Photo-Rechargeable Electric Energy Storage Systems Based on Silicon Solar Cells and Supercapacitor-Engineering Concept

Abstract

:1. Introduction

- Criteria when the energy is stored,

- Charging/discharging conditions,

- Depth of discharge,

- Lifetime,

- Storage period/self-discharge [2].

- Analysis of the parameters of individual components of the demonstrator based on commercial components: photovoltaic cell, supercapacitor, supercapacitor charging and discharging module, and the control and measurement system.

- Preliminary model design containing a description of individual model blocks (physical properties) with the model block system including power balance (mathematical models).

- Visualization of the physical model in graphic form using computer aided design (CAD programs including MathCAD and Altium).

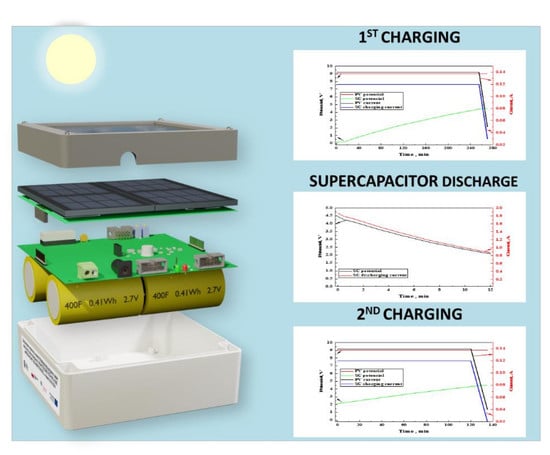

- Construction of three fully functional demonstrators of energy storage system based on supercapacitors and silicon solar cells in various architectures (Scheme 1).

- Experimental measurements of the properties of individual elements contained in three types of demonstrators, including current–voltage characteristics of photovoltaic systems and charging and discharging characteristics of supercapacitors.

2. Experimental

2.1. Materials

2.2. Energy Storage Systems Constructions

- (a)

- 40 PV cells connected in series–in parallel in a 2 × 10 × 2 system with parameters of open circuit voltage Voc = 12.5 V and short-circuit current Isc = 155 mA in two pieces.

- (b)

- 14 PV cells connected in series in a 14 × 1 system with parameters of open circuit voltage Voc = 7.95 V and short-circuit current Isc = 360 mA in two pieces.

- (c)

- Circuit board of the power source block, charging voltage control system, and supercapacitors system with a total capacity of CSC = 400 F and operating voltage VCw = 5 V.

- (d)

- Power source block board, charging voltage control system, and supercapacitors system with a total capacity of CSC = 425 F and operating voltage VCw = 5.4 V.

- (e)

- Power source block board, charging voltage control system, and supercapacitors system with a total capacity of CSC = 400 F and operating voltage VCw = 5.4 V.

2.3. Characterization Methods

- (a)

- A single cell with 50 mm × 20 mm photosensitive field dimensions, Figure S1a;

- (b)

- A set of 10 cells in series with a total dimension of the photosensitive field 65 mm × 65 mm, Figure S1b.

3. Results and Discussions

3.1. Theoretical Concepts

- VCw—voltage to which the supercapacitor set is charged;

- Cw—resultant capacity of the supercapacitors’ set;

- CSC—capacity of a single supercapacitor;

- n—amount of supercapacitors.

3.2. Silicon Solar Cells to Supercapacitors Charging Efficiency Optimization

- Measurements of current–voltage characteristics of the assembled PV panel,

- Measurements of charging, discharging, and recharging characteristics of supercapacitors.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schmidt, D.; Hager, M.D.; Schubert, U.S. Photo-rechargeable electric energy storage systems. Adv. Energy Mater. 2016, 6, 1500369. [Google Scholar] [CrossRef]

- Chauhan, A.; Saini, R.P. A review on Integrated Renewable Energy System based power generation for stand-alone applications: Configurations, storage options, sizing methodologies and control. Renew. Sustain. Energy Rev. 2014, 38, 99–120. [Google Scholar] [CrossRef]

- Christen, T.; Ohler, C. Optimizing energy storage devices using Ragone plots. J. Power Sources 2002, 110, 107–116. [Google Scholar] [CrossRef]

- Roy, P.K.S.; Karayaka, H.B.; Yana, Y.; Alqudah, Y. Investigations into best cost battery-supercapacitor hybrid energy storage system for a utility scale PV array. J. Energy Storage 2019, 22, 50–59. [Google Scholar] [CrossRef]

- Thounthonga, P.; Chunkag, V.; Sethakul, P.; Sikkabut, S.; Pierfederici, S.; Davat, B. Energy management of fuel cell/solar cell/supercapacitor hybrid power source. J. Power Sources 2011, 196, 313–324. [Google Scholar] [CrossRef]

- Gunawardane, K. Capacitors as energy storage devices-simple basics to current commercial families. In Energy Storage Devices for Electronic Systems: Rechargeable Batteries and Supercapacitors; Academic Press: New York, NY, USA, 2015; pp. 137–148. ISBN 978-012408119-2. [Google Scholar]

- Beaudin, M.; Zareipour, H.; Schellenberg, A.; Rosehart, W. Energy Storage for mitigating the variability of renewable electricity sources, energy storage for smart grids. In Planning and Operation for Renewable and Variable Energy Resources (VERs); Academic Press: New York, NY, USA, 2015; pp. 1–33. ISBN 978-0-12-410491-4. [Google Scholar]

- Logerais, P.-O.; Riou, O.; Camara, M.A.; Durastanti, J.-F. Study of photovoltaic energy storage by supercapacitors through both experimental and modelling approaches. J. Sol. Energy 2013, 659014. [Google Scholar] [CrossRef] [Green Version]

- Kularatna, K.M.; Round, W.H. Supercapacitor energy storage in solar application: A design approach to minimize a fundamental loss issue by partitioning the load and the storage device. In Proceedings of the 2015 IEEE 24th International Symposium on Industrial Electronics (ISIE), Buzios, Brazil, 3–5 June 2015; pp. 1308–1312, ISBN 978-1-4673-7554-2. [Google Scholar]

- Li, L.; Huang, Z.; Li, H.; Lu, H. A high-efficiency voltage equalization scheme for supercapacitor energy storage system in renewable generation applications. Sustainability 2016, 8, 548. [Google Scholar] [CrossRef] [Green Version]

- Fahmi, M.I.; Rajkumar, R.K.; Arelhi, R.; Isa, D. Study on the effect of supercapacitors in solar PV system for rural application in Malaysia. In Proceedings of the 2015 50th International Universities Power Engineering Conference (UPEC), Stoke on Trent, UK, 1–4 September 2015; ISBN 978-1-4673-9682-0. [Google Scholar]

- Andreotti, A.; Mottola, F.; Pagano, M.; Velotto, G. Design of ultracapacitor based filter for isolated PV source feeding pulsing load. Electr. Power Syst. Res. 2008, 78, 1038–1046. [Google Scholar] [CrossRef] [Green Version]

- Bergonzini, C.; Brunelli, D.; Benini, L. Comparison of energy intake prediction algorithms for systems powered by photovoltaic harvesters. Microelectron. J. 2010, 41, 766–777. [Google Scholar] [CrossRef]

- Hande, A.; Polk, T.; Walker, W.; Bhatia, D. Indoor solar energy harvesting for sensor network router nodes. Microprocess. Microsyst. 2007, 31, 420–432. [Google Scholar] [CrossRef]

- Janek, A.; Trummer, C.; Steger, C.; Weiss, R.; PreishuberPfluegl, J.; Pistauer, M. Simulation based verification of energy storage architectures for higher class tags supported by energy harvesting devices. Microprocess. Microsyst. 2008, 32, 330–339. [Google Scholar] [CrossRef]

- Sahin, M.E.; Blaabjerg, F. A hybrid PV-battery/supercapacitor system and a basic active power control proposal in MATLAB/Simulink. Electronics 2020, 9, 129. [Google Scholar] [CrossRef] [Green Version]

- Westover, A.S.; Share, K.; Carter, R.; Cohn, A.P.; Oakes, L.; Pint, C.L. Direct integration of a supercapacitor into the backside of a silicon photovoltaic device. Appl. Phys. Lett. 2014, 104, 213905. [Google Scholar] [CrossRef]

- Vega-Garita, V.; Ramirez-Elizondo, L.; Narayan, N.; Bauer, P. Integrating a photovoltaic storage system in one device: A critical review. Prog Photovolt. Res. Appl. 2019, 27, 346–370. [Google Scholar] [CrossRef] [Green Version]

- Plebankiewicz, I.; Bogdanowicz, K.A.; Iwan, A. Electronic System for Charger of Supercapacitors from Solar Cells. Polish Patent Application P.32868, 10 February 2020. [Google Scholar]

| Parameter | Symbol | Total Area | |

|---|---|---|---|

| 50 mm × 20 mm | 65 mm × 65 mm | ||

| Short circuit current | Isc | 355.3 (mA) | 56.7 (mA) |

| Open circuit current | Voc | 597.3 (mV) | 6.4 (V) |

| Maximum current | Imax | 322.9 (mA) | 72.4 (mA) |

| Maximum voltage | Vmax | 465.4 (mV) | 4.8 (V) |

| Maximum power | Pmax | 150.3 (mW) | 345.2 (mW) |

| Fill factor | FF | 0.7 | 0.7 |

| Photovoltaic conversion efficiency | PCE | 15.4% | 8.3% |

| Series resistance | Rs | 205.6 (mΩ) | 268.6 (Ω) |

| Shunt resistance | Rsh | 187.9 (Ω) | 18.0 (kΩ) |

| No. of Capacitors, n | Series Connection | Paralel Connection | ||||

|---|---|---|---|---|---|---|

| Working Voltage VCw, (V) | Final Capacity Cw = CSC/n, (C) | Energy E, (Ws) | Working Voltage VCw, (V) | Final Capacity Cw = CSC × n, (C) | Energy E, (Ws) | |

| 1 | 2.5 | 400.00 | 1250 | 2.5 | 400 | 1250 |

| 2 | 5 | 200.00 | 2500 | 2.5 | 800 | 2500 |

| 3 | 7.5 | 133.33 | 3750 | 2.5 | 1200 | 3750 |

| 4 | 10 | 100.00 | 5000 | 2.5 | 1600 | 5000 |

| 5 | 12.5 | 80.00 | 6250 | 2.5 | 2000 | 6250 |

| 6 | 15 | 66.67 | 7500 | 2.5 | 2400 | 7500 |

| Selected Parameters | Symbol | Demonstrator no. 1 | Demonstrator no. 2 | Demonstrator no. 3 |

|---|---|---|---|---|

| Rated voltage of supercapacitor set | VCw | 5.0 V | 5.4 V | 5.4 V |

| Rated capacity of supercapacitor set | CCw | 400 F | 425 F | 400 F |

| The theoretical amount of energy stored | 1.39 Wh | 1.72 Wh | 1.56 Wh | |

| First charge time | tn | 255 min | 345 min | 270 min |

| Efficiency of system during the first charging of supercapacitors | 0.20 | 0.20 | 0.36 | |

| Possible energy to recover | Ere | 0.23 Wh | 0.21 Wh | 0.57 Wh |

| Supercapacitor set voltage after connecting the load Rload = 2.4 Ω during tn | Vloadc | 4.65 V | 4.15 V | 5.3 V |

| Discharge time to voltage Vload = 2 V | tr | 720 s | 780 s | 900 s |

| Energy supplied to supercapacitors during recharging | Erc | 0.3 Wh | 0.22 Wh | 0.61 Wh |

| Top up time | tn | 135 min | 165 min | 150 min |

| The efficiency of system when charging supercapacitors | 0.76 | 0.93 | 0.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plebankiewicz, I.; Bogdanowicz, K.A.; Iwan, A. Photo-Rechargeable Electric Energy Storage Systems Based on Silicon Solar Cells and Supercapacitor-Engineering Concept. Energies 2020, 13, 3867. https://doi.org/10.3390/en13153867

Plebankiewicz I, Bogdanowicz KA, Iwan A. Photo-Rechargeable Electric Energy Storage Systems Based on Silicon Solar Cells and Supercapacitor-Engineering Concept. Energies. 2020; 13(15):3867. https://doi.org/10.3390/en13153867

Chicago/Turabian StylePlebankiewicz, Ireneusz, Krzysztof Artur Bogdanowicz, and Agnieszka Iwan. 2020. "Photo-Rechargeable Electric Energy Storage Systems Based on Silicon Solar Cells and Supercapacitor-Engineering Concept" Energies 13, no. 15: 3867. https://doi.org/10.3390/en13153867

APA StylePlebankiewicz, I., Bogdanowicz, K. A., & Iwan, A. (2020). Photo-Rechargeable Electric Energy Storage Systems Based on Silicon Solar Cells and Supercapacitor-Engineering Concept. Energies, 13(15), 3867. https://doi.org/10.3390/en13153867