myers, R.; Cheeseman, C. Analysis of Barriers to Transitioning from a Linear to a Circular Economy for End of Life Materials: A Case Study for Waste Feathers. Sustainability 2020, 12, 1725. [Google Scholar] [CrossRef] [Green Version]

- Seruga, P.; Krzywonos, M.; Wilk, M. Thermophilic Co-Digestion of the Organic Fraction of Municipal Solid Wastes—The Influence of Food Industry Wastes Addition on Biogas Production in Full-Scale Operation. Molcules 2018, 23. [Google Scholar] [CrossRef] [Green Version]

- Abad, V.; Avila, R.; Vicent, T.; Font, X. Promoting Circular Economy in the Surroundings of an Organic Fraction of Municipal Solid Waste Anaerobic Digestion Treatment Plant: Biogas Production Impact and Economic Factors. Bioresour. Technol. 2019, 283, 10–17. [Google Scholar] [CrossRef]

- Zaman, A.U. A Comprehensive Study of the Environmental and Economic Benefits of Resource Recovery from Global Waste Management Systems. J. Clean. Prod. 2016, 124, 41–50. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Bányai, T.; Tamás, P.; Illés, B.; Stankevičiūtė, Ž.; Bányai, Á. Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. Int. J. Environ. Res. Public Health 2019, 16. [Google Scholar] [CrossRef] [Green Version]

- Seruga, P.; Krzywonos, M.; Wilk, M. Treatment of By-Products Generated from Anaerobic Digestion of Municipal Solid Waste. Waste Biomass Valorization 2019. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Fu, L.; Liu, X.; Cheng, M. Evaluating the Efficiency of Municipal Solid Waste Management in China. Int. J. Environ. Res. Public Health 2018, 15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lim, L.S.; Lee, L.H.; Wu, T.Y. Sustainability of Using Composting and Vermicomposting Technologies for Organic Solid Waste Biotransformation: Recent Overview, Greenhouse Gases Emissions and Economic Analysis. J. Clean. Prod. 2016, 111, 262–278. [Google Scholar] [CrossRef]

- Bölükbaş, A.; Aklncl, G. Solid Waste Composition and the Properties of Biodegradable Fractions in Izmir City, Turkey: An Investigation on the Influencing Factors. J. Environ. Heal. Sci. Eng. 2018, 16, 299–311. [Google Scholar] [CrossRef]

- Carmo-Calado, L.; Hermoso-Orzáez, M.J.; Mota-Panizio, R.; Guilherme-Garcia, B.; Brito, P. Co-Combustion of Waste Tires and Plastic-Rubber Wastes with Biomass Technical and Environmental Analysis. Sustainbility 2020, 12, 1036. [Google Scholar] [CrossRef] [Green Version]

- Kluska, J.; Ochnio, M.; Kardaś, D. Carbonization of Corncobs for the Preparation of Barbecue Charcoal and Combustion Characteristics of Corncob Char. Waste Manag. 2020, 105, 560–565. [Google Scholar] [CrossRef]

- Pavi, S.; Kramer, L.E.; Gomes, L.P.; Miranda, L.A.S. Biogas Production from Co-Digestion of Organic Fraction of Municipal Solid Waste and Fruit and Vegetable Waste. Bioresour. Technol. 2017, 228, 362–367. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Tsapekos, P.; Alvarado-Morales, M.; Angelidaki, I. Process Performance and Modelling of Anaerobic Digestion Using Source-Sorted Organic Household Waste. Bioresour. Technol. 2018, 247, 486–495. [Google Scholar] [CrossRef] [Green Version]

- Pawlak-Kruczek, H.; Niedzwiecki, L.; Sieradzka, M.; Mlonka-Mędrala, A.; Baranowski, M.; Serafin-Tkaczuk, M.; Magdziarz, A. Hydrothermal Carbonization of Agricultural and Municipal Solid Waste Digestates—Structure and Energetic Properties of the Solid Products. Fuel 2020, 275. [Google Scholar] [CrossRef]

- Banks, C.J.; Chesshire, M.; Heaven, S.; Arnold, R. Anaerobic Digestion of Source-Segregated Domestic Food Waste: Performance Assessment by Mass and Energy Balance. Bioresour. Technol. 2011, 102, 612–620. [Google Scholar] [CrossRef] [Green Version]

- Beggio, G.; Schievano, A.; Bonato, T.; Hennebert, P.; Pivato, A. Statistical Analysis for the Quality Assessment of Digestates from Separately Collected Organic Fraction of Municipal Solid Waste (OFMSW) and Agro-Industrial Feedstock. Should Input Feedstock to Anaerobic Digestion Determine the Legal Status of Digestate? Waste Manag. 2019, 87, 546–558. [Google Scholar] [CrossRef] [PubMed]

- Di Maria, F.; Micale, C.; Morettini, E. Impact of the Pre-Collection Phase at Different Intensities of Source Segregation of Bio-Waste: An Italian Case Study. Waste Manag. 2016, 53, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Biogas Production from the Organic Fraction of Municipal Solid Waste. Energy Sources Part A Recover. Util. Environ. Eff. 2006, 28, 1127–1134. [Google Scholar] [CrossRef]

- Linville, J.L.; Shen, Y.; Wu, M.M.; Urgun-Demirtas, M. Current State of Anaerobic Digestion of Organic Wastes in North America. Curr. Sustain. Energy Rep. 2015, 2, 136–144. [Google Scholar] [CrossRef] [Green Version]

- Jamal, M.; Szefler, A.; Kelly, C.; Bond, N. Commercial and Household Food Waste Separation Behaviour and the Role of Local Authority: A Case Study. Int. J. Recycl. Org. Waste Agric. 2019, 8, 281–290. [Google Scholar] [CrossRef] [Green Version]

- Stretton-Maycock, D.; Merrington, G. The Use and Application to Land of MBT Compost-Like Output—Review of Current European Practice in Relation to Environmental Protection; Environment Agency: Bristol, UK, 2009.

- Paritosh, K.; Kushwaha, S.K.; Yadav, M.; Pareek, N.; Chawade, A.; Vivekanand, V. Food Waste to Energy: An Overview of Sustainable Approaches for Food Waste Management and Nutrient Recycling. Biomed Res. Int. 2017, 2017, 1–19. [Google Scholar] [CrossRef]

- Rice, E.W.; Baird, R.B.; Eaton, A.D.; Clesceri, L.E. APHA, AWWA, WEF. Standard Methods for Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Guendouz, J.; Buffière, P.; Cacho, J.; Carrère, M.; Delgenes, J. Dry Anaerobic Digestion in Batch Mode: Design and Operation of a Laboratory-Scale, Completely Mixed Reactor. Waste Manag. 2010, 30, 1768–1771. [Google Scholar] [CrossRef]

- Campuzano, R.; González-Martínez, S. Characteristics of the Organic Fraction of Municipal Solid Waste and Methane Production: A Review. Waste Manag. 2016, 54, 3–12. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, J. Enhancement of Methane Production in Anaerobic Digestion Process: A Review. Appl. Energy 2019, 240, 120–137. [Google Scholar] [CrossRef]

- Drosg, B. Process Monitoring in Biogas Plants; IEA Bioenergy: Tulln, Austria, 2013; ISBN 9781910154038. [Google Scholar]

- Wu, D.; Li, L.; Zhao, X.; Peng, Y.; Yang, P.; Peng, X. Anaerobic Digestion: A Review on Process Monitoring. Renew. Sustain. Energy Rev. 2019, 103, 1–12. [Google Scholar] [CrossRef]

- Owusu-Agyeman, I.; Plaza, E.; Cetecioglu, Z. Production of Volatile Fatty Acids Through Co-Digestion of Sewage Sludge and External Organic Waste: Effect of Substrate Proportions and Long-Term Operation. Waste Manag. 2020, 112, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Tampio, E.A.; Blasco, L.; Vainio, M.M.; Kahala, M.M.; Rasi, S.E. Volatile Fatty Acids (VFAs) and Methane from Food Waste and Cow Slurry: Comparison of Biogas and VFA Fermentation Processes. GCB Bioenergy 2019, 11, 72–84. [Google Scholar] [CrossRef]

- Kor-Bicakci, G.; Ubay-Cokgor, E.; Eskicioglu, C. Comparative Analysis of Bacterial and Archaeal Community Structure in Microwave Pretreated Thermophilic and Mesophilic Anaerobic Digesters Utilizing Mixed Sludge under Organic Overloading. Water (Switz.) 2020, 12. [Google Scholar] [CrossRef] [Green Version]

| Fraction | Mass Share |

|---|---|

| Organic (incl. green waste) (%) | 48.3 ± 2.7 |

| Wood (%) | 7.2 ± 0.8 |

| Paper (%) | 3.6 ± 0.8 |

| Plastics (%) | 3.9 ± 0.7 |

| Glass (%) | 3.6 ± 1.1 |

| Inert waste (%) | 2.9 ± 1.0 |

| Textiles (%) | 0.3 ± 0.5 |

| Metals (%) | 0.1 ± 0.1 |

| Hazardous (%) | 0.1 ± 0.1 |

| Tetra Pak (%) | 0.7 ± 0.2 |

| Others (%) | 0.6 ± 0.2 |

| Fine fraction 0–15 mm (%) | 28.7 ± 3.8 |

| Fraction | Mass Share |

|---|---|

| Organic (incl. green waste) (%) | 68.1 ± 5.2 |

| Wood (%) | 8.1 ± 0.5 |

| Paper (%) | 2.4 ± 0.7 |

| Plastics (%) | 1.1 ± 0.4 |

| Glass (%) | 0.8 ± 0.4 |

| Inert waste (%) | 1. 4 ± 0.9 |

| Textiles (%) | 0.1 ± 0.4 |

| Metals (%) | 0.1 ± 0.1 |

| Hazardous (%) | 0.1 ± 0.1 |

| Tetra Pak (%) | 0.3 ± 0.1 |

| Others (%) | 0.4 ± 0.1 |

| Fine fraction 0–15 mm (%) | 17.1 ± 2.3 |

| Parameter | ms-OFMSW | ss-OFMSW |

|---|---|---|

| pH (−) | 7.1 ± 0.2 | 8.0 ± 0.2 |

| Suspended solids (SS) (%) | 49.8 ± 0.3 | 46.2 ± 0.3 |

| Ammonium nitrogen (g/L) | 1453 ± 65 | 3879 ± 87 |

| Acidity (mg CH3COOH/kg) | 655 ± 50 | 463 ± 44 |

| Alkalinity (mg CaCO3/kg) | 4210 ± 145 | 6758 ± 163 |

| Acetic acid (mg/kg) | 98 ± 8 | 107 ± 6 |

| Propionic acid (mg/kg) | 6.0 ± 0.5 | 3.0 ± 0.5 |

| Butyric acid (mg/kg) | 1.0 ± 1.0 | 1.0 ± 1.0 |

| Isobutyric acid (mg/kg) | 1.0 ± 1.0 | 1.0 ± 1.0 |

| Valeric acid (mg/kg) | 1.0 ± 1.0 | 1.0 ± 1.0 |

| Isovaleric acid (mg/kg) | 1.0 ± 1.0 | 1.0 ± 1.0 |

| Input Material | Biogas Yield | Yearly Biogas Production Capacity | Methane Content | Electrical Production Possibility | CHP Units Efficiency | Electricity Yield | Yearly Electricity Production Capacity |

|---|---|---|---|---|---|---|---|

| m3/ton | m3 | % | kWh/m3CH4 | % | kWh/ton | MWh | |

| ms-OFMSW | 105.3 | 1,579,500 | 52 | 10 | 40 | 219.0 | 3285.4 |

| ss-OFMSW | 111.1 | 1,666,500 | 59 | 10 | 40 | 262.2 | 3932.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seruga, P.; Krzywonos, M.; Seruga, A.; Niedźwiecki, Ł.; Pawlak-Kruczek, H.; Urbanowska, A. Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock. Energies 2020, 13, 3768. https://doi.org/10.3390/en13153768

Seruga P, Krzywonos M, Seruga A, Niedźwiecki Ł, Pawlak-Kruczek H, Urbanowska A. Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock. Energies. 2020; 13(15):3768. https://doi.org/10.3390/en13153768

Chicago/Turabian StyleSeruga, Przemysław, Małgorzata Krzywonos, Anna Seruga, Łukasz Niedźwiecki, Halina Pawlak-Kruczek, and Agnieszka Urbanowska. 2020. "Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock" Energies 13, no. 15: 3768. https://doi.org/10.3390/en13153768

APA StyleSeruga, P., Krzywonos, M., Seruga, A., Niedźwiecki, Ł., Pawlak-Kruczek, H., & Urbanowska, A. (2020). Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock. Energies, 13(15), 3768. https://doi.org/10.3390/en13153768