1. Introduction

Wood is a fibrous but porous structural organic material found in the stems and roots of trees and other woody plants [

1]. In a living tree, wood performs a support function, enabling the plant to stand up by itself and conveying water and nutrients between the leaves, other growing tissues, and the roots. It is common to classify wood as either softwood (e.g., conifers) or hardwood (e.g., broad-leaved deciduous trees in temperate climates). The chemical composition of wood varies from species to species, but is approximately 50% carbon, 42% oxygen, 6% hydrogen, 1% nitrogen, and 1% of other macro-elements (mainly calcium, potassium, sodium, magnesium, iron, and manganese) as well as micro-elements (sulfur, chlorine, silicon, phosphorus, and others) [

2]. The composition of wood, or of woody biomass as it is also known, consists of six major components: cellulose, hemicellulose, lignin, mineral components, extractives, and water. Water may constitute about 40% to 50% by weight of freshly cut wood, but it can be reduced to almost one quarter as much at about 12%, if the wood is dried thoroughly in air. Cellulose, a crystalline polymer derived from glucose, which is a six-carbon sugar, constitutes about 41–43% of dry matter in wood. Hemicellulose, which varies from about 20% in deciduous trees to near 30% in conifers, both on a dry matter basis, consists mainly of five-carbon sugars that are linked in an irregular, i.e., amorphous, manner. Lignin, which varies from around 27% in conifers to 23% in deciduous trees, both on a dry basis, is a polymer of phenolic compounds (aromatic rings) that confer its hydrophobic properties. It should be noted that the difference between hardwood and softwood is reflected in the phenolic composition of the constituent lignin component [

3]. Wood may also contain, up to 5% by dry weight, a number of low molecular weight organic compounds called extractives. These compounds comprise fatty acids, resins, waxes, and terpenes and their extraction provides valuable chemicals, among others tannin, tall oil, turpentine, and rosin [

4,

5].

The molecules of cellulose, hemicellulose, and lignin are interwoven in such a way that direct strong chemical linkages exist between the lignin matrix and cellulose as well as hemicellulose, making wood a very stable material resisting degradation by external factors, particularly microbial ones. Because of its chemical stability and its structural mechanical strength, wood has been historically employed as construction material for houses, furniture, utensils, tools, weapons, and boats [

6]. A major use of wood in recent times is for paper manufacturing that necessitates the separation of the lignin from the cellulose, from which paper is made, via the use of chemical processes (Kraft Process). Wood has had obviously a long history of being used as fuel via combustion, which continues to this day, mostly in rural areas of the world [

7]. Hardwoods are preferred over softwoods because they create less smoke and burn longer. Wood combustion has been the only practical method to extract its energy, but it is also by-and-large an air-polluting and inefficient process in a modern economy. The employment of a microbial-based process to extract the energy in wood as a gaseous fuel, i.e., bio-methane, is possible as presented herein.

2. The Magnitude of the Wood Waste Resource

As of 2020, the growing stock of forests worldwide stands at about 557 billion m

3 and approximately 4.3 billion m

3 of wood is harvested annually [

8]. Dominant uses are for building construction, furniture, papermaking, and heating fuel [

9]. Forestland in the United States covers 33% of the surface area of the country or about 329 million hectares, of which 57% is privately owned and 67% of it is in commercial use for timber extraction [

10]. The growing stock in 2017 was about 27 billion m

3, of which 16 billion m

3 were softwoods and about 11 billion m

3 were hardwoods. The annual removal rate is about 450 million m

3 and the annual mortality rate is about 200 million m

3, while the annual new growth amounts to almost 700 million m

3, thereby leading to small net annual growth of the stock. Wood supplies a little over 2% of the annual energy use in the United States, amounting to 2.356 quads (1 quad = 1.000 × 10

15 Btu = 1.055 × 10

18 J), with 65% of it for industrial uses (wood products and paper manufacturers), 22% for residential uses (home heating and cooking), 9% for power generation, and 4% for commercial uses (building heating) [

11]. Assuming an average dry wood energy content of 20 GJ per mt, we calculate that the amount of wood used today in the country for energy production is about 125 million mt. By comparison, the dry wood mass of the harvested annually 450 million m

3 is about 225 million mt, assuming an average dry wood density of 0.5 mt per m

3. This suggests that about 100 million mt of dry wood is used in the United States annually for building construction materials (56%), furniture and other wood products (10%), and paper manufacturing (34%). The annual wood mortality has a dry mass of about 100 million mt, is not collected currently, and is left on the ground to decay over time.

A complimentary and quite significant source of wood biomass would come from the thinning and improvement cuttings that are needed to increase the production of quality timber, as well as the thinning of forest standing to reduce the danger of fire. Studies have shown that the amount of dry wood that could be removed from forest thinning could be quite significant [

12]. Moreover, there are various ways of forest thinning [

13]. Thus, the amount of dry wood available to be obtained by forest thinning across the country would be on the order of four times that of the mortality rate or about 400 million dry mt of biomass per year, including the mortality amount. Thinning will be carried out initially on a rotation basis of 20 years average or about 15 million hectares per year. Thinning will obviously subsume mortality. It should be noted that forest thinning would result in an increase in the rate of growth of trees in the forested land that would eventually more than offset the thinning itself. In the long run, i.e., in 20 years time or after one full rotation of initial thinning across all forested land, the annual growth would rise to be 1250 million m

3 per year. Of these, 450 million m

3 will be harvested annually to maintain the current uses and 800 million m

3 will be used annually as the feedstock for an advanced biofuel via fermentation as it is discussed in this paper. Thus, the size of the present forest stock will be maintained indefinitely.

It should be noted that environmental groups have raised strong objections to forest thinning as constituting a license to cut old tree stands. As a result, no long-term plans for forest thinning have been implemented, particularly in the southwest where the forested lands are highly susceptible to fires due to the prevailing dry climate. The devastating fires in California in recent years are a testimony to the no forest thinning implementation in the state. Such fires not only result in the destruction of valuable wood biomass but also generate huge amounts of greenhouse gas emissions. Alternatively, the forest land of the United States, if managed properly, can supply, in a sustainable fashion, an additional large amount of wood biomass up 400 million dry mt/yr, while maintaining the current forest stock unchanged, for the exclusive production of bio-methane as an advanced transportation fuel as well as a replacement of the fossil natural gas used today.

3. Wood Fermentation to Bio-Methane

Wood represents an abundant, carbon-neutral renewable resource and woody materials have been of intense interest as a source of renewable energy. However, the large-scale combustion of wood to extract energy is no longer deemed to be a most efficient and environmentally desirable choice and other pathways must be developed [

14]. One very promising such pathway is the microbial fermentation or anaerobic digestion of wood and wood wastes into bio-methane as an advanced transportation fuel, commercial grade phosphate, nitrogen and potash bio-fertilizers, and green carbon dioxide as either an industrial gas or better yet, as a feedstock for other chemicals and fuels, including additional bio-methane production with the aid of wind and solar power.

As it has been mentioned, wood is highly resistive to microbial decomposition. In fact, there is no known single microorganism that can directly attack wood in its natural state and decompose it in order to extract its energy content. However, we do observe that wood decomposes naturally, albeit slowly, in most instances. Thus, wood microbial decomposition is possible but relies on a fairly complex symbiotic natural process comprised of several organisms, some macro and most micro ones, as researchers have been trying to elucidate in recent years [

15]. This complex symbiotic natural process, manifested in the exclusively wood-feeding lower termites, consists of three major steps that can be simplified as follows: (a) mechanical size reduction of the wood by the insect into very small particles of millimeter size in order to increase the surface area of the material by several orders of magnitude and allow access to its cellulose and hemicellulose components by other symbionts, the insect also serving as the bio-reactor vessel for the decomposition process; (b) assimilation of the small wood particles by eukaryotic single cell organisms comprised of flagellate protozoa (

Parabasalia and

Preaxostyla phyla) to hydrolyze cellulose and hemicellulose sugars into short chain fatty acids and acetate; and (c) fermentation of fatty acids and acetate into methane as well as the mineralization of nitrogen from the environment into ammonia by bacteria (mostly

spirochaetes, but also

bacteroides,

firmicutes,

proteobacteria, and others) and archaea (all types of

methanogens), the ammonia being recycled back into the insect and the protists to supplement their nitrogen diet. This entire process is shown schematically in

Figure 1. The insect bioreactor releases methane and carbon dioxide along with lignin-rich feces. It is estimated that the termite bioreactor is very efficient as it removes between 74% and 99% of cellulose and 65% to 87% of hemicellulose in the digested wood [

16]. Thus, the digestion of lingo-cellulose in termite guts is used as a basic model for the industrial conversion of lingo-cellulosic biomass by microbes into methane biofuel and other bio-products. From a practical point of view, the lack of understanding of all the details of the intricate degradation of wood by lower termites and other insects, which may take decades, if ever, to fully elucidate, is not an impediment to developing a commercial process for the fermentation of wood into bio-methane fuel and a host of other co-products, as already mentioned. This situation is actually quite similar to the current status of the scientific elucidation of anaerobic digestion of agricultural wastes and other organics, which has been commercially available for over three decades at an industrial level, but which is still investigated in the laboratory to determine the interactive dynamics of the various microorganisms participating in it.

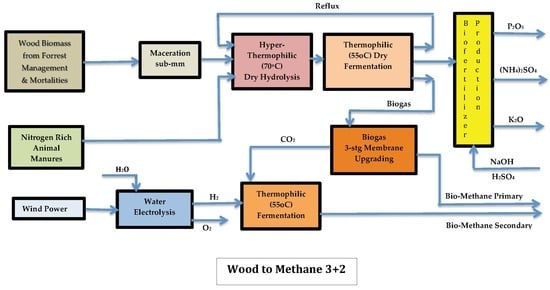

4. Practical Conversion of Wood to Bio-Methane

The practical fermentation of wood wastes into bio-methane fuel has been developed based on the aforementioned process suggested by the behavior of termites combined with our experience in the commercialization of dry, thermophilic anaerobic digestion over the past thirty-five years [

17,

18]. The proposed “wood to methane” fermentation process, or W2M in its abbreviated form, follows the example of the termite process with certain important modifications and improvements in order to enhance conversion efficiency and maintain control of the process. A major improvement includes the co-fermentation or co-digestion of wood with a nitrogen-rich organic waste, namely, pig manure or poultry litter. The justification for selecting these manures will be explained shortly. Another improvement consists of the thermophilic operation of the bioreactor vs. the mesophilic operation in termites for reasons to be also discussed below. The W2M process is comprised of “3 + 2” steps, i.e., five steps altogether, hence “W2M 3 + 2”. The initial “three” steps are as follows: (a) Maceration of wood into millimeter-size particles; (b) Homogenization and mostly aerobic, hyperthermophilic hydrolysis of the macerated wood with the manure relying primarily on thermophilic fungi; and (c) anaerobic digestion of the hydrolyzed materials by bacteria and archaea under dry thermophilic conditions to yield biogas, namely, a mixture of about 60% methane and 40% carbon dioxide. These three steps comprise the biological degradation of wood into a gaseous fuel. The last “two” steps are as follows: (d) Membrane separation of the biogas into 99% + pure bio-methane fuel; and (e) sequestration of the carbon dioxide in the biogas to generate additional bio-methane fuel via its dry thermophilic anaerobic digestion, with a requisite amount of hydrogen to be generated by wind or solar driven power. All five steps will be discussed in detail in the remainder of this section.

The decomposition of wood in the gut of termites by flagellate protozoa requires, among others, a source of nitrogen that is used for the growth of these organisms as well as of that of the host insects. Wood serves as the source of carbon for all these organisms. The source of nitrogen in the termite bioreactor comes from food sources assimilated by the insects, but primarily comes from the atmosphere. Atmospheric nitrogen is fixed into ammonia by suitable bacteria that exist in the gut of the insect. In the large-scale implementation of the wood decomposition process, an external source of nitrogen must also be employed and a source of choice is either pig manure or poultry litter. It is well known that pig manure, which is about 10% total solids (TS), contains roughly 10% nitrogen in its dry state, i.e., 1% nitrogen in the wet state. This nitrogen in manure is mostly in the form of proteins and about 30% is in the form of ammonia. Poultry manure has similar nitrogen content, the main difference being that it is typically much drier at TS of about 70% and therefore, would need dilution with water to 10% TS in order to be mixed properly with wood. Both pig manure and poultry litter also contain fats and some carbohydrates that make them an excellent source of methane on their own in an anaerobic digestion process, so long as there is a sufficient amount of carbon in the digested materials. The optimal ratio of carbon to nitrogen in a thermophilic anaerobic digestion process is about 20 to 1 [

19,

20]. Given that dry wood contains 50% carbon and dry pig manure or poultry litter contain about 10% nitrogen, we would need to co-digest 1 mt of wood with ¼ mt of dry pig manure or dry poultry litter or a mixture of the two in order to obtain the 20 to 1 ratio.

Assuming for practical purposes that the wood to be processed for fermentation has an 80% TS content and the pig manure/poultry litter has a 10% TS content, we would need to co-digest 2 mt of pig manure (20 kg of N) with 1 mt of wood (400 kg of C). Incidentally, a major difference between poultry litter (broilers and turkeys) and pig manure is that the former is much drier in its natural state at about 75% TS, thereby requiring dilution with process wastewater to the 10% TS level. An additional advantage of co-digesting wood with either pig manure or poultry litter is that about 30% of the nitrogen in these manures is already mineralized in the form of ammonia. Ammonia is known to degrade wood by dissolving the lignin. Thus, during the hydrolysis step of the process and even during the fermentation, the ammonia present may accelerate the degradation of the macerated wood, such that the enzymes secreted from the fungi, bacteria, and archaea in the mix convert more cellulose and hemicellulose into methane and carbon dioxide.

The selection of the thermophilic operating temperature at 55 °C has several advantages, but it also imposes a perceived restriction. The advantages include: (a) vast operating experience with dry thermophilic anaerobic digestion over the past three decades; (b) more than doubling of the rate of biogas production, which is due to the accelerated degradation of the feedstock materials in general and wood in particular; (c) reduction in the retention time in the digesters that reduces the size of the fermentation vessels and the associated costs; (d) sterilization of the digester effluent, thereby increasing its value as a fertilizer; and (e) synergistic operation with a dry, i.e., high in total solids, process to further reduce the volume of the digesters/bio-reactors and keep the cost lower. The perceived restriction is that the thermophilic operating temperature regime eliminates the flagellate protozoa operating in termites because all of them are mesophilic. The only eukaryotic organisms that operate in an elevated temperature above 45 °C and are known to decompose wood are thermophilic fungi, which as it turns out, constitute a small fraction even among fungi, i.e., a few hundred species out of approximately 50,000 recorded species of fungi [

21,

22,

23]. However, thermophilic fungi are ubiquitous in the environment as

Figure 2 shows [

23]. Thermophilic fungi are, in general, of wide interest due to their potential for the production of thermo-stable enzymes that can be used in industrial high-temperature processes.

The reliance on thermophilic fungi for the controlled co-digestion of wood with suitable animal manures is just such another industrial process described herein. Wood decomposition in wood chip piles, stored peat, and composting piles, which rise internally in temperature to hyperthermophilic levels of over 70 °C, has been known for a long time to rely on a small number of thermophilic fungi, such as

Humicola insolens (or

Scytalidium Thermophilum under a recent but not universally accepted change in name) and

Sporotrichum thermophile (or

Myceliophthora thermophila under the new name), among others, to proceed very effectively under certain moisture (more than 50% water), temperature (over 45 °C), pH (range 4 to 8, optimal around 6.8), and oxygen (0.7 to 1.05% for moderate growth) conditions to ferment cellulose and hemicellulose [

21,

23,

24]. The cross-sectional distribution of temperature and oxygen in a mushroom compost pile shown in

Figure 3 is indicative of the operational versatility of thermophilic fungi [

23]. Moreover, the thermophilic fungus

Humicola insolens has also been found to operate better under anaerobic or micro-aerobic conditions [

25,

26]. Thus, this fungus in particular and fungi of the

Humicola sp. in general are expected to play a central role in wood hydrolysis and fermentation. It should be also noted that the relatively small number of known wood-digesting thermophilic fungi is not any smaller than the number of wood-decomposing flagellate protozoa found in the gut of termites [

27].

The aforementioned “W2M 3 + 2” process is shown schematically in

Figure 4. Its first “3” steps mimic the steps employed by termites to digest wood. Thus, the breaking up of wood into small particles by the mandibles of the termites and the further comminuting of these particles in the gizzard of the insect are represented in our system by the wood maceration unit. It is well established that size reduction enhances the methane yield of biological wood fermentation by about 50% for a decrease in particle size from about 1 cm to about 1 mm [

28,

29]. The wood maceration unit consists of a proprietary device employing hammer mills to break the wood and the wood fibers into small particles. This device, called “Molares”, will accept wood chips 1–3 cm in size, obtained from wood processed through a commercial woodchipper and generate wood particles 0.2–2 mm in size. This wood maceration reduces cellulose crystallinity and facilitates immensely the exposure of cellulose and hemicellulose to the enzymes secreted by the thermophilic fungi as well as thermophilic bacteria such as thermophilic actinomycetes operating synergistically, although the fungi are the hydrolysis process drivers [

30,

31,

32].

The macerated wood is then mixed with the manure in proportions as already described along with an amount of effluent from the fermenter exit in order to attain the typical 30% TS content. This mixture is pumped into the hydrolysis vessel. A vertical mixing device inside the vessel ensures homogenization and facilitates the hydrolysis. The vessel is maintained at a hyperthermophilic operating condition of 70 °C via circulating hot water as necessary, while exterior-wall insulation ensures the temperature inside the vessel is the same throughout. The temperature is a process parameter and could be varied to optimize the hydrolysis of cellulose and hemicellulose. The introduced effluent is at about 10% of the rate of the incoming materials (wood and manure) and has as a major function the fast inoculation of the fresh materials with the functioning organisms (fungi, bacteria and archaea) in the digester and as a secondary function the adjustment of the water content in the hydrolysis vessel to the desirable 30% TS content. If pig manure is used there will be no need to add any external water. If poultry litter If poultry manure is used as the co-digested material, there will be a need to add external wastewater such that the 30% TS is maintained. The retention time of the co-digested materials in the hydrolysis vessel varies between three and five days and is a process parameter. This retention time of up to five days is based on the observed wood and straw decomposition rates in composting as well as in studies of two-stage hyperthermophilic–thermophilic co-digestion studies, where the optimal solids retention time is found to be four days [

23,

33]. This step of the process is mostly aerobic and thermophilic fungi are mostly, but not exclusively, operating to hydrolyze particularly the wood component of the materials into simple compounds such as fatty acids. Small amounts of metered air as a processes parameter are injected into the hydrolysis vessel to optimize its operation, given that thermophilic fungi are aerobic but apparently function under reduced air conditions, as already indicated in the previous section and as the air distribution in

Figure 3 confirms. Incidentally the tolerance of fungi to high temperatures and low oxygen levels could be the result of their symbiotic existence with viruses and bacteria that is just beginning to be recognized [

34]. The sugars comprising the cellulose and hemicellulose are hydrolyzed into short chain fatty acids and acetate. The hyperthermophilic hydrolysis step of the “W2M 3 + 2”process constitutes a departure from the standard thermophilic hydrolysis step in the ECOCORP process dealing with non-wood substrates. It is in direct emulation of the typical compost pile temperature profile per

Figure 3 and provides considerable advantages particularly in treating the wood portion of the substrates by enhancing and accelerating the normally recalcitrant acidification process of its sugars as well as of proteins and fats in the hydrolysis vessel [

31,

32,

33]. Moreover, the hyperthermophilic operational temperature of the hydrolysis vessel is not detrimental to the functioning of the various microbes operating synergistically to hydrolyze the complex sugar substrate molecules into fatty acids as the example of the compost pile shown in

Figure 3 would suggest and as lab-scale digester reactors have confirmed [

33].

The hydrolyzed materials are then pumped into the fermentation vessel, which is maintained at 55 °C. The fermentation vessel is a plug flow reactor, where the materials move forward over a period of about 20 days, the typical retention time, which is also another process parameter. The roof of this reactor is made of an expandable membrane and serves as a temporary storage of the generated biogas (60% CH4 and 40% CO2). A longitudinal mixing device along the length of the reactor and a moving floor ensure that the materials in the reactor are continuously stirred and do not accumulate at the bottom. The thermophilic bacteria and archaea into the reactor consume the fatty acids and acetate and generate biogas that escapes out of the liquid effluent. Metered amounts of air are also introduced into the fermentation reactor to suppress the release of H2S into the biogas, thereby resulting in the sulfur remaining in the liquid phase, i.e., reactor effluent, as sulfates and simultaneously support the functionality of certain thermophilic fungi operating better near anaerobic conditions to continue the degradation of the remaining cellulose and hemicellulose.

The next two steps in the process do not occur in the termite bioreactor, but are integral parts of the “W2M 3 + 2” process. The generated biogas is collected in the membrane roof of the fermentation vessel and from there, is directed to the biogas-upgrading unit, following the removal of water and the sulfur compounds in it. The biogas-upgrading unit consists of a standard commercially available membrane separation system [

35]. A three-stage system will be used to recover over 99.8% of the methane in the biogas and produce 99% methane gas purity. Compared to other biogas upgrading systems, this system has a higher recovery rate and purity of methane, lower electricity use and requires an operational pressure of over 50 bar, which is ideal for the delivery of the generated bio-methane into a transmission natural gas pipeline. The fifth and final step in the process entails the sequestration of the carbon dioxide in the biogas and its utilization either as an industrial gas or to generate more bio-methane fuel.

The exhaust from the membrane separation system, which consists of 95–99% carbon dioxide, is then directed into a standard CO

2 liquefaction unit to obtain pure carbon dioxide [

36]. The liquid CO

2 is then stored into cryogenic cylinders until it is picked up by industrial gas companies for sale to their customers. A more recent alternative use of the sequestered carbon dioxide in the exhaust of the membrane-upgrading system is to be used along with hydrogen in an anaerobic digester to produce bio-methane via a biological methanation process according to the reaction: 4H

2 + CO

2 = CH

4 + H

2O [

37]. Hydrogen gas is produced from the electrolysis of water with wind or solar PV electricity. The hydrogen gas is then introduced into an anaerobic trickle bed reactor along with the sequestered carbon dioxide operating at 55 °C. Hydrogenotrophic archaea predominated by

Methanothermobacter thermautotrophicus convert almost 99% of the carbon dioxide into a higher than 98% methane gas output [

37,

38]. This technology has been developed as a means to store wind and solar power when the demand is below the supply, whereby the produced bio-methane serves as the storage medium [

39]. One commercial size facility is operational in Denmark. The same technology can be used to convert the sequestered carbon dioxide into additional bio-methane fuel. One metric ton of carbon dioxide requires 182 kg of hydrogen to generate 363 kg of bio-methane. The required electricity to electrolyze water to obtain the hydrogen and also to operate the anaerobic digester for the production of the bio-methane is on the order of 10,000 kWh per mt of carbon dioxide, assuming an efficiency of 53.4 kWh per kg H

2 or 4.8 kWh per m

3 H

2. The required wind power to generate this amount of electricity annually is on the order of 3.8 kW at 30% or higher wind capacity factor. The sizing of a functional system for the fermentation of wood into bio-methane will be examined in the next section of this document.

5. System Design for the Conversion of Wood into Bio-Methane

The design and sizing of an industrial type standardized modular system for the fermentation of wood into bio-methane incorporating the five process steps described in the previous section is the basis of the design of the standardized commercially available modular biogas plant unit operating under dry, thermophilic conditions that has been developed by our team [

40,

41]. This unit consists of two plug-flow reactors made of precast concrete with a flexible double-membrane roof, each having a gross volume of about 3500 m

3 comprised of 1500 m

3 for the liquid and 2000 m

3 for the gaseous components. Each plug flow reactor has its own hydrolysis vessel comprised of a vertical steel vessel with a gross volume of 350 m

3 sized for this application. A slowly rotating longitudinal mixing device with paddles made of steel is installed in each plug-flow reactor along with a moving steel floor. A vertical mixing device also slowly rotating and made of steel is part of each hydrolysis vessel. The hyperthermophilic operating temperature of 70 °C is maintained in the hydrolysis vessels and a thermophilic temperature of 55 °C is maintained in the plug-flow reactors via hot water circulation. Two hammer mill-type solids macerators rated at 1 mt per hour each are part of the system, each macerator feeding the respective hydrolysis vessel. Positive displacement pumps are employed to move the nominally 30% TS feedstock materials between the components of the system. The biogas collected in the membrane roofs of both reactors is directed into and upgraded to bio-methane by a three-stage membrane separation system rated nominally at 1000 m

3 per hour. A carbon dioxide liquefaction system rated at 20 mt per day is employed to sequester the carbon dioxide in the biogas. The liquid effluent from the two reactors is centrifuged via two high speed units rated at 5 mt per h each. The solid fraction is dried via aeration over a period of two weeks to yield stabilized soil conditioner rich in phosphate and humic substances. The liquid fraction is first subjected to micro-filtration so that any remaining suspended solids are removed and returned to the solid fraction and is then subjected to a three-stage ammonia stripping process to yield commercial grade ammonium sulfate bio-fertilizer. The rejected liquid rich in potassium is subjected to evaporation to yield potassium concentrate as a bio-fertilizer. A processing building with a 1000-m

2 footprint contains the plant controls as well as the aforementioned processing equipment associated with the operation of the plant, excluding the hydrolysis vessels, plug-flow reactors, and biogas-upgrading units. The feedstock materials are kept in fully enclosed spaces and are transported into the processing building as needed. The operation of the plant is continuous with a nominal operating capability of 95% of the time.

Based on the physical size of commercially available plug-flow digesters and the physical properties of the wood and manure substrates, the standardized wood fermentation unit would process annually 12,000 mt of wood wastes at 80% TS and 24,000 mt of pig manure at 10% TS. If poultry litter is used at nominally 75% TS, 3200 mt of it will be diluted with 20,800 mt of process wastewater to 10% TS. The generated annually amount of biogas would be 7.5 million m

3, of which bio-methane would be 4.5 million Nm

3 and carbon dioxide 3.0 million Nm

3. It is assumed that 90% of the cellulose and 80% of the hemicellulose in the wood are hydrolyzed. A summary of the material inputs and outputs of the standardized wood fermentation unit is given in

Table 1. This mass balance is based on the aforementioned assumed hydrolysis of wood in conjunction with production rates of similar operating conditions in biogas plants. The three-stage membrane separation system for the upgrading of the biogas will capture 99.6% of the available methane. The energy content in the bio-methane is 45,000,000 kWh (10 kWh per Nm

3). The energy content in the processed wood is on the order of 55,000,000 kWh (5750 kWh per dry mt) and in the processes manure is on the order of 13,000,000 kWh for a total of 68,000,000 kWh. Thus, about 66% of the total energy contained in the wood and in the manure is converted into bio-methane.

The amount of carbon dioxide produced as an industrial gas will be just short of 6000 mt/yr. As we have already discussed, this carbon dioxide will be used in conjunction with water electrolysis and additional anaerobic digestion to produce more bio-methane. The stoichiometric amount of bio-methane to be produced is at a rate of 363 kg per mt of CO2. At a CO2 capture efficiency of 98%, some 2226 mt/yr of additional bio-methane output would be obtained or about 3.1 million m3 per year. This amount is just 69% of the bio-methane produced from the direct fermentation of the wood and is obviously quite significant. However, a large amount of wind power would be required on the order of 25 MW for the standardized wood fermentation plant unit, including the electricity use for the primary bio-methane production, which is about 10% of the total. A wind installation of 25 MW collocated or accessible via power lines would be required.

A related benefit associated with this conversion of waste wood and animal manures into bio-methane fuel and bio-fertilizers is the reduction in the emissions of greenhouse gases. As we have already noted, some 6000 mt of carbon dioxide will be sequestered in the standardized plant and be converted to additional bio-methane. The electricity use for the primary and secondary production of the bio-methane and the bio-fertilizers would be derived from renewable wind power and would have a near zero carbon footprint. Likewise, the heat requirement for the process will be supplied by the generated biogas itself and will also have a near zero carbon emissions footprint. Of the feedstock materials, wood as a renewable resource would also have a near zero carbon footprint. The utilization of the animal manures with an energy content of 13,000,000 kWh, however, would generate a negative carbon footprint. This can be estimated on the basis of the energy content in the manures and the average carbon footprint in fossil fuels that the bio-methane would replace. The average carbon footprint of fossil fuels themselves in carbon dioxide emissions ranges from a high of 0.325 kg/kWh for coal, to 0.248 kg/kWh average for diesel/gasoline to 0.181 kg/kWh for natural gas. The resulting annual negative footprint of the utilized manure would range from a high of 4225 mt as a coal replacement to 3224 mt as a diesel/gasoline replacement to 2353 mt as a natural gas replacement. Thus, the nominal reduction in greenhouse gas emissions from the operation of the standardized plant would be conservatively around 10,000 mt per year.

6. The US Potential of Bio-Methane Production from Wood Wastes

As it was analyzed in

Section 2, the annual production of wood wastes in the US can range from a minimum of 100 million dry mt, representing just the collection of the tree mortalities, to a potential maximum of 400 million dry mt with proper forest management including tree thinning and collection of the mortalities. The annual production of collectable pig manure and of poultry litter in the US is on the order of 130 million dry mt [

42]. Based on the required carbon to nitrogen ratio, about 74% of it would be co-digested with the maximum available wood waste as shown in

Table 2. Consequently, over 41,500 modular fermentation units would be required to process these wood wastes along with manure into bio-methane. The produced “primary” bio-methane would amount to 187 billion m

3/yr (6.4 quads annually). In addition, almost 250 million mt of carbon dioxide would be sequestered for conversion to additional bio-methane with the input of wind power. The “secondary” bio-methane would amount to 129 billion m

3/yr (4.4 quads annually).

The required wind power would be on the order of 1000 GW. This wind power is less than 10% of the wind power potential of the US estimated at 12,000 GW on-shore at 100 m turbine height and at 30% or higher capacity factor and over 2000 GW off-shore [

43]. We conclude then that the dry, thermophilic co-digestion of wood wastes along with hog manure and poultry litter would generate over 316 billion m

3 of renewable natural gas or over 11 trillion standard cubic feet. This amount of natural gas would represent about 35% of the current production of fossil natural gas in the US [

44]. Lastly, this bio-methane production would represent over 10 quads of energy annually or almost 11% of the energy consumption of the country. Consequently, the dry, thermophilic co-digestion of wood wastes along with hog manure and poultry litter has the potential to become a very significant source of a renewable fuel in the form of bio-methane.

The cost associated with the development of the standardized “W2M 3 + 2” fermentation unit will consist of the main anaerobic digestion unit to produce biogas, the upgrading system of biogas to primary bio-methane, the sequestration of the carbon dioxide system, the hydrogen production electrolysis unit, the microbial conversion of the carbon dioxide and hydrogen into the secondary bio-methane system, and the wind power installation. The present cost of the entire “W2M” unit is summarized in

Table 3 and is based on currently available best values of the various major components. Economies of scale, particularly for wind power and water electrolysis systems, will drive down the associated cost as is also shown in

Table 3 [

45,

46]. A conservative reduction in total cost by a factor of two to three is, thus, a realistic projection [

47]. The levelized cost of bio-methane production over a 20-year plant life and 20% O&M is reduced also by a factor of three, as shown in

Table 3. By comparison, the current price of natural gas in the US is 0.075 USD per m

3 as a commodity, although this price increases to about 0.450 USD per m

3 as an advanced transportation fuel, if the renewable fuel standard (RFS) and the low carbon fuel standard (LCFS) pricing are included.

The production of the 316 billion m

3/yr of bio-methane as a transportation fuel represents the equivalent of over 350 billion liters gasoline. This amount of renewable bio-methane transportation fuel is three times the amount prescribed by the RFS (Renewable Fuel Standard) legislation in 2005 and represents 70% of the gasoline used in the US in 2018 [

48]. We may also note that the utilization of the remaining 30 million mt/yr hog manure and poultry litter along with 412 million mt/yr of non-wood-based agricultural residues can yield 6.7 quads of primary bio-methane, 4.6 quads of secondary bio-methane, and will require an additional 1100 GW of wind power [

49]. The generated bio-methane from these non-wood wastes would be 11.3 quads of energy per annum, with a volume of 331 billion Nm

3 per annum and would represent 37% of the current natural gas production in the US. Altogether then, the conversion of collectable organic wastes to bio-methane, including wood wastes and utilizing wind power for converting carbon dioxide to additional bio-methane, can supply 22 quads annually or 22% of the annual use of energy in the United States.

The current investment cost for the 41,000 “W2M 3 + 2” plants is on the order of 2.45 trillion USD with a future investment cost reduced to 840 billion USD over a period of 20 years due to economies of scale as well as advancements in technology. An annual investment starting at 120 billion USD to be reduced ultimately to 40 billion USD is well within the means of the US economy to develop these facilities. The levelized cost of the produced renewable natural gas can be justified at the present time if the fuel is used as a transportation fuel under the prevailing renewable fuel standard as well as the low carbon fuel standard. This is a very large investment essentially in infrastructure of the country and would require a public–private partnership in order to be carried out. The plants would be developed, constructed, and be operated by the private sector. The federal and state governments would provide financial support in terms of grants and loans up to 50% of the cost, while the private sector would raise the remaining 50% of the cost. The federal government could also support the renewable fuel pricing as it is already doing through existing and new standards that would need to include the price of avoided carbon emissions. Co-operation between the state governments and the federal government would be also necessary in order to facilitate and streamline the siting and permitting of the plants. Lastly, the implementation of appropriate forest management practices should be carried out by the federal and state agencies along with private owners in order to ensure that the waste wood fuel is harvested and available for use. This effort represents a most effective undertaking to utilize a large, but underutilized biomass resource to contribute along with other renewable energy sources to the so-called “de-carbonization” of the economy.