Hardware-in-the-Loop Simulation Using Real-Time Hybrid-Simulator for Dynamic Performance Test of Power Electronics Equipment in Large Power System

Abstract

:1. Introduction

2. HILS for Dynamic Performance Test in Large-Scale Power System

2.1. Definition and Features of HILS-DPT

- A sufficiently wide area of power system should be required to reflect the system dynamics and control characteristics of an adjacent power electronics equipment.

- A power system reliability study should be carried out whether it satisfies technical specifications though contingency analysis. Actual operation strategies and schemes (e.g., special protection scheme (SPS), emergency control) need to be applied.

- Even though the parameters were approved in FAT, the controller parameter can be changed upon request of electric utility based on the results of HILS-DPT.

2.2. Responsibility, Experience, and Lessons of HILS-DPT

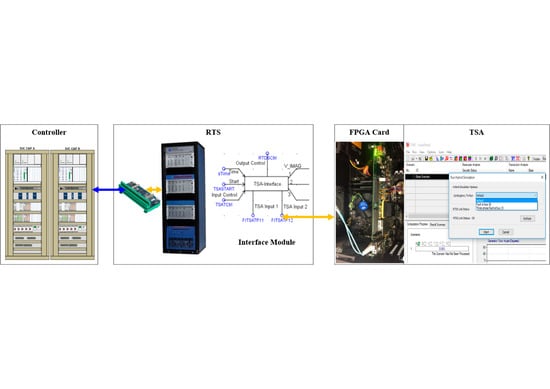

3. HILS-DPT Using RTHS

3.1. Features of HILS-DPT Using RTHS

- Wide network dynamicsThe simulation case network using RTHS is divided into the network simulated with the RTS as the internal subsystem and the remaining network simulated with the TSA as the external subsystem. Wide area AC network dynamics, including hundreds of generators and transmission lines, can be modeled in an external subsystem. This allows us to study the system-wide impact efficiently and effectively.

- FlexibilityThe flexibility of the simulation study is enhanced because the external subsystem network topology can easily be modified with the TSA program. Various load conditions (such as peak and off-peak cases) and models (such as dynamic load model, composite load model, and constant load model), contingencies, operating points, and strategies can be applied in the external subsystem unless internal subsystem has a significant change of network topology. The dynamic load model is especially difficult to apply to large-scale RTS, due to the numerical instability and the highly required computational hardware resources. Whereas, RTHS can apply for a dynamic load model in the entire power system with the TSA program, and the power system characteristics using a dynamic load model becomes more accurate than those using a constant load model. Thus, RTHS with a dynamic load model enables the achievement of a more accurate response of power system and power electronics equipment.

- Economical advantageLarge-scale RTS requires more than 28 racks to simulation the entire Korean power system, and the future power system will be larger and more complicated. Expanding RTS more and more is not an economical solution for future power system studies. From the KEPCO experience since 2016, RTHS requires five or fewer racks to simulate the entire Korean power system, and RTHS is free for the power system expanding issue.

3.2. The Procedure of RTHS for HILS-DPT

3.3. Determination of Boundary Area of RTHS for HILS-DPT

- Select boundary buses with an electrical distance of more than a certain threshold (0.4) from the bus with the most serious fault (765 kV transmission line fault).

- Select boundary buses with an electrical distance of more than a certain threshold (0.4) from the power electronics equipment, if the power electronics are nearby the boundary.

- Select the boundary buses without island areas.

- Include the generators in the RTS area, if there are the generators around the boundaries.

- Determines the number of hardware racks of the RTS system, satisfying the above conditions.

- Expand the RTS area as wide as possible.

4. A Practical Application of HILS-DPT Using RTHS; Shin-Jecheon SVC HILS-DPT

4.1. Background and RTHS Case Set Up

4.2. Results of HILS-DPT Using RTHS and Large-Scale RTS

- Case 1: A 345 kV line fault (3-phase to ground)The 3-phase to ground fault is applied to Shin-Jecheon bus during six cycles at 0.5 s. During the fault, the bus voltage drops to zero and SVC could not compensate it. After the fault is cleared, the bus voltage recovers immediately, and the reactive power output of SVC increased according to network recovery characteristics. Overall, the SVC dynamic performance of RTHS is almost the same as HILS-DPT using large-scale RTS. Figure 9 shows the bus voltage at Shin-Jecheon and reactive power of SVC of RTHS simulation and RTS simulation when 3-phase fault is applied. A small difference of less than 10 MVar of SVC reactive power dynamics between RTHS and RTS simulation can be seen in Figure 9. Even though the bus voltage has a small difference of less than 0.01 p.u., SVC responses to the voltage and reactive power output are slightly different from each other. The authors concluded that this amount of difference is acceptable, and HILS-DPT using RTHS is feasible.

- Case 2: A 345 kV unbalanced fault (single line to ground)The A-phase to ground fault was applied to Shin-Jecheon bus during six cycles at 0.5 s. During the fault, the bus voltage drops to around 0.9 p.u. Figure 10 shows the bus voltage at Shin-Jecheon and reactive power of SVC of RTHS simulation and RTS simulation when a single-phase fault is applied. Even though unbalanced fault is applied at Shin-Jecheon bus, the bus voltage at Shin-Jechoen and reactive power output of SVC is almost the same. The authors concluded that this amount of difference is acceptable, and HILS-DPT using RTHS is feasible.

- Case 3: A 765 kV line fault (3-phase to ground), generator trip SPS, and emergency controlThe 765 kV transmission double line fault has complicated sequences, such as TCSC boost up and nearby generators trip, as shown in Figure 11. Moreover, its impact on the network is larger than any other contingencies. The faulted location is just 3-level away from Shin-Jecheon bus, where the SVC is installed. When the fault occurred at 0.5 s, the Shin-Jecheon bus voltage dropped to around 0.7 p.u., and SVC fully outputs reactive power to compensate for the low voltage. After the fault cleared, it recovered to a lower limit of voltage deadband and swing according to the network dynamics. Figure 12 shows the bus voltage at Shin-Jecheon and reactive power of SVC of RTHS simulation and RTS simulation when 3-phase fault is applied at 765 kV transmission lines. A small difference of less than 10 MVar of SVC reactive power dynamics between RTHS and RTS simulation can be seen in Figure 12. Even in this case, HILS-DPT using RTHS and RTS have almost the same dynamic. Therefore, the authors concluded that this amount of difference is acceptable, and HILS-DPT using RTHS is feasible.

- Case 4: A 765 kV line fault (3-phase to ground), generator trip SPS, and emergency control; dynamic load model appliedAs mentioned in the previous section, RTHS has the strength of flexibility for modeling of the external subsystem. For RTS simulation, it is not easy to apply various load models to the entire network, due to its computational burden. However, it depends on the study purpose; consideration of the various load models (e.g., induction motors and ZIP) in the external subsystem could be required. Figure 13 shows the result for SVC responses using RTHS when different the load model is applied, and 765 kV 3-phase fault occurs. The simulation results of the constant impedance load model (blue line) and induction motor and ZIP load model (green line) are shown in Figure 13. Because the induction motor and ZIP load model absorb more reactive power than the constant impedance load model, the voltage at Shin-Jechoen bus in Figure 13 shows that voltage drop with induction motor and ZIP load model is higher than voltage drop with constant impedance load model. This analysis might be important in future power system studies. As can be seen in Figure 13, the flexibility of the external subsystem will be great advantages of RTHS for HILS-DPT.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| The list of DPT is as follows: |

|

|

|

|

|

|

|

|

| The contingency list of HILS-DPT is as follows: |

|

|

|

|

|

|

References

- Kim, H.; Kim, J.; Song, J.; Lee, J.; Han, K.; Shin, J.; Kim, T.; Hur, K. Smart and Green Substation Shaping the Electric Power Grid of Korea. IEEE Power Energy Mag. 2019, 17, 16–24. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.; Lee, H.; Lee, J.; Lee, B.J.; Jang, G.; Lan, X.; Kim, T.; Jeon, D.; Kim, Y.; et al. Expanding power systems in the Republic of Korea feasibility studies and future challenges. IEEE Power Energy Mag. 2019, 17, 61–72. [Google Scholar] [CrossRef]

- Hur, K.; Lee, J.; Song, J.; Ko, B.; Shin, J. Advanced Real Time Power System Simulator for Korea Electric Power Systems: Challenges and Opportunities. Presented at IEEE PES, Portland, OR, USA, August 2018; Available online: http://site.ieee.org/pes-itst/files/2018/08/2018-Panel-1.pdf (accessed on 25 July 2020).

- Lin, X.; Zadehkhost, P.; Lee, J.; Song, J.; Ko, B.; Hur, K. TSAT-RTDS Interface-The Development of a Hybrid Simulation Tool. Presented at IEEE PES, Chicago, IL, USA, July 2017; IEEE PES. 2017. Available online: http://site.ieee.org/pes-itst/files/2018/08/2018-Panel-1.pdf (accessed on 25 July 2020).

- RTDS Technologies Inc. IEEE PES. 2018. Available online: https://knowledge.rtds.com/hc/en-us/articles/360034295014-TSAT-RTDS-Interface/ (accessed on 25 July 2019).

- Powertech Labs Inc. IEEE PES. 2018. Available online: https://www.dsatools.com/tsat-rtds-interface-tri/ (accessed on 25 July 2020).

- Park, I.K.; Lee, J.; Song, J.; Kim, Y.; Kim, T. Large-scale ACDC EMT level system simulations by a real time digital simulator (RTDS) in KEPRI-KEPCO. KEPCO J. Electr. Power Energy 2017, 3, 17–21. [Google Scholar] [CrossRef]

- Song, J.; Oh, S.; Lee, J.; Shin, J.; Jang, G. Application of the First Replica Controller in Korean Power Systems. Energies 2020, 13, 3343. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Hu, Y.; Han, W.; Ou, K.; Jackson, G.; Zhang, Y. Analysis on the effects of STATCOM on CSG based on RTDS. In Proceedings of the IEEE PES ISGT Europe 2013, Lyngby, Denmark, 6–9 October 2013. [Google Scholar]

- Lee, H.; Lee, J.; Ko, B.; Hur, K. Internal System Selection for TSAT-RTDS Hybrid Simulation by Electrical Distance. In Proceedings of the 24th International Conference on Electrical Engineering (ICEE 2018), Seoul, Korea, 24–28 June 2018. [Google Scholar]

- Zhang, Y.; Gole, A.M.; Wu, W.; Zhang, B.; Sun, H. Development and Analysis of Applicability of a Hybrid Transient Simulation Platform Combining TSA and EMT Elements. IEEE Trans. Power Syst. 2013, 28, 357–366. [Google Scholar] [CrossRef]

- Lin, X.; Gole, A.M.; Yu, M. A Wide-Band Multi-Port System Equivalent for Real-Time Digital Power System Simulators. IEEE Trans. Power Syst. 2019, 24, 237–249. [Google Scholar] [CrossRef]

- Lin, X. System Equivalent for Real Time Digital Simulator. Ph.D. Thesis, University of Manitoba, Winnipeg, MB, Canada, 2011. [Google Scholar]

- Hu, Y.; Wu, W.; Zhang, B.; Guo, Q. Development of an RTDS-TSA hybrid transient simulation platform with frequency dependent network equivalents. In Proceedings of the IEEE PES ISGT Europe 2013, Lyngby, Denmark, 6–9 October 2013. [Google Scholar]

- Shu, D.; Xie, X.; Dinavahi, V.; Zhang, C.; Ye, X.; Jiang, Q. Dynamic Phasor Based Interface Model for EMT and Transient Stability Hybrid Simulations. IEEE Trans. Power Syst. 2018, 33, 3930–3939. [Google Scholar] [CrossRef]

- Panigrahy, N.; Gopalakrishnan, K.S.; Ilamparithi, T.; Kashinath, M.V. Real-time phasor-EMT hybrid simulation for modern power distribution grids. In Proceedings of the 2016 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Trivandrum, India, 14–17 December 2016. [Google Scholar]

- Palensky, P.; Van Der Meer, A.A.; Lopez, C.D.; Joseph, A.; Pan, K. Co-simulation of intelligent power systems. IEEE Ind. Electron. Mag. 2017, 11, 34–50. [Google Scholar] [CrossRef]

- Palensky, P.; Van Der Meer, A.A.; Lopez, C.D.; Joseph, A.; Pan, K. Applied Co-simulation of Intelligent Power Systems: Implementing Hybrid Simulators for Complex Power Systems. IEEE Ind. Electron. Mag. 2017, 11, 6–21. [Google Scholar] [CrossRef]

| Time (Cycle) | Action |

|---|---|

| 0 | Fault occurs |

| 5 | 765 kV line circuit breaker open TCSC compensation boost (50% → 70%) |

| 9 | Generator Trip (1.5 GW) |

| 71 | 765 kV line reclose attempted |

| 76 | Reclose failure |

| Type (Modeling Region) | Location | Control Mode (Setpoint) | Ratings (Number of Equipment) |

|---|---|---|---|

| HVDC (External) | Bukdangjin Godeok | Power control (1.0 p.u.) | 1.5 GW |

| TCSC (Internal) | Sinyoungju | Impedance control (50%) | 555 MVar (2) |

| Shin-Jecheon | Impedance control (50%) | 595 MVar (2) | |

| STATCOM (Internal) | Donghae | Q reserve control (1.0 p.u.) | 400 MVar |

| Sinyoungju | Q reserve control (1.0 p.u.) | 400 MVar | |

| Sinchungju | Q reserve control (1.0 p.u.) | 400 MVar | |

| SVC (Internal) | Shin-Jecheon | Q reserve control (1.0 p.u.) | +675/−225 MVar |

| Types | RTHS | Large-Scaled RTS |

|---|---|---|

| Number of RTDS rack | 4 | 29 |

| Number of bus | 103 | 1140 |

| Equipment | 8 | 10 |

| (1 SVC, 3 STATCOMs, 4 TCSCs) | (1 HVDC, 1 SVC, 4 STATCOMs, 4 TCSCs) | |

| Generators | 12 (11.12 GW) | 228 (87.5 GW) |

| Time step | 75 μsec (RTS), 4 msec (TSA Program) | 75 μsec |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Hur, K.; Lee, J.; Lee, H.; Lee, J.; Jung, S.; Shin, J.; Kim, H. Hardware-in-the-Loop Simulation Using Real-Time Hybrid-Simulator for Dynamic Performance Test of Power Electronics Equipment in Large Power System. Energies 2020, 13, 3955. https://doi.org/10.3390/en13153955

Song J, Hur K, Lee J, Lee H, Lee J, Jung S, Shin J, Kim H. Hardware-in-the-Loop Simulation Using Real-Time Hybrid-Simulator for Dynamic Performance Test of Power Electronics Equipment in Large Power System. Energies. 2020; 13(15):3955. https://doi.org/10.3390/en13153955

Chicago/Turabian StyleSong, Jiyoung, Kyeon Hur, Jeehoon Lee, Hyunjae Lee, Jaegul Lee, Solyoung Jung, Jeonghoon Shin, and Heejin Kim. 2020. "Hardware-in-the-Loop Simulation Using Real-Time Hybrid-Simulator for Dynamic Performance Test of Power Electronics Equipment in Large Power System" Energies 13, no. 15: 3955. https://doi.org/10.3390/en13153955

APA StyleSong, J., Hur, K., Lee, J., Lee, H., Lee, J., Jung, S., Shin, J., & Kim, H. (2020). Hardware-in-the-Loop Simulation Using Real-Time Hybrid-Simulator for Dynamic Performance Test of Power Electronics Equipment in Large Power System. Energies, 13(15), 3955. https://doi.org/10.3390/en13153955