Gasification of Cup Plant (Silphium perfoliatum L.) Biomass–Energy Recovery and Environmental Impacts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

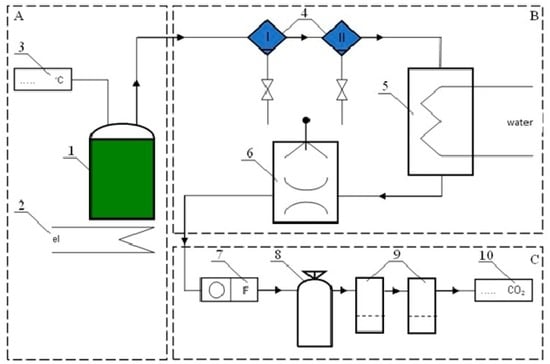

2.2. Experimental Setup

2.2.1. Determination of the Mass and Energy Balance

2.2.2. Seed Germination and Root Elongation Bioassay

2.3. Statistical Analysis

3. Results and Discussion

3.1. The Mass and Energy Balance during Cup Plant Biomass Gasification Process

3.2. Phytotoxicity Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Mast, B.; Lemmer, A.; Oechsner, H.; Reinhardt-Hanisch, A.; Claupein, W.; Graeff-Hönninger, S. Methane yield potential in new perennial biogas crops affected by the harvest date. Ind. Crops Prod. 2014, 58, 194–203. [Google Scholar] [CrossRef]

- Haag, N.L.; Nägele, H.-J.; Reiss, K.; Biertümpfel, A.; Oechsner, H. Potential for methane formation in a cup (Silphium perfoliatum). Biomass Bioenergy 2015, 75, 126–133. [Google Scholar] [CrossRef]

- Sapkota, A.; Haghverdi, A.; Avila, C.C.E.; Ying, S.C. Irrigation and Greenhouse Gas Emissions: A Review of Field-Based Studies. Soil Syst. 2020, 4, 20. [Google Scholar] [CrossRef]

- Ercoli, L.; Mariotti, M.; Masoni, A.; Bonari, E. Effect of irrigation and nitrogen fertilization on biomass yield and efficiency of energy use in crop production of Miscanthus. Field Crops Res. 1999, 63, 3–11. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Tworkowski, S.J.; Załuski, D.; Bieniek, A.; Gołaszewski, J. Effect of Increased Soil Fertility on the Yield and Energy Value of Short-Rotation Woody Crops. Bioenergy Res. 2015, 8, 1136–1147. [Google Scholar] [CrossRef] [Green Version]

- Krzystek, L.; Wajszczuk, K.; Pazera, A.; Matyka, M.; Slezak, R.; Ledakowicz, S. The Influence of Plant Cultivation Conditions on Biogas Production: Energy Efficiency. Waste Biomass Valorization 2020, 11, 513–523. [Google Scholar] [CrossRef] [Green Version]

- Kaia, G.; Tie-Xiaa, Z.; Qi-Bing, W. Nitrogen fertilization, irrigation, and harvest times affect biomassand energy value of Helianthus tuberosus L. J. Plant Nutr. 2016, 13, 1906–1914. [Google Scholar] [CrossRef]

- Szwaja, S.; Poskart, A.; Zajemska, M.; Szwaja, M. Theoretical and Experimental Analysis on Co-Gasification of Sewage Sludge with Energetic Crops. Energies 2019, 12, 1750. [Google Scholar] [CrossRef] [Green Version]

- Jayaraman, K.; Gökalp, I. Pyrolysis, combustion and gasification characteristics of Miscanthus and sewage sludge. Energy Convers. Manag. 2015, 89, 83–91. [Google Scholar] [CrossRef]

- Dudyński, M.; van Dyk, J.C.; Kwiatkowski, K.; Sosnowska, M. Biomass gasification: Influence of torrefaction on syngas production and tar formation. Fuel Process. Technol. 2015, 131, 203–212. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 3): Gasification technologies. Bioresour. Technol. 2002, 83, 55–63. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef] [Green Version]

- Srirangan, K.; Akawi, L.; Moo-Young, M.; Chou, C.P. Towards sustainable production of clean energy carriers from biomass resources. Appl. Energy 2012, 100, 172–186. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Jones, D.D.; Hanna, M.A. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef] [Green Version]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J.J.G. A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 2003, 24, 125–140. [Google Scholar] [CrossRef]

- Rios, M.L.V.; González, A.M.; Lora, E.E.S.; del Olmo, O.A.A. Reduction of tar generated during biomass gasification: A review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Hawrot-Paw, M.; Koniuszy, A.; Pizoń, D.; Karbowy, A. Microbial and energetic stability of biomass used for thermochemical conversion in gasification process. Przem. Chem. 2018, 97, 706–708. (In Polish) [Google Scholar]

- Wolfesberger, U.; Aigner, I.; Hofbauer, H. Tar content and composition in producer gas of fluidized bed gasification of wood: Influence of temperature and pressure. Environ. Prog. Sustain. Energy 2009, 28, 372–379. [Google Scholar] [CrossRef]

- Farzad, S.; Mandegari, M.A.; Görgens, J.F. A critical review on biomass gasification, co-gasification, and their environmental assessments. Biofuel Res. J. 2016, 3, 483–495. [Google Scholar] [CrossRef]

- Hawrot-Paw, M.; Koniuszy, A.; Mikiciuk, M.; Izwikow, M.; Stawicki, T.; Sędłak, P. Analysis of ecotoxic influence of waste from the biomass gasification process. Environ. Sci. Pollut. Res. 2017, 24, 15022–15030. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Von Cossel, M.; Amarysti, C.; Wilhelm, H.; Priya, N.; Winkler, B.; Hoerner, L. The replace-ment of maize (Zea mays L.) by cup plant (Silphium perfoliatum L.) as biogas substrate and its implications for the energy and material flows of a large biogas plant. Biofuel Bioprod. Biorefin. 2020, 14, 152–179. [Google Scholar] [CrossRef] [Green Version]

- Titei, V. The evaluation of biomass of the Sida hermaphrodita and Silphium perfoliatum for renewable energy in Moldova. Sci. Pap. Ser. A Agron. 2017, 60, 534–540. [Google Scholar]

- Titei, V. The potential growth and the biomass quality of some herbaceous species for the production of renewable energy in Moldova. J. Bot. 2019, 1, 83–91. [Google Scholar]

- Polish Standard PN-ISO 1928:2020-05. Paliwa Stałe—Oznaczanie Ciepła Spalania Metodą sPalania w Bombie Kalorymetrycznej i Obliczanie Wartości Opałowej/Solid Fuels—Determination of the Calorific Value by the Calorimetric Method of Combustion and Calculation of the Calorific Value. (In Polish). Available online: https://sklep.pkn.pl/catalogsearch/advanced (accessed on 21 September 2020).

- Hawrot-Paw, M.; Zmuda, A.; Koniuszy, A. Thermochemical biomass conversion processes and their impact on the environment. Przem. Chem. 2019, 98, 1126–1129. (In Polish) [Google Scholar]

- Li, Y.; Khanal, S.K. Bioenergy: Principles and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Operating Instruction. Available online: http://www.mru-instruments.pl/produkty/analizatory-przemyslowe/varioplus-iv (accessed on 21 May 2019). (In Polish).

- Polish Standard PN-EN 50379-1:2013-03. Wymagania Dotyczące Przenośnych Przyrządów Elektrycznych do Pomiaru Parametrów gazu Spalinowego Urządzeń Grzewczych. Cz. 1. Wymagania Podstawowe i Metody Badań/Requirements for Portable Electrical Instruments for Measuring Exhaust Gas Parameters of Heating Devices. Th. 1. Basic Requirements and Test Methods. (In Polish). Available online: https://sklep.pkn.pl/catalogsearch/advanced (accessed on 21 September 2020).

- Barbero, P.; Beltrami, M.; Baudo, R.; Rossi, D. Assessment of Lake Orta sediments phytotoxicity after the liming treatment. J. Limnol. 2001, 60, 269–276. [Google Scholar] [CrossRef] [Green Version]

- Cumplido-Marin, L.; Graves, A.R.; Burgess, P.J.; Morhart, C.; Paris, P.; Jablonowski, N.D.; Facciotto, G.; Bury, M.; Martens, R.; Nahm, M. Two Novel Energy Crops: Sida hermaphrodita (L.) Rusby and Silphium perfoliatum L.—State of Knowledge. Agronomy 2020, 10, 928. [Google Scholar] [CrossRef]

- Bridgwater, A.V. The technical and economic feasibility of biomass gasification for power generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Brewer, C.E.; Schmidt-Rohr, K.; Satrio, J.A.; Brown, R.C. Characterization of Biochar from Fast Pyrolysis and Gasification Systems. Environ. Prog. Sustain. Energy 2009, 28, 386–396. [Google Scholar] [CrossRef]

- Situmorang, Y.A.; Zhao, Z.; Yoshida, A.; Abudula, A.; Guan, G. Small-scale biomass gasification systems for power generation (<200 kW class): A review. Renew. Sustain. Energy Rev. 2020, 117, 109486. [Google Scholar] [CrossRef]

- Chidikofan, G.; Benoist, A.; Sawadogo, M.; Volle, G.; Valette, J.; Coulibaly, Y.; Pailhes, J.; Pinta, F. Assessment of environmental impacts of tar releases from a biomass gasifier power plant for decentralized electricity generation. Energy Procedia 2017, 158–163. [Google Scholar] [CrossRef]

- Nguyen, H.N.T.; Seemann, M.; Thunman, H. Fate of polycyclic aromatic hydrocarbons during tertiary tar formation in steam gasification of biomass. Energy Fuels 2018, 32, 3499–3509. [Google Scholar] [CrossRef]

- Smith, M.J.; Flowers, T.H.; Duncan, H.J.; Alder, J. Effects of polycyclic aromatic hydrocarbons on germination and subsequent growth of grasses and legumes in freshly contaminated soil and soil with aged PAHs residues. Environ. Pollut. 2006, 141, 519–525. [Google Scholar] [CrossRef] [PubMed]

| Condensate | Dose [mg kg−1] | Germination Index [%GI] | |||||

|---|---|---|---|---|---|---|---|

| W(−)/N0 | W(−)/N40 | W(−)/N80 | W(+)/N0 | W(+)/N40 | W(+)/N80 | ||

| I | 0 | 100 | 100 | 100 | 100 | 100 | 100 |

| 100 | 90 | 50 | 66 | 60 | 83 | 69 | |

| 1000 | 32 | 29 | 48 | 46 | 40 | 54 | |

| 10,000 | 0 | 0 | 0 | 0 | 0 | 0 | |

| II | 0 | 100 | 100 | 100 | 100 | 100 | 100 |

| 100 | 100 | 74 | 77 | 74 | 83 | 80 | |

| 1000 | 44 | 50 | 55 | 59 | 60 | 65 | |

| 10,000 | 6 | 6 | 1 | 0 | 0 | 2 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koniuszy, A.; Hawrot-Paw, M.; Podsiadło, C.; Sędłak, P.; Możdżer, E. Gasification of Cup Plant (Silphium perfoliatum L.) Biomass–Energy Recovery and Environmental Impacts. Energies 2020, 13, 4960. https://doi.org/10.3390/en13184960

Koniuszy A, Hawrot-Paw M, Podsiadło C, Sędłak P, Możdżer E. Gasification of Cup Plant (Silphium perfoliatum L.) Biomass–Energy Recovery and Environmental Impacts. Energies. 2020; 13(18):4960. https://doi.org/10.3390/en13184960

Chicago/Turabian StyleKoniuszy, Adam, Małgorzata Hawrot-Paw, Cezary Podsiadło, Paweł Sędłak, and Ewa Możdżer. 2020. "Gasification of Cup Plant (Silphium perfoliatum L.) Biomass–Energy Recovery and Environmental Impacts" Energies 13, no. 18: 4960. https://doi.org/10.3390/en13184960

APA StyleKoniuszy, A., Hawrot-Paw, M., Podsiadło, C., Sędłak, P., & Możdżer, E. (2020). Gasification of Cup Plant (Silphium perfoliatum L.) Biomass–Energy Recovery and Environmental Impacts. Energies, 13(18), 4960. https://doi.org/10.3390/en13184960